Wire-dragging device of rail shuttle vehicle matched with shuttle storage rack in use

A shuttle rack and shuttle car technology, applied in the field of machinery, can solve the problems of reducing cargo carrying capacity, high manufacturing and maintenance costs, poor stability, etc., and achieve the effects of avoiding cargo carrying capacity, reducing energy consumption, and reducing manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

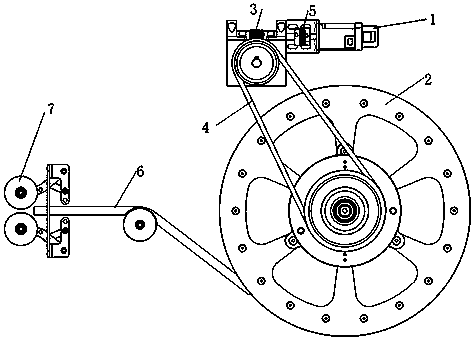

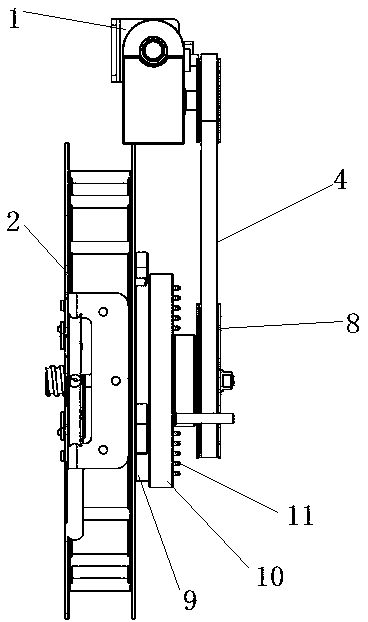

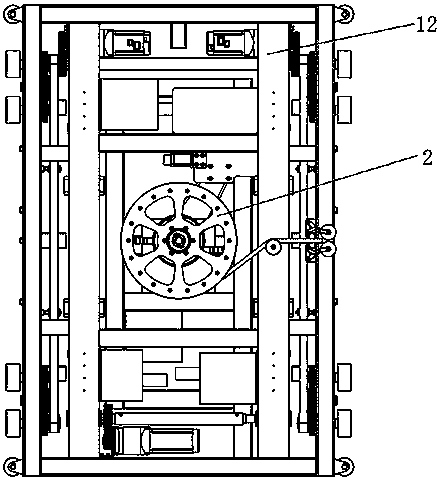

[0028] like figure 1 , figure 2 and image 3 As shown, a wire-drawing device for a rail shuttle used in conjunction with a shuttle rack includes a wire-drawing device, the wire-drawing device includes a wiring assembly, a winding assembly, and a coiled wire fixed axle, and the wiring assembly includes a sliding contact Disc 9, a wiring reel 10, the winding assembly includes a driving motor 1, a winding reel 2, a winding guide 7, two guide wheels 6; the driving motor passes through a synchronous belt 4 and the reel screw of the winding reel Linkage, the power cord is wound on the winding reel, and the power cord protruding from the reel passes through the winding guide, and then passes through the space between the two guide wheels; there is a ring-shaped Sliding contact rail, the wiring board is provided with a terminal head 11 in contac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com