Expanding sleeve centering clamp

A technology of centering fixtures and expansion sleeves, which is applied in the direction of expanding the mandrel, etc., can solve the problems of complex structure, poor machining accuracy, and long auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

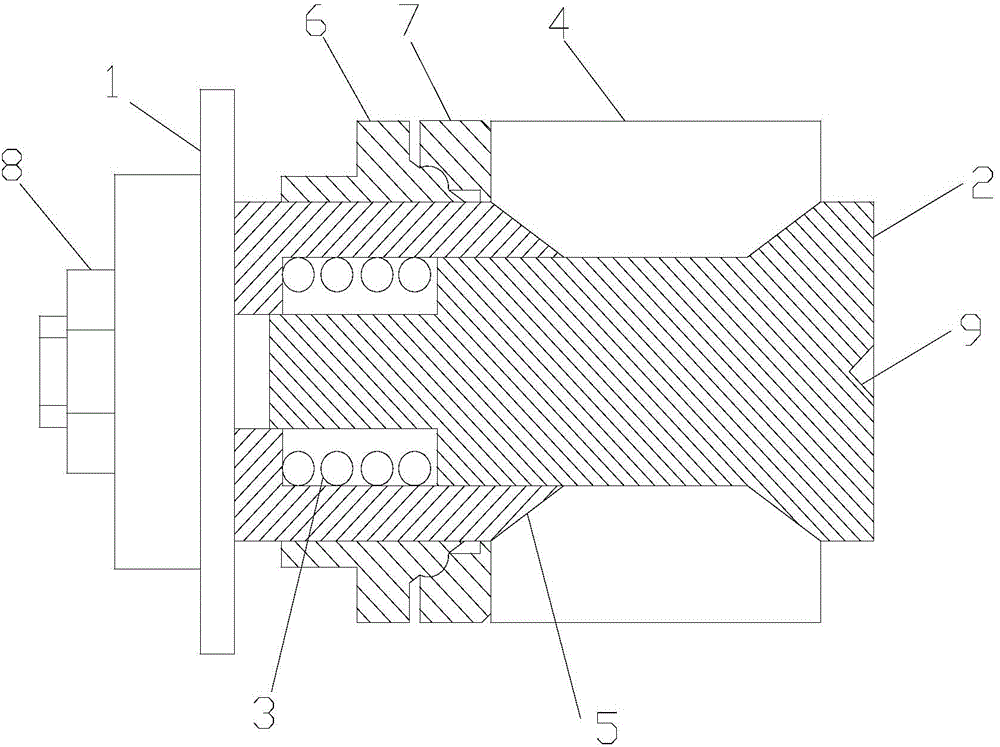

[0012] Such as figure 1 , an expansion sleeve centering fixture, comprising a clamp body 1, an expansion sleeve disc body 4 and a guide strut 2, the guide strut 2 is sleeved in the clamp body 1, and the inner part of the guide strut 2 connected with the clamp body 1 is formed There is a cavity, and the spring 3 connecting the guide strut 2 and the clamp body 1 is arranged in the cavity, and the outer surface connected between the guide strut 2 and the clamp body 1 is provided with a groove 5 for setting the expansion sleeve circular petal body 4, and the concave The two sides of the slot 5 are provided with slopes, and the end surface of the tail of the guide column 2 is provided with a central hole 9. The clamp body 1 is also provided with a spherical nut 6, and a spherical nut 6 is also provided between the spherical nut 6 and the expansion s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com