Making method of yolkless poultry egg

A production method and technology of poultry eggs, which are applied in the field of production of poultry eggs without yolks, can solve the problems of partial loss of nutrition, complex methods, poor taste of egg yolks, etc., and achieve the effect of increasing edible varieties and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

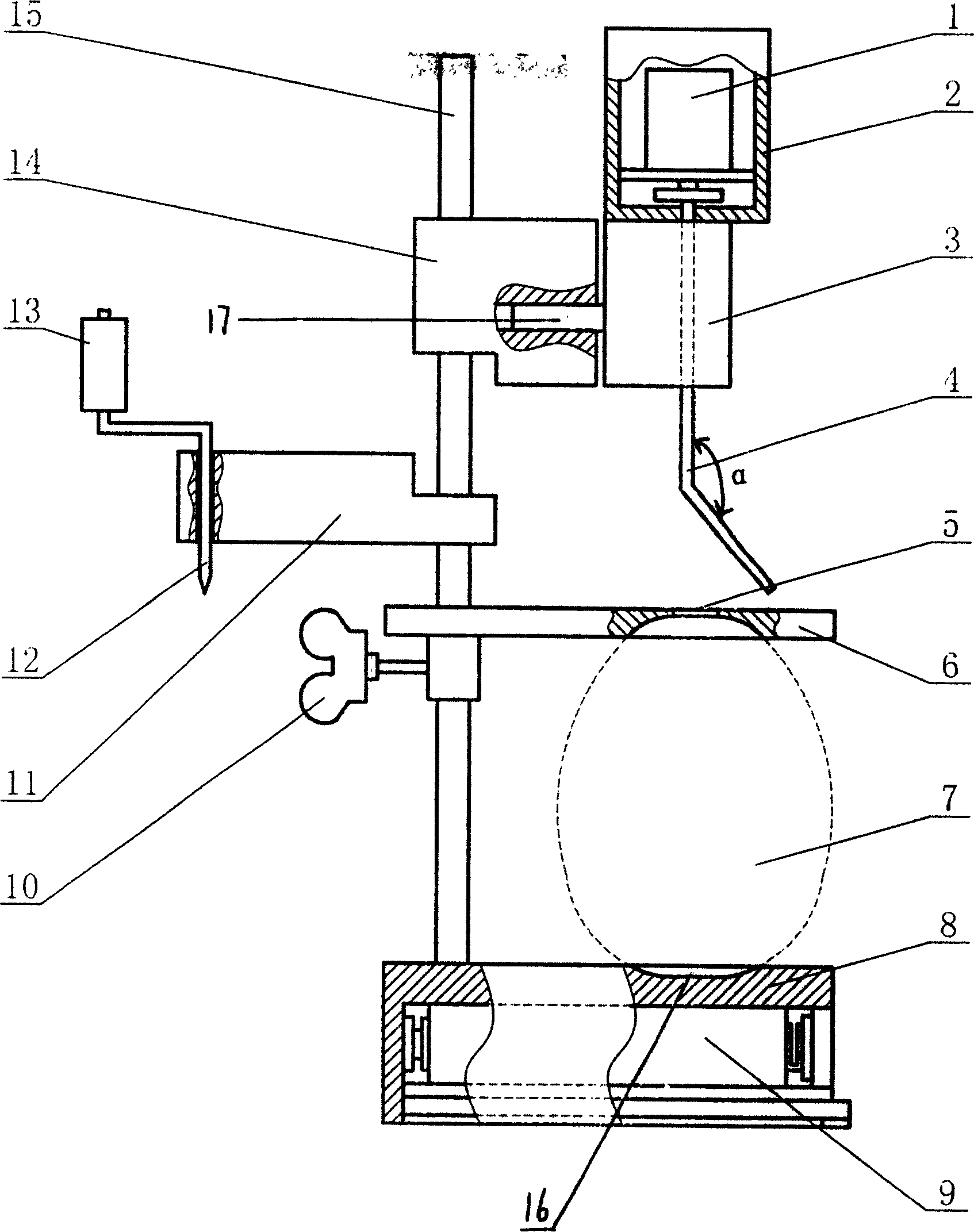

[0007] The preparation method of the yolk-free poultry eggs of the present invention is that poultry eggs are cleaned, and a hole is opened at the end of the poultry eggshell in the direction of the long axis. 12 opened. The diameter of this hole is generally 0.8-2.5 millimeters, through a large number of experiments, considering the overflow situation in the production speed and cooking process, the diameter of this hole is better at 0.8-1.5 millimeters. After opening the hole, put the stirring needle 4 into the egg shell through the hole. The end of the stirring needle 4 and its axis are provided with an inclination angle α. If the inclination angle α is greater than 90°, the effect is better, and the processing speed can be accelerated. The egg yolk and egg white liquid in the shell are evenly stirred to obtain raw poultry eggs without yolk. A further solution of the present invention is: the stirring needle 4 is driven by a mechanical structure, so that the drilling and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com