Packaging structure of flat plate type oxygen sensor

An oxygen sensor and packaging structure technology, applied in the field of flat oxygen sensor packaging structure, can solve the problems of complex packaging process, poor contact between chip electrode pins and wire terminals 8, and reliable conduction, etc., and achieve simple and convenient assembly , The assembly process is simple and easy to operate, and the effect of not easy to slide and leak air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

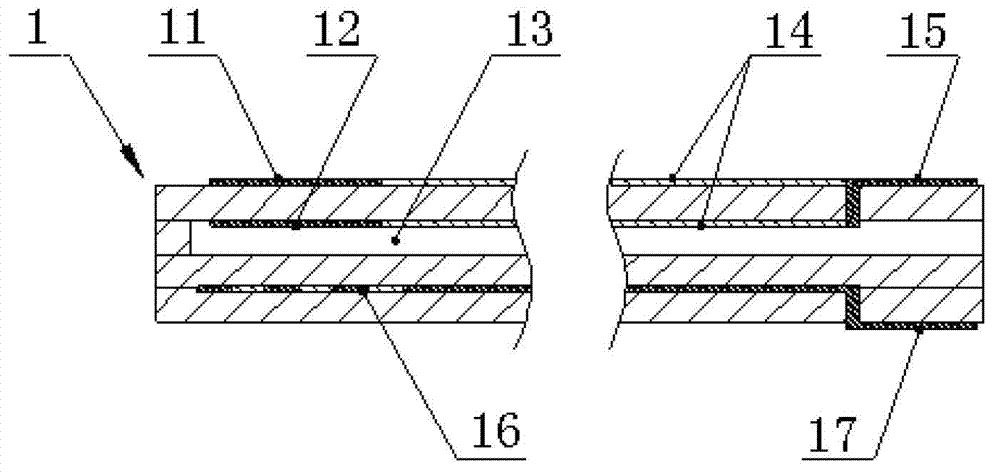

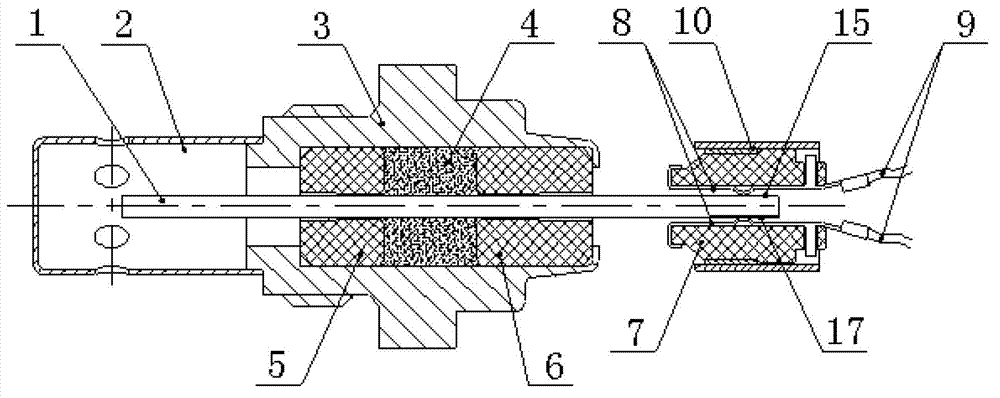

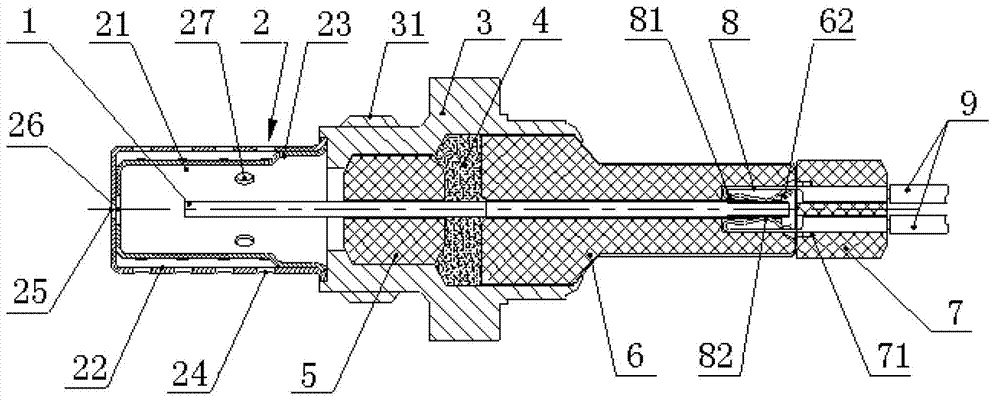

[0029] A package structure of a planar oxygen sensor, such as image 3 shown. The oxygen sensor chip 1 is sealed in the base 3 , and the outer cylindrical surface of the base 3 is provided with an external thread 31 . The middle section of the chip 1 is located in the central hole of the upper positioning ceramic part 6, the sealing powder block 4 and the lower positioning ceramic part 5, and the base is set on the outside of the upper positioning ceramic part 6, the sealing powder block 4 and the lower positioning ceramic part 5.

[0030] The above-mentioned lower positioning ceramic part 5, sealing powder block 4 and upper positioning ceramic part 6 are all cylindrical structures, wherein the upper positioning ceramic part 6 is two sections of cylinders connected with different diameters, and the first section of the upper positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com