Stamping device suitable for machining automobile parts in different sizes

A technology of auto parts and stamping devices, which is applied in the field of stamping machines, can solve the problems of being unable to adapt to different sizes of auto parts, difficult to meet the use needs, and increasing the investment cost of enterprises, so as to improve convenience, reduce investment costs, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

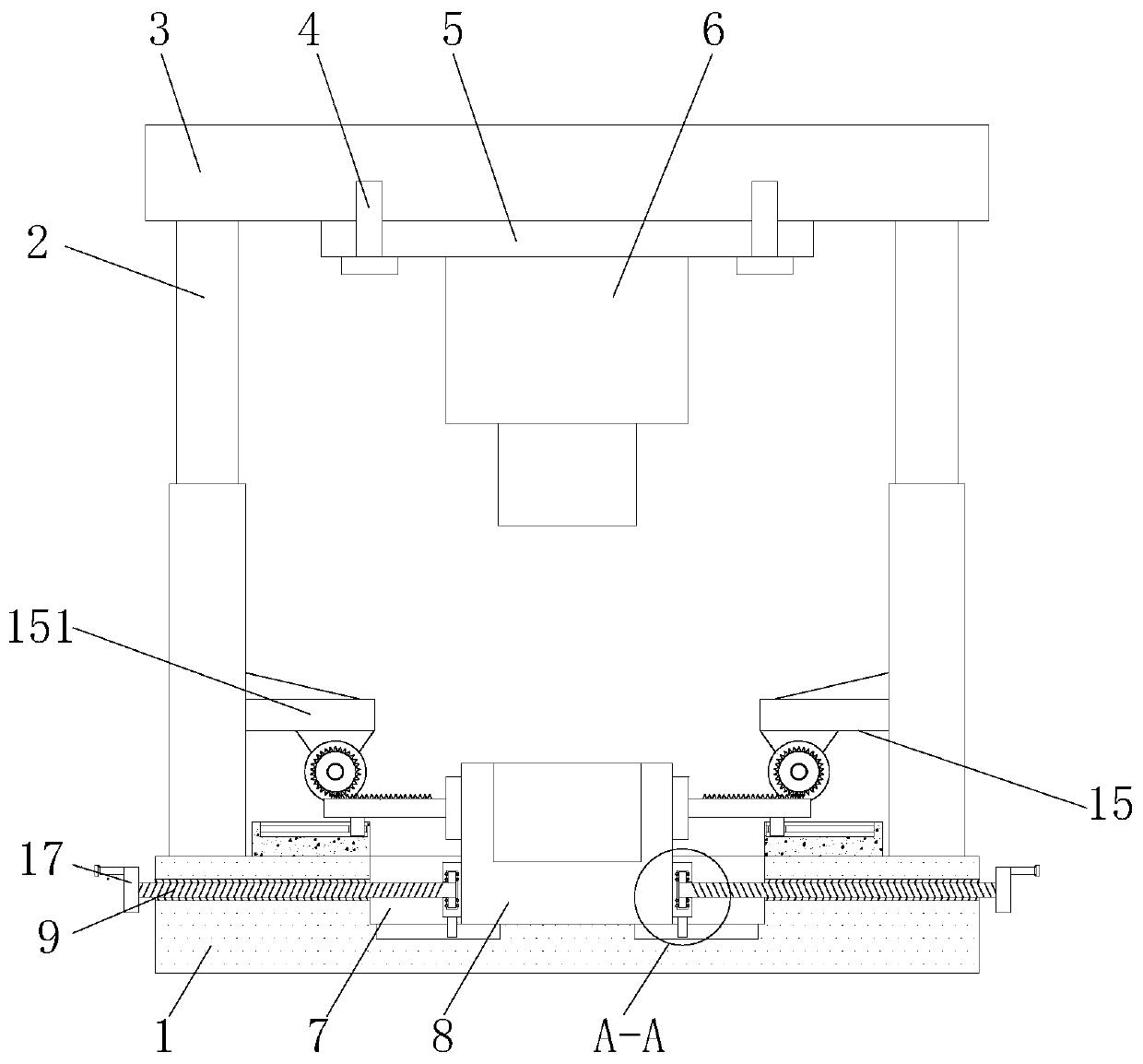

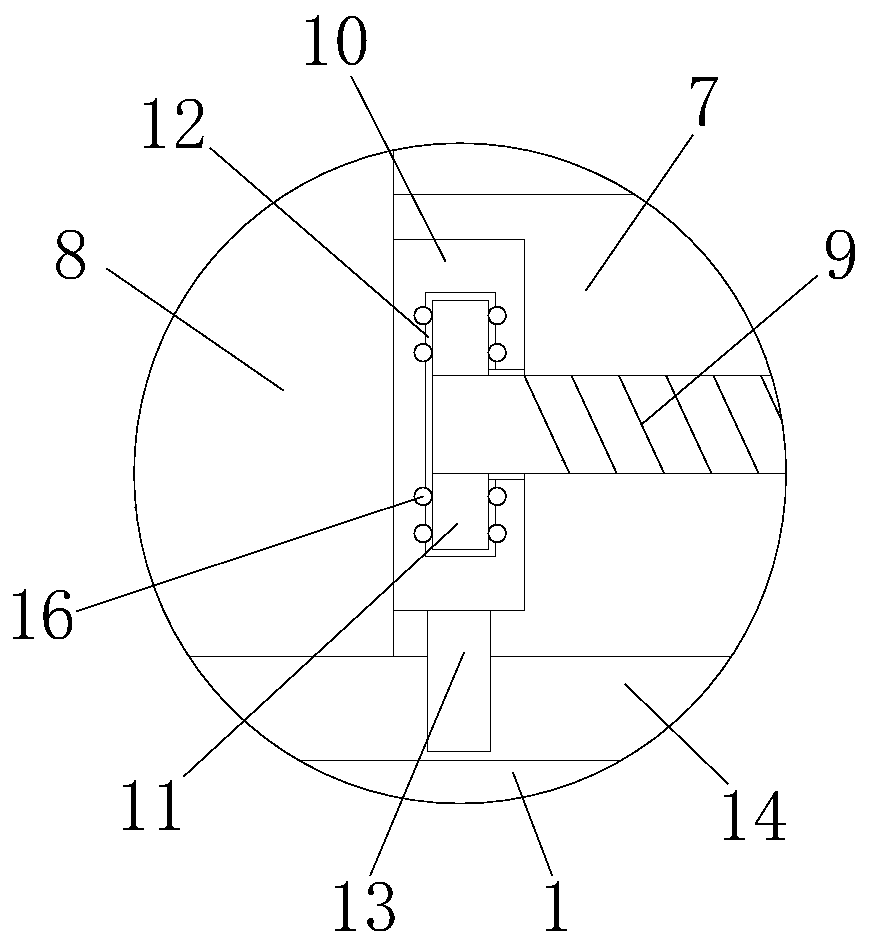

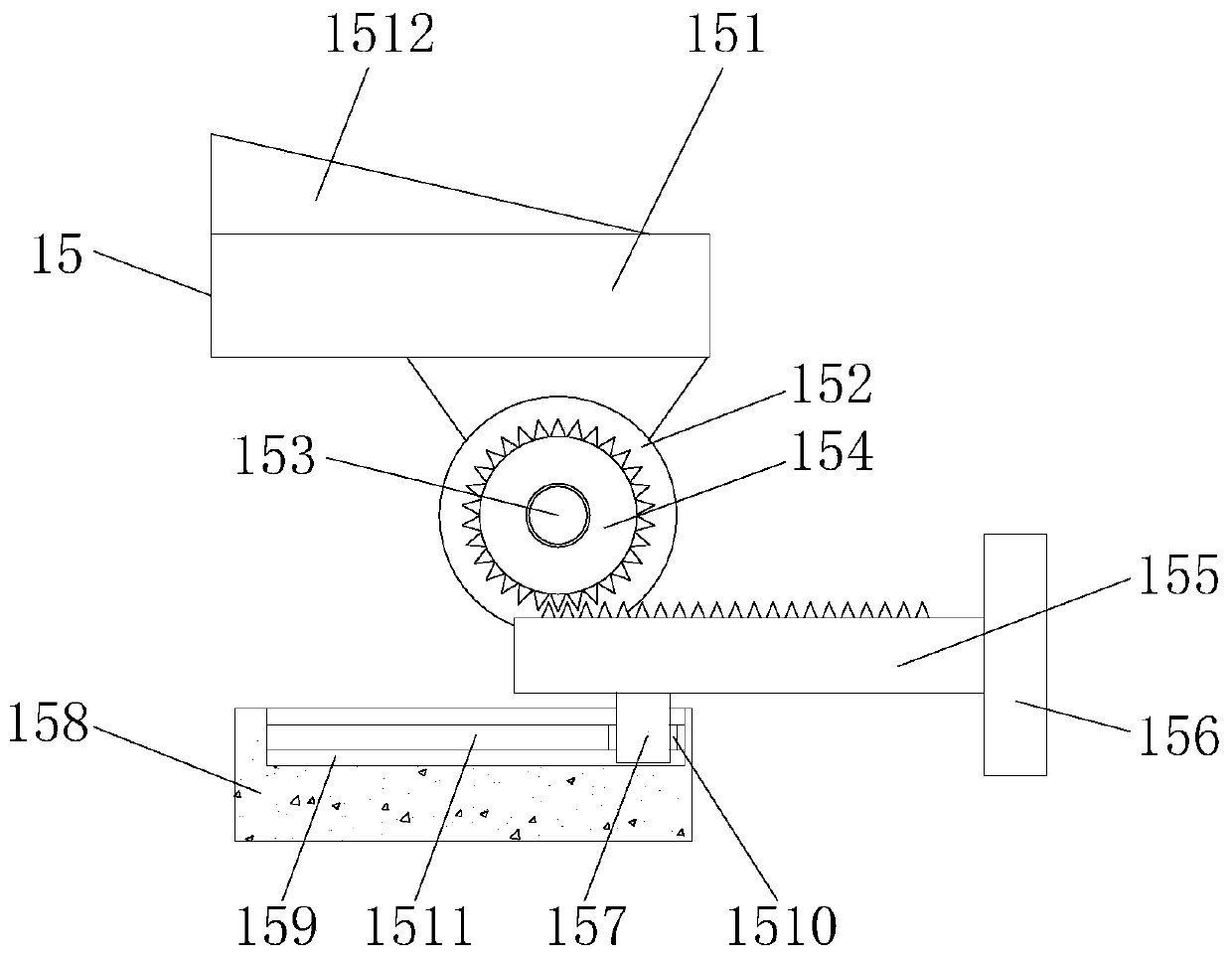

[0022] Example 1: See Figure 1-4 , a stamping device suitable for processing auto parts of different sizes, including a base 1, the left and right sides of the top of the base 1 are fixedly connected with an upper top plate 3 through a telescopic column 2, and the bottom of the upper top plate 3 is threaded through a mounting bolt 4. The upper mold mounting plate 5, the bottom of the upper mold mounting plate 5 is fixedly connected with the upper mold body 6, the top of the base 1 is provided with a lower mold fixing groove 7, and the inside of the lower mold fixing groove 7 is provided with a lower mold body 8, and the base 1 is left and right Threaded rods 9 are provided on both sides and corresponding to the position of the lower mold fixing groove 7. The end of the threaded rod 9 away from the base 1 is fixedly connected with a rocker 17. The end of the threaded rod 9 close to the base 1 runs through the base 1 and the lower mold in turn. The groove 7 extends to the insid...

Embodiment 2

[0025]Embodiment 2: On the basis of the first embodiment, on the right side of each second clamping plate 156 and increase a T-shaped thin strip with a scale, so that the verticality of the lower mold when it is clamped and the lower mold and The centering or fixed-distance placement of the upper mold is specifically designed to be provided with a T-shaped thin strip on the side away from the rack 155 on the second clamping plate 156. The T-shaped thin strip includes a straight line segment and two perpendicular to the straight line segment. Horizontal section, one end of the straight section is connected to the intersection point of the two horizontal sections, scales are provided on the straight section and the two horizontal sections and both can be stretched, the ends of the two horizontal sections and the ends of the two horizontal sections The front end on the handover point is provided with a magnet, and the specific working process of this embodiment is as follows: when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com