Plastic granular material drying device for production of plastic products

A technology of plastic granules and plastic products, which is applied in the field of plastic product processing, can solve the problems of slow water volatilization, restriction of drying efficiency, and poor drying effect of plastic granules, and achieve the effects of increasing drying rate, promoting rapid volatilization, and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

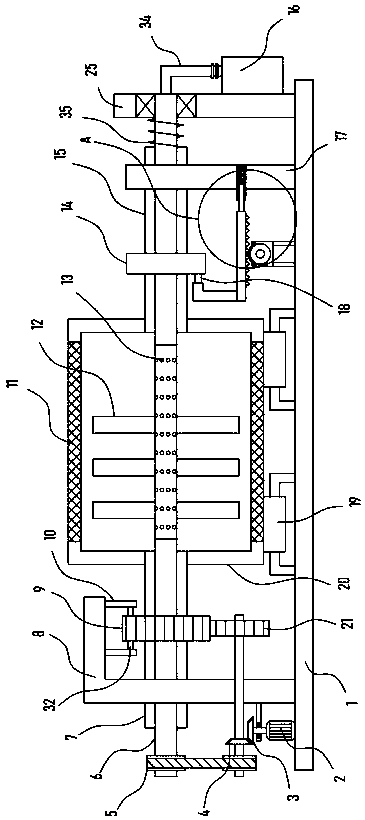

[0024] see Figure 1-5 A device for drying plastic granule raw materials for plastic product production, comprising a bottom plate 1, on which a support frame I8, a support frame II17 and a limit frame 25 are vertically fixedly installed, and the support frame I8 and the support frame II17 are rotated through respectively A transmission sleeve I7 and a transmission sleeve II15 are provided, a drying box 20 is fixedly installed between the transmission sleeve I7 and the transmission sleeve II15, and a breathable mesh plate 11 is embedded and installed on the surface of the drying box 20 .

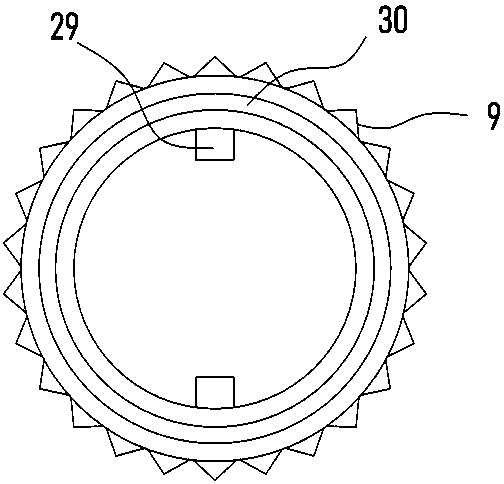

[0025] The provided drying box 20 is used to store the plastic particles to be dried, and the meshes in the provided air-permeable screen 11 are used for the discharge of the volatilized water vapor of the plastic particles, and the mesh diameter of the air-permeable screen 11 is smaller than the diameter of the plastic particles. In addition, a driven gear 9 is sheathed and connected to the...

Embodiment 2

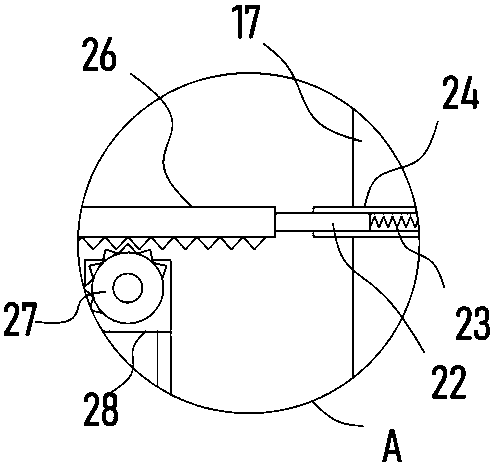

[0030] In order to improve the scope of the stirring blade 12 to stir the plastic particles in the drying box 20, on the basis of Embodiment 1, in addition, the transmission sleeve II15 is sleeved with a fixed sleeve plate 14, and the fixed sleeve plate 14 is circumferentially opened with a The annular groove II33 is connected with a reciprocating mechanism driven by the drive motor II28 on the bottom plate 1, and the reciprocating mechanism is driven and connected with a contact block I18 slidably embedded in the annular groove II33.

[0031] During the rotation of the drying box 20 driven by the transmission sleeve II15, the reciprocating mechanism drives the contact block I18 to reciprocate, and the contact block I18 pushes the fixed sleeve plate 14 back and forth by engaging with the annular groove II33, thereby realizing The transmission sleeve II15 realizes reciprocating motion while rotating with the drying box 20 and the stirring shaft 6 , and the agitation range of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com