Isolating membrane of electrochemical device and preparation method of isolating membrane

An isolation film and electrochemical technology, which is applied in the direction of circuits, electrical components, battery pack components, etc., can solve the problems of difficult to control the accuracy of film thickness, difficult to grasp the dispersion of ceramic particles, etc., to increase stability and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present invention will be described in more detail below with reference to the drawings and reference numerals, so that those skilled in the art can implement it after studying this specification.

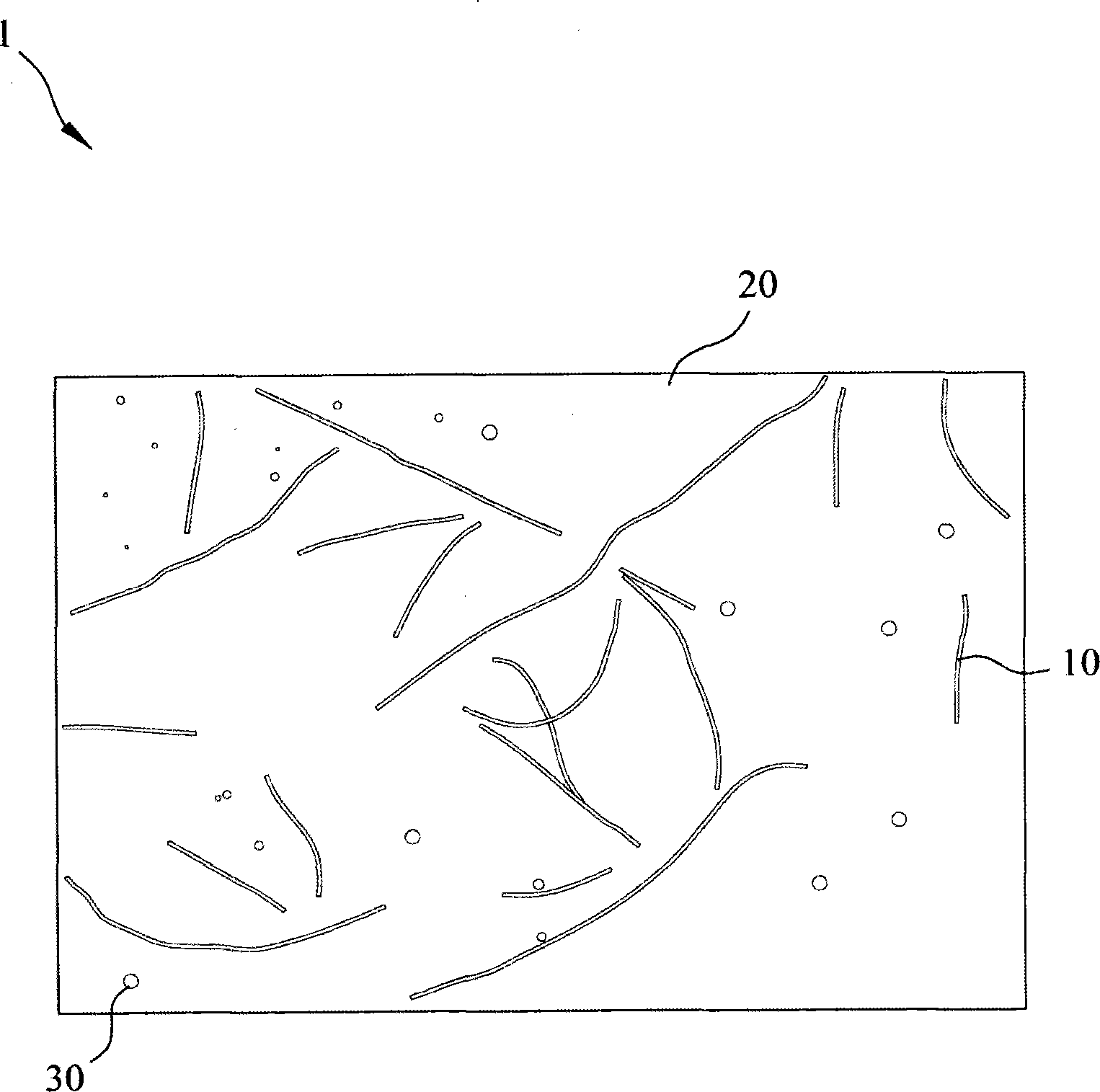

[0033] like figure 1 , Schematic diagram of the structure of the separator of the electrochemical device of the present invention. The electrochemical device separator 1 of the present invention comprises a porous substrate 10, a colloidal polymer 20 and a plurality of ceramic particles 30, the colloidal polymer 20 is coated on at least one surface of the porous substrate 10, The plurality of ceramic particles 30 are fully dispersed in the colloidal polymer 20, wherein the porosity of the porous substrate is greater than 30%, the particle size of the plurality of ceramic particles is 0.01 to 5um, and the electrochemical device The thickness of the isolation film ranges from 10 to 60um.

[0034]The colloidal polymer material is selected from polyvi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com