Building sand stone screening device

A screening device and sand and gravel material technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of screening efficiency decline, achieve screening efficiency improvement, promote sufficient screening, and promote sufficient rotation dispersion and vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

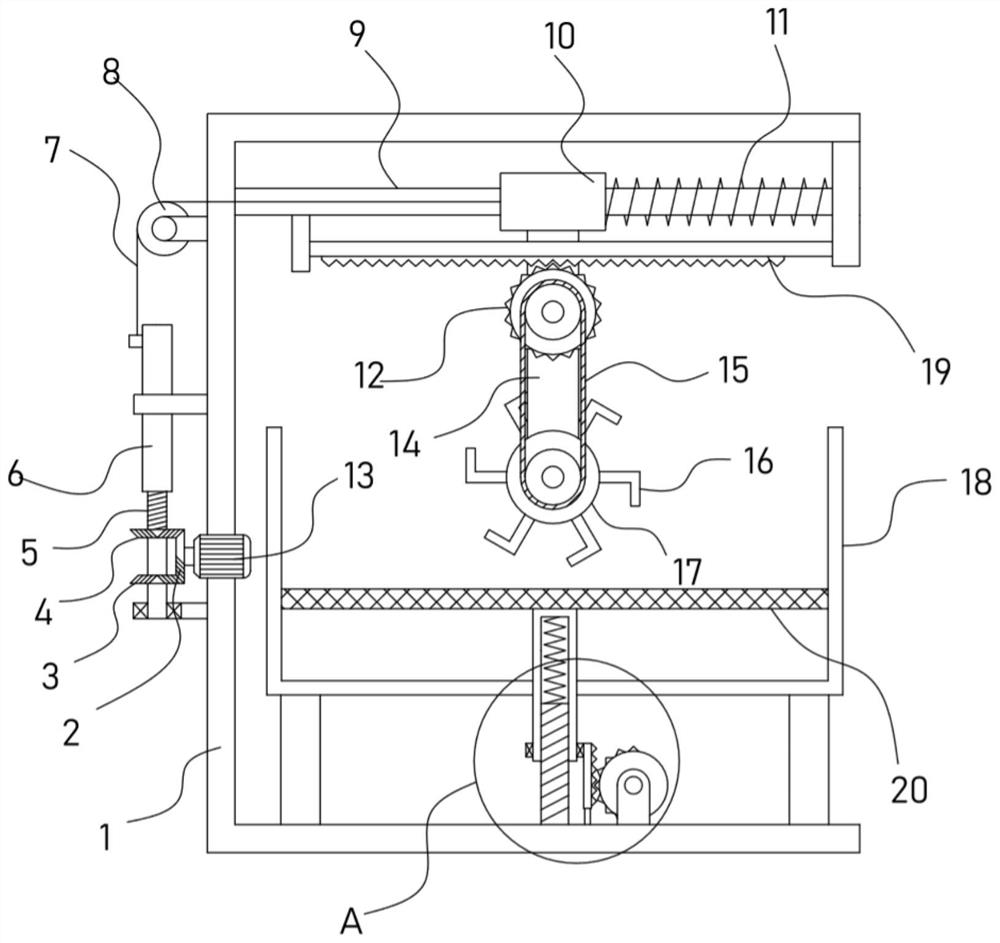

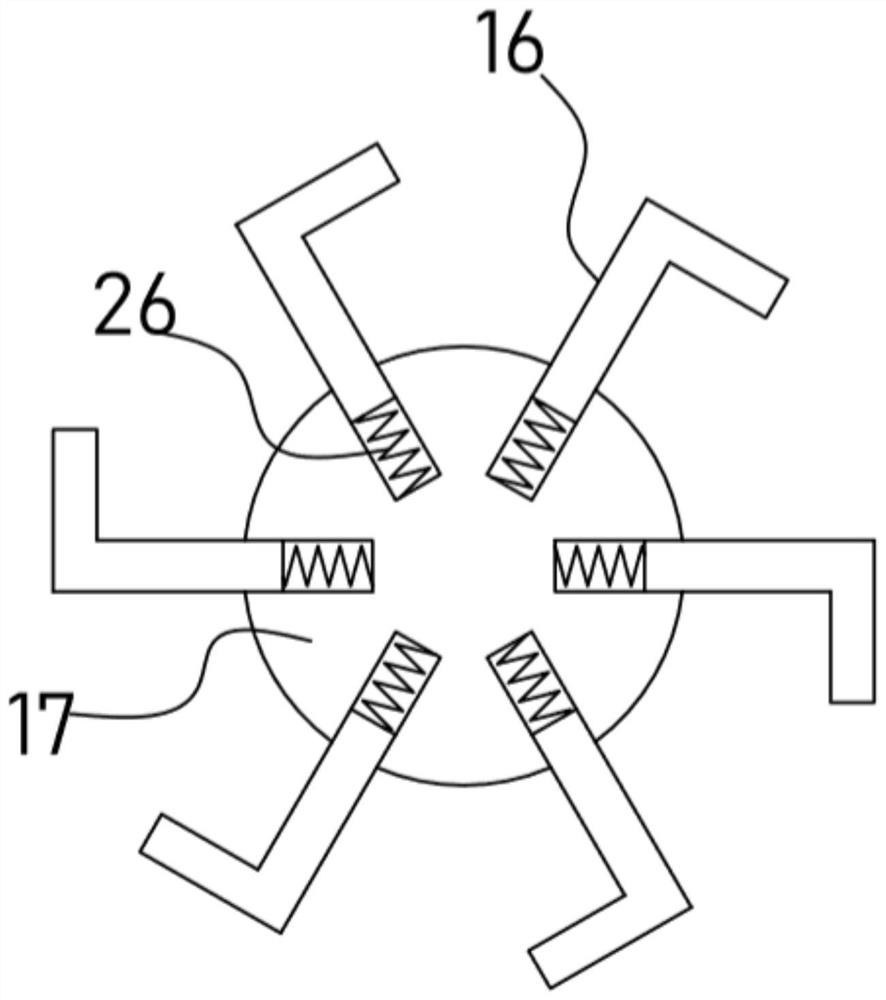

[0022] see Figure 1-4 , a sand and gravel material screening device for construction, comprising a fixed frame 1, a screening tank 18 is fixed on the fixed frame 1, a sieve plate 20 is arranged in the screening tank 18, a servo motor 13 is fixed on the fixed frame 1, The servo motor 13 is driven and connected with a forward and reverse mechanism, the fixed frame 1 is fixed with a horizontal rod 9, and the sliding sleeve on the horizontal rod 9 is provided with a traction mechanism connected with the forward and reverse mechanism. The bottom of the sliding block 10 is vertical A vertical plate 14 is directly fixed, and the vertical plate 14 is provided with a turning mechanism for turning the sand and gravel in the screening tank 18. The fixed frame 1 is rotatably equipped with an incomplete gear 23, on which the incomplete gear 23 The drive is connected with a reciprocating push mechanism for driving the sieve plate 20 to lift vertically.

[0023] The inside of the screening...

Embodiment 2

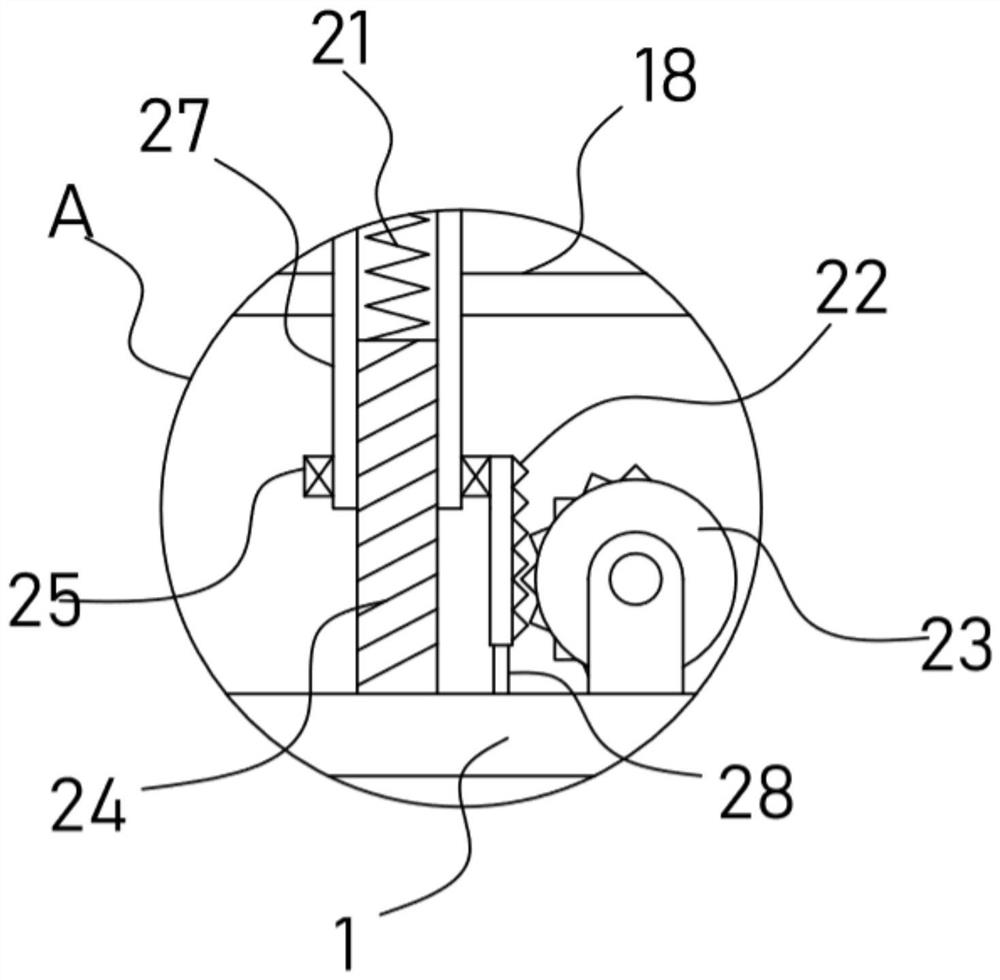

[0029] On the basis of Embodiment 1, in addition, this device is also provided with a reciprocating lifting mechanism, specifically including a vertical rack 22 that is intermittently meshed with an incomplete gear 23, and the side wall of the vertical rack 22 is fixed with a sleeve plate 25, the sleeve plate 25 upper bearings are connected with a threaded sleeve II27 that vertically slides and extends into the screening tank 18, and the upper end of the threaded sleeve II27 is fixed with the bottom of the sieve plate 20.

[0030] The incomplete gear 23 has a motor of the prior art to drive and rotate, and the incomplete gear 23 drives the vertical rack 22 meshed with it to realize the lifting of the cover plate 25, and the reciprocating lifting mechanism also includes a vertically fixed on the fixed frame 1. Threaded rod 24, the threaded rod 24 is threaded and extends to the inside of the threaded sleeve II27, the push spring 21 is abutted between the threaded sleeve II27 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com