Ballot sorting module adopting side open paper feeding channel

A paper-feeding channel and channel technology, applied in the field of ballot sorting modules, can solve problems such as error-prone, time-consuming and labor-intensive, and achieve the effects of facilitating maintenance, improving sorting efficiency, and reducing stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

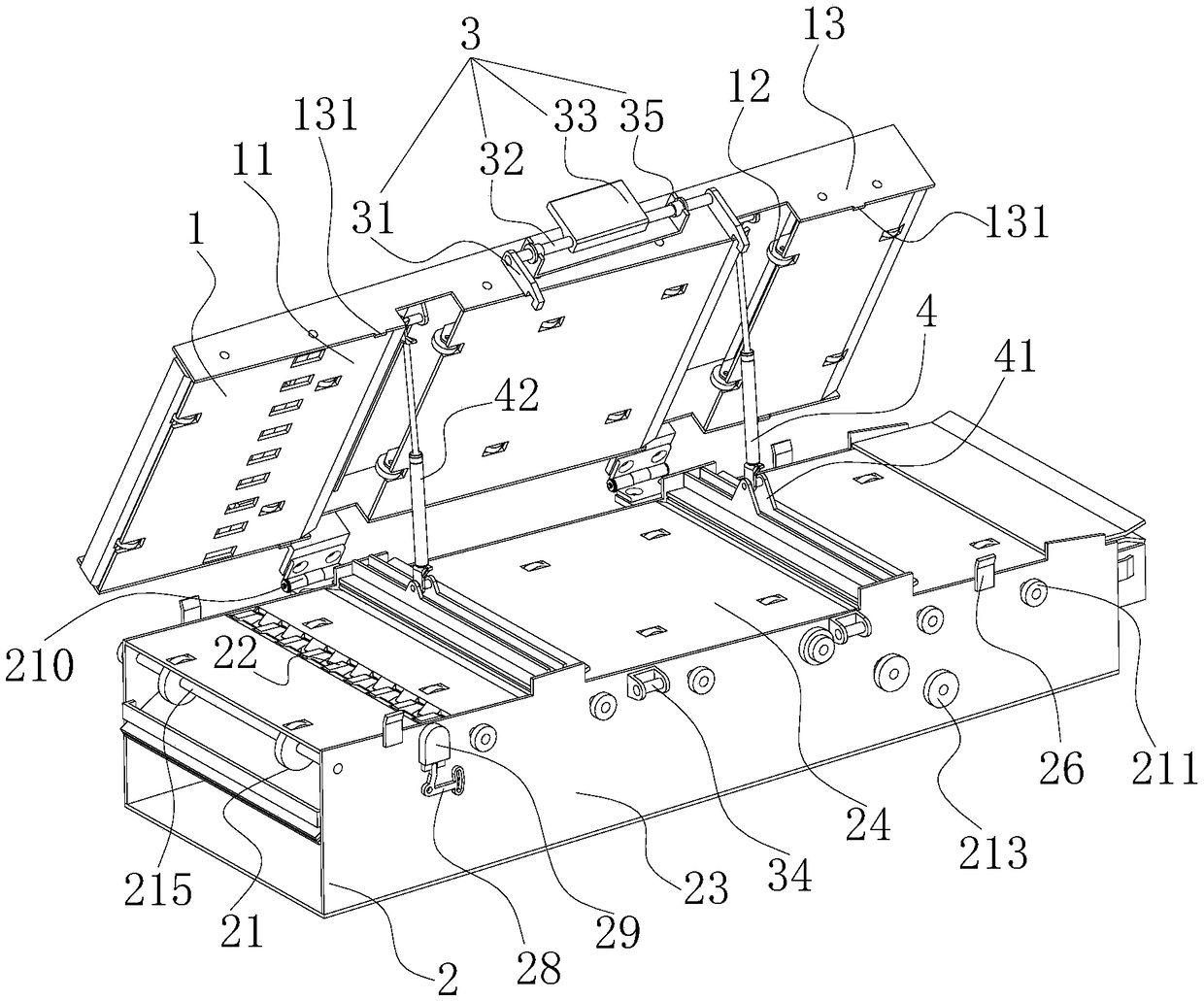

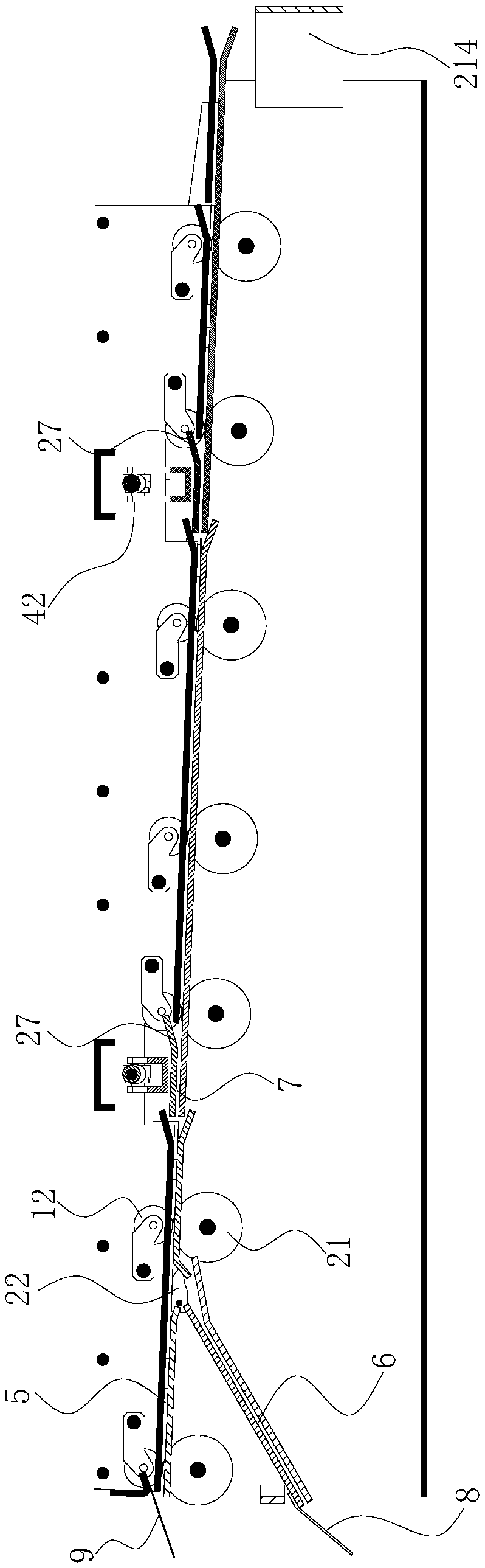

[0035] This embodiment provides a ballot sorting module using a side-opening paper feeding channel, including a first channel 7; a positioning connection structure is provided between the first channel 7 and the reader, so that the first channel 7 The entrance communicates directly with the exit of the reader; the second passage 5 and the third passage 6 are respectively provided at the end of the first passage 7 away from the reader; between the entrance of the second passage 5 and the entrance of the third passage 6 A rotating sorting element 22 is arranged between them; the sorting element 22 is connected with a first driving device that drives it to rotate, and when the sorting element 22 is at the starting position, the second channel 5 communicates with the first channel 7 , forming a first sorting channel, when the sorting element 22 is located at the terminal position, the third channel 6 communicates with the first channel 7 to form a second sorting channel;

[0036] ...

Embodiment 2

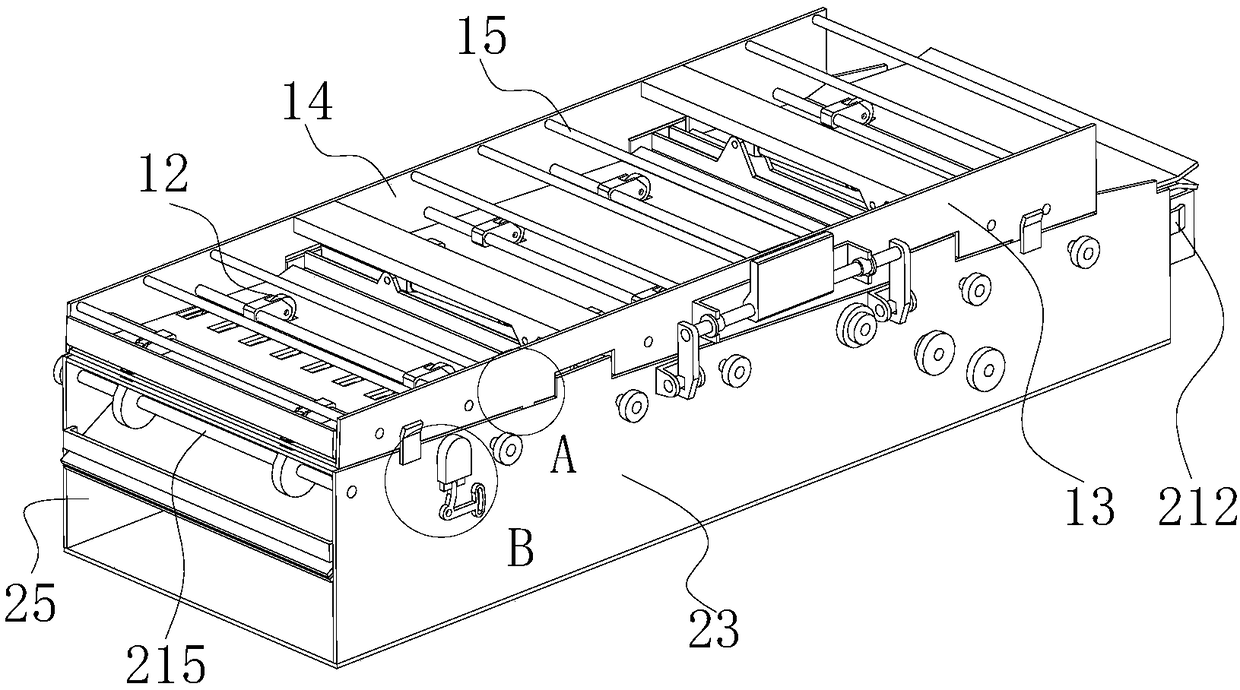

[0046] After the paper press assembly 1 is opened, if there is no support structure, then it is necessary to manually hold the paper press assembly 1 to operate, which is inconvenient and unsafe to operate. Therefore, this embodiment is based on the first embodiment. A support structure 4 is provided between the paper assembly 1 and the paper assembly 2, and when the paper pressing assembly 1 and the paper assembly 2 are opened, the support structure keeps the paper pressing assembly 1 and the paper assembly 2 in an open state. Specifically, such as figure 1 As shown, the supporting structure 4 includes a gas spring 42; Such as image 3 with 4 As shown, a first mount 41 is fixedly connected between the first lower side plate 23 and the second lower side plate 25, the first mount 41 is located above the first bottom plate 24, the cylinder body of the gas spring 42 is connected to the first The mounting seat 41 is hinged, and the piston rod of the gas spring 42 is hinged to t...

Embodiment 3

[0048] In this embodiment, on the basis of Embodiment 1 or 2, the first sorting channel is gradually inclined upward along the conveying direction of the ballot paper. To slow down the conveying speed of the ballots, prevent the ballots from rushing out of the ballot sorting channel quickly, causing the ballots to fly off the receiving tray. At the same time, in this embodiment, a first buffer sheet 9 is fixed at the end of the second channel 5 away from the first channel 7; a second buffer sheet 8 is fixed at the end of the third channel 6 away from the first channel 7 . In order to further avoid the problem that the ballots are rushed out of the receiving tray due to the excessive delivery speed of the ballots when they are sent out of the ballot sorting module.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com