Regenerated waterproof putty powder and application method thereof

A technology of putty powder and water resistance, which is applied in the direction of filling slurry, etc., can solve the urgent problem of resource utilization of waste aerated concrete blocks, and achieve the effects of prolonging the opening time of construction, improving utilization rate, and improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

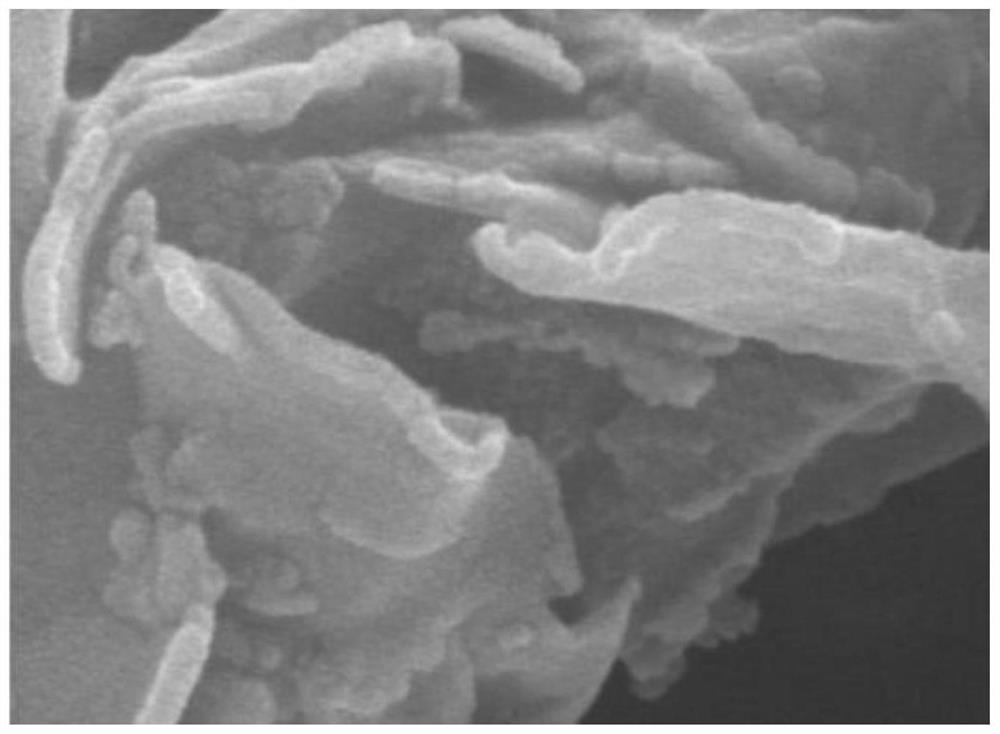

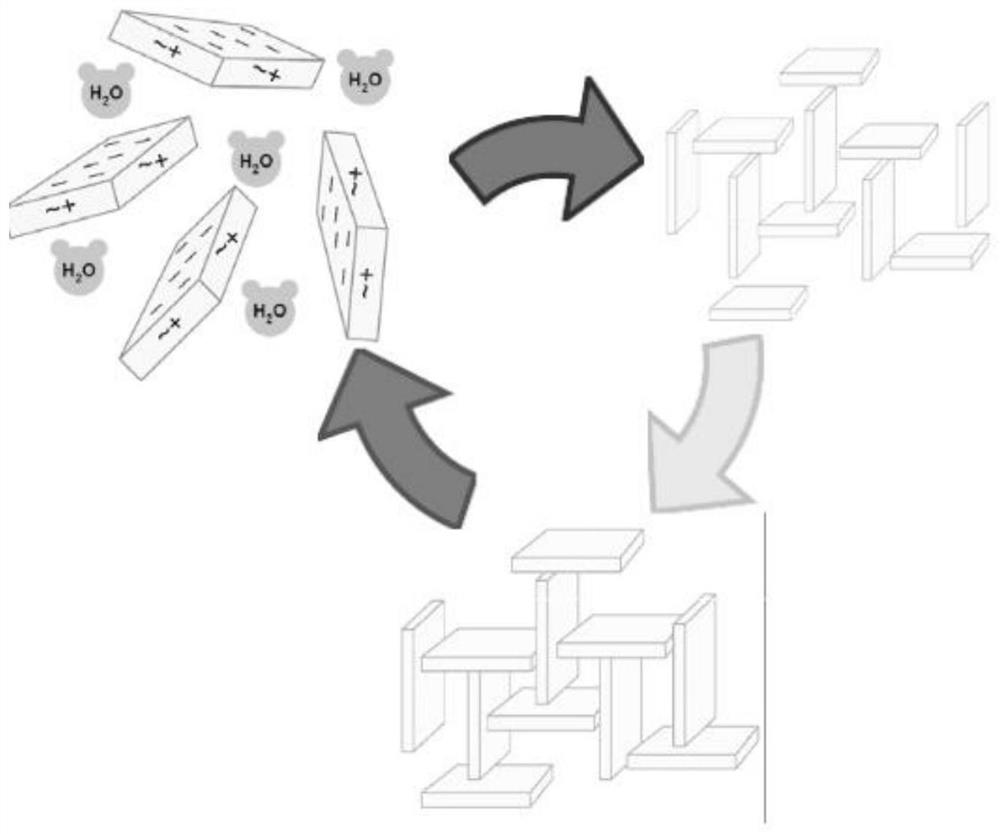

Image

Examples

preparation example Construction

[0056] In the present invention, there is no special limitation on the preparation method of the regenerated water-resistant putty powder, which can be prepared by the preparation method of the composition well-known to those skilled in the art.

[0057] The present invention also provides the application method of the regenerated water-resistant putty powder described in the above technical solution, comprising the following steps:

[0058] Portland cement, waste aerated concrete powder, lime calcium powder, double fly powder, talcum powder, hydroxypropyl methylcellulose, dispersible latex powder, magnesium aluminum silicate Al 2 MgO 8 Si 2 Mix with dry powder polycarboxylate superplasticizer to obtain the regenerated water-resistant putty powder;

[0059] After the regenerated water-resistant putty powder is mixed with water, construction work is carried out.

[0060] In the present invention, the water is preferably tap water or drinking water.

[0061] In the present i...

Embodiment 1

[0074] Prepare various raw materials according to the process requirements, and weigh them at one time according to the weight fraction:

[0075] 250 parts of white Portland cement, 100 parts of gray calcium powder, 450 parts of waste aerated concrete powder, 100 parts of Shuangfei powder, 100 parts of talcum powder, 3 parts of hydroxypropyl methylcellulose, 4 parts of dispersible latex powder, Magnesium Aluminum Silicate Al 2 MgO 8 Si 2 5 parts, 5 parts of dry powder polycarboxylate superplasticizer, 320 parts of drinking water.

[0076] The preparation method of the recycled water-resistant putty powder is as follows: Portland cement, waste aerated concrete powder, lime calcium powder, double fly powder, talcum powder, hydroxypropyl methylcellulose, dispersible latex powder, aluminum silicate Magnesium Al 2 MgO 8 Si 2 Mix with dry powder polycarboxylate superplasticizer to get recycled water-resistant putty powder.

[0077] After bagging, there is no agglomeration, the ...

Embodiment 2

[0079] Prepare various raw materials according to the process requirements, and weigh them at one time according to the weight fraction:

[0080] 250 parts of white Portland cement, 100 parts of gray calcium powder, 500 parts of waste aerated concrete powder, 80 parts of Shuangfei powder, 70 parts of talcum powder, 4 parts of hydroxypropyl methylcellulose, 3 parts of dispersible latex powder, Magnesium Aluminum Silicate Al 2 MgO 8 Si 2 5 parts, 7 parts of dry powder polycarboxylate superplasticizer, 300 parts of drinking water.

[0081] The preparation method of the regenerated water-resistant putty powder is the same as that of Example 1.

[0082] After bagging, there is no agglomeration, the putty powder is evenly distributed, and there is no obstacle for construction and scratching; the surface drying time is 12 minutes, which meets the requirements of the standard JG / T 157-2009 surface drying time ≤ 5 hours; there is no crack after drying for 6 hours, which meets the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com