Manufacturing technology of package print

A production process and printing technology, applied in the field of self-adhesive processing, can solve problems such as tearing of self-adhesive films, and achieve the effects of enhancing adhesion strength, blocking water splashes, and protecting the conveyor belt body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

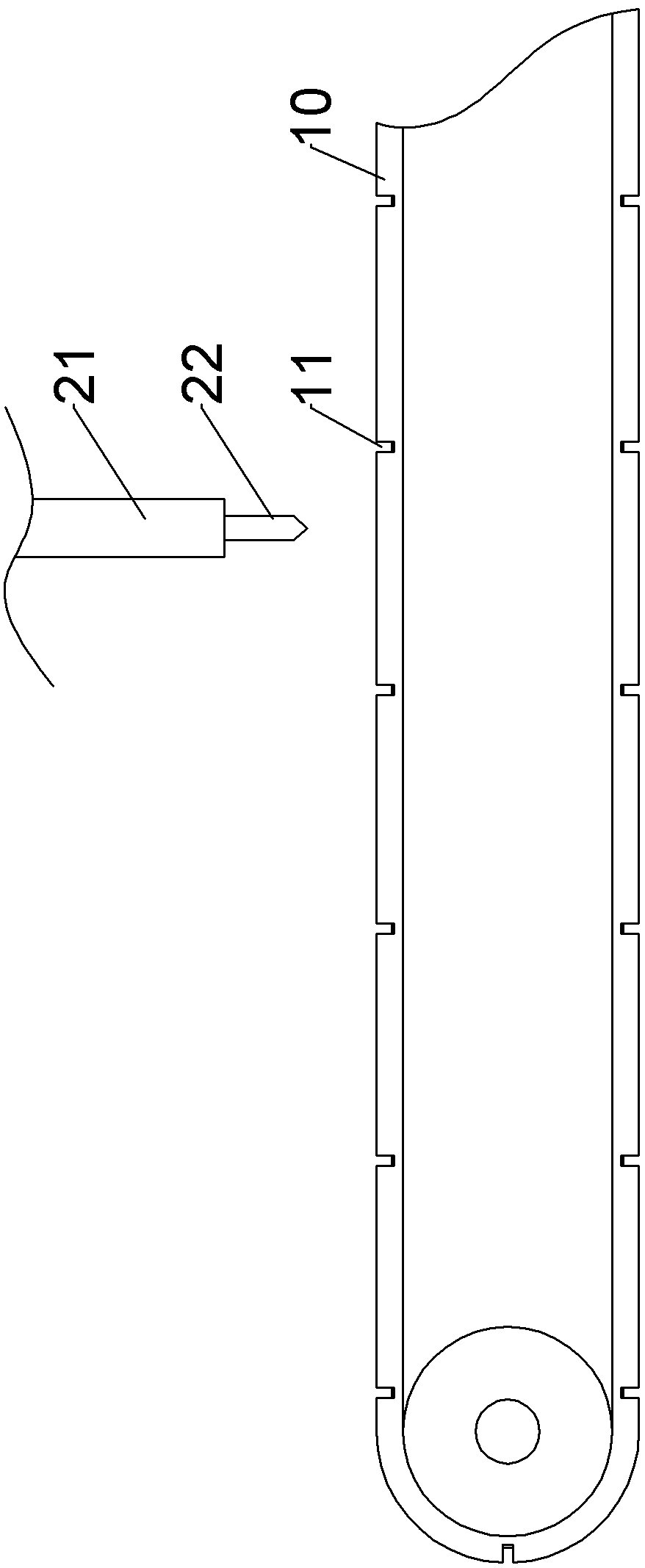

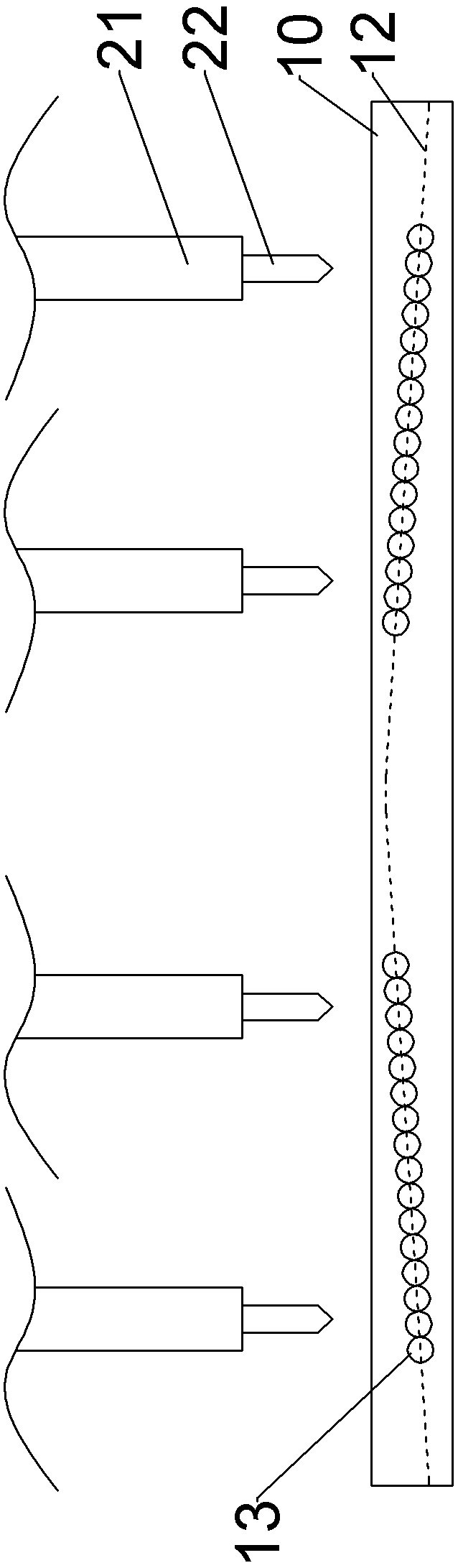

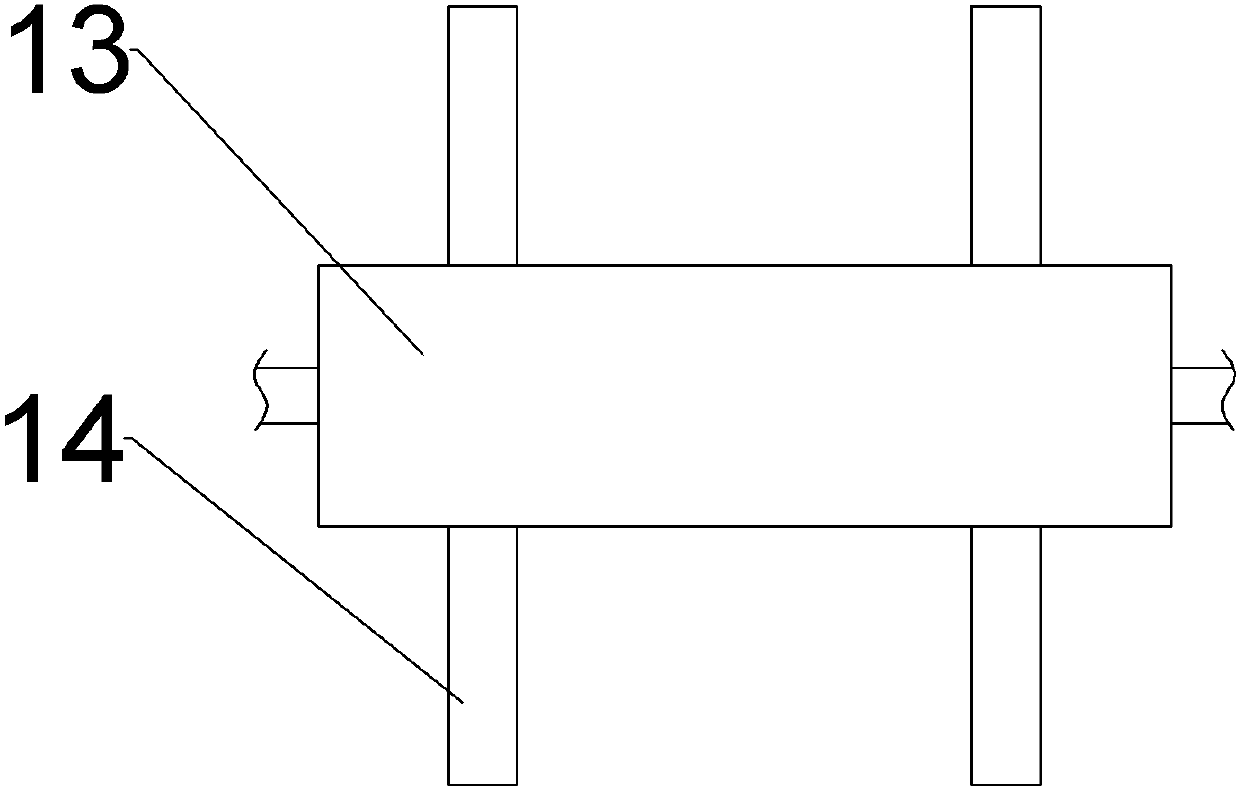

[0022] The reference numerals in the accompanying drawings of the description include: conveyor belt body 10 , drainage groove 11 , drainage slope 12 , water suction roller 13 , blast blade 14 , water cutter main body 21 , and water cutter cutter head 22 .

[0023] A process for producing packaged printed matter, which is completed by means of a packaged printed matter processing device. The process includes the following steps: Step 1, film coating, attaching the film to the conveyor belt body, and the transmission speed of the conveyor belt body is 3-5m / min ;Step 2, cutting, start the water cutting machine and shut it down quickly, the water jet is sprayed out and contacts the film to cut holes, the whole process takes 0.01-0.02s; Step 3, repeat steps 1 to 2, and so on. Until the hole cutting operation on the film is completed.

[0024] Such as figure 1 Shown: the pac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com