Sulfur-carbon composite positive electrode material for lithium-sulfur battery and preparation method of sulfur-carbon composite positive electrode material

A technology of carbon composite materials and lithium-sulfur batteries, which is applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte battery electrodes, etc., can solve the problems of high electrochemical active discharge specific capacity, poor cycle performance, and low conductivity, and achieve Improve the utilization rate of active materials, improve the cycle stability, and the effect of high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Disperse 0.1 g of conductive carbon black BP2000 in 27 ml of deionized water and 3 ml of absolute ethanol and ultrasonically disperse at room temperature for 1 h to form a solution with a concentration of 3.3 g / L. Then 32 wt.% sodium polysulfide (Na 2 S 4 ) solution 1.2g continued to ultrasonically disperse for 30 min. After the dispersion was complete, the mixed solution was stirred on a magnetic stirrer at a constant temperature of 60°C until it was dry (it took 5 hours). Transfer to a mortar and grind into powder to get Na 2 S 4 / CCB mixed powder.

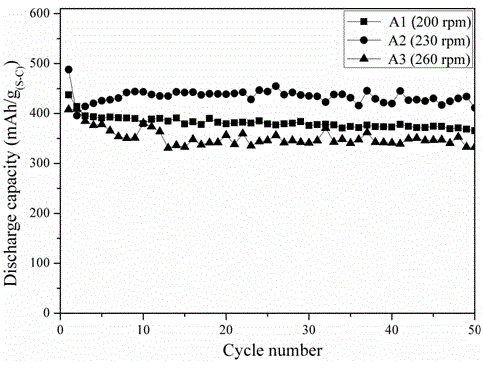

[0036] 2. Put the mixed powder in a zirconia ball mill jar, add NMP (N-methylpyrrolidone) as a solvent, add HCOOH as a reactant, wet ball mill at a milling speed of 230 rpm for 12 h, and vacuum dry at 60 °C The sulfur / carbon composites were obtained by drying in medium temperature for more than 12 h.

[0037] 3. Transfer the prepared sulfur-carbon composite material to a polytetrafluoroethylene reactor filled with...

Embodiment 2

[0039] The difference between this embodiment and Example 1 is the reaction acid selected for preparing the sulfur-carbon composite cathode material in step 2. The specific preparation method is as follows:

[0040] Na prepared in step 1 2 S 4 / CCB mixed powder was placed in a zirconia ball mill jar, NMP (N-methylpyrrolidone) was added as a solvent, and HCl was added as a reactant, wet ball milled at a milling speed of 230 rpm for 12 h, and placed in a vacuum oven at 60 °C Dry for more than 12 h to obtain sulfur / carbon composites.

[0041] Other steps are identical with embodiment 1. The positive electrode composite material in the present invention is obtained, coded as S2, and the sulfur content in the positive electrode composite material is 65%.

Embodiment 3

[0043] The difference between this embodiment and Example 1 is the reaction acid selected for preparing the sulfur-carbon composite cathode material in step 2. The specific preparation method is as follows:

[0044] Na prepared in step 1 2 S 4 / CCB mixed powder is placed in a zirconia ball mill jar, NMP (N-methylpyrrolidone) is added as a solvent, and NaH 2 PO 4 As a reactant, the sulfur / carbon composite material was obtained by wet ball milling at a ball milling speed of 230 rpm for 12 h, and dried in a vacuum oven at 60 °C for more than 12 h. The sulfur content in the positive electrode composite material was 65%.

[0045] Other steps are identical with embodiment 1. The positive electrode composite material in the present invention was obtained, coded as S3.

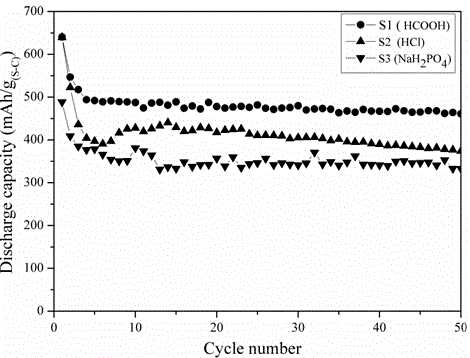

[0046] Three kinds of sulfur-carbon composite positive electrode materials S1, S2, S3 prepared by embodiment 1, embodiment 2, embodiment 3 are the cycle life figure measured under the current density of 160 mA / g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com