Wrapping-type iron wire binding tool for sleeve joint of soft pipe and hard pipe and binding method

A soft and hard tube, wrapping technology, applied in the direction of construction, building structure, building materials processing, etc., can solve the problems of easy twisting, iron wire twisting, low conversion efficiency, etc., and achieve high tightening effect , avoid twisting, high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

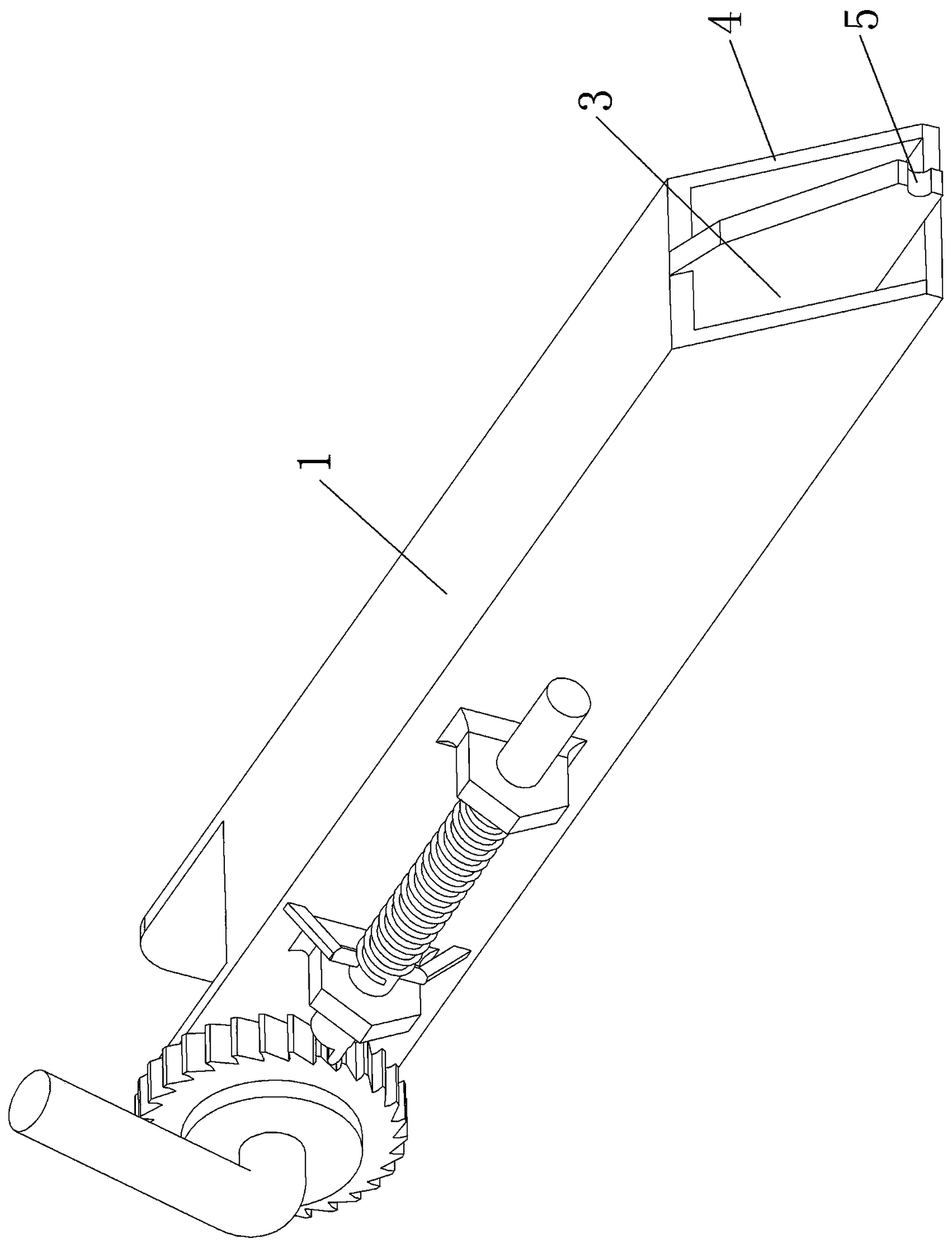

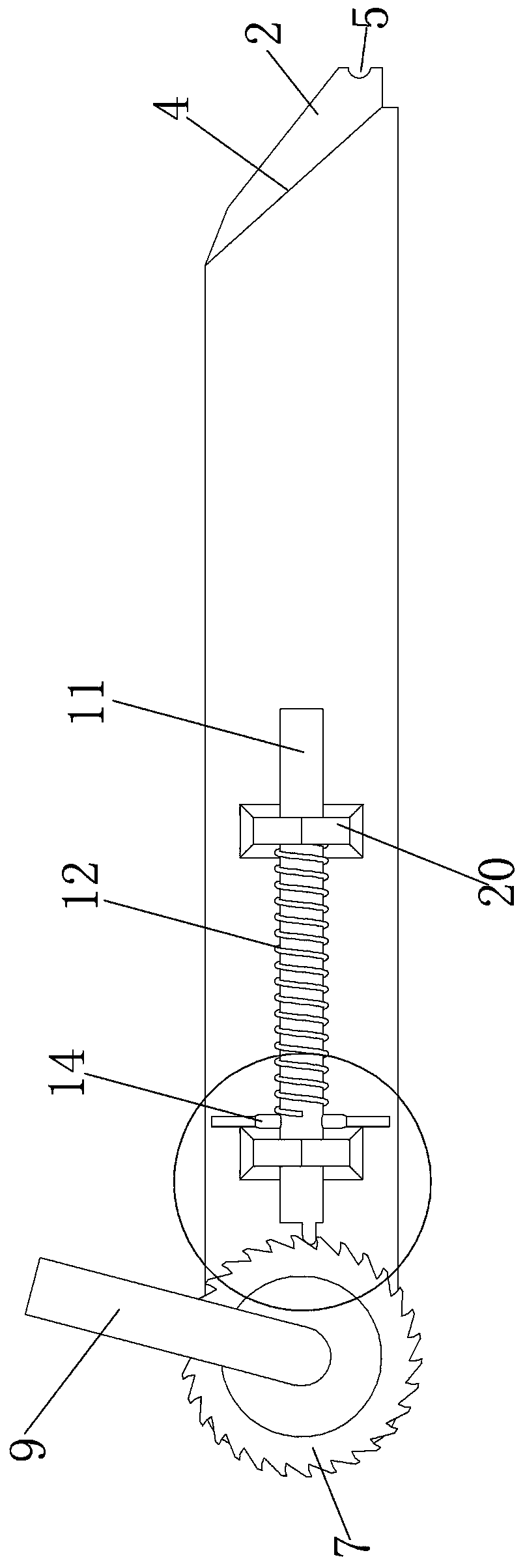

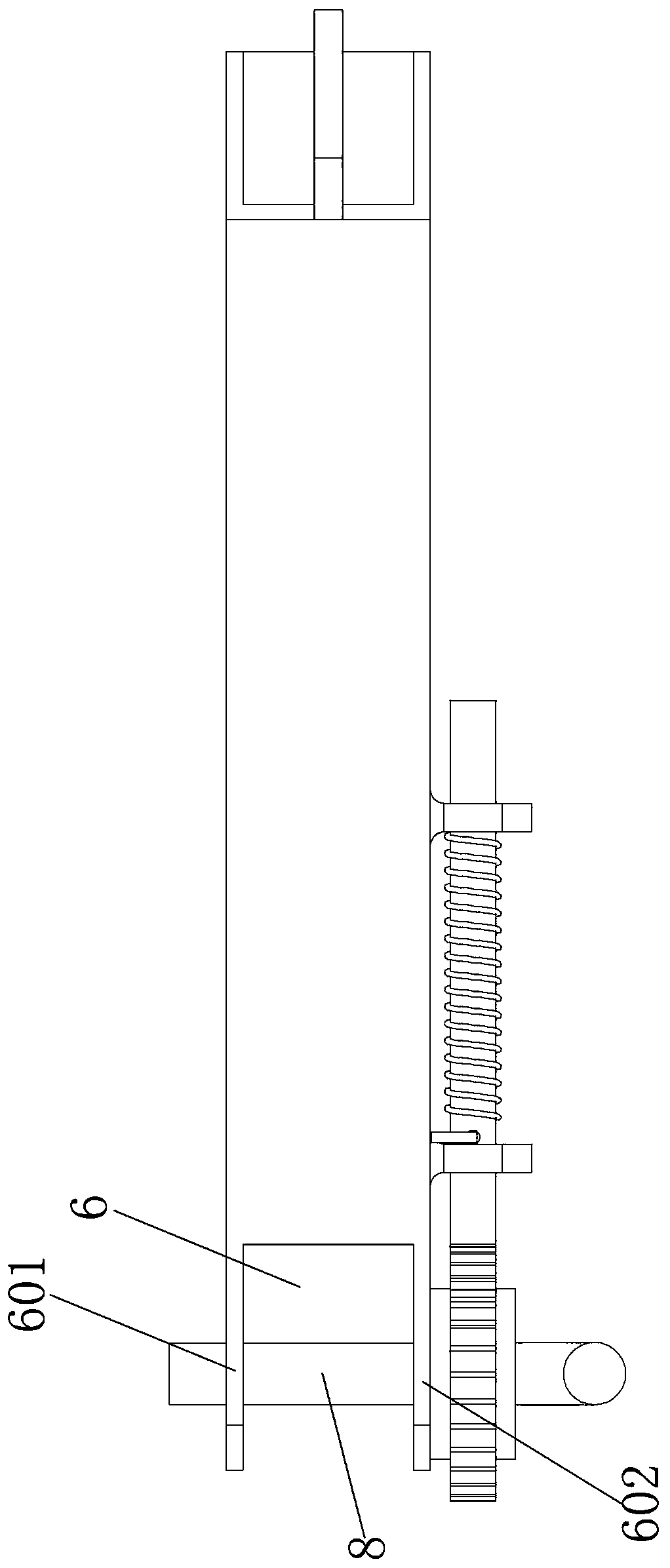

[0035] Embodiment one, with reference to the attached Figure 1-9 , a wrap-around iron wire binding tool for soft and hard pipe sockets, the tool includes a tool body and a tensioning device and a positioning device installed on the tool body, characterized in that: the tool body is open at both ends Cuboid shell, the tool body is provided with a long partition along the length direction to divide the inside of the tool body into two iron wire channels with matching sizes, the free end of the iron wire is snapped into the slit from the channel; one end of the tool body There is an oblique cutout at the opening, and the above-mentioned long partition protrudes from the cutout, and the lower end of the protruding part is provided with an arc-shaped iron wire pressing groove, and the constant pressure groove can press against the fixed end of the iron wire, and the other end of the tool body The two side walls of the opening extend upwards into left and right support plates, and ...

Embodiment 2

[0040] Embodiment two: with reference to attached Figure 1-9 , a kind of method that adopts above-mentioned soft and hard pipe socket to use wrap-around type iron wire binding tool to carry out soft and hard pipe socket binding, concrete steps are as follows:

[0041] ①Suit

[0042] Put the hose that needs to be connected with the hard pipe on the hard pipe, and fold a piece of iron wire in half to form a U shape;

[0043] ② wire winding

[0044] Put the U-shaped end of the iron wire tightly on the hose, and wrap the two free ends of the iron wire around the pipe wall for at least one turn at the same time, and when winding each turn of the iron wire, the two free ends of the iron wire pass through the U-shaped end of the iron wire ; ③Installation of binding tools

[0045] After the iron wire is wound, there is a certain margin in the length of the two free ends of the iron wire, and the two free ends of the iron wire are respectively passed through the two iron wire passa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com