Stably clamping drilling tool

A cutting tool processing and drilling technology, which is applied to drilling tool accessories, manufacturing tools, metal processing equipment, etc., can solve the difficulty of accurately controlling the interference size of the pitch diameter of the thread, difficulty in ensuring the axial and circumferential runout accuracy of the cutter head, Problems such as poor centering ability of the cutter head in the circumferential direction can achieve the effect of increasing clamping repeatability, improving clamping stability and reducing cutting vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

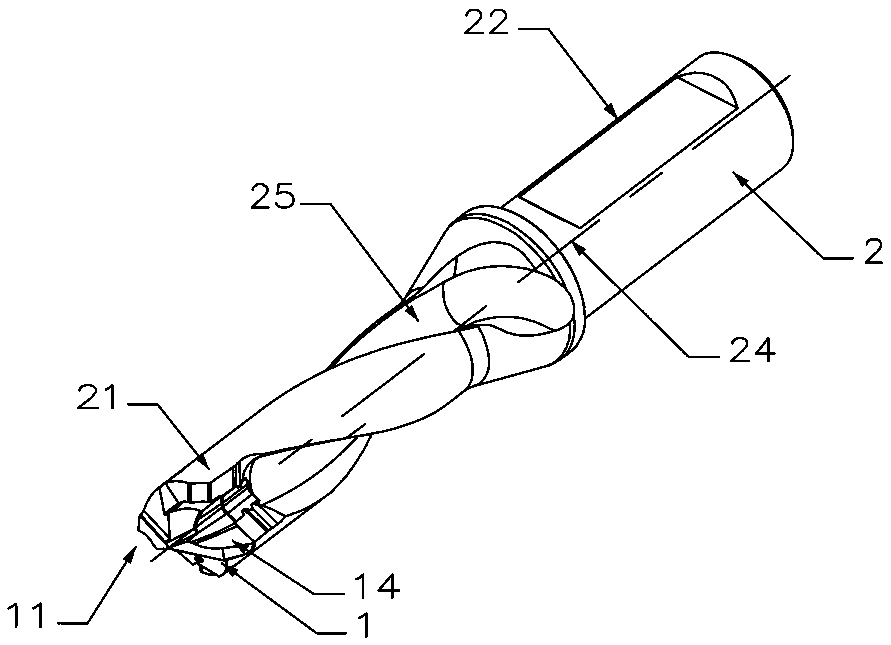

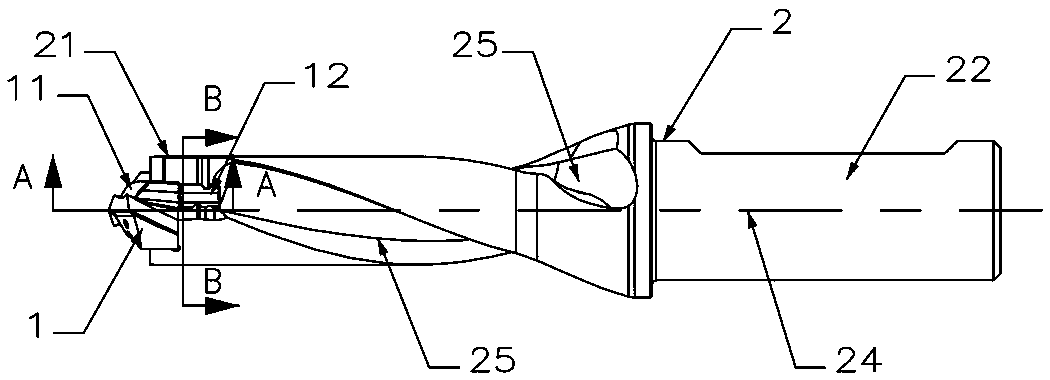

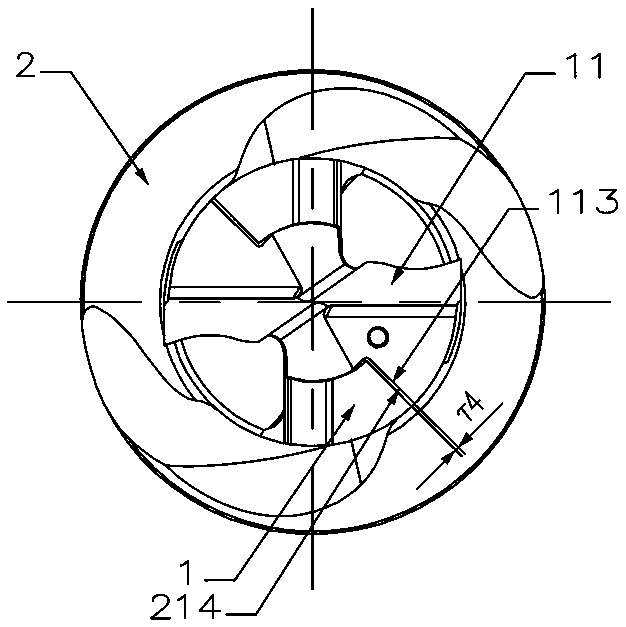

[0044] Figure 1 to Figure 12 An embodiment of a clamping stable drilling tool according to the invention is shown comprising a cutting part 1 and a clamping part 2 which are symmetrical about a central axis 24 The cutting part 1 includes a cutting part 11 and a connecting part 12 connected to the lower end of the cutting part 11. The clamping part 2 includes a handle 22 and two clamping parts 21 located at the front end of the handle 22. On the cutting part 11 of the cutting part 1 There are two cutting edges, the connecting portion 12 is provided with a plurality of chip pockets 14 penetrating the cutting portion 11, the connecting portion 12 is provided with an outer peripheral surface 13 between adjacent chip pockets 14, and the clamping portion 21 is provided with The spiral groove 25 corresponding to the chip flute 14 and exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com