H-shaped beam longitudinal joint automatic welding machine and welding machine head

An automatic welding machine and welding head technology, applied in welding equipment, metal processing equipment, metal processing and other directions, can solve the problems of increased labor intensity, inconsistent welding quality, trouble in production, etc., to improve welding efficiency, improve welding quality, The effect of ensuring the quality of the welding machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

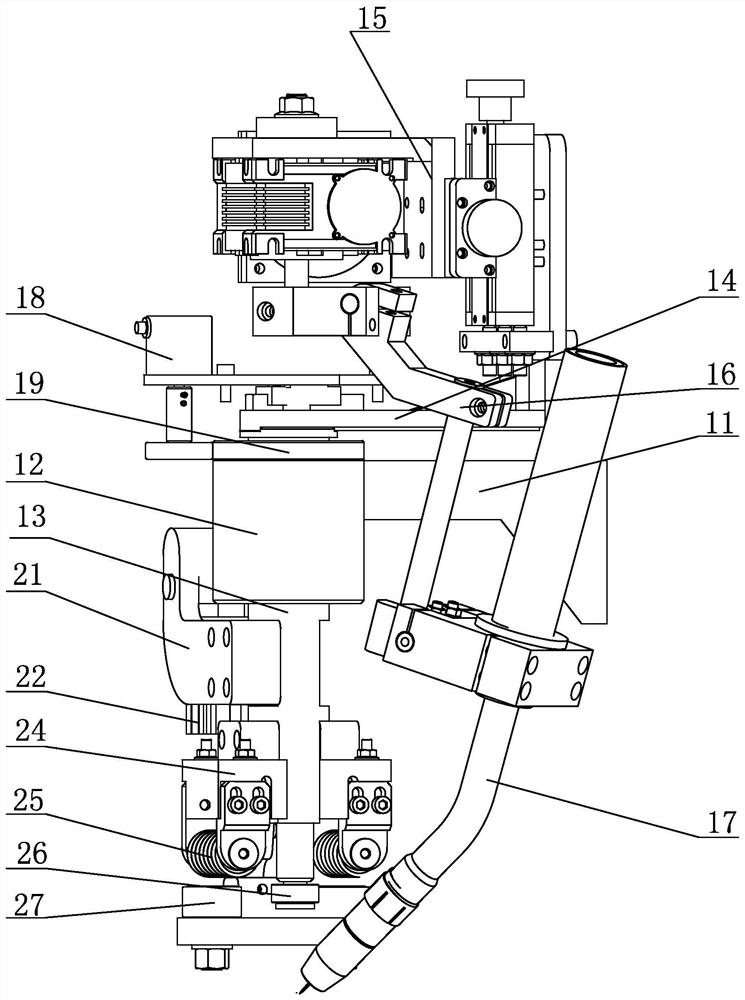

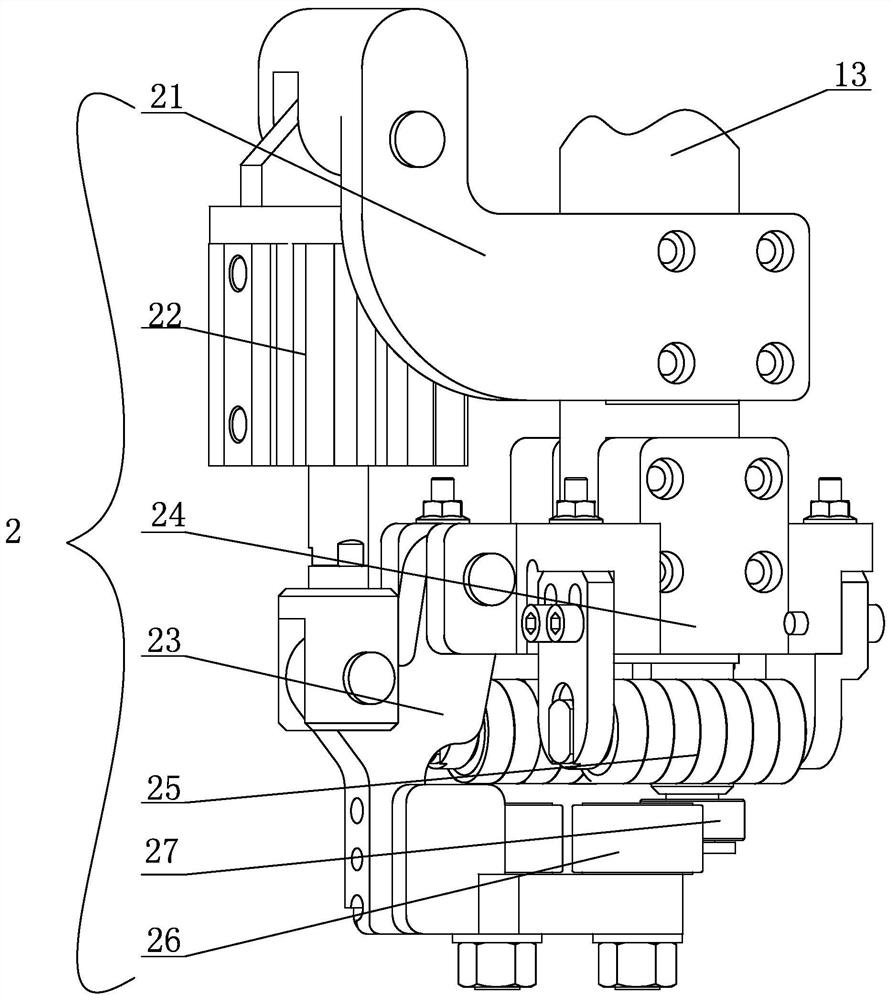

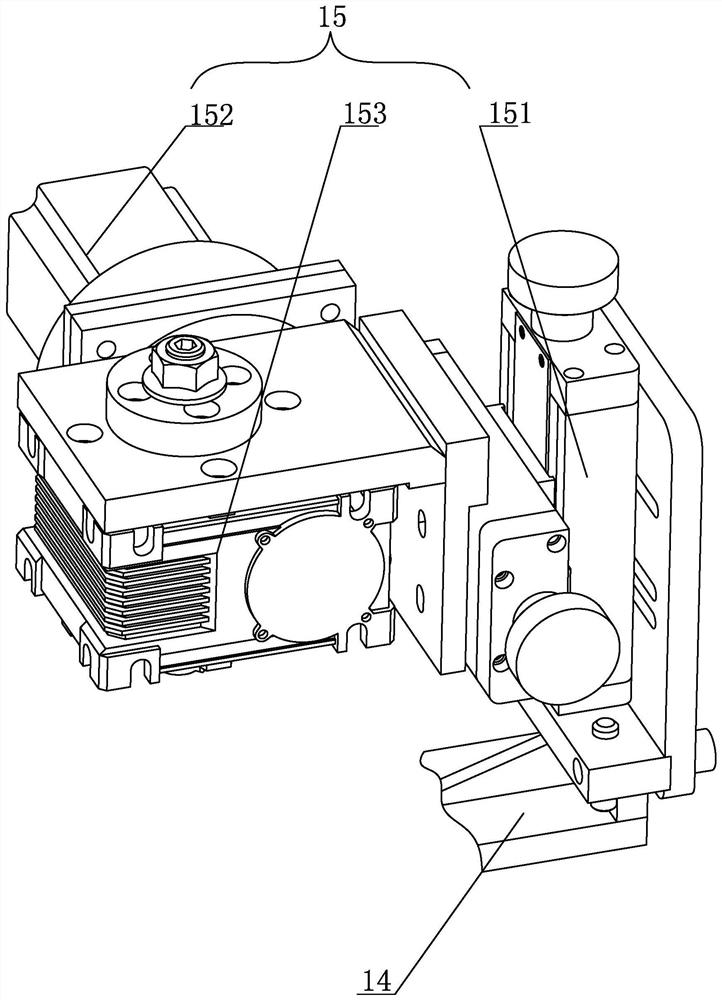

[0021] A kind of welding machine head 1 described in the present invention, as figure 1 As shown, the installation frame 11 is included, and one end of the installation frame 11 is provided with a sleeve 12, and a vertical shaft 13 arranged vertically is installed in the sleeve 12. The upper end is fixedly connected with a mounting plate 14, the mounting plate 14 is provided with an angle adjustment device 15, the output shaft of the angle adjustment device 15 is equipped with a welding torch 17 through a welding gun clamp 16, and the welding torch 17 can be adjusted according to welding requirements through the angle adjustment device 15 The welding angle is adjusted to ensure the welding quality of the weld, wherein the angle adjustment device 15 can be an invention authorized by China, and the patent number is the angle adjustment mechanism described in CN201510562939.1.

[0022] A rotary encoder 18 is also provided on the mounting plate 14. A rotary positioning disc 19 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com