Air-cooled oil cooling system capable of automatically detecting temperature

An automatic detection and heat dissipation system technology, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve the problems of wasting energy and need to be improved, and achieve energy saving, good secondary heat dissipation effect, The effect of ensuring work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with the examples, the present invention is further described, the following examples are illustrative, not limiting, and the protection scope of the present invention cannot be limited by the following examples.

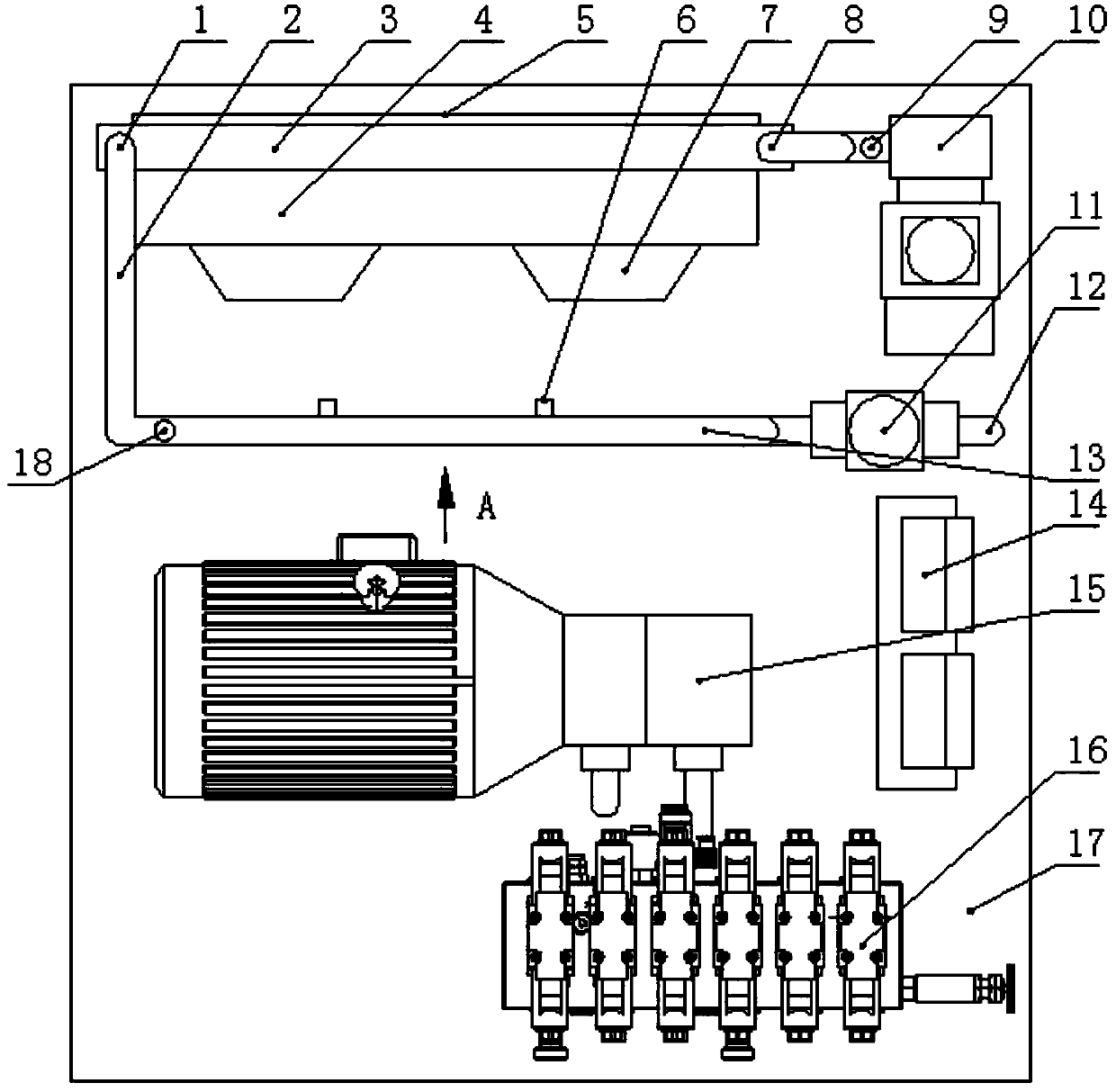

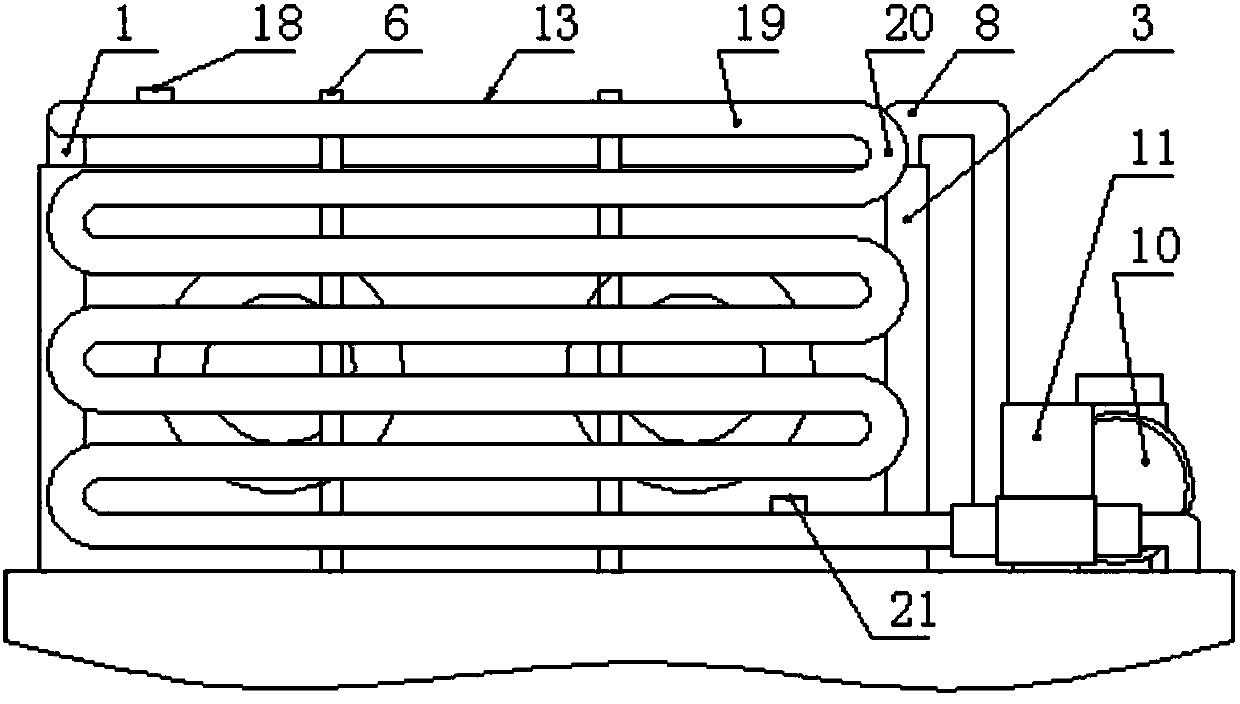

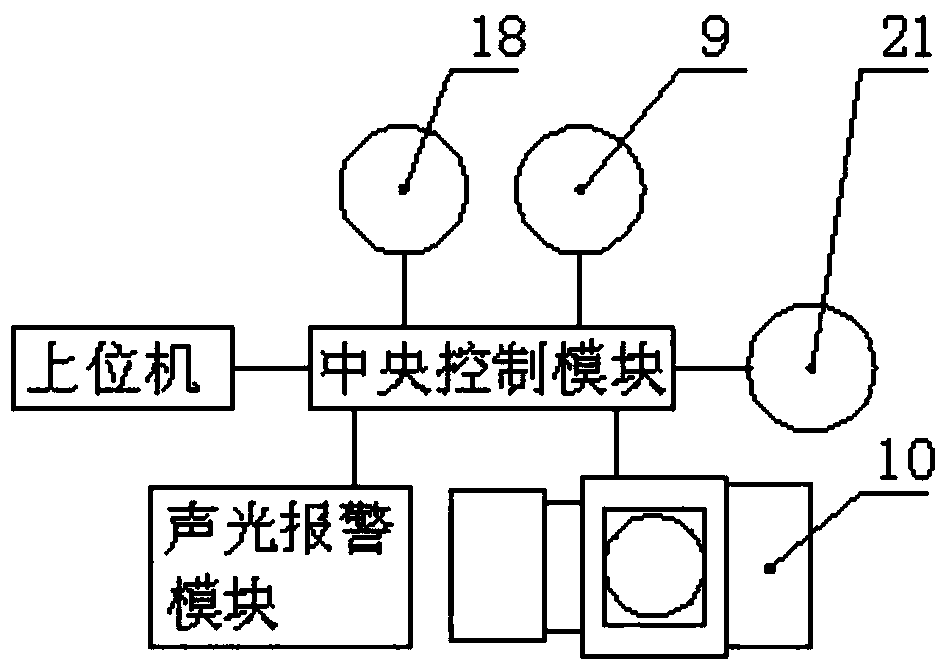

[0016] An air-cooled oil cooling system with automatic temperature detection, such as figure 1 , 2 , 3, including oil tank 17, fuel supply power source 15, switch valve group 16, radiator 3 and fan housing 4, the innovation of the present invention is: the switch valve group is installed on the front end of the upper end face of the fuel tank, and the switch valve group The oil supply power source is installed on the upper end surface of the fuel tank at the rear, and the fan housing is installed on the rear end of the upper end surface of the fuel tank. The fan housing is installed with a radiator facing the outside of the fuel tank, and cooling fins 5 are installed on the radiator. The fan casing is facing the inside of the fuel tank. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com