Patents

Literature

114 results about "Plastics processor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

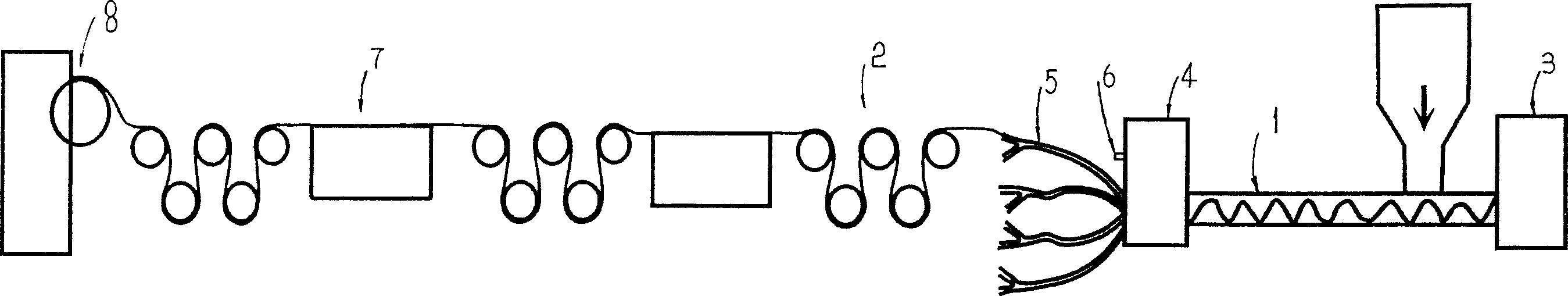

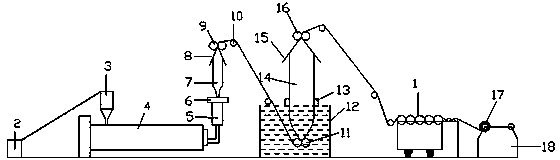

Crab feed

InactiveCN101642192AMeet the needs of different growth periodsIn line with eating habitsClimate change adaptationAnimal feeding stuffDiseaseAnimal science

The invention belongs to the field of feed and is particularly suitable for feeding crabs. The crab feed is mainly characterized in that: (1) various animal and vegetable proteins, starch, trace elements, an auxiliary agent, a feeding promotion agent and the like serving as raw materials are compounded, so that the nutrient contents of the crab feed are more balance and comprehensive, and the requirements of the crabs during different growing periods can be met only by adjusting the ration of relative raw materials in the formula; and (2) the modified plastic processing machinery and process are used, and simultaneously the processes of mixing, shearing, curing, swelling, granulating and the like of the raw materials are also completed. Under the joint action of the two factors, the shapeof the product is stable, the flexibility is adjustable, and the product is not loosened after being soaked in water for several hours, so that the product is in accordance with the feeding habit of the crabs. Because the raw materials comprise fly maggots and earthworms that provide a certain amount of natural antibiotic and immunological factor, the product is insusceptible to decay and deterioration and can improve the disease-resisting capability of the crabs taking the crab feed. The crabs cultivated by the crab feed have the advantages of quick growth, fresh and smooth meat and rich nutrition.

Owner:吴天祥 +2

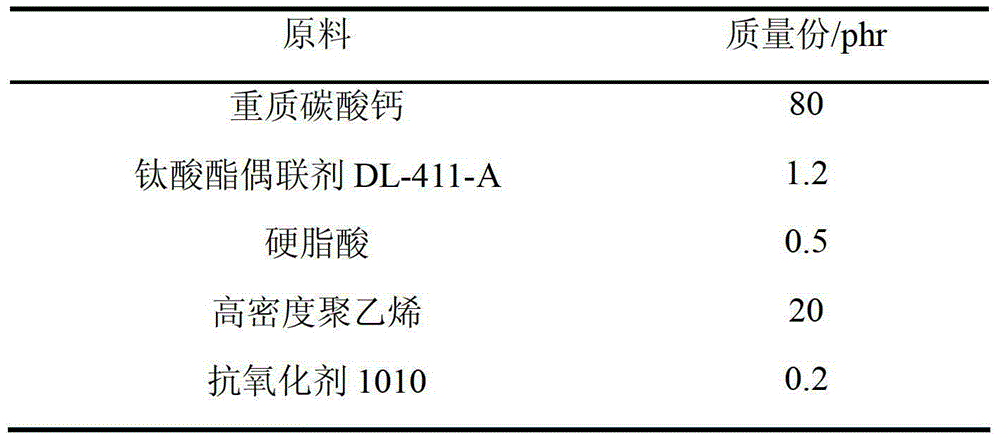

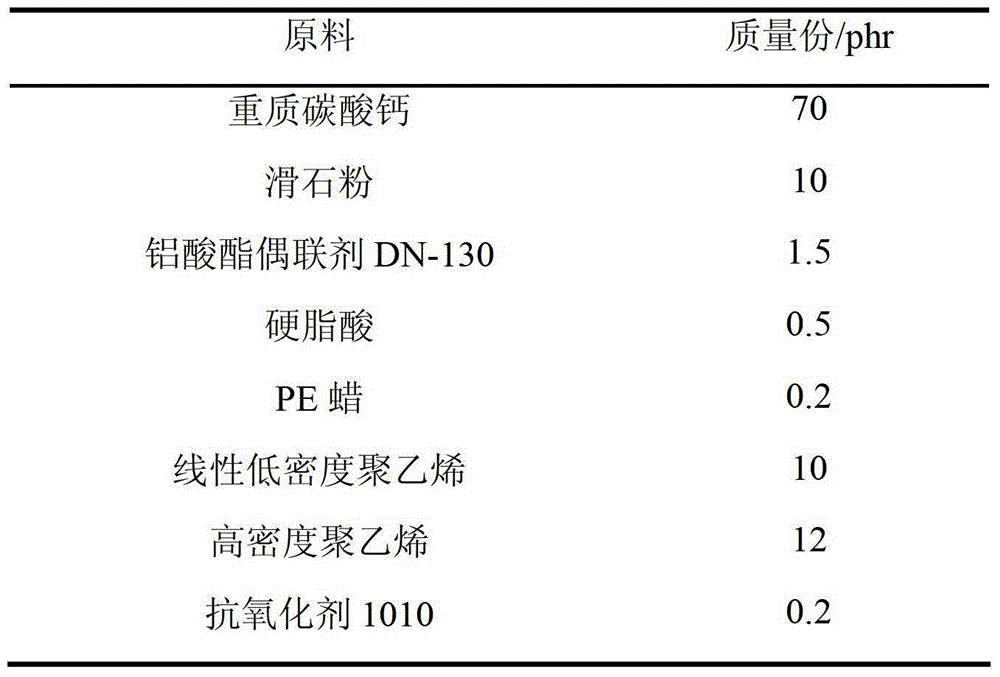

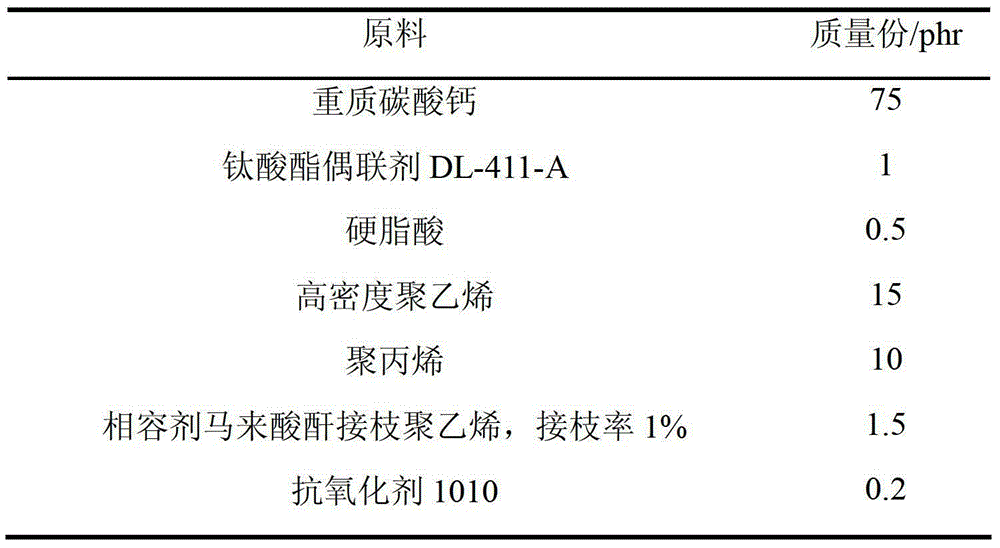

High fill polyolefin composite film masterbatch and preparation method thereof

The invention discloses a high fill polyolefin composite film masterbatch and a preparation method thereof. The high fill polyolefin composite film masterbatch comprises the following raw materials in parts by mass: 70-80 parts of inorganic filler, 13-27 parts of high polymer resin, 0.5-1.5 parts of coupling agent, 0.5-1 part of lubricant, 0.1-0.2 parts of antioxidant and 0-0.2 parts of compatilizer. The masterbatch is prepared by the traditional plastics processing machine, the production technology is simple, the filling quantity of inorganic powder is large and can reach 80%, the price is low, the masterbatch can be directly used for extruded blow molding, extruded tape casting and extruded traction forming to prepare films in various thicknesses. The prepared films are green and environment-friendly new materials, have good water resistance, moisture protection, oil resistance, physical properties, printability and writability, and can serve as materials such as packaging paper, letter paper and wallpaper.

Owner:HEFEI UNIV OF TECH

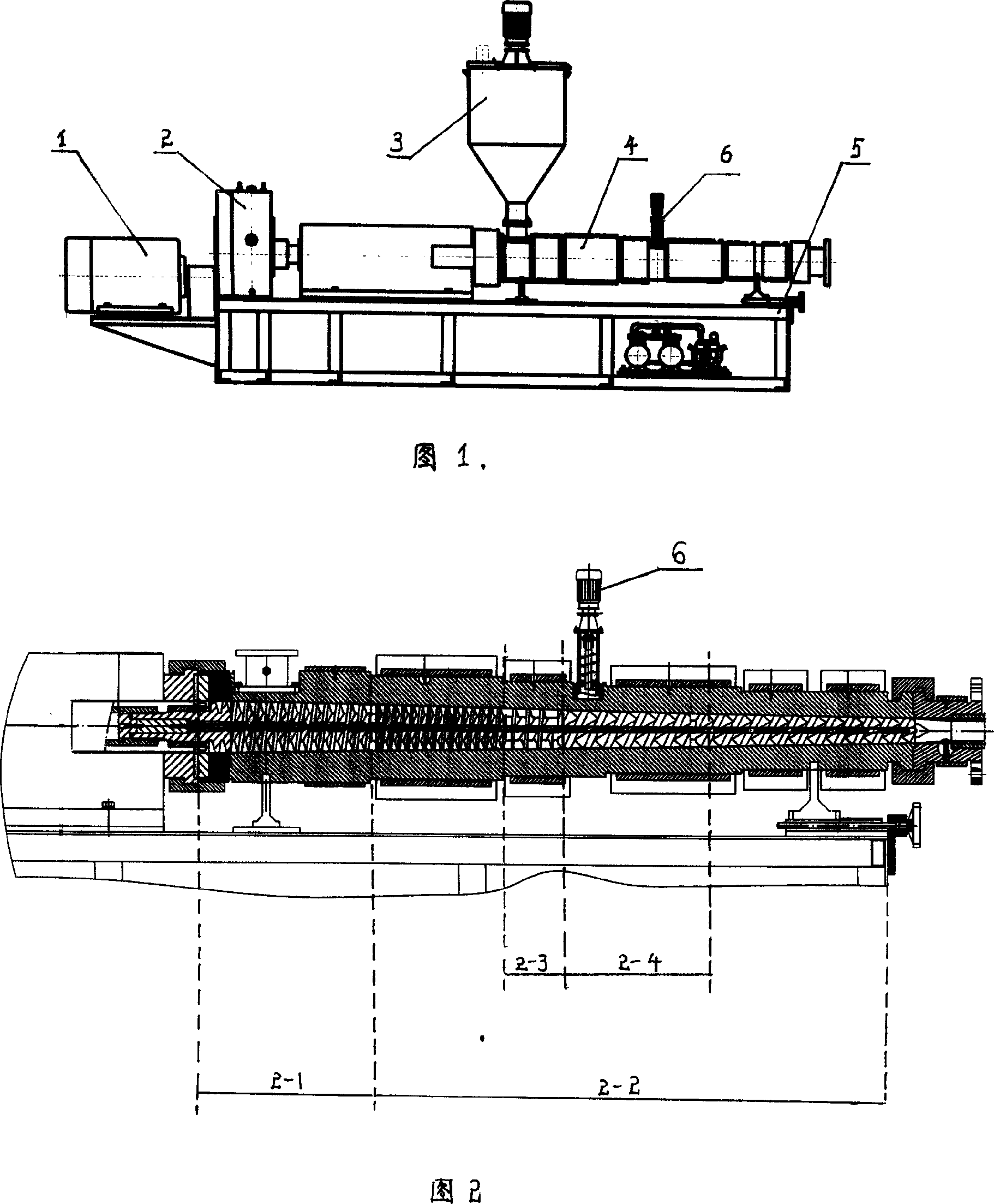

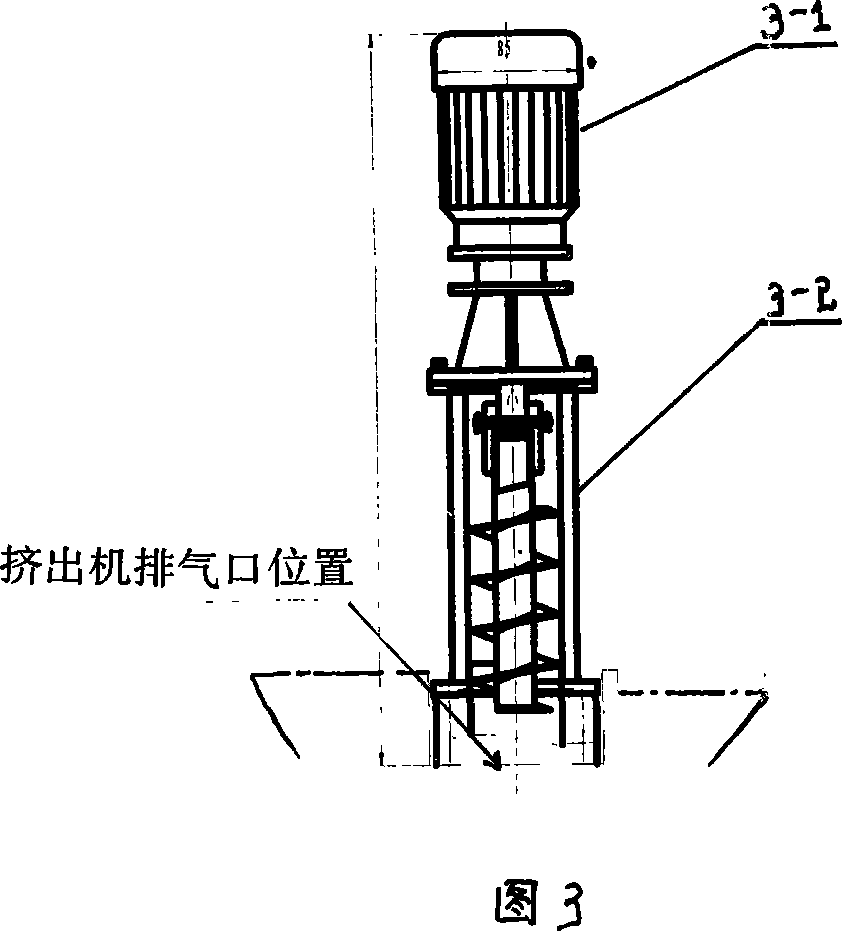

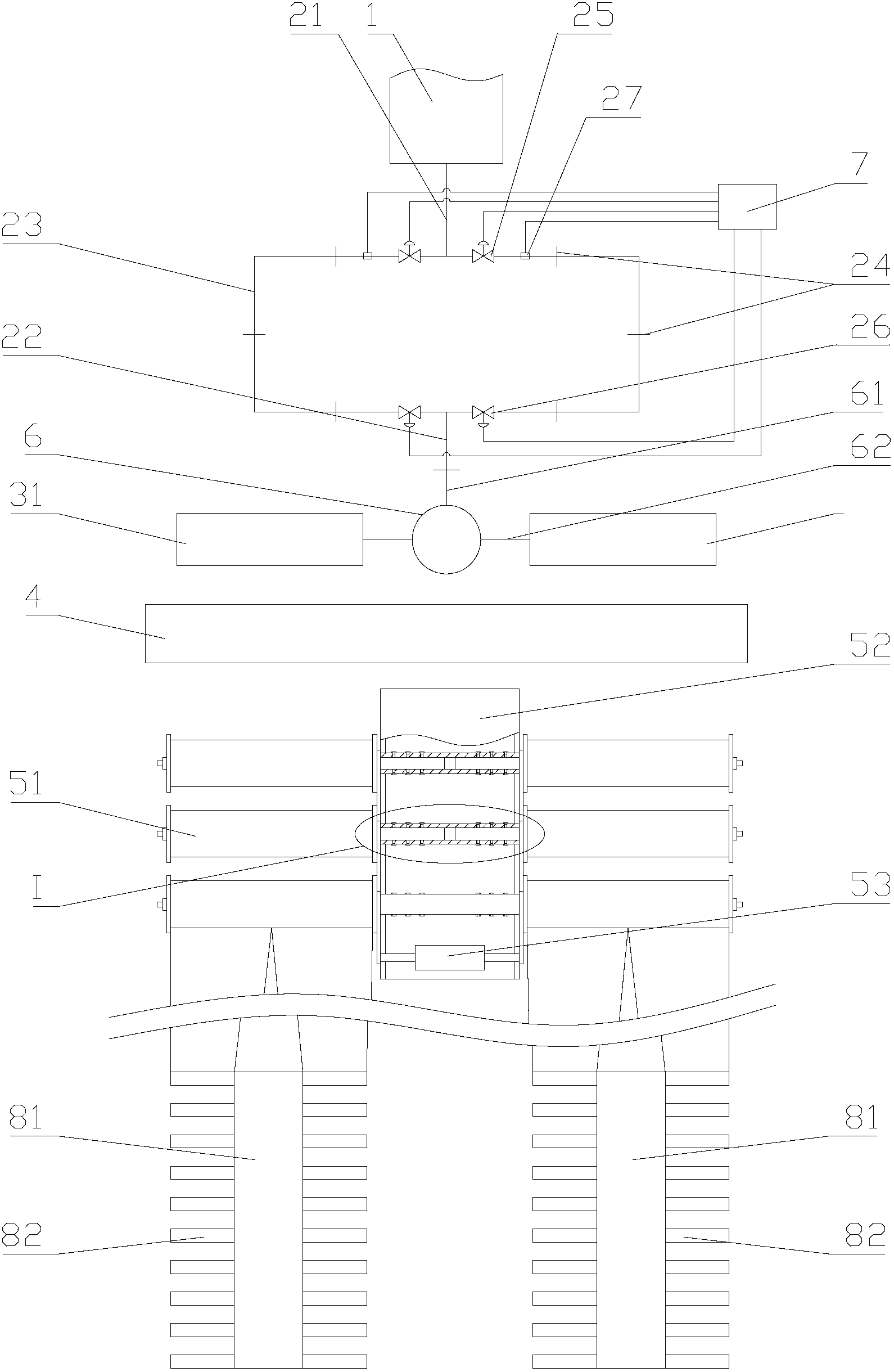

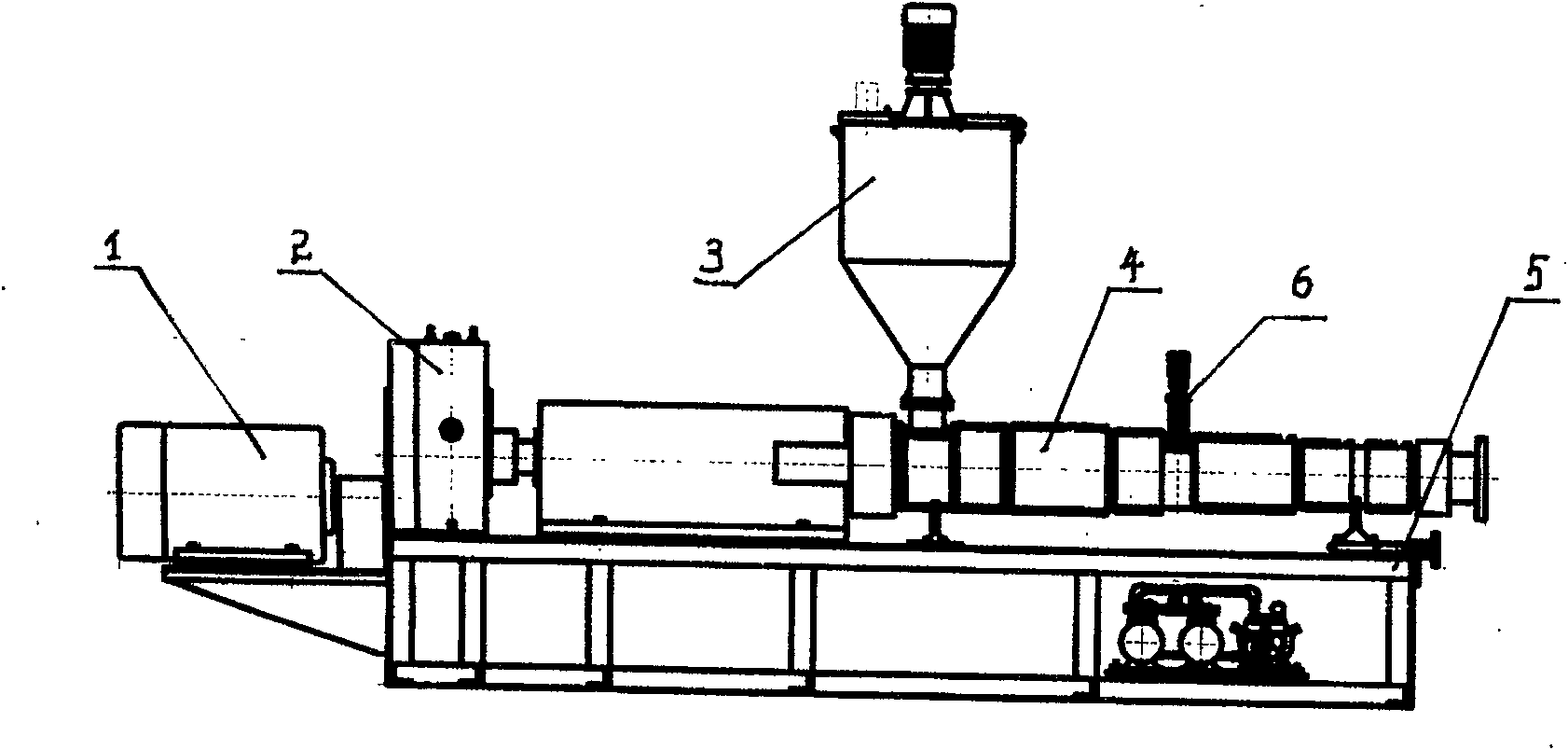

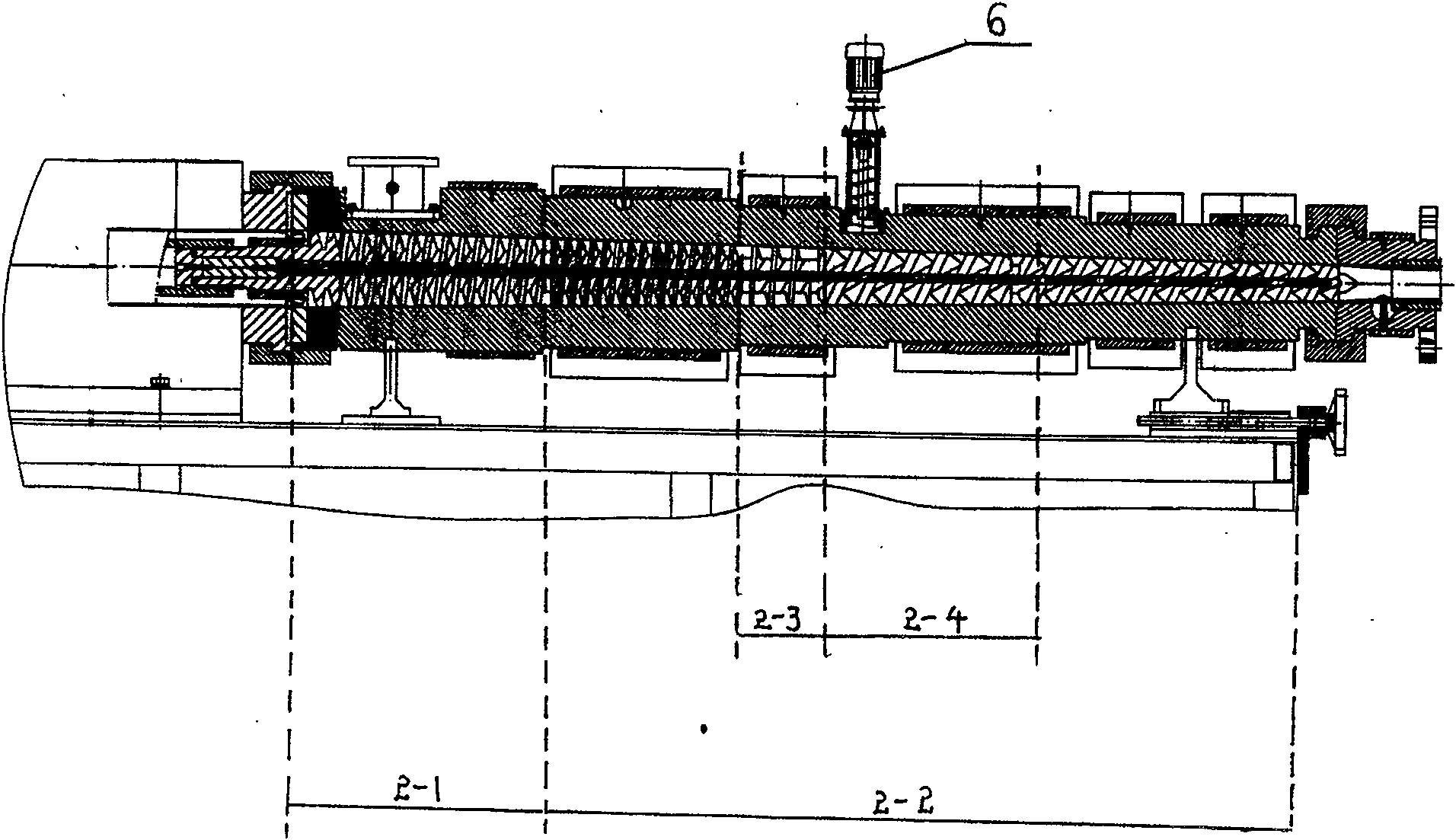

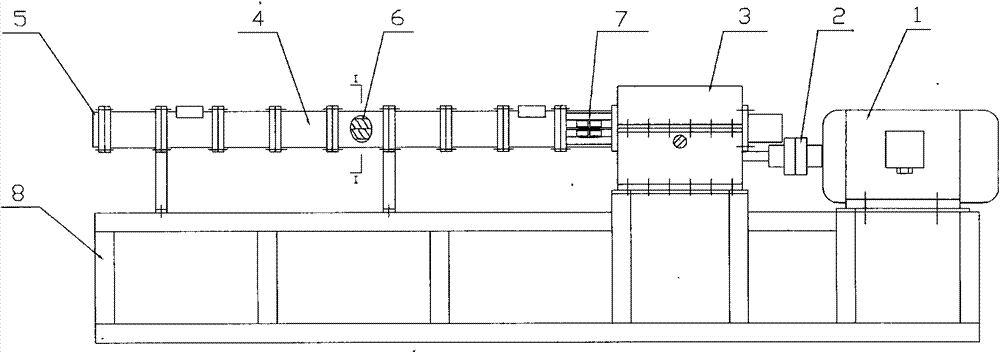

Conical double screw extruder special for wood plastic composite material

The present invention belongs to a special cone-shaped double-screw extruding machine for a wood-plastic composite material of the plastic processing machine, including a power source, a reduction gear box, a screw-machine barrel accessory, a machine frame and a feeding bucket. The power source is connected with a screw inside the screw-machine barrel accessory through the reduction gear box. The feeding bucket communicates with a machine barrel inside the screw-machine barrel accessory. The screw is installed inside the machine barrel. Cooling and temperature-reducing device are installed at the lower part of a feeding opening of the machine barrel and at a closely adjacent section to make the two sections as cooling sections, the sections after which are provided with heating devices which make the rest sections as the heating sections. Only one vent is arranged at the machine barrel. The screw, which is installed inside the machine barrel, is the cone-shaped screw and is provided with a mixing section, and the same time the length-diameter ratio of the machine barrel and the screw is more than 30. Before the vent, the present invention can convey, compress, heat and plastify the wood-plastic composite material under the quite low temperature; after being completely plastified, the plastic can complete enwrap the heated wooden powder before the vent and mix with the wooden powder uniformly; a double-screw vacuum exhausting and flash-preventing device which continuously rotates downwards can exhaust as well as never flash.

Owner:BAOJI QINCHUAN FUTURE PLASTIC MECHINE

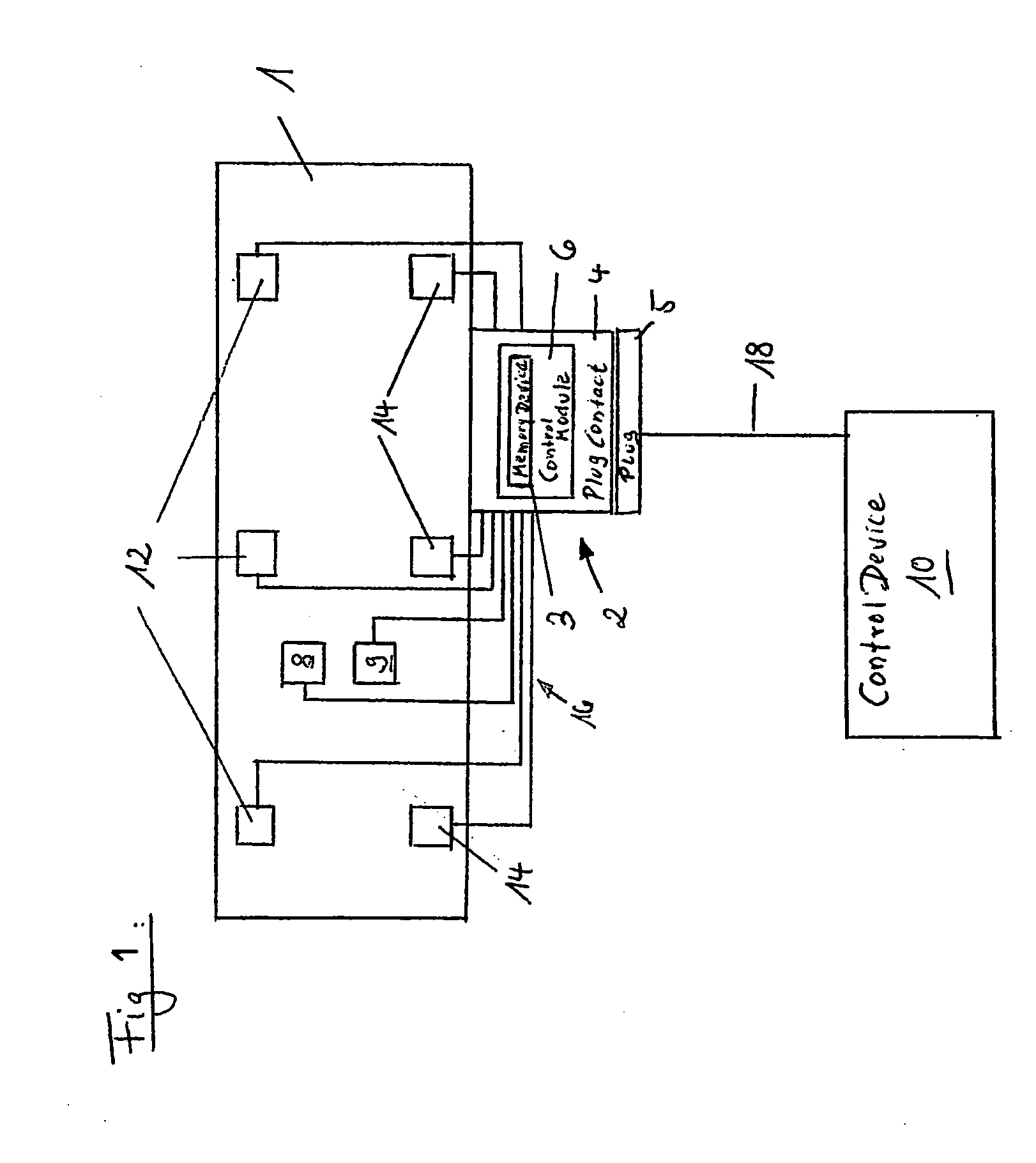

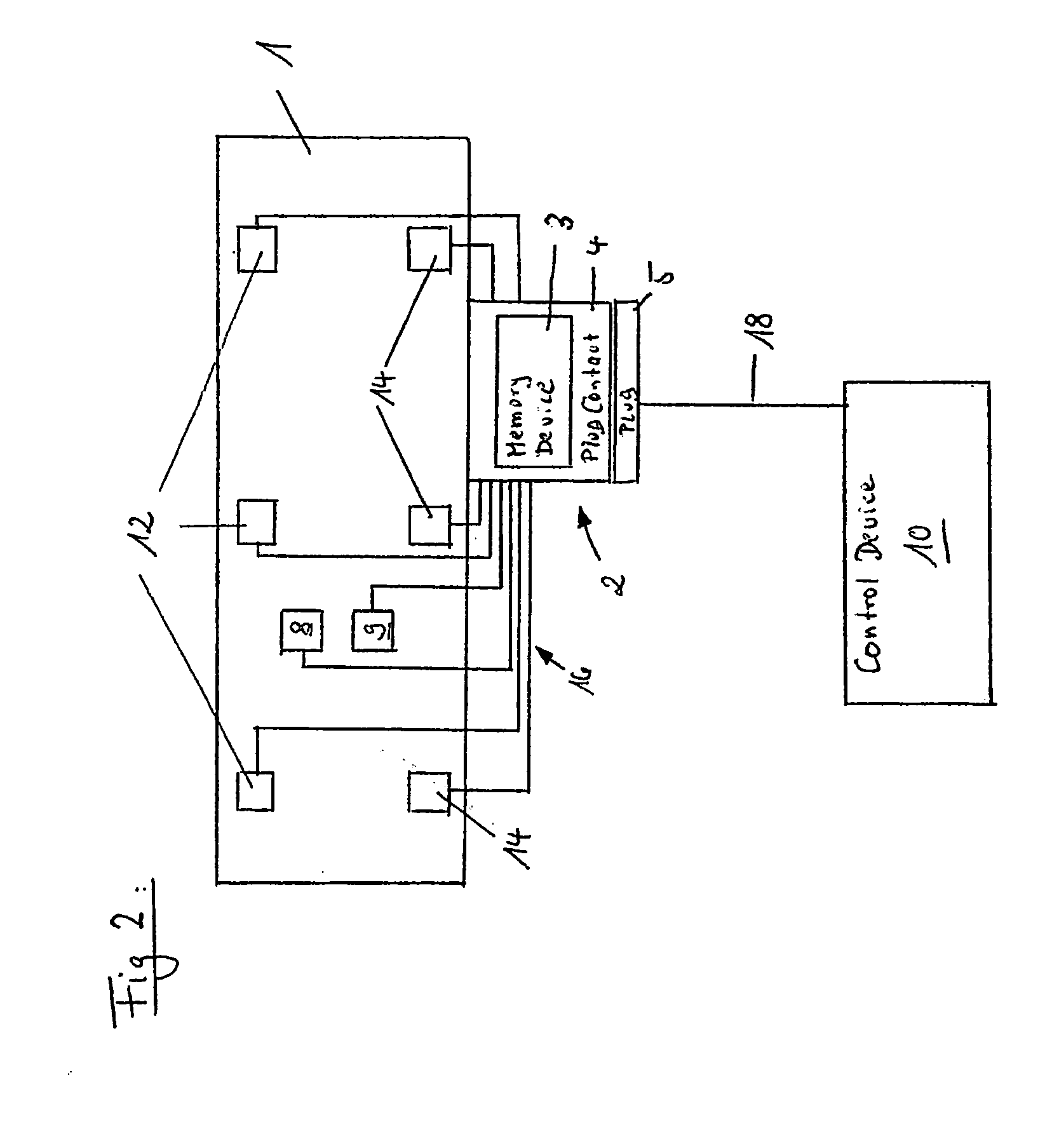

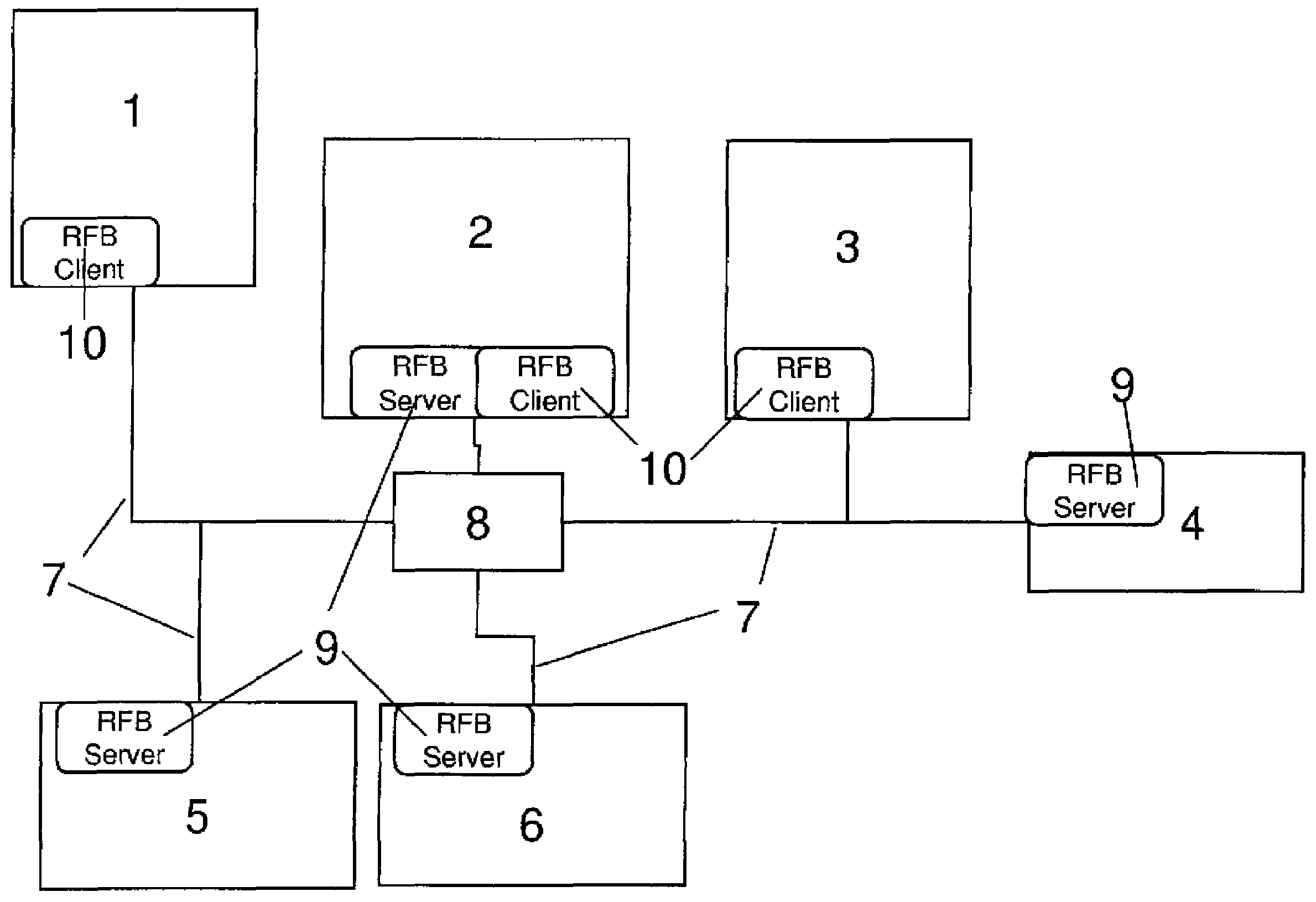

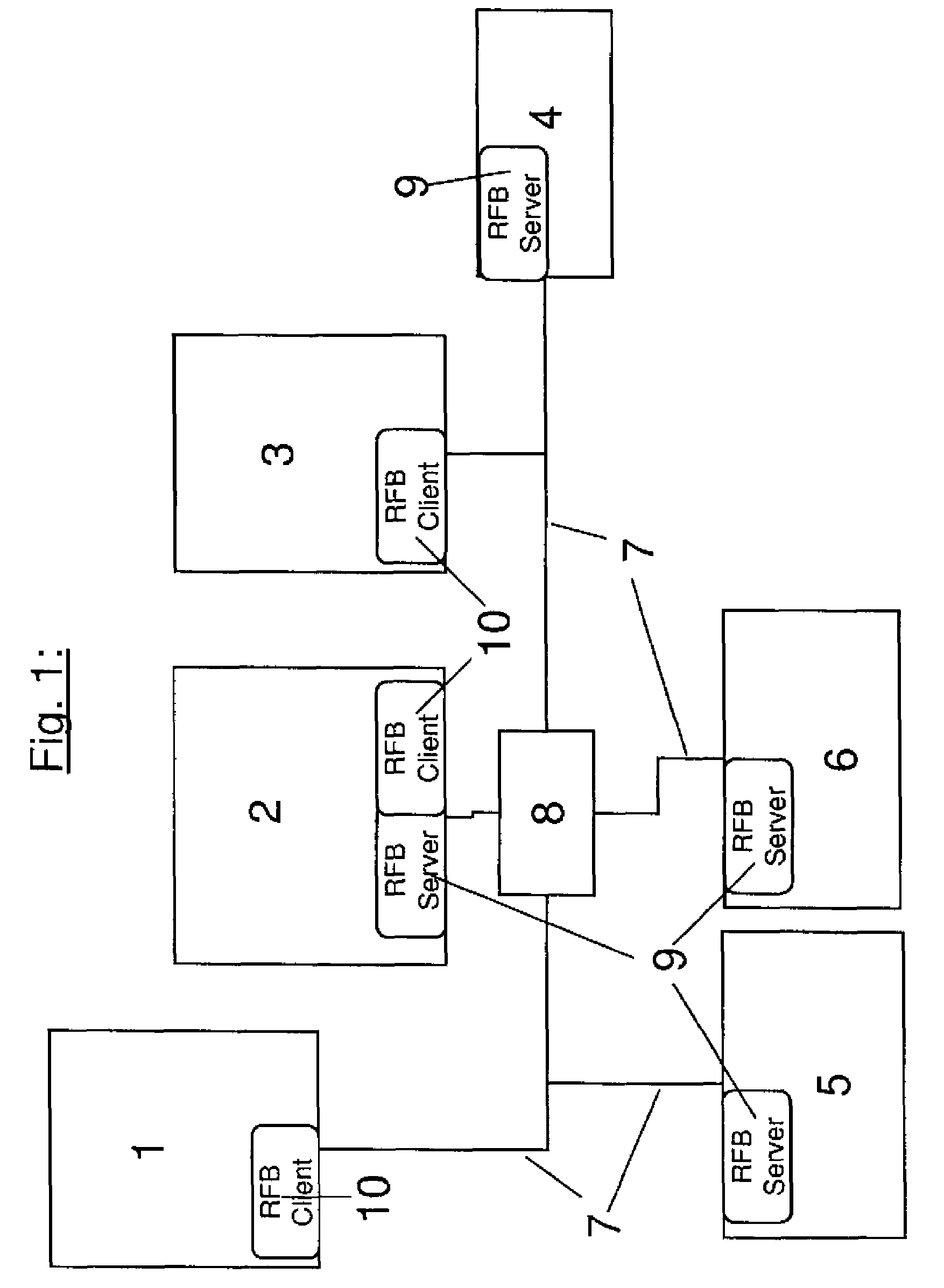

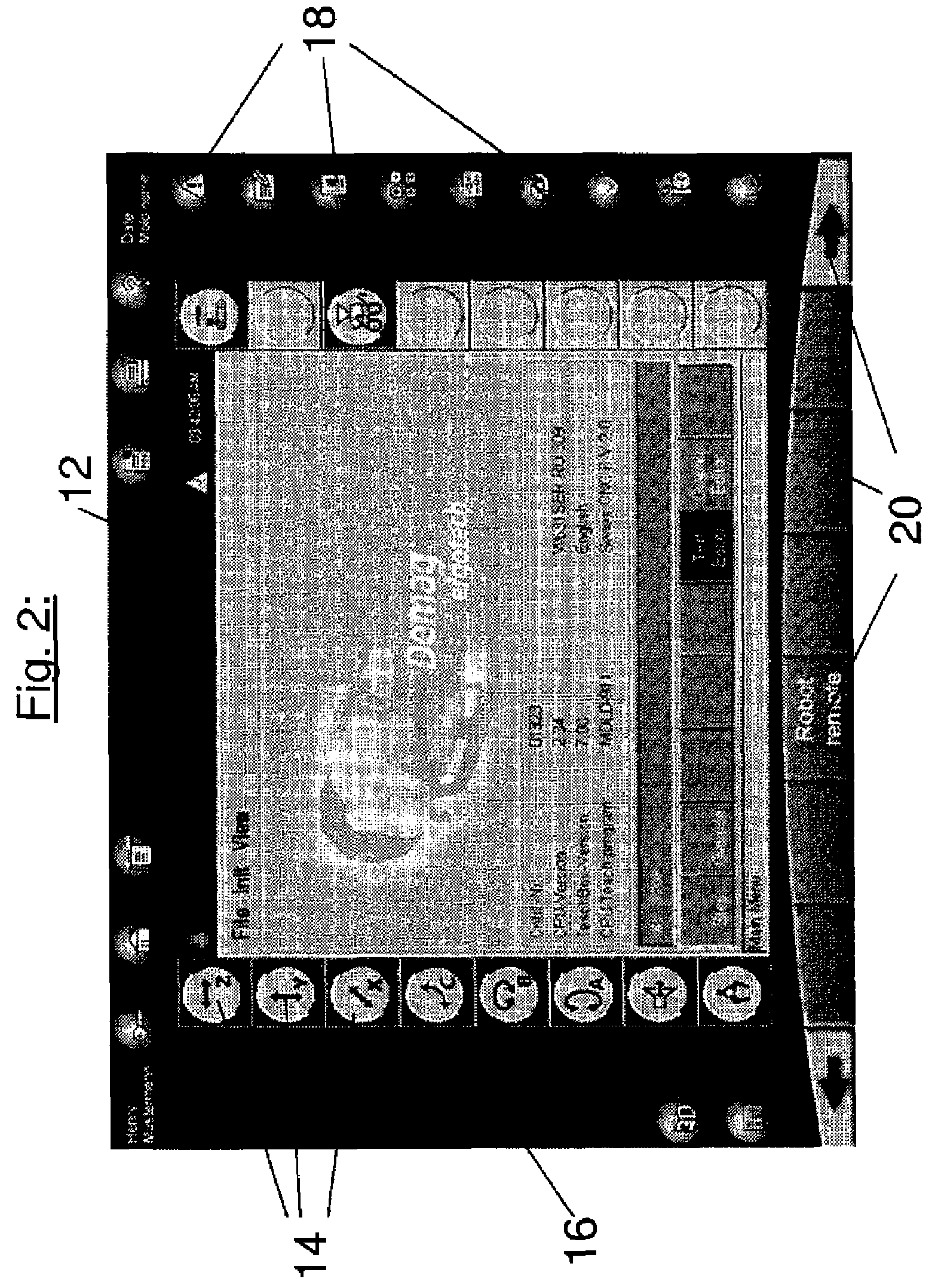

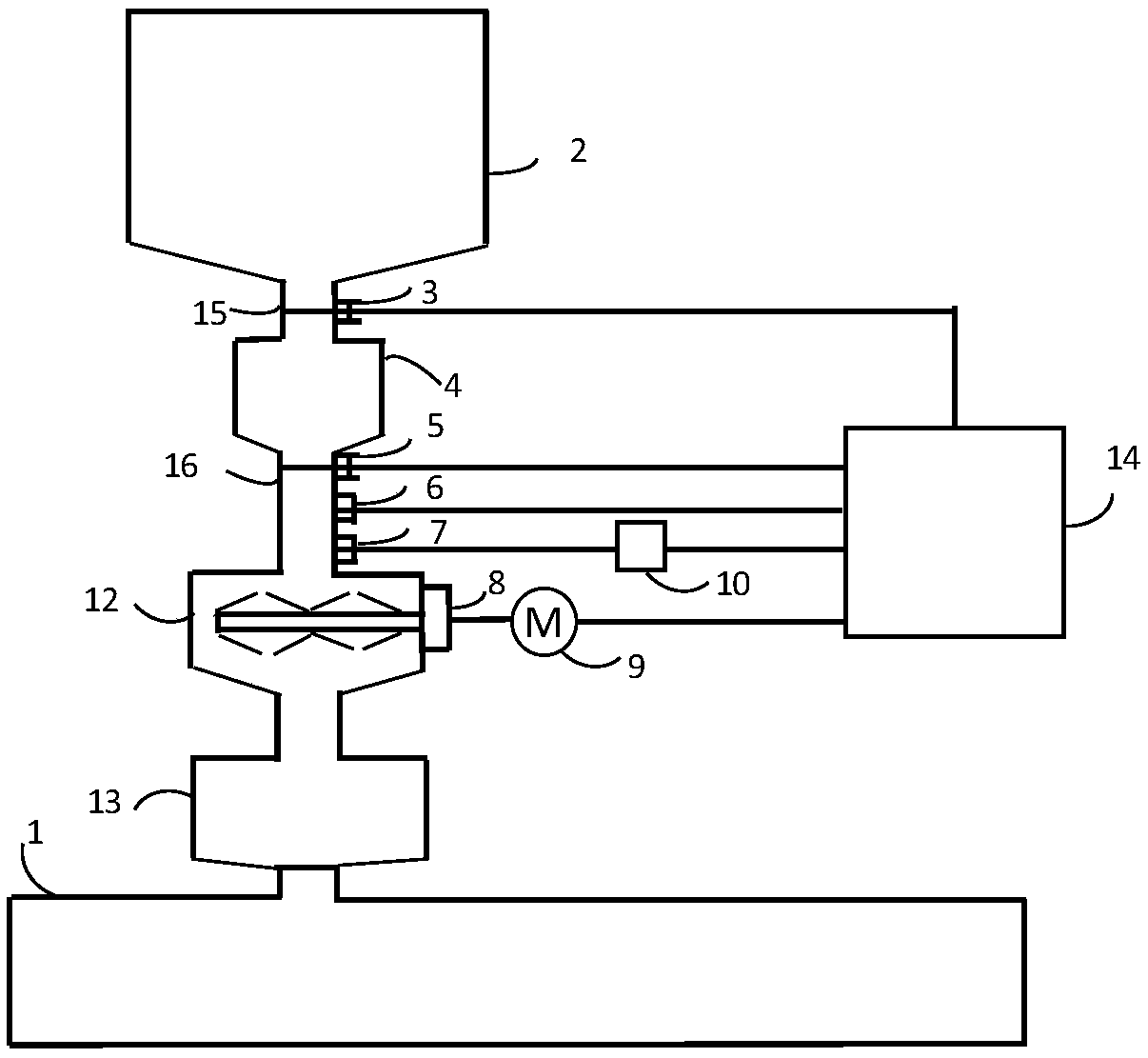

Plastics processing machine

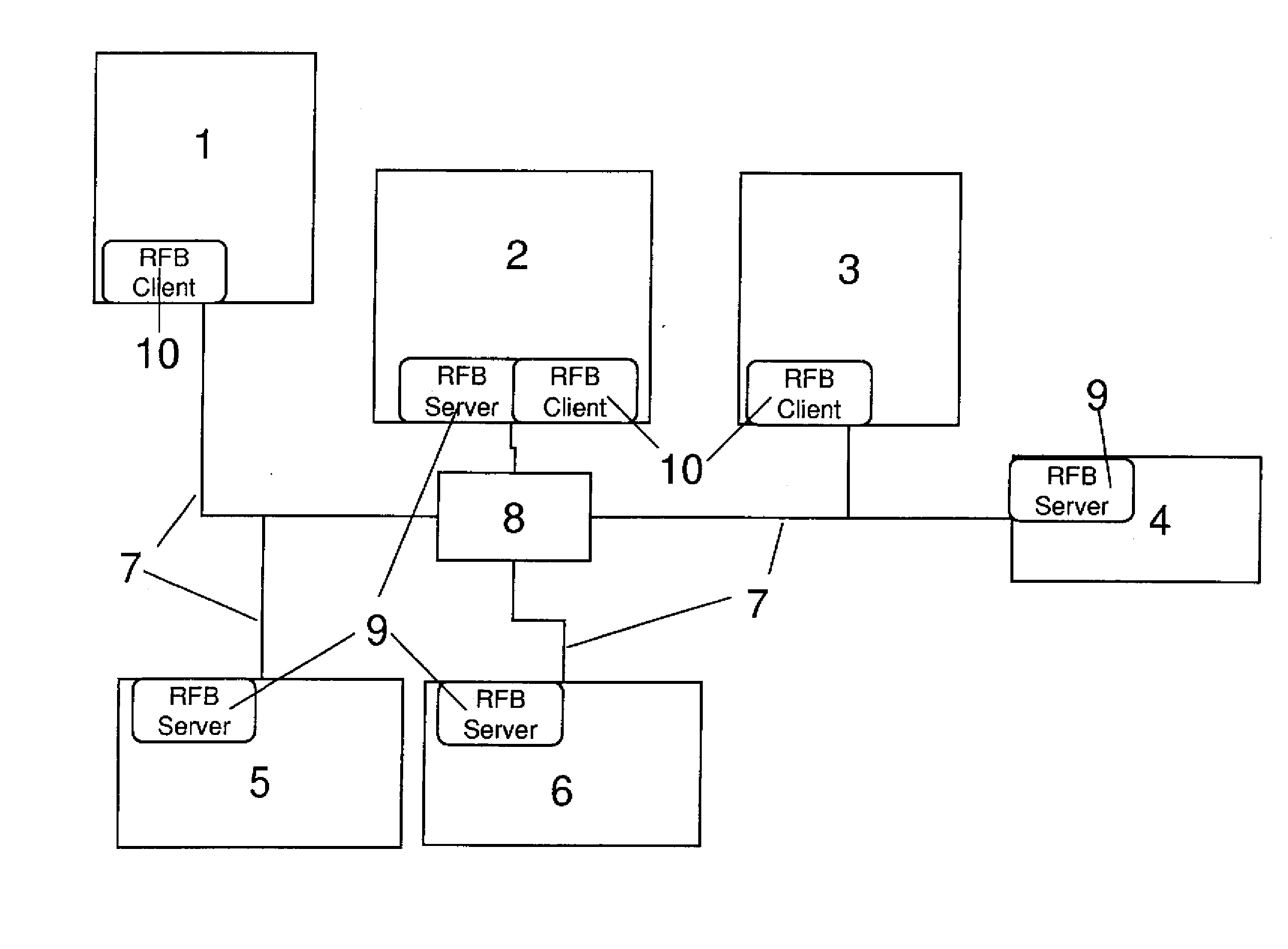

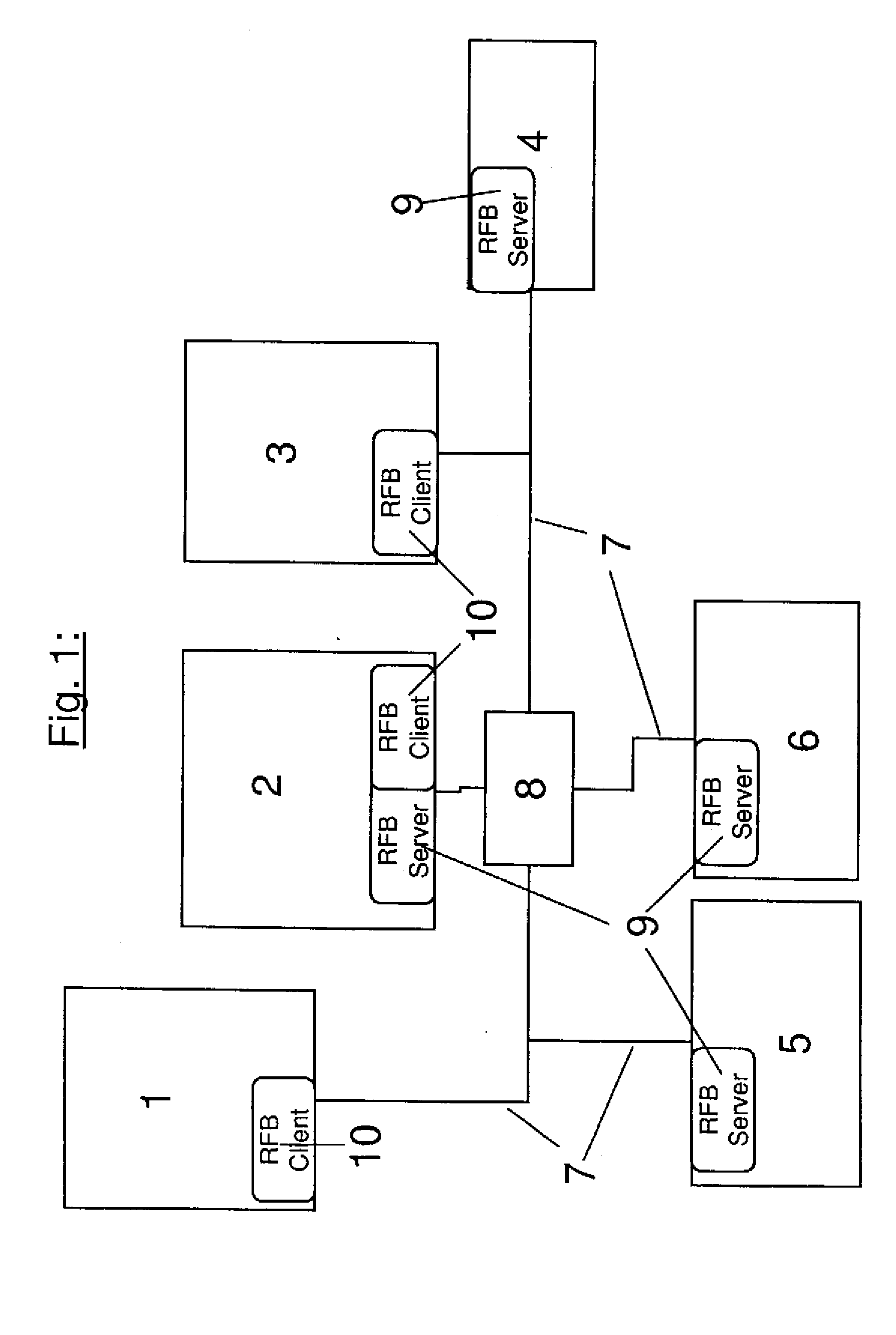

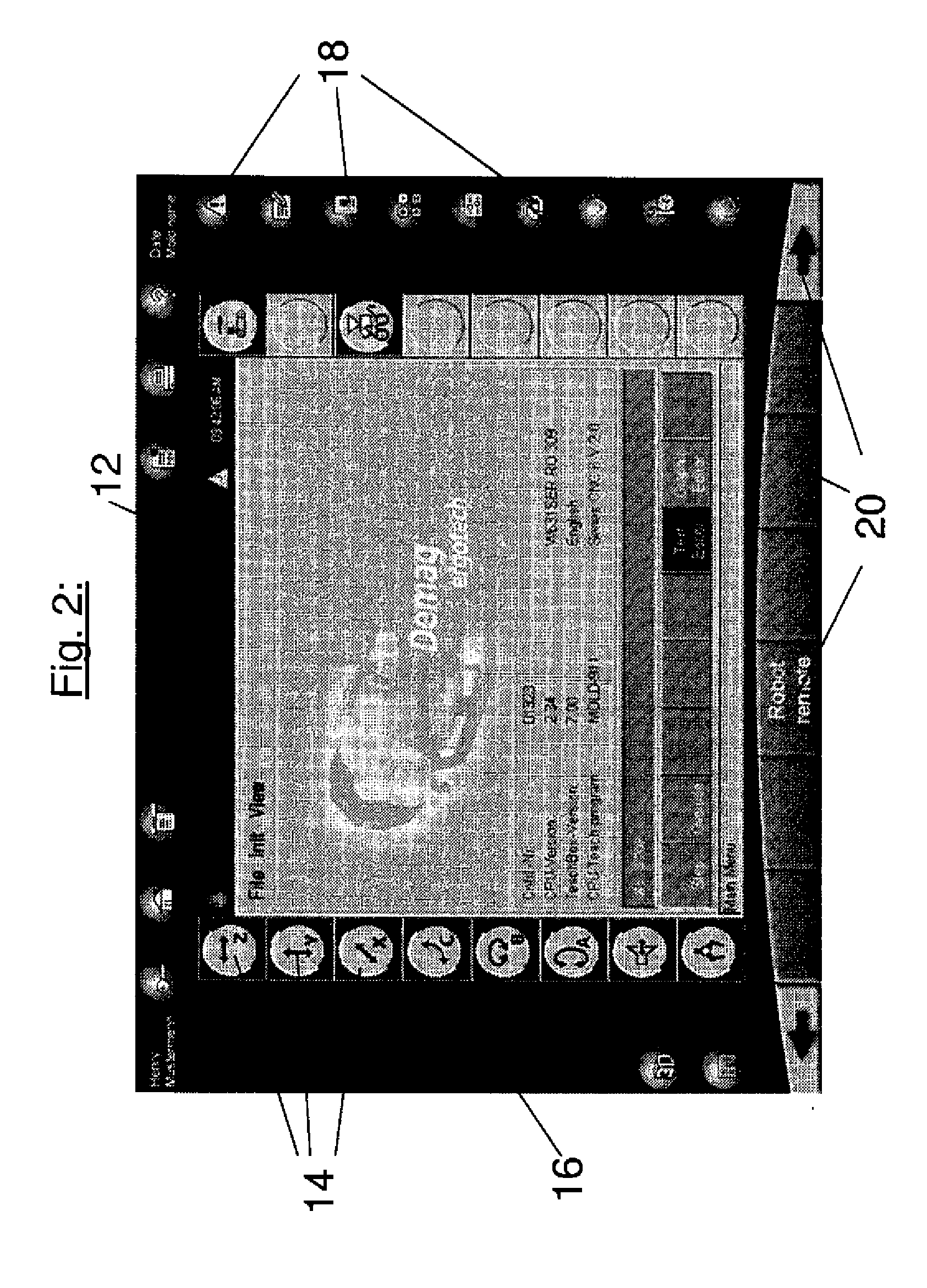

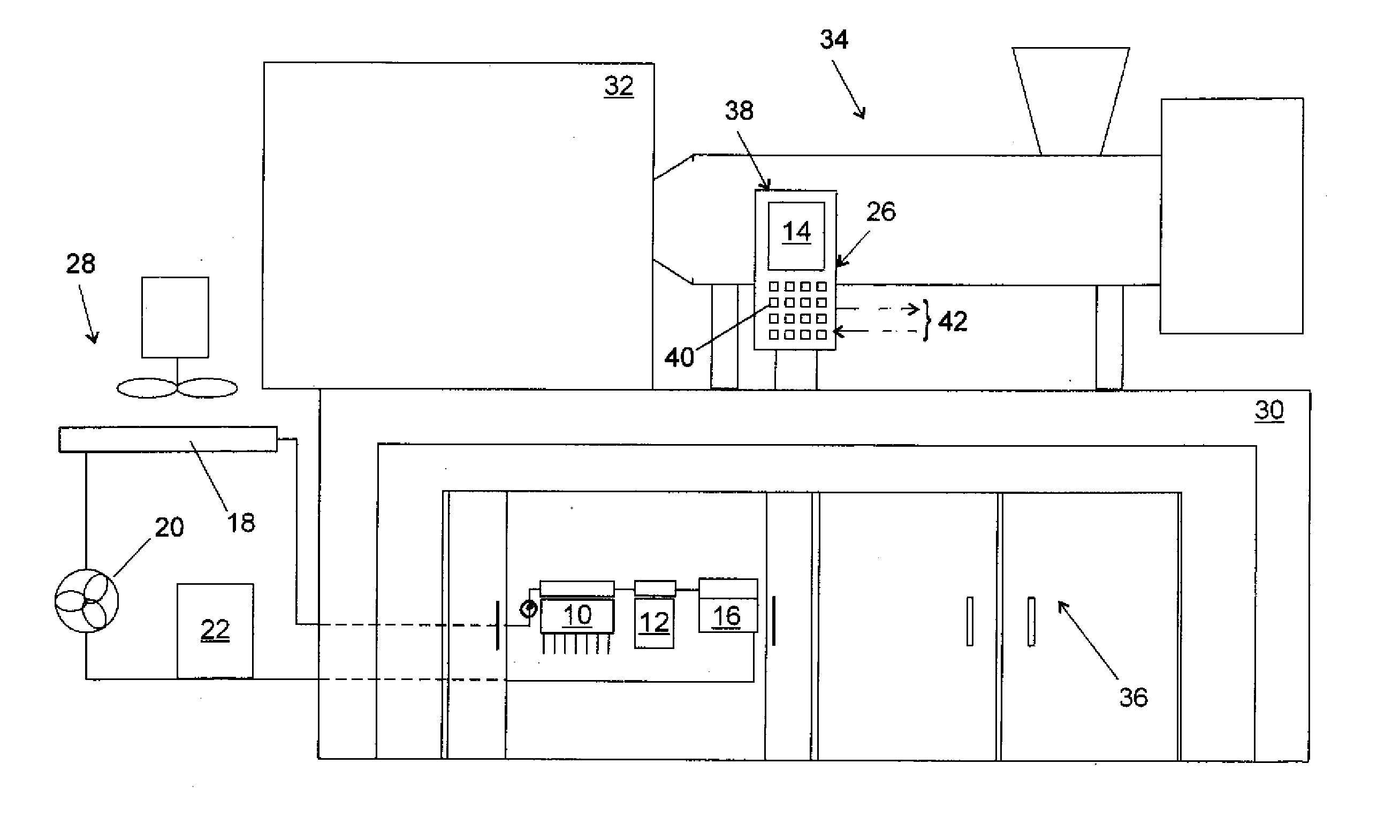

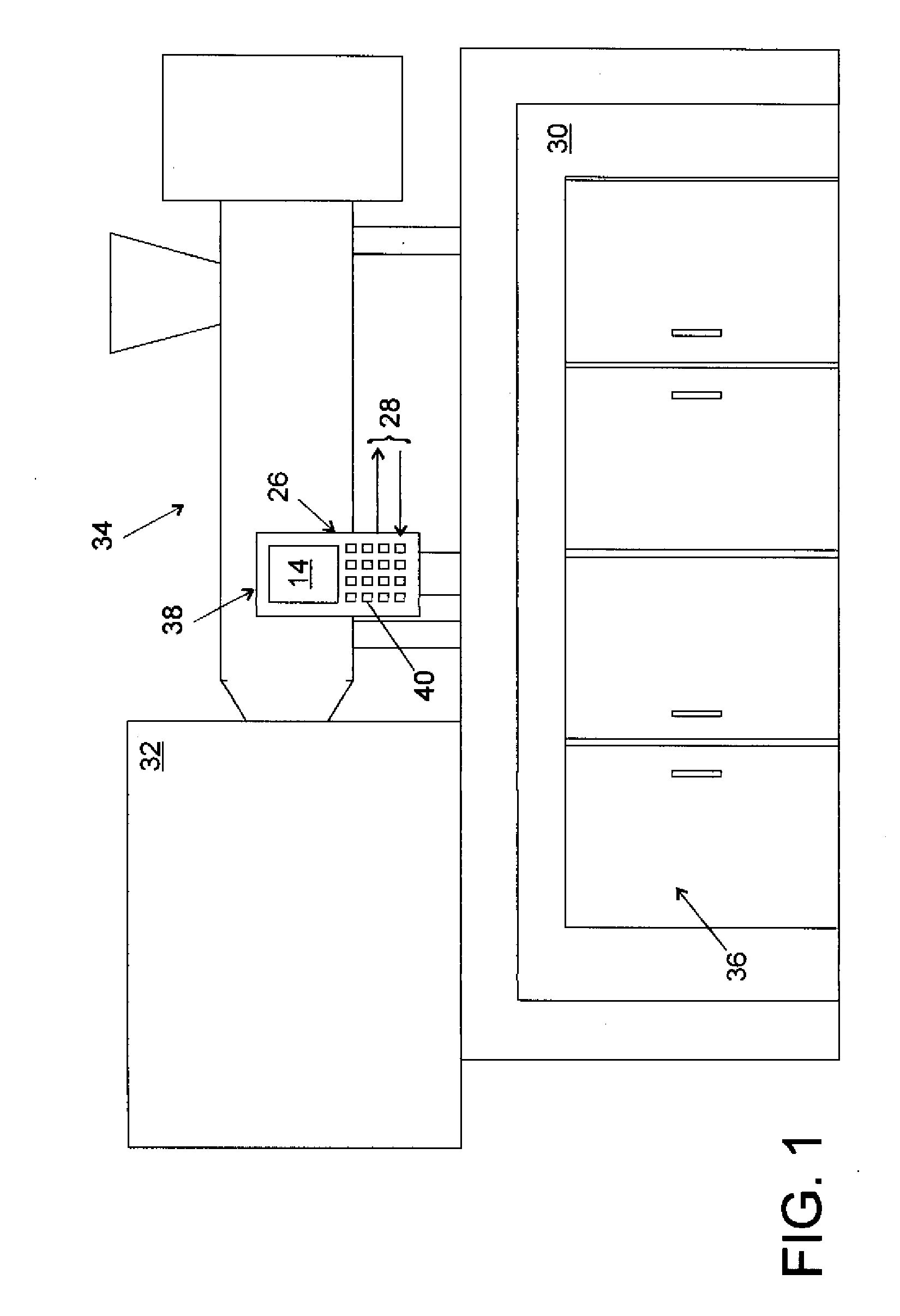

InactiveUS20070186144A1Easy to operateLow costProgramme controlComputer controlMachine controlControl cell

A plastics processing machine, particularly an injection molding machine, with an operating unit, a machine controller, and a subsystem having its own dedicated control unit is described. The machine controller and control device each generate a screen display and can be operated via the screen display. The operating unit is connected or can be connected for data transmission to both the machine controller and the control unit. Both of the machine controller and the control unit can be monitored and controlled by reproducing the original screen output from the machine controller and the control unit on the display screen of the operating unit, where new information can be entered. The information entered on the display screen of the operating unit is then transmitted back to the corresponding controller or unit associated with the reproduced screen display where the information was entered.

Owner:SUMITOMO SHI DEMAG PLASTICS MACHINERY

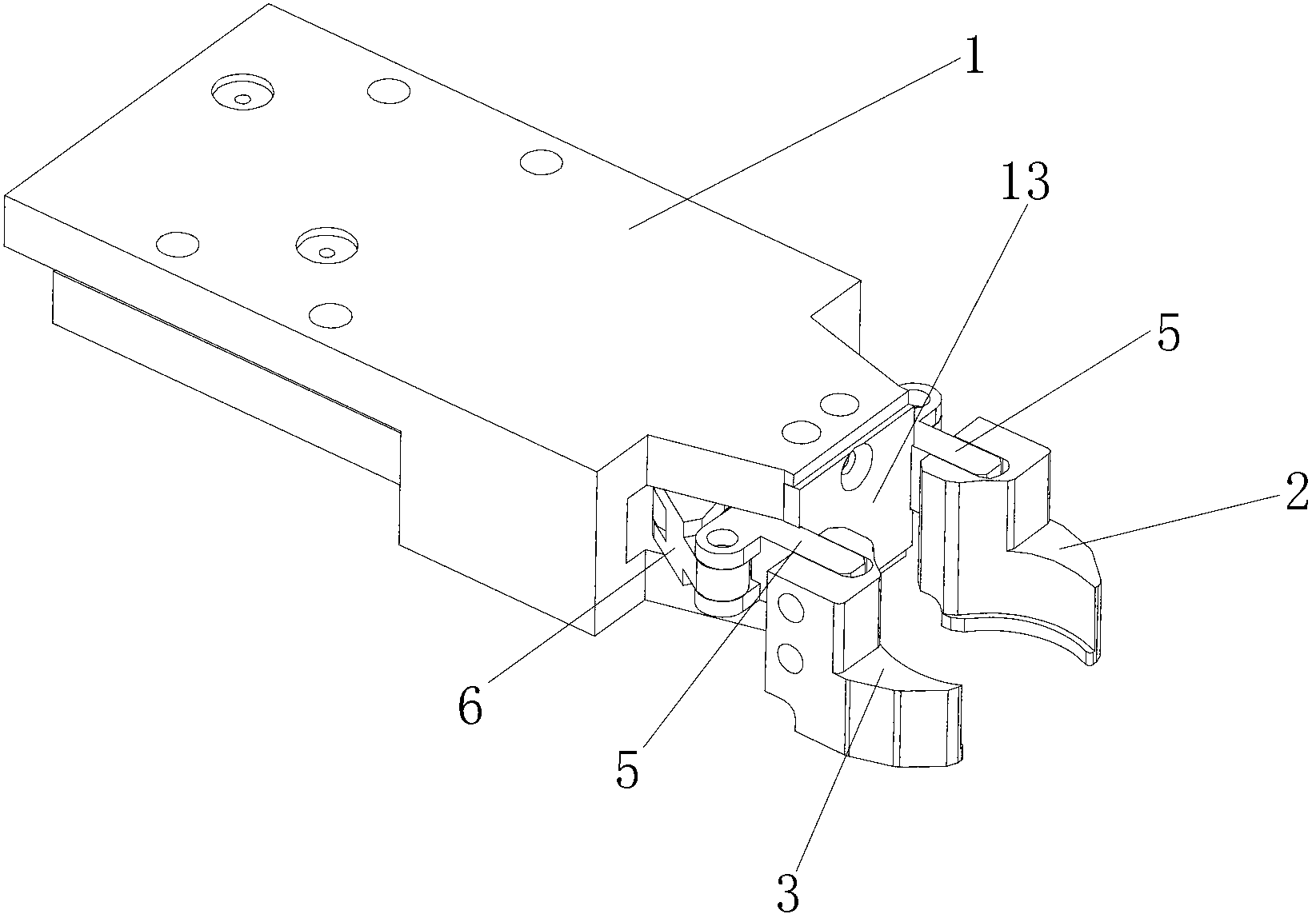

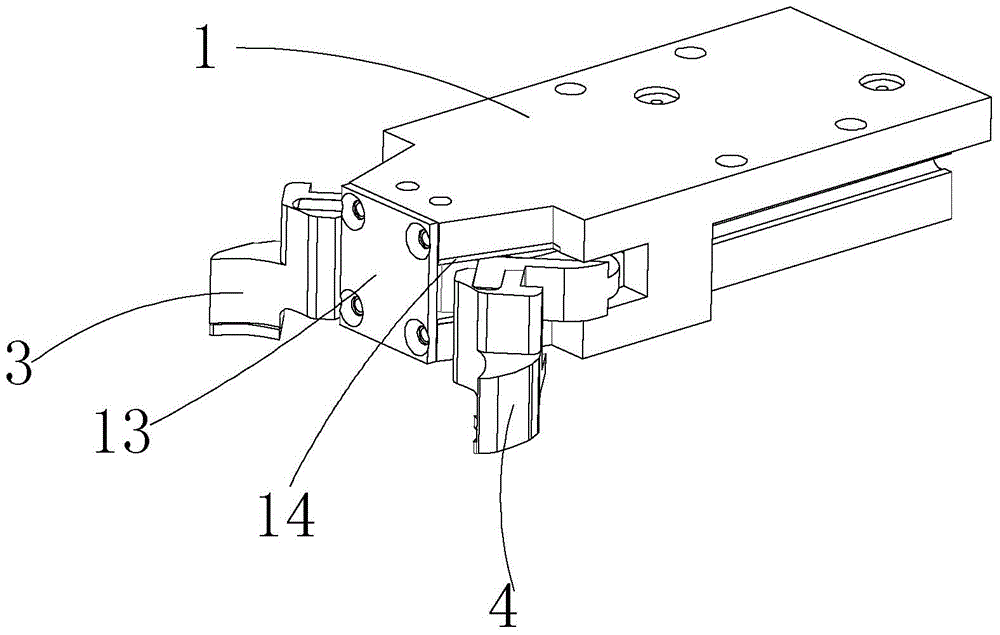

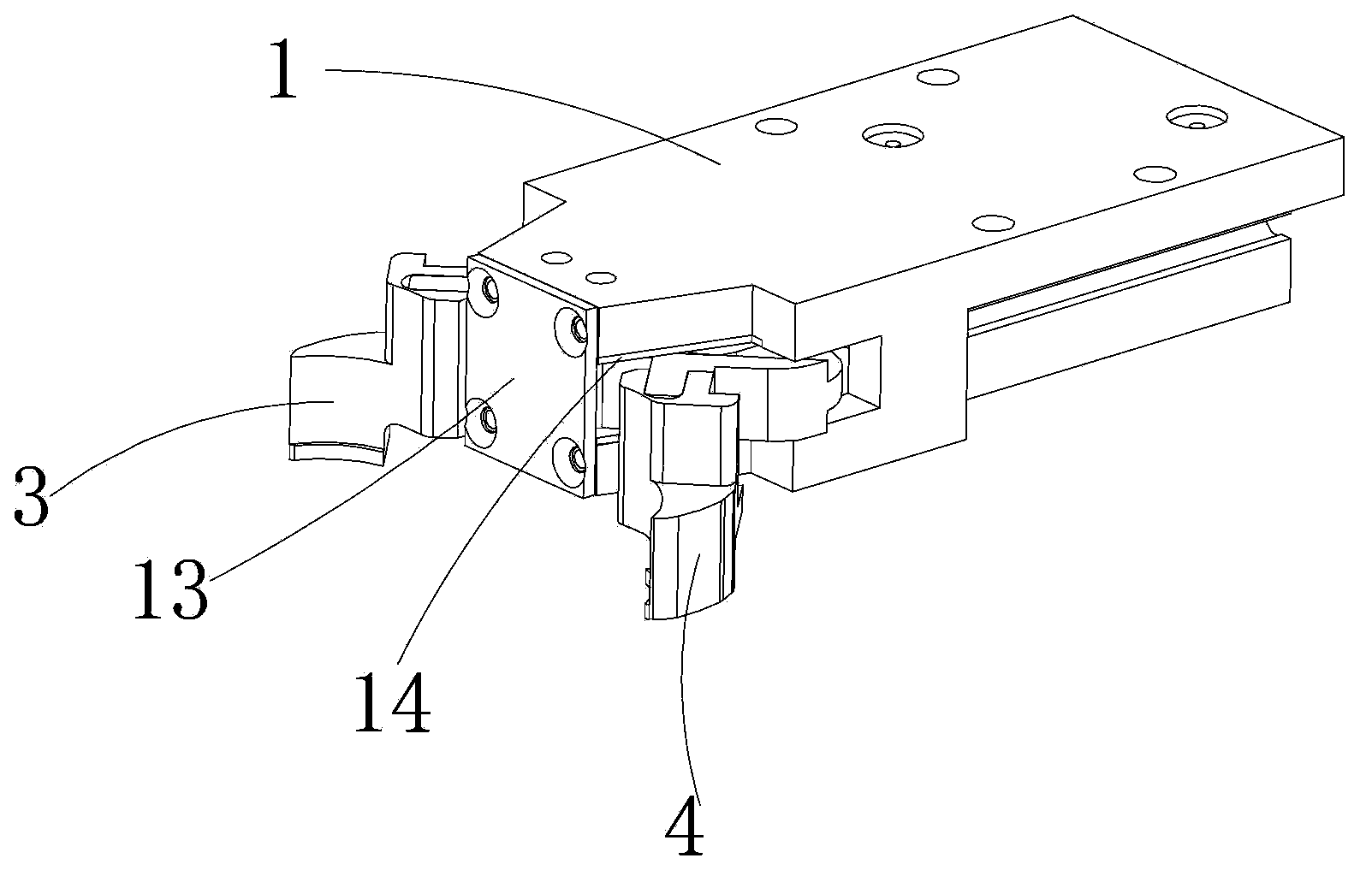

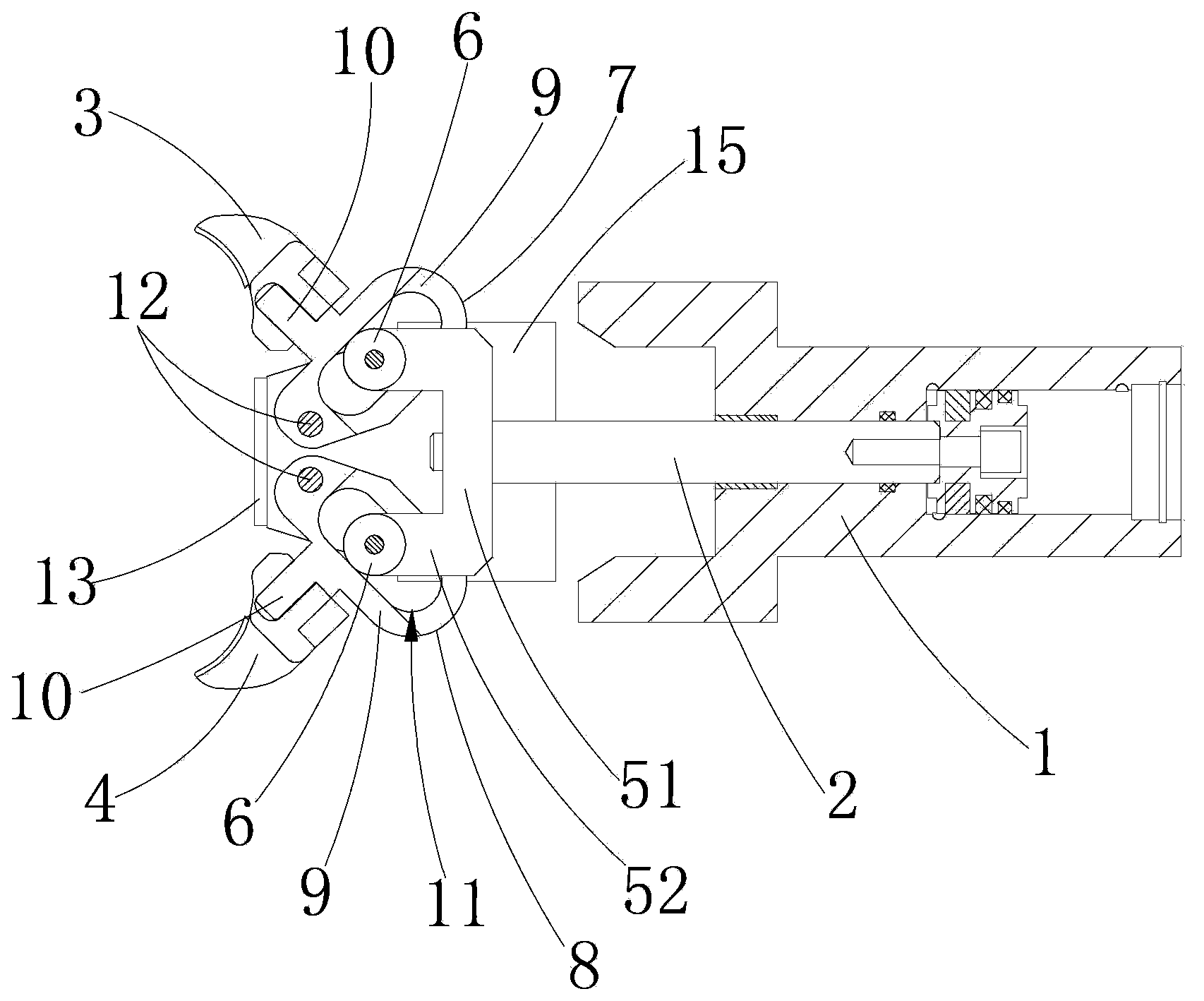

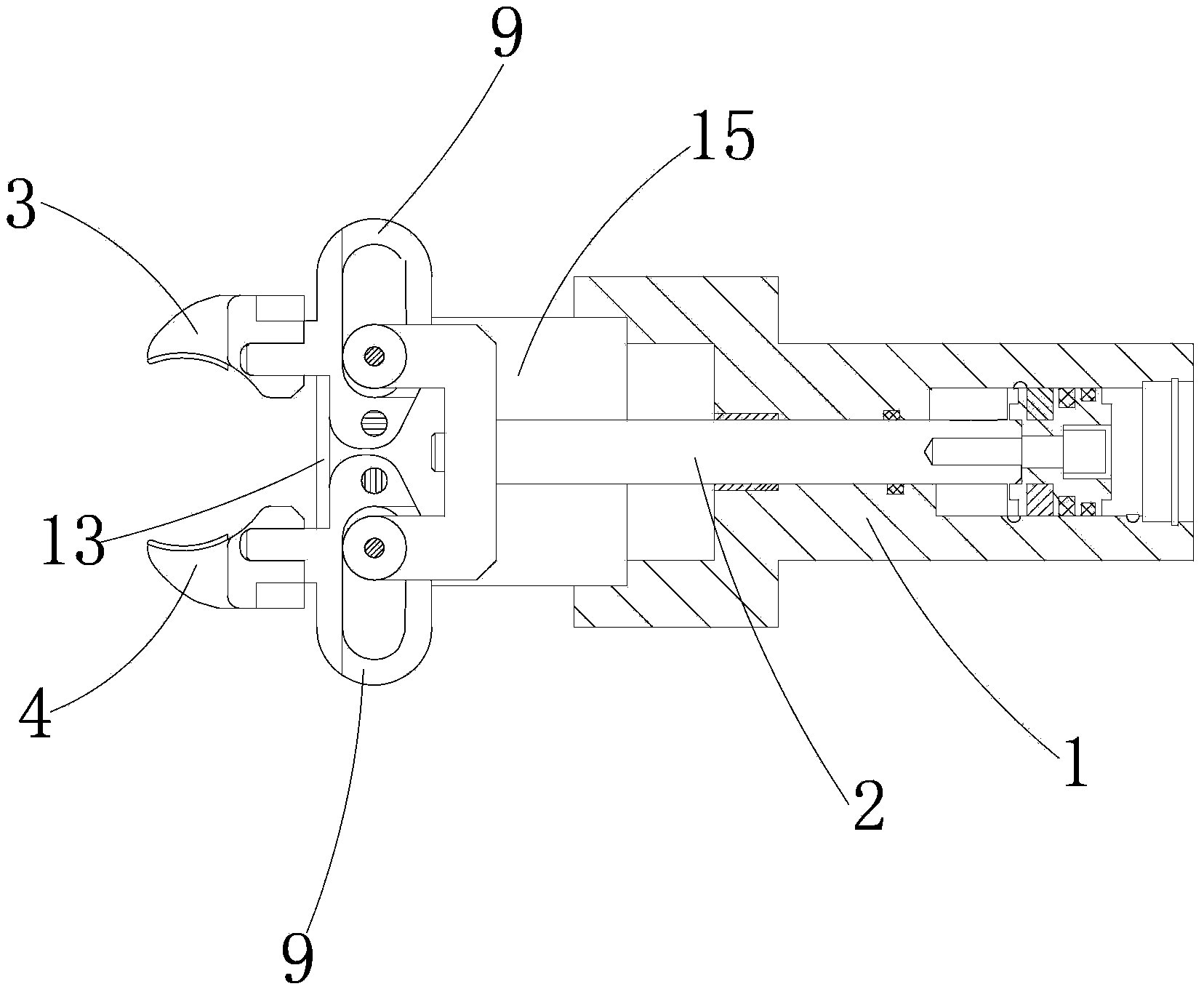

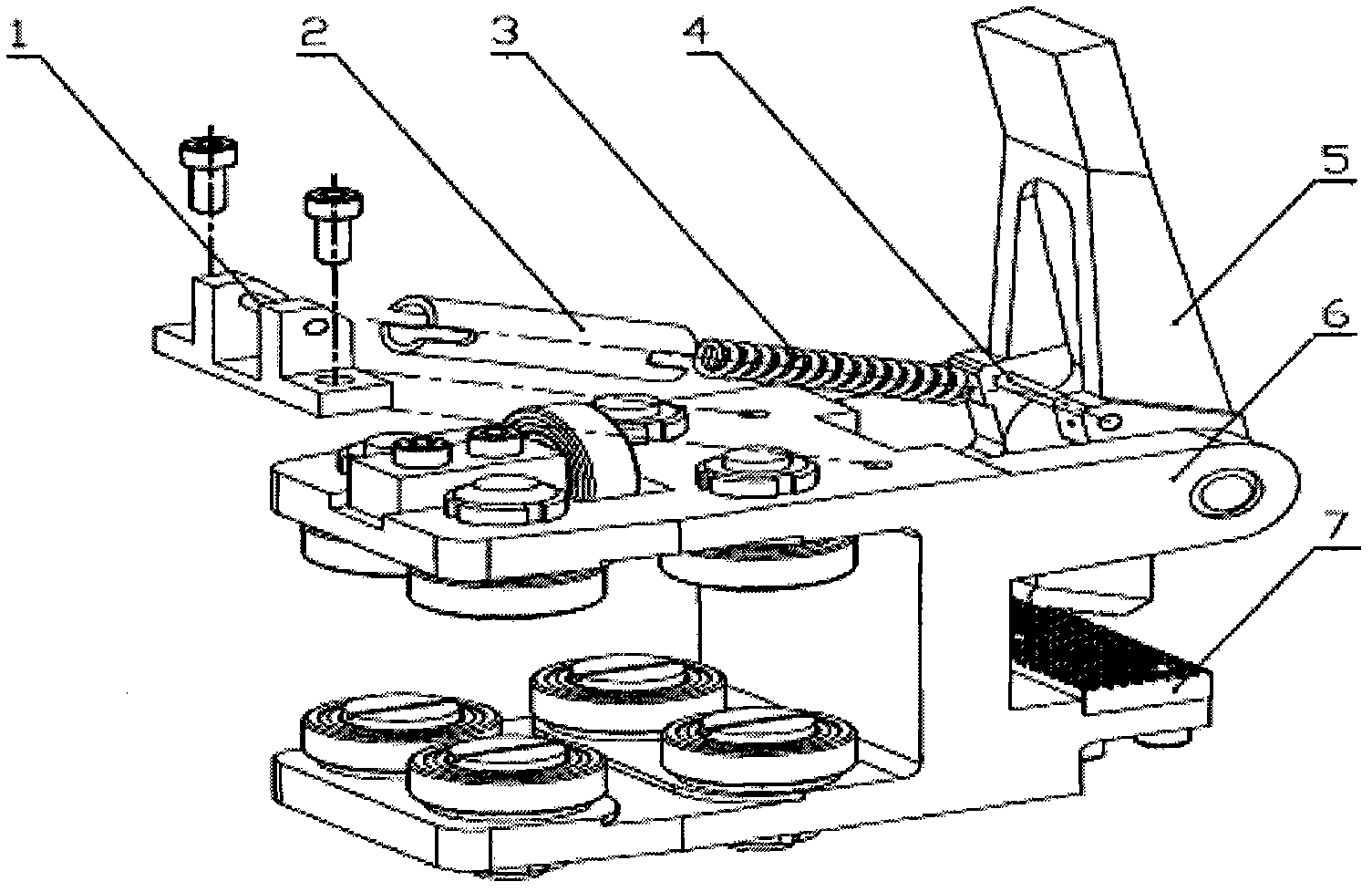

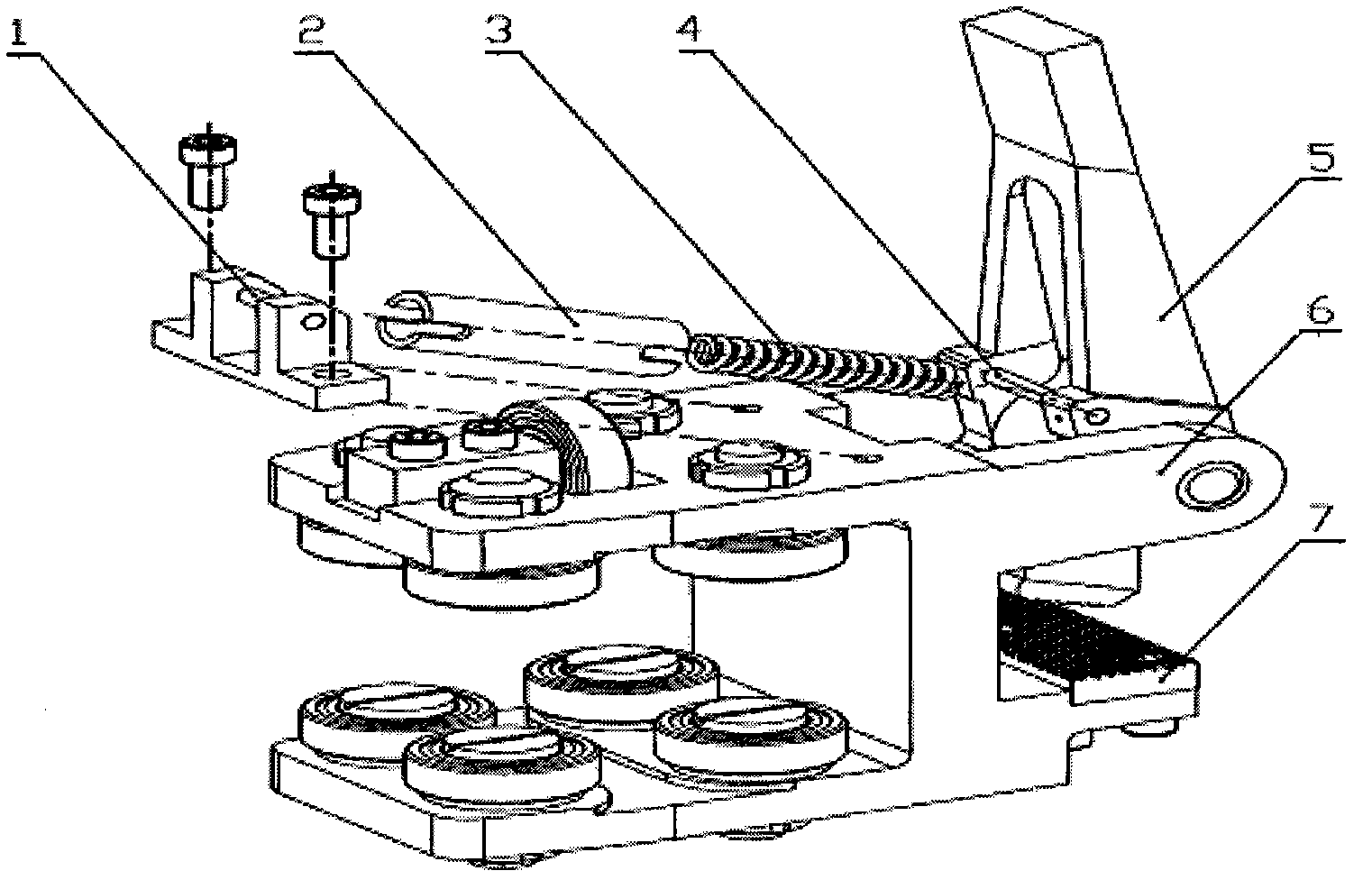

Manipulator

The invention discloses a manipulator and belongs to the technical field of plastic processing machinery. The manipulator comprises a manipulator body, a pair of clamp arms which are rotationally connected through a rotating shaft and can relatively retract and open, as well as a drive device which drives the clamp arms to retract or open. The manipulator is characterized in that a first connecting rod is arranged on each clamp arm, and the first connecting rods are connected onto the drive device through second connecting rods respectively. The manipulator has the advantages of simple structure, compactness, small size and the like.

Owner:台州迈格机械模具有限公司

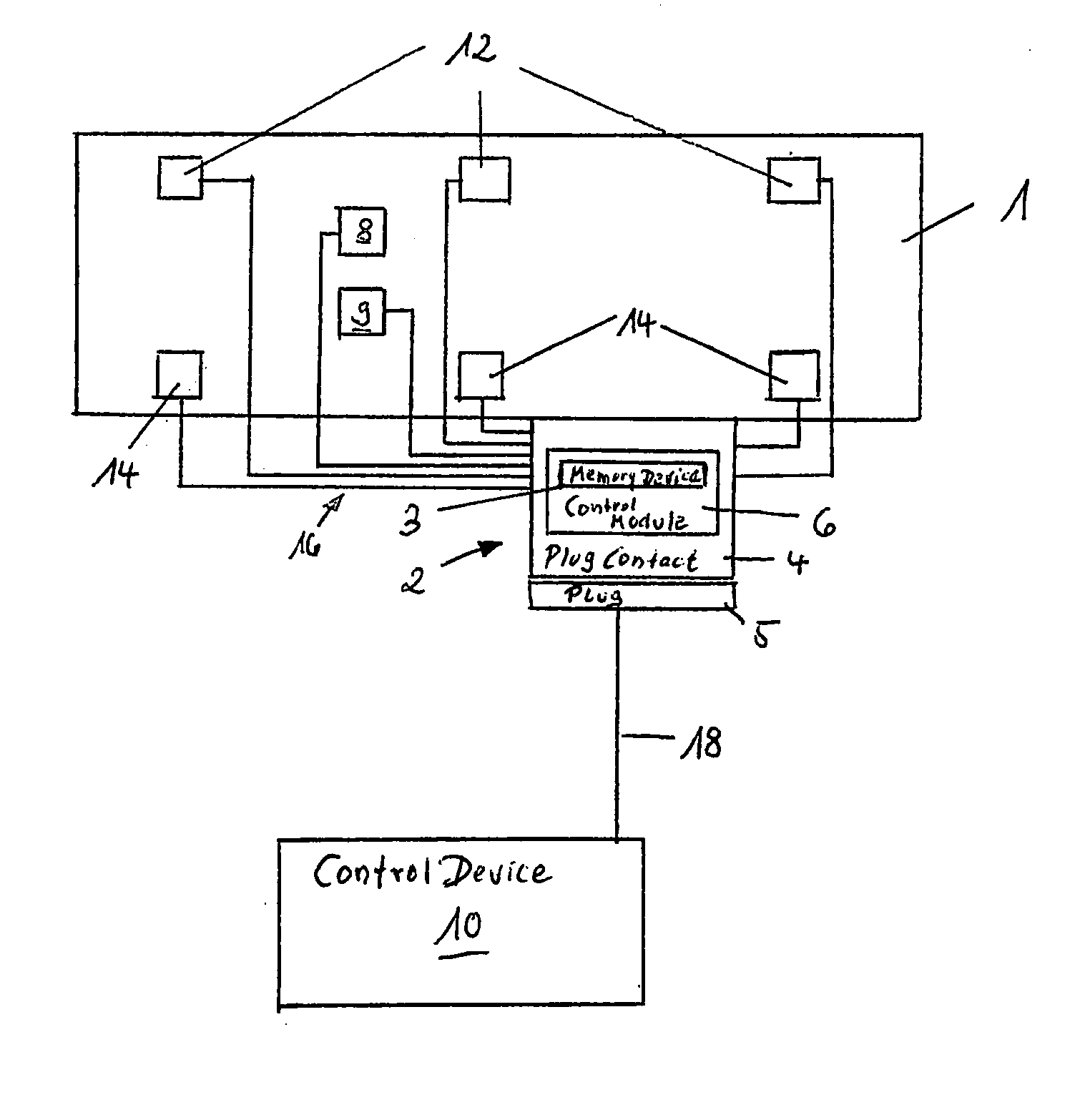

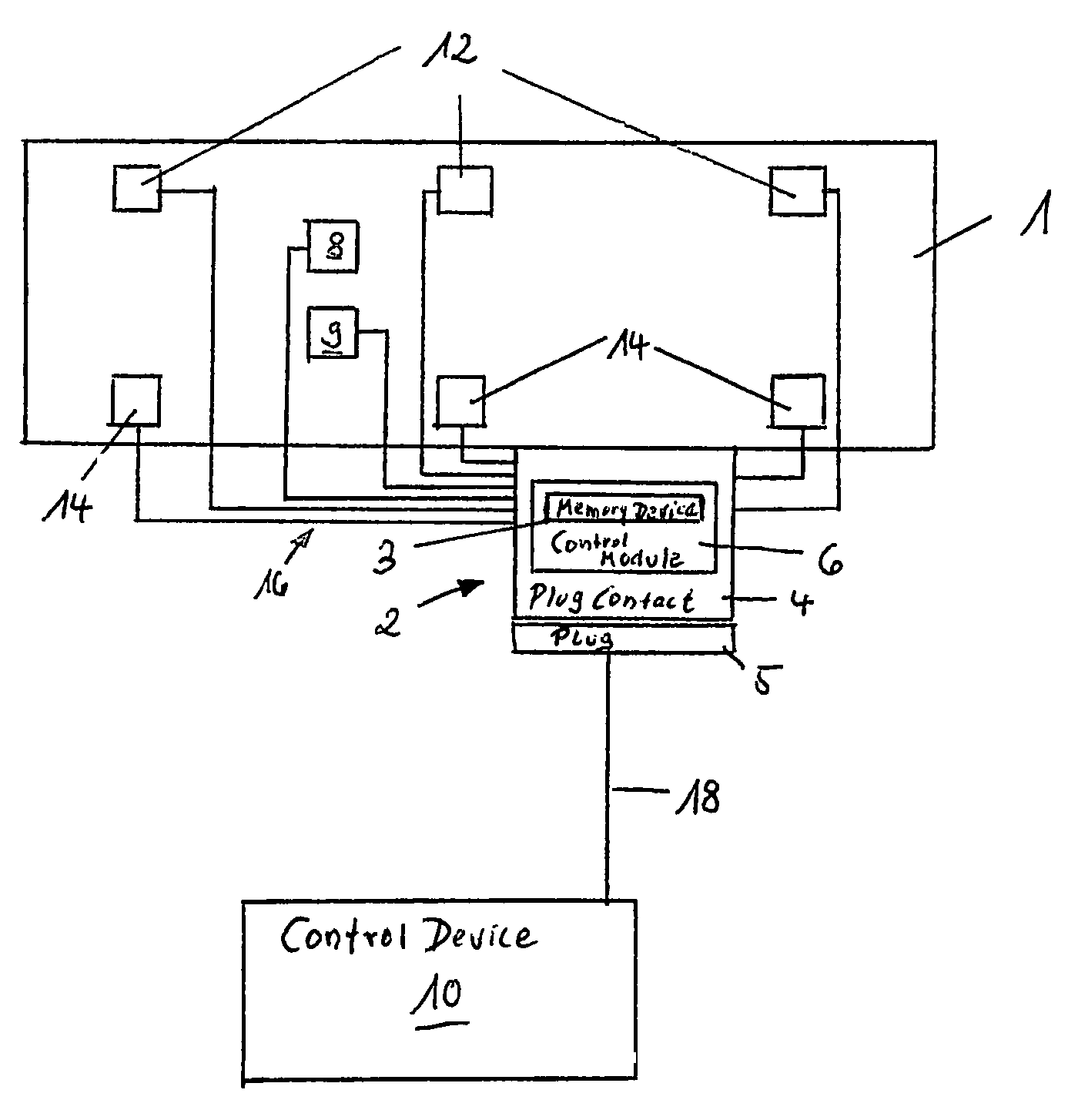

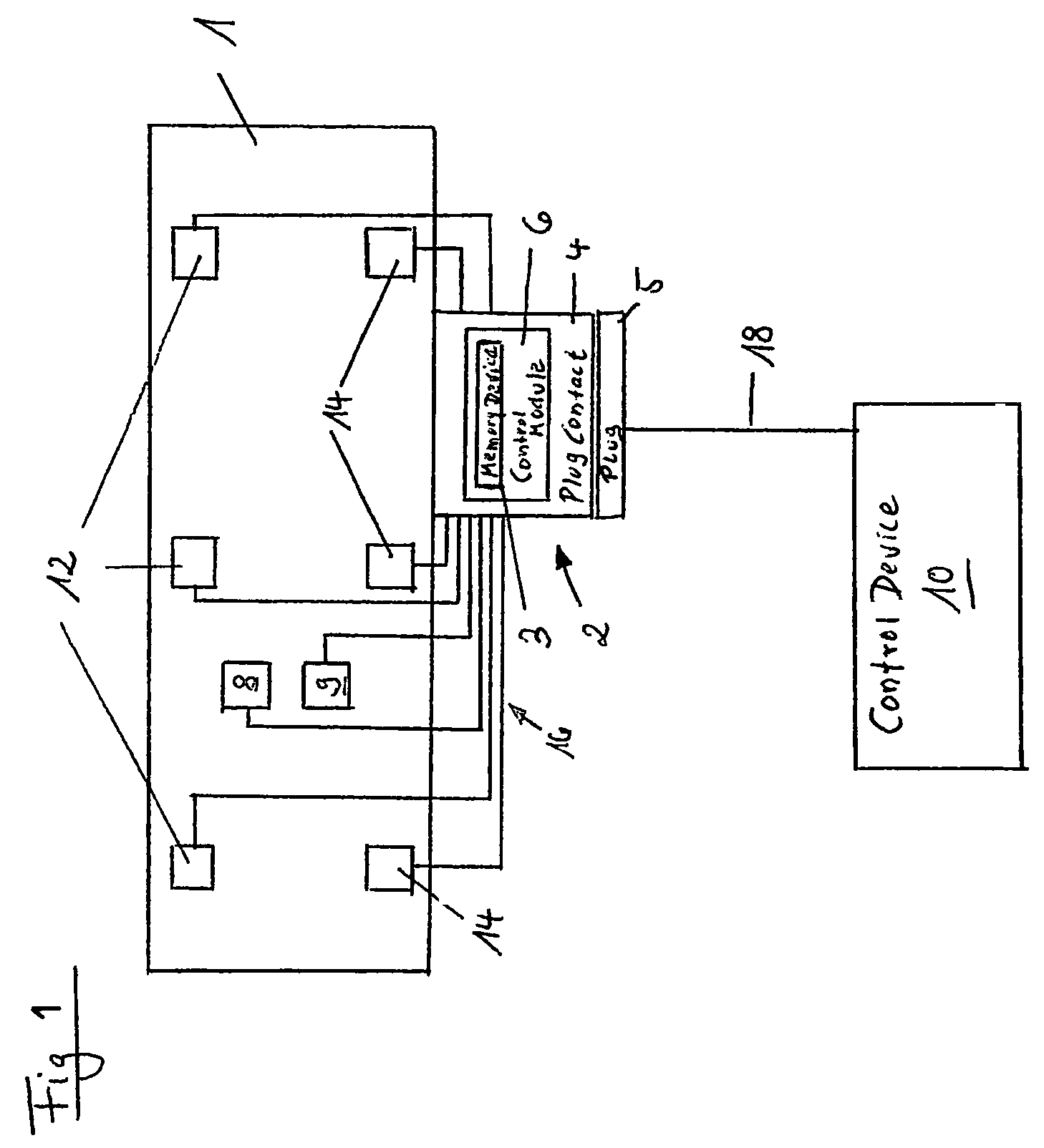

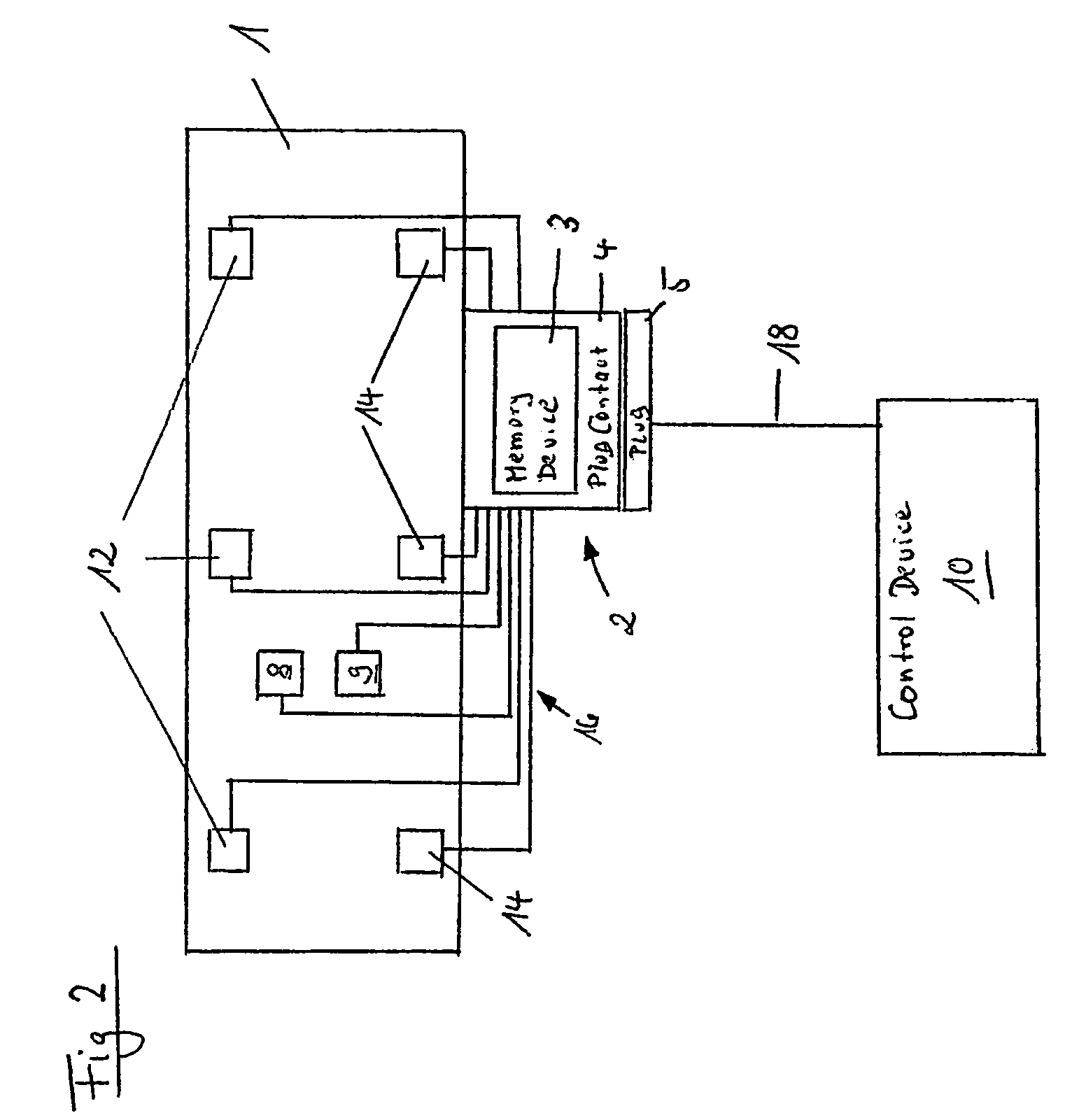

Identification of a modular machine component

ActiveUS20050283271A1Firmly connectedMinimize wiring complexityComputer controlSimulator controlModularityInjection molding machine

A plastics processing machine, in particular injection molding machine or extruder, includes at least one component represented by a clamping unit, feed and metering apparatus, plasticizing unit, injection unit, or separate injection apparatus, and characterized by specific parameters for carrying out at least one working or process step. A control device is connected to the at least one component and configured to control the at least one component, with the component-specific parameters being useable in the control device for control of the component. Provided for the component is a separate memory device in which the component-specific parameters are stored and can be transmitted to the control device prior to or upon startup of operation of the component.

Owner:SUMITOMO SHI DEMAG PLASTICS MACHINERY

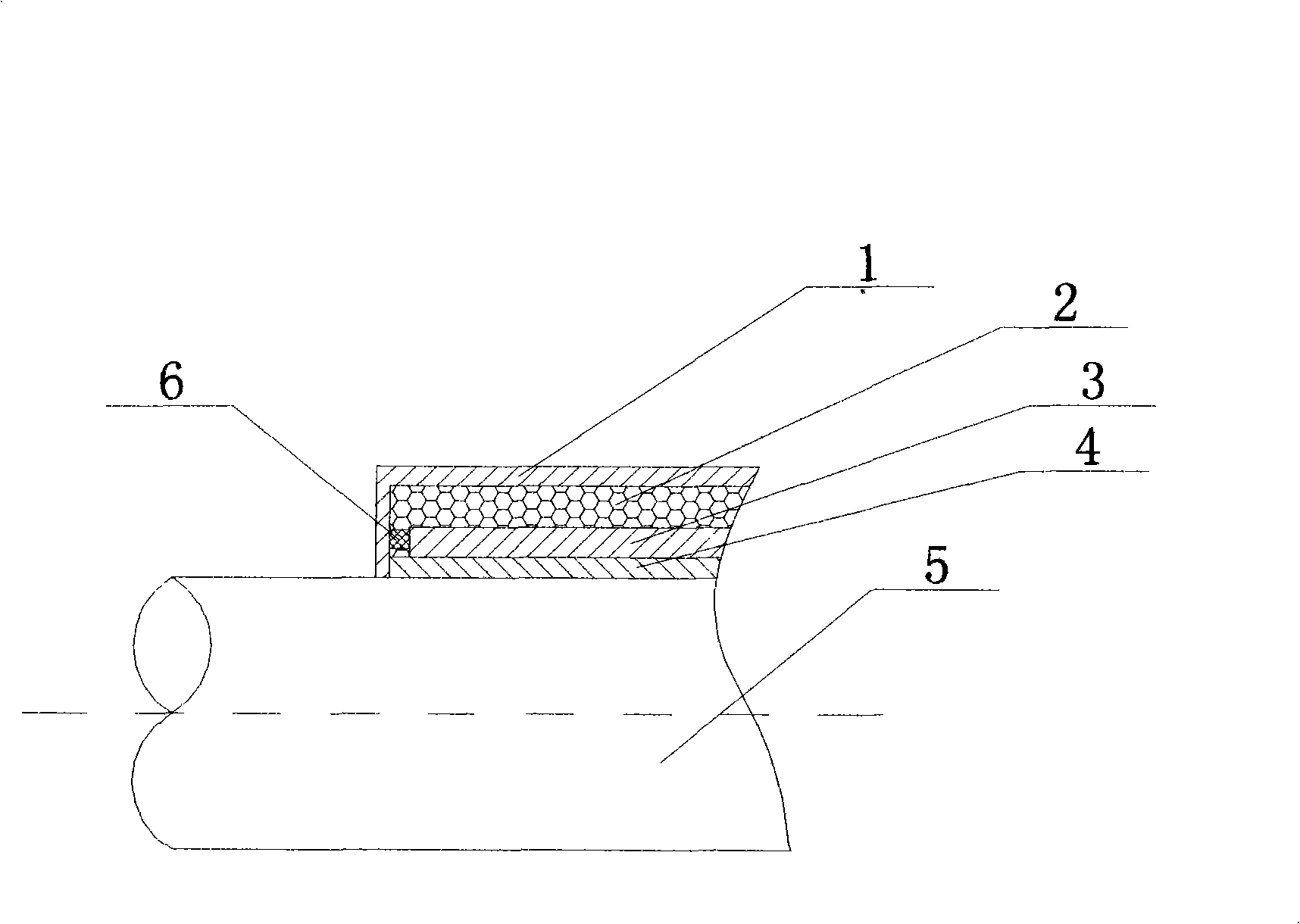

Environment protection high-efficiency energy-saving heating ring for TMD electric heating membrane

ActiveCN101330778AReduce pollutionStrong heat transfer capabilityHeating element shapesHeating element materialsEngineeringInjection molding machine

An environmental protecting high efficient energy-saving TMD electrothermal diaphragm heating ring relates to an improved plastic processing machine, in particular to an improved injection molding machine heating ring. The heating ring is composed of a metal outer shell (1), an aluminium silicate wool heat insulation layer (2), an electrothermal diaphragm layer (3), an aluminium inner liner layer (4); an injection molding machine gun barrel (5) is wrapped with the aluminium inner liner layer (4); the aluminium inner liner layer (4) is covered with the electrothermal diaphragm layer (3); the aluminium silicate wool heat insulation layer (2) is arranged on the outer surface of the electrothermal diaphragm layer (3); the aluminium silicate wool heat insulation layer (2) is wrapped with the metal outer shell (1). Aiming to solve problems with the resistance wire heating ring, the improved injection molding machine heating ring adopts the heating technology of the electrothermal diaphragm; because the electrothermal diaphragm has the characteristics of thermal oxidation resistance, corrosion resistance, etc., the service life of the electrothermal diaphragm is longer than that of the resistance wire. The heating ring has the advantages of high efficiency, less environmental pollution, strong heat transfer capacity and long service life.

Owner:GUANGDONG HALLSMART INTELLIGENCE TECH CORP LTD

Plastic extrusion flat film wire drawing machine

The invention discloses a plastic extrusion flat film wire drawing machine which is a plastic processing machine. The film is easily drawn while the product yield is not reduced, so that the requirement on strength and power of a traction unit is reduced. The plastic extrusion flat film wire drawing machine comprises an extrusion mechanism and a film discharging mechanism; the extrusion mechanism comprises a screw material barrel and a filtering device; the film discharging mechanism comprises a forming die, a cooling water tank, a roller assembly and a rolling assembly; the screw material barrel is communicated with the filtering device; the filtering device is communicated with the forming die; the filtering device is communicated with the forming die through a three-way distributor; the forming die comprises two die heads; a feeding port of the three-way distributor is communicated with the filtering device; and two discharging ports are respectively communicated with the two die heads. The plastic extrusion flat film wire drawing machine is mainly used for producing plastic filaments for plastic knitting bags.

Owner:PINGYANG DAYU PLASTIC MACHINERY +1

Wire drawing machine

ActiveCN104357926AReduce labor intensityReduce manufacturing costArtificial thread manufacturing machinesStretch-spinning methodsEngineeringDrive motor

The invention discloses a wire drawing machine, belongs to plastic processing machinery, and solves the problem that different requirements on extension ratio of different raw materials and different masses cannot be met in the prior art. In order to solve the problem, the invention adopts the technical scheme that an input shaft, a first output shaft, a transitional shaft set and a second output shaft are arranged in a gearbox in parallel in sequence; a drive motor is in transmission connection with the input shaft; the input shaft and the first output shaft are in transmission connection or form a coaxial structure; the first output shaft is in transmission connection with a draw roller; the second output shaft is in transmission connection with a pull roller; the first output shaft is in transmission connection with a transitional shaft set through a shifting gear set; the transitional shaft set is in transmission connection with the second output shaft through the shifting gear set; the shifting gear set comprises a sliding gear and at least two transmission gears; an adjusting component used for adjusting meshing of the sliding gear and different transmission gears is arranged in the gearbox body. The wire drawing machine is mainly applied to plastic wire drawing.

Owner:雁峰集团有限公司

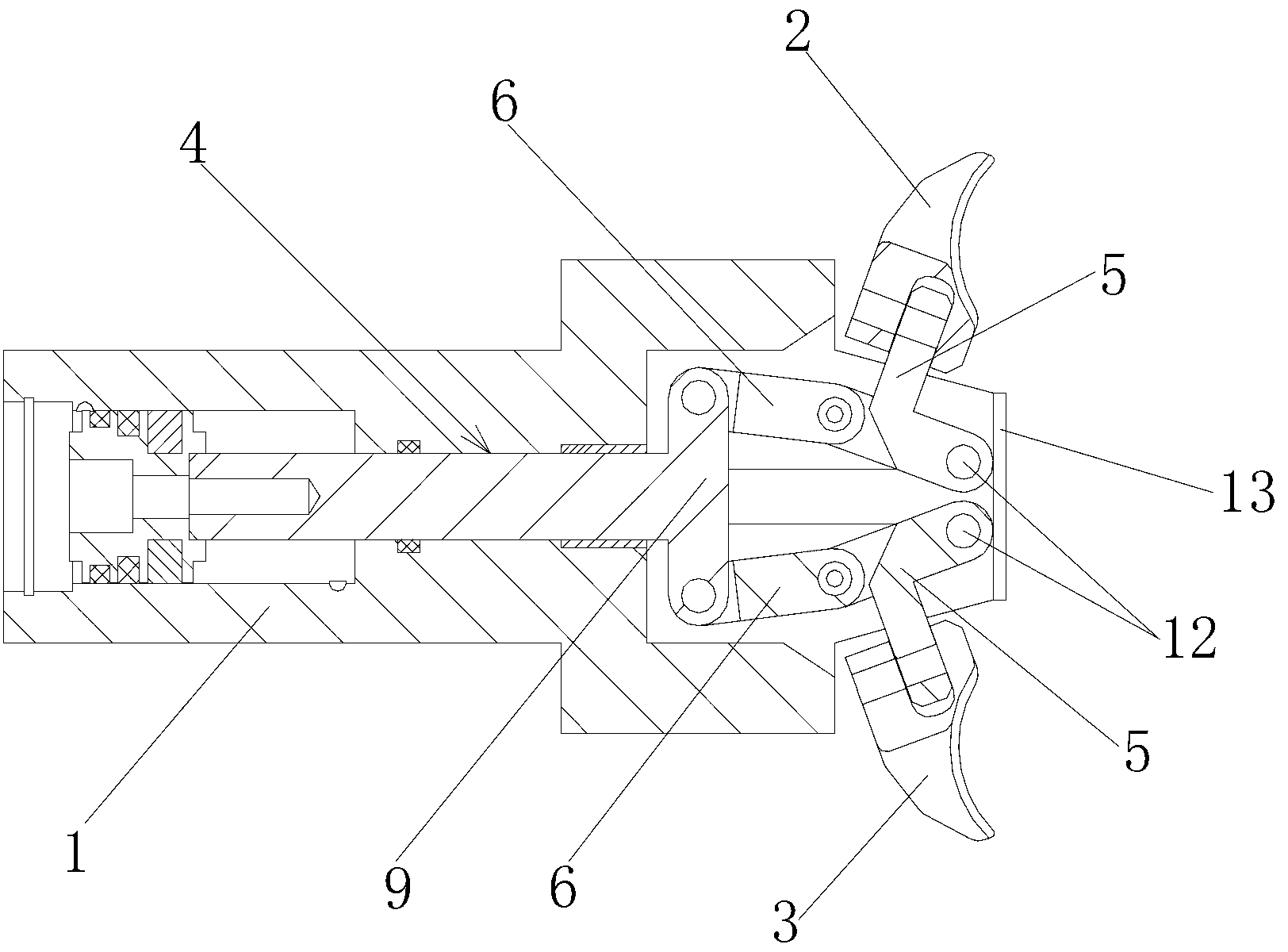

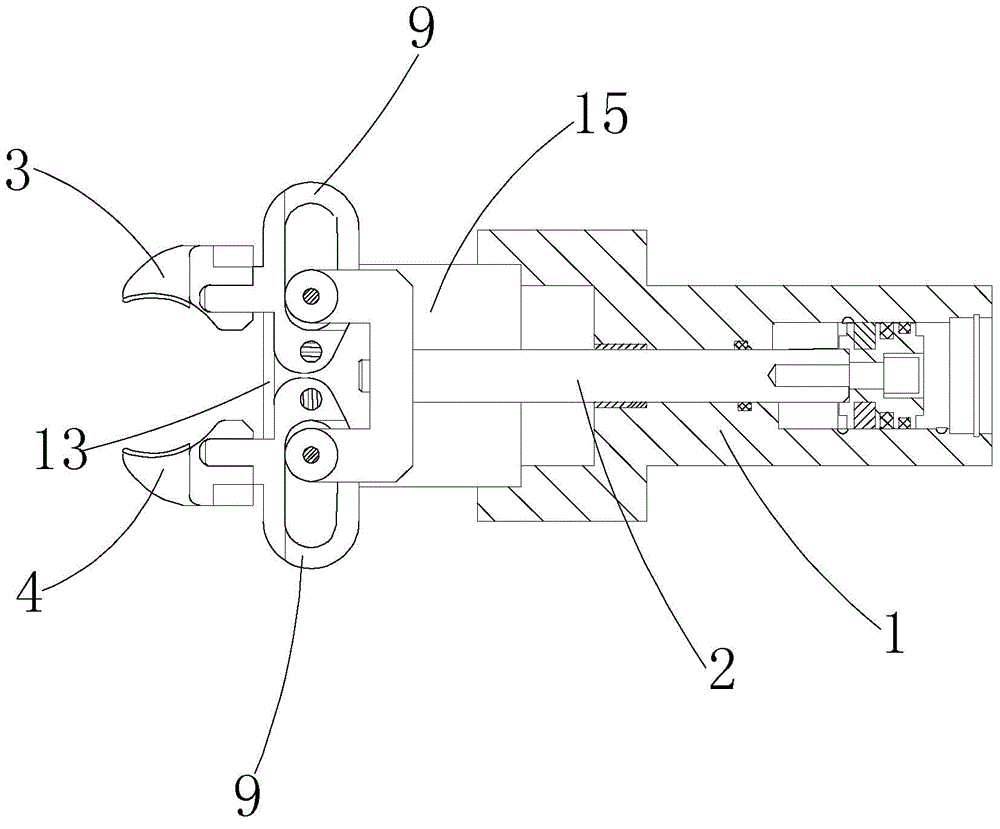

Pneumatic gripper mechanical arm

The invention discloses a pneumatic gripper mechanical arm and belongs to the technical field of plastics machining machinery. The pneumatic gripper mechanical arm comprises an air cylinder body, a piston, an air cylinder rod, and a pair of clamping arms which are connected to the air cylinder rod and can be oppositely folded and unfolded. The pneumatic gripper mechanical arm is characterized in that one end of the air cylinder rod, which is connected with the clamping arms, is provided with a U-shaped frame, the cross arm of the U-shaped frame is connected with the air cylinder rod, and the end portions of the two longitudinal arms of the U-shaped frame are respectively provided with a bearing; the pair of clamping arms are slidingly connected to the two vertical arms of the U-shaped frame through a support with a bearing groove, the bearings work inside the bearing groove, and the support is rotatably connected to the air cylinder body through a support pin. The pneumatic gripper mechanical arm has the advantages of being simple and compact in structure, small in size, low in energy consumption and the like.

Owner:台州迈格机械模具有限公司

Identification of a modular machine component

A plastics processing machine, in particular injection molding machine or extruder, includes at least one component represented by a clamping unit, feed and metering apparatus, plasticizing unit, injection unit, or separate injection apparatus, and characterized by specific parameters for carrying out at least one working or process step. A control device is connected to the at least one component and configured to control the at least one component, with the component-specific parameters being useable in the control device for control of the component. Provided for the component is a separate memory device in which the component-specific parameters are stored and can be transmitted to the control device prior to or upon startup of operation of the component.

Owner:SUMITOMO SHI DEMAG PLASTICS MACHINERY

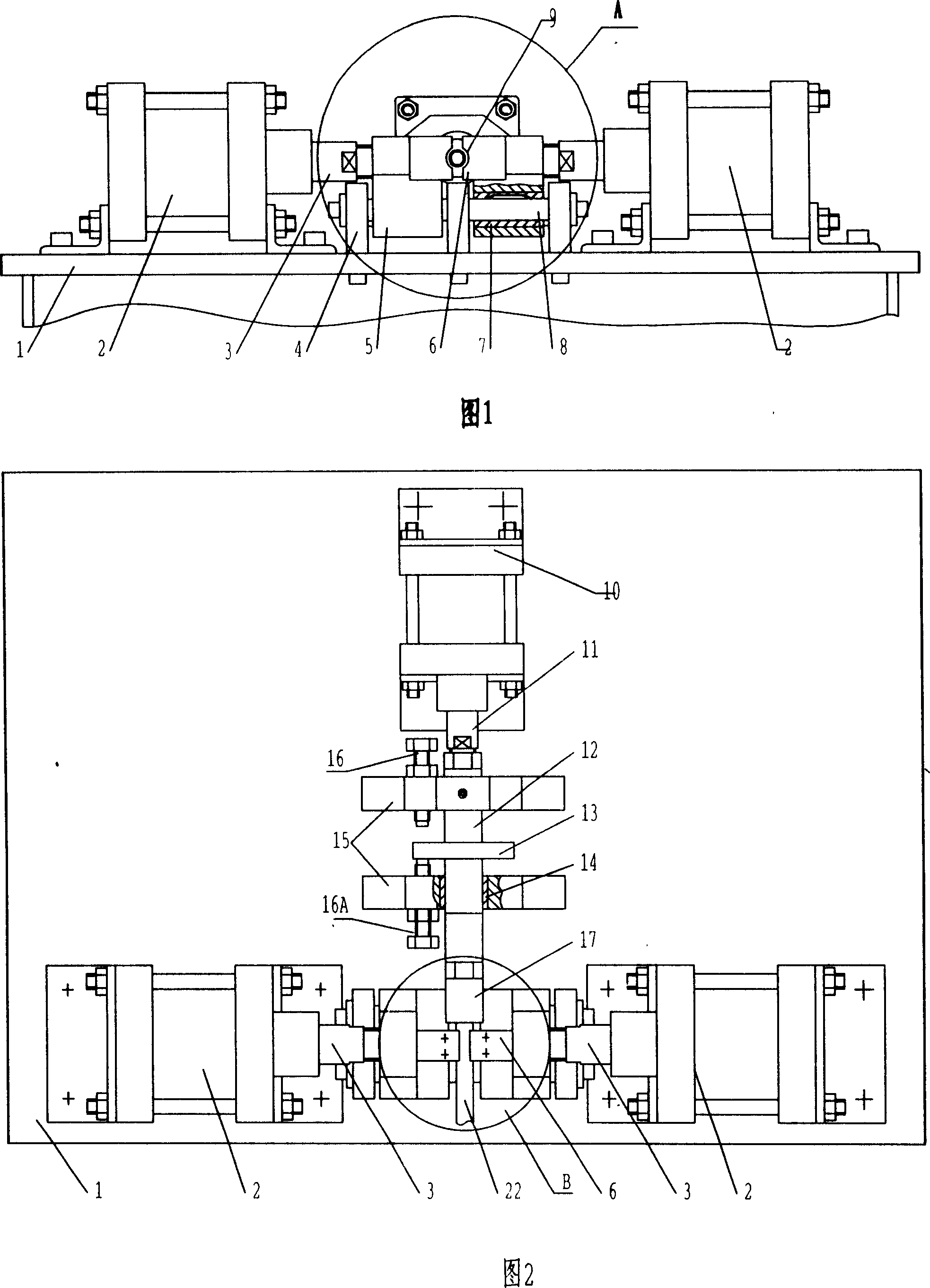

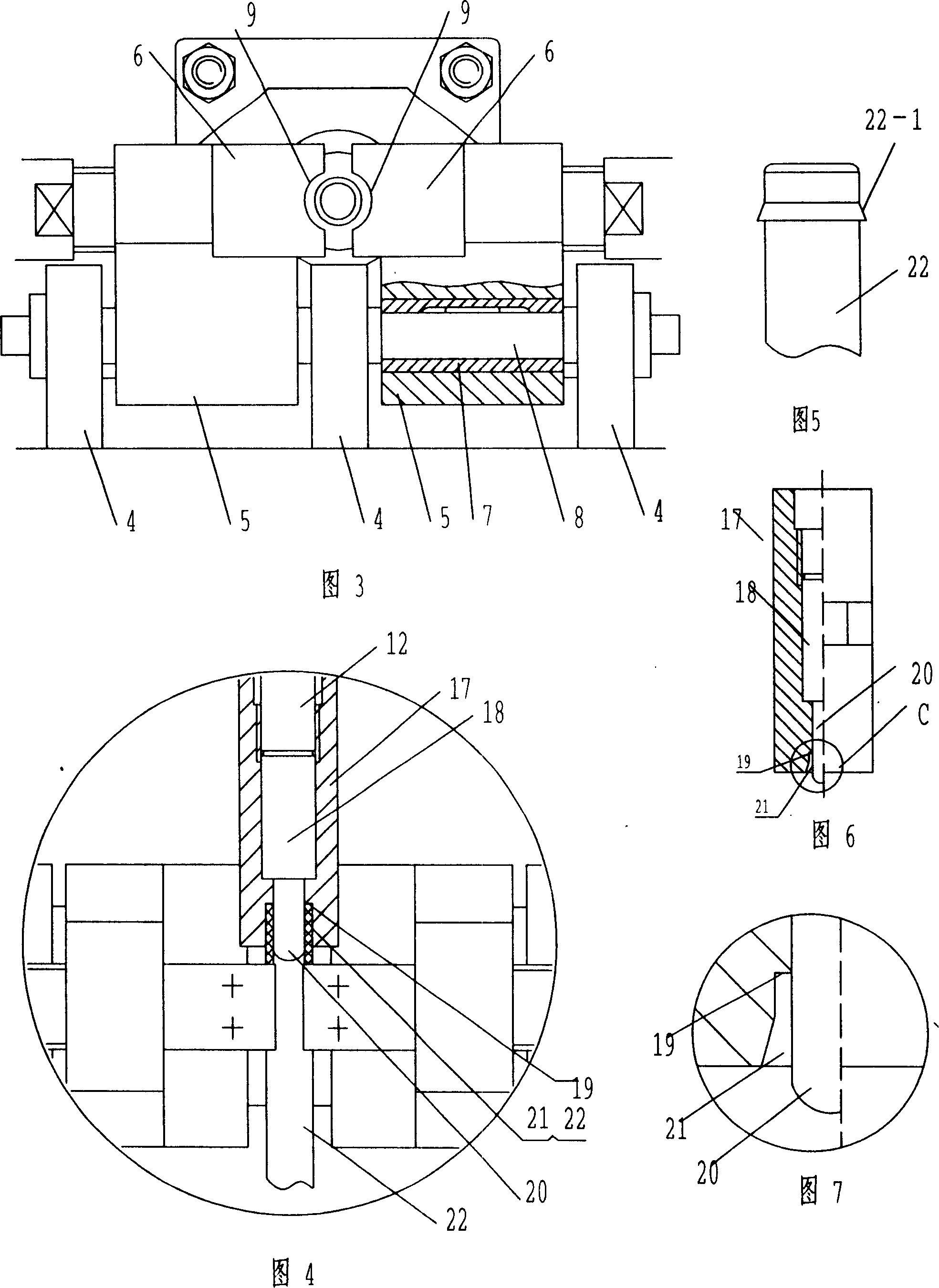

Cold shaping machine for vehicle oil pipe end squeeze pack

InactiveCN100999134AImprove quality and efficiencyImprove processing efficiencyTubular articlesPulp and paper industryPlastics processor

The present invention relates to a vehicle fuel pipe end portion squeezing-covering cold-forming machine, belonging to the field of plastic processing machinery technology. Said forming machine includes fuel pipe clamping device, stamping device and machine frame. The stamping device is formed from stamping cylinder, guide stroke-regulating mechanism and stamping head, said stamping head is driven by stamping cylinder. The described fuel pipe clamping device includes two clamping cylinders which are symmetrically-arranged at two sides of stamping cylinder, every clamping cylinder rod is fixedly connected with clamping block said stamping cylinder rod is perpendicular to said two clamping cylinder rods.

Owner:HEBEI CHINAUST AUTOMOTIVE PLASTICS CORP LTD

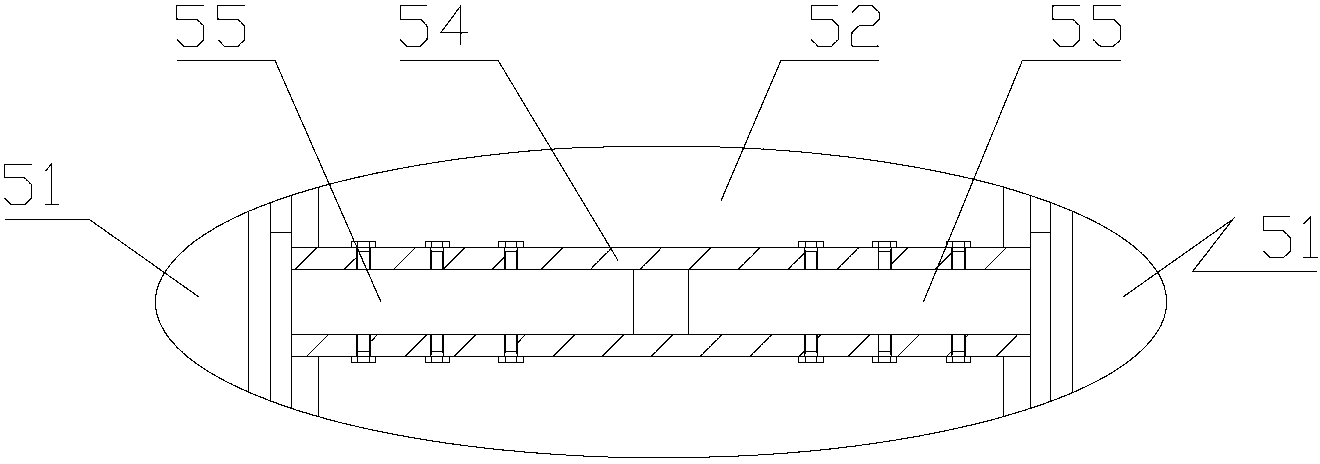

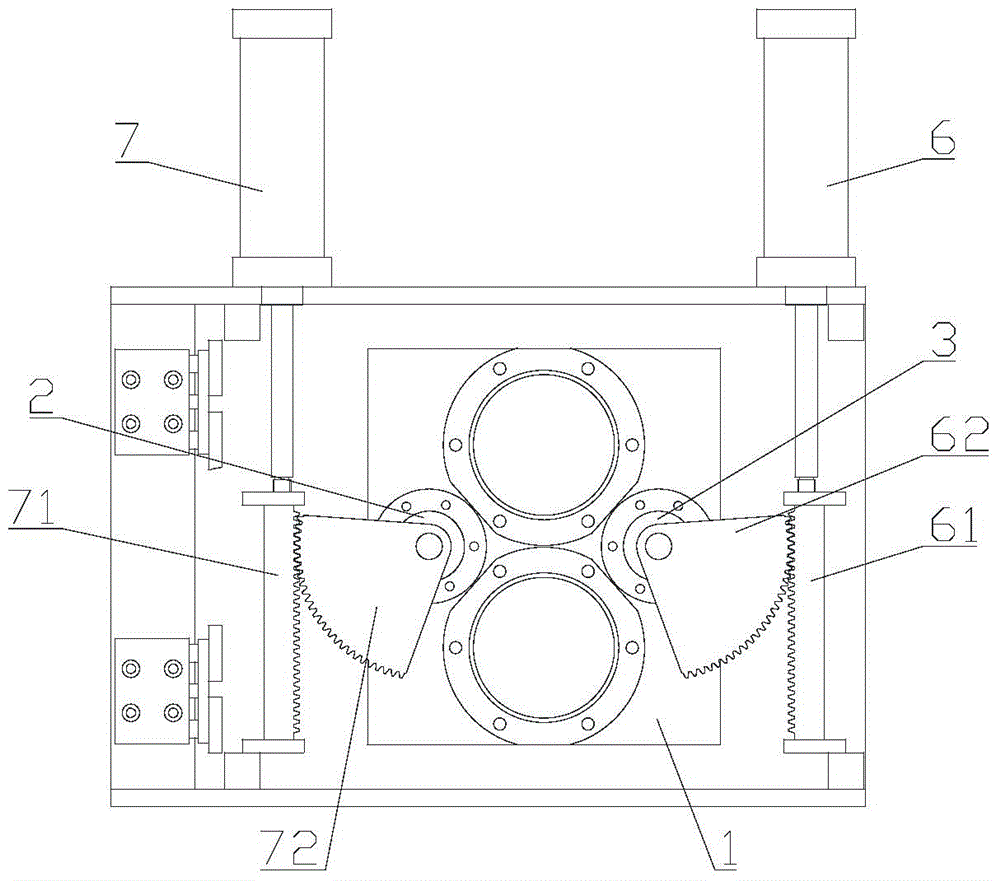

Non-stop screen exchanger and plastic extruder

The invention discloses a non-stop screen exchanger, belongs to the field of plastic processing machinery, and aims at solving the problem in the prior art that air bubbles can be mixed in plastic melt. According to the technical scheme for solving the problem, the non-stop screen exchanger mainly comprises a main body, wherein a feeding opening, a first channel, a second channel and a discharge opening are formed in the main body; a feeding valve core is arranged at the communicated part of the feeding opening, the first channel and the second channel; a discharge valve core is arranged at the communicated part of the discharge opening, the first channel and the second channel; an exhaust hole which is communicated with the outside is formed in the main body; an exhaust groove is formed in the peripheral side wall of the discharge valve core and is located on the back surface of the discharge valve core opposite to a first overflow groove; and when one of the first channel and the second channel is communicated with the discharge opening by the first overflow groove, the other one of the first channel and the second channel is communicated with the exhaust hole by the exhaust groove. The non-stop screen exchanger is mainly applied to a plastic extruding machine. In addition, the invention further provides a plastic extruder, which comprises the non-stop screen exchanger.

Owner:雁峰集团有限公司

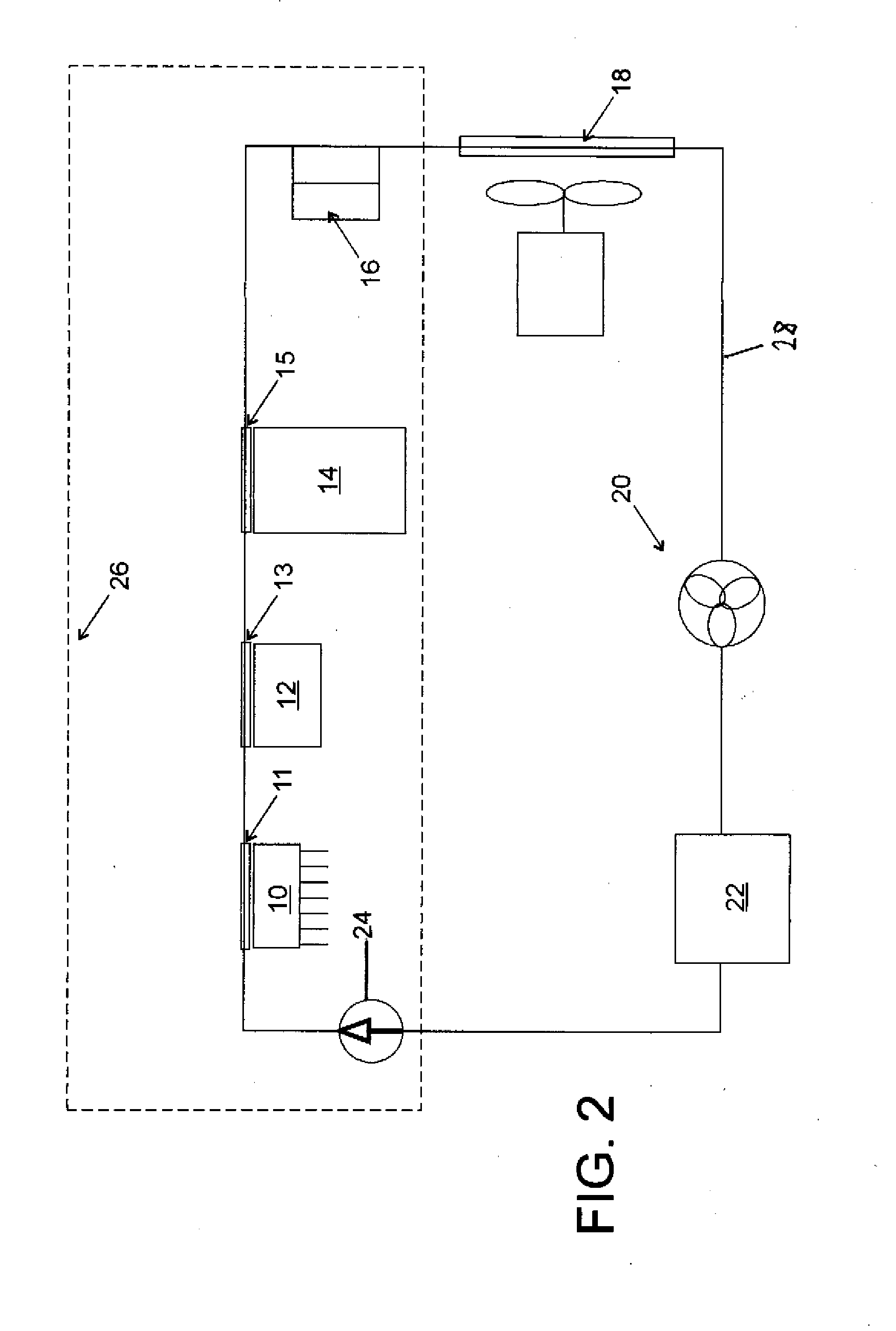

Water-cooled control device for a plastics processing machine

InactiveUS20070134365A1Reliable coolingImprove cooling effectSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsNuclear engineeringInjection molding machine

A control device for use with a plastics processing machine, e.g. an injection molding machine, includes a housing which is constructed for protection against ingress of water in compliance with the IP code and accommodates a heat source such as a CPU unit or a display unit. A cooling system is provided for dissipating heat generated by the heat source and includes a pump for pumping a coolant, at least one cooling element arranged inside the housing, a cooler provided outside the housing, and a coolant circuit for circulation of the coolant. The coolant circuit fluidly connects hereby the pump, the cooling element and the cooler with one another.

Owner:KRAUSS MAFFEI KUMSTSTOFFTECHNIK GMBH

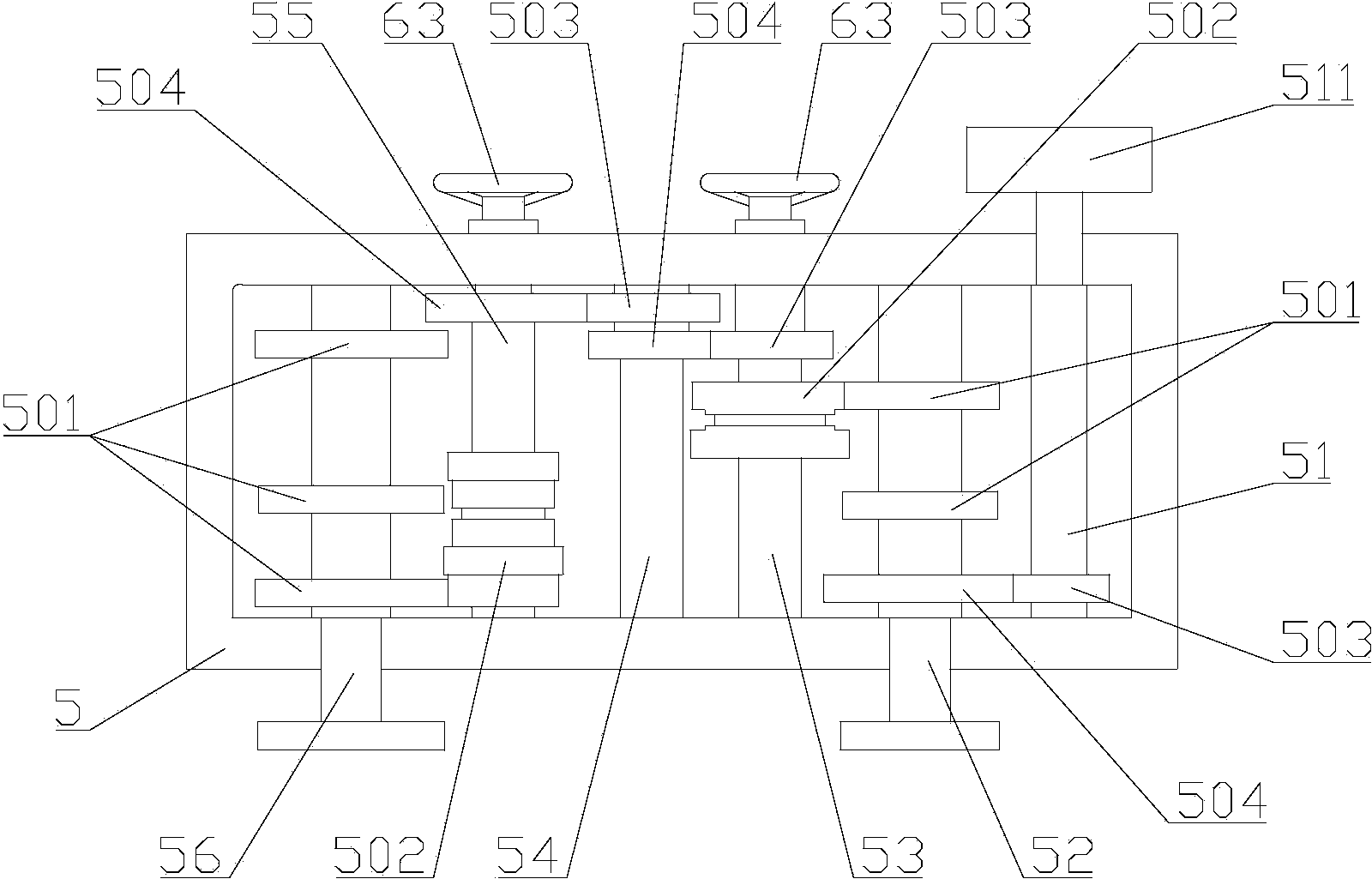

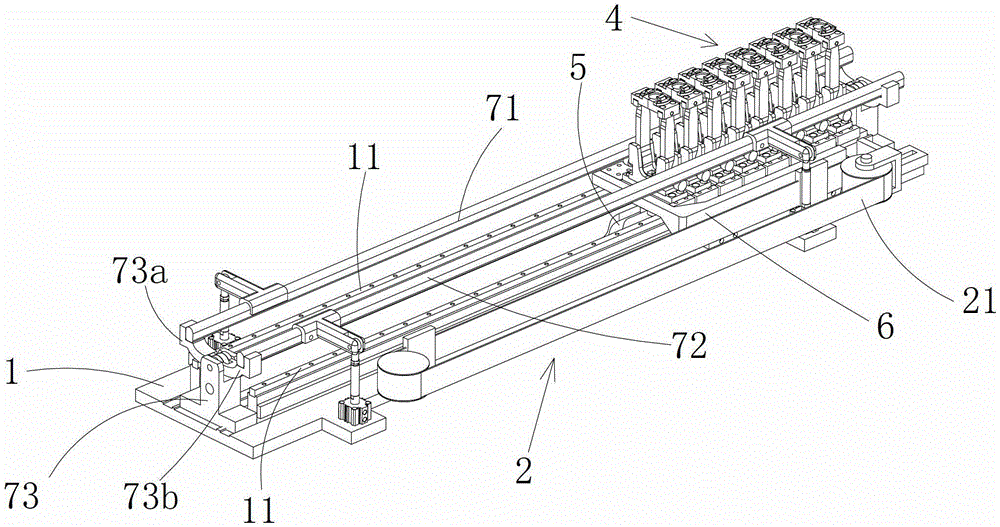

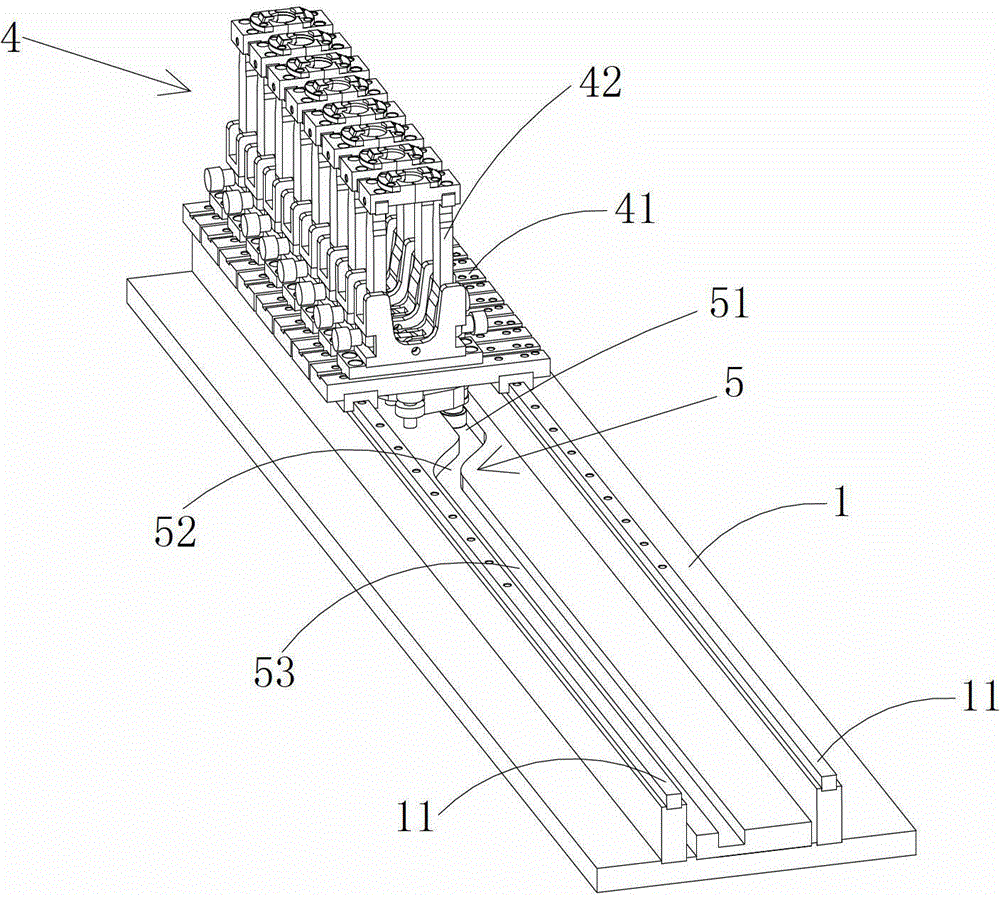

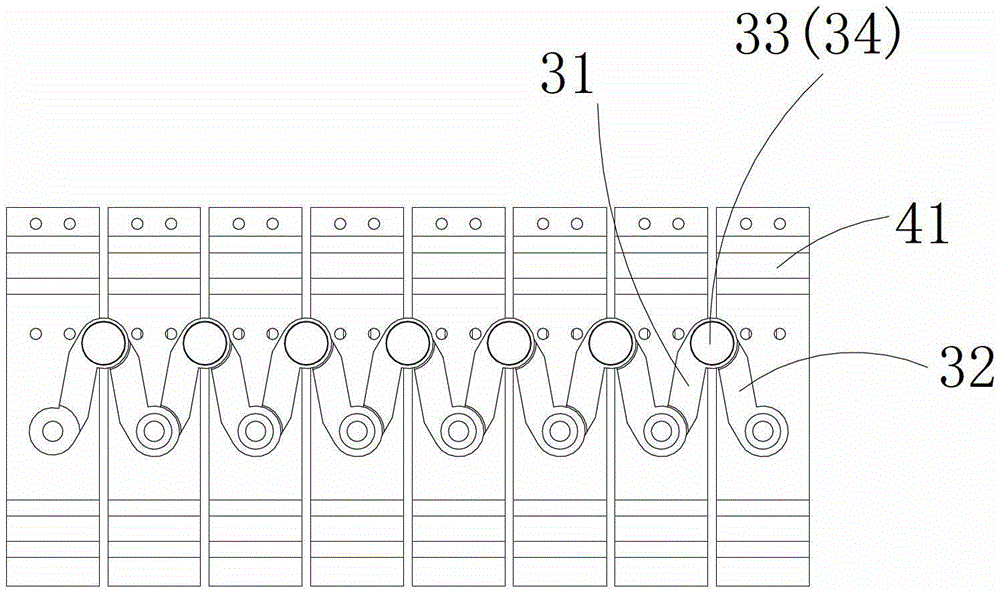

Conveying device

The invention discloses a conveying device, which belongs to the technical field of plastic processing machinery. The conveying device comprises a base, a group of mechanical hands and a driving device, wherein the group of mechanical hands is arranged on the base, and can move in a reciprocating way along a conveying path; and the driving device is used for driving the mechanical hands to move in a reciprocating way. The conveying device is characterized in that each mechanical hand comprises a mechanical hand seat and a clamping part arranged on the mechanical hand seat; two adjacent mechanical hand seats are connected with each other through a linkage mechanism, and the middle part of the linkage mechanism is provided with at least one movable hinge joint; the base is provided with a moving track which can be used for moving the movable hinge point to drive the two adjacent mechanical hand seats to move relatively; the at least one movable hinge point is provided with a connecting piece; and the movable hinge point is connected with the moving track through the connecting piece. Due to the adoption of the conveying device, continuous and rapid operation of conveying and distance changing are realized, operation is easy, and the production efficiency is high.

Owner:台州迈格机械模具有限公司

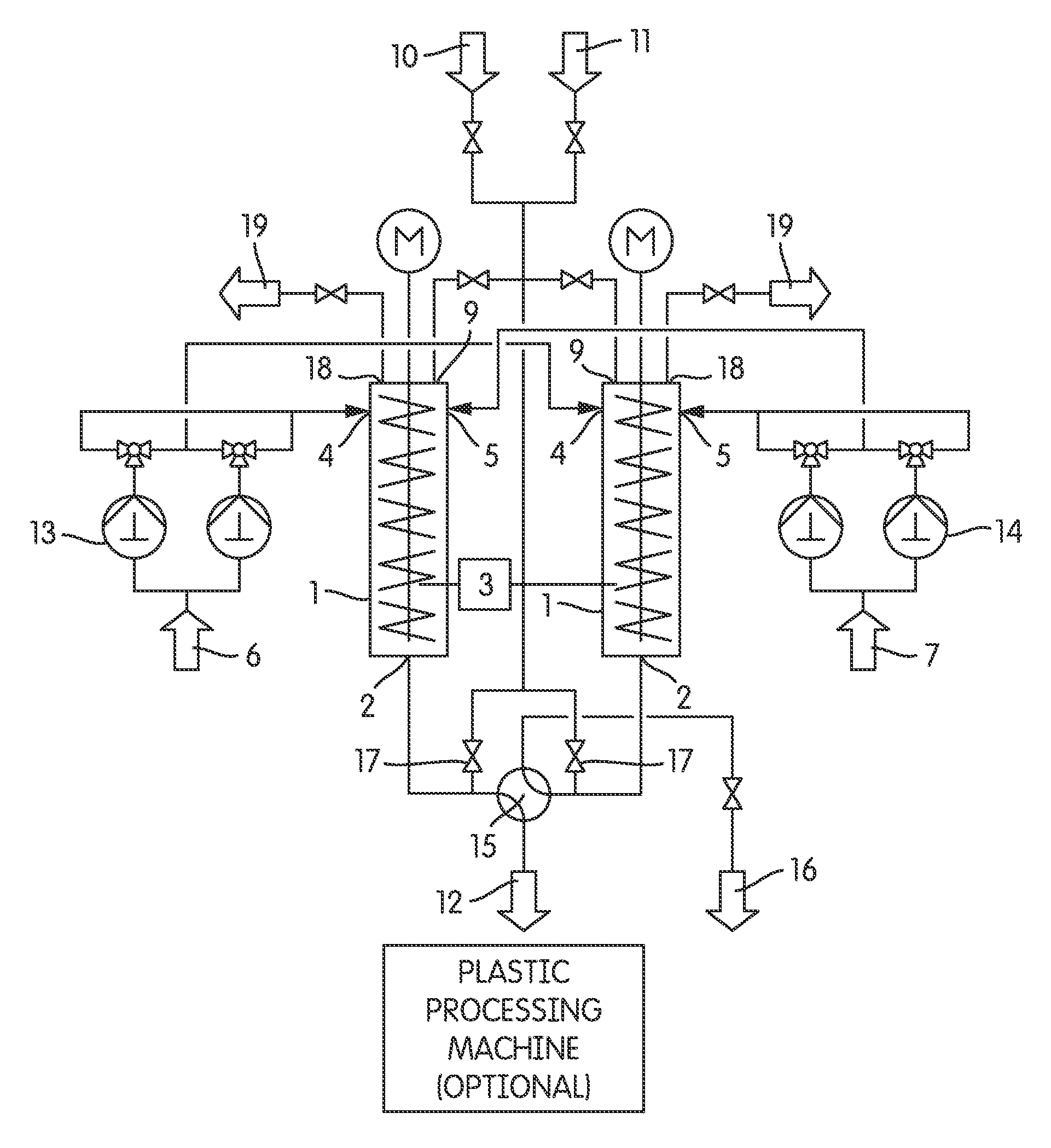

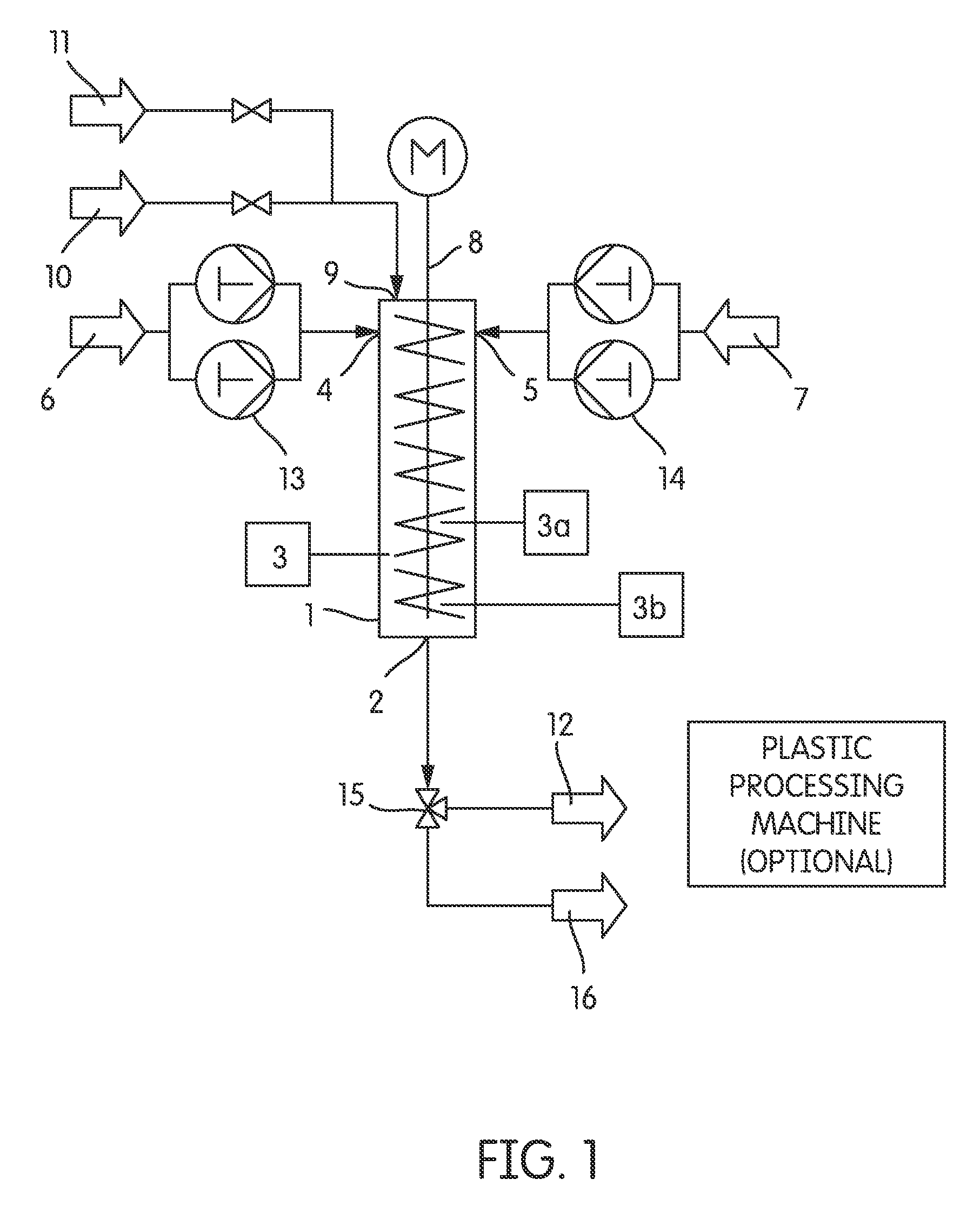

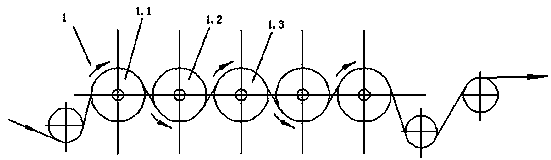

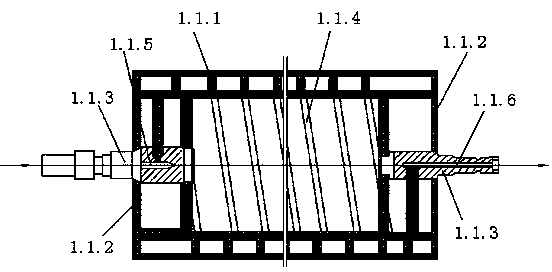

Mixer for liquid colorants and method for mixing liquid colorants

InactiveUS8123394B2Increase shear forceWell mixedRotary stirring mixersTransportation and packagingEngineeringViscosity

A mixer having a mixing pipe (1), a rotatable mixing unit (3) having back-mixing action, and a supply of the liquid colorant (4, 5) through the wall of the mixing pipe in the area of the mixing unit allows uniform mixing of liquid colorants of differing viscosities even with fixed-cycle supply of the liquid colorants. Mixing liquid colorants using this mixer allows direct dosing of the mixed liquid colorant into a plastic processing machine in the event of volumetric dosing of the employed liquid colorants.

Owner:EVONIK DEGUSSA GMBH

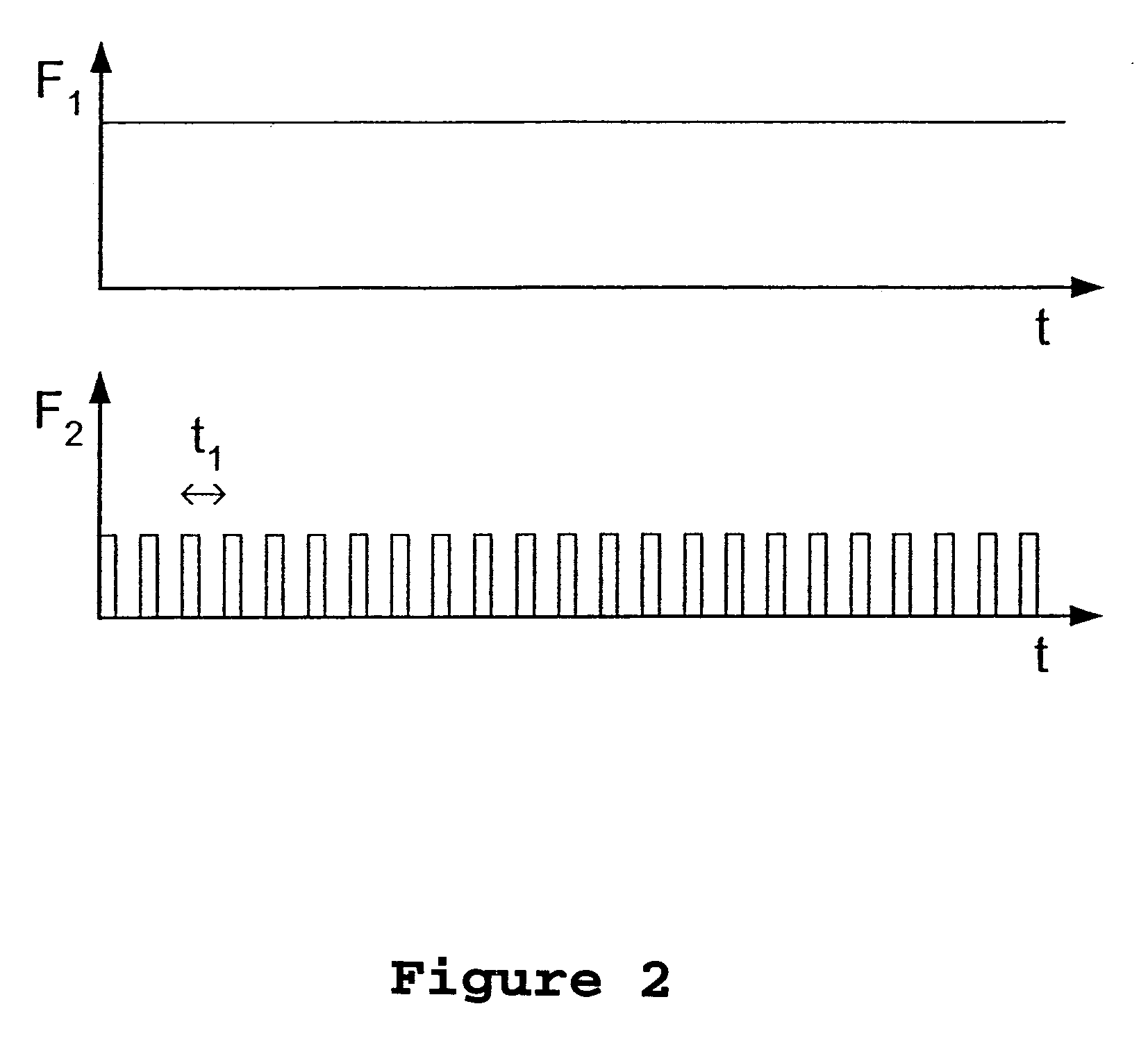

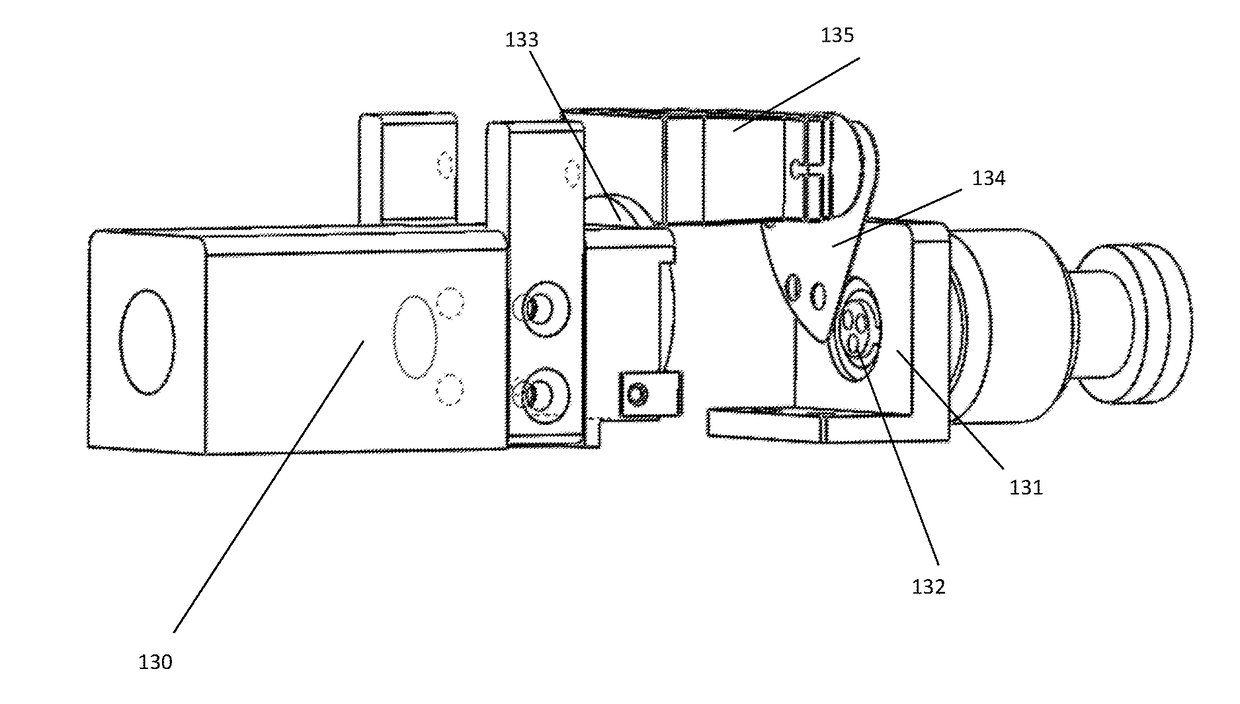

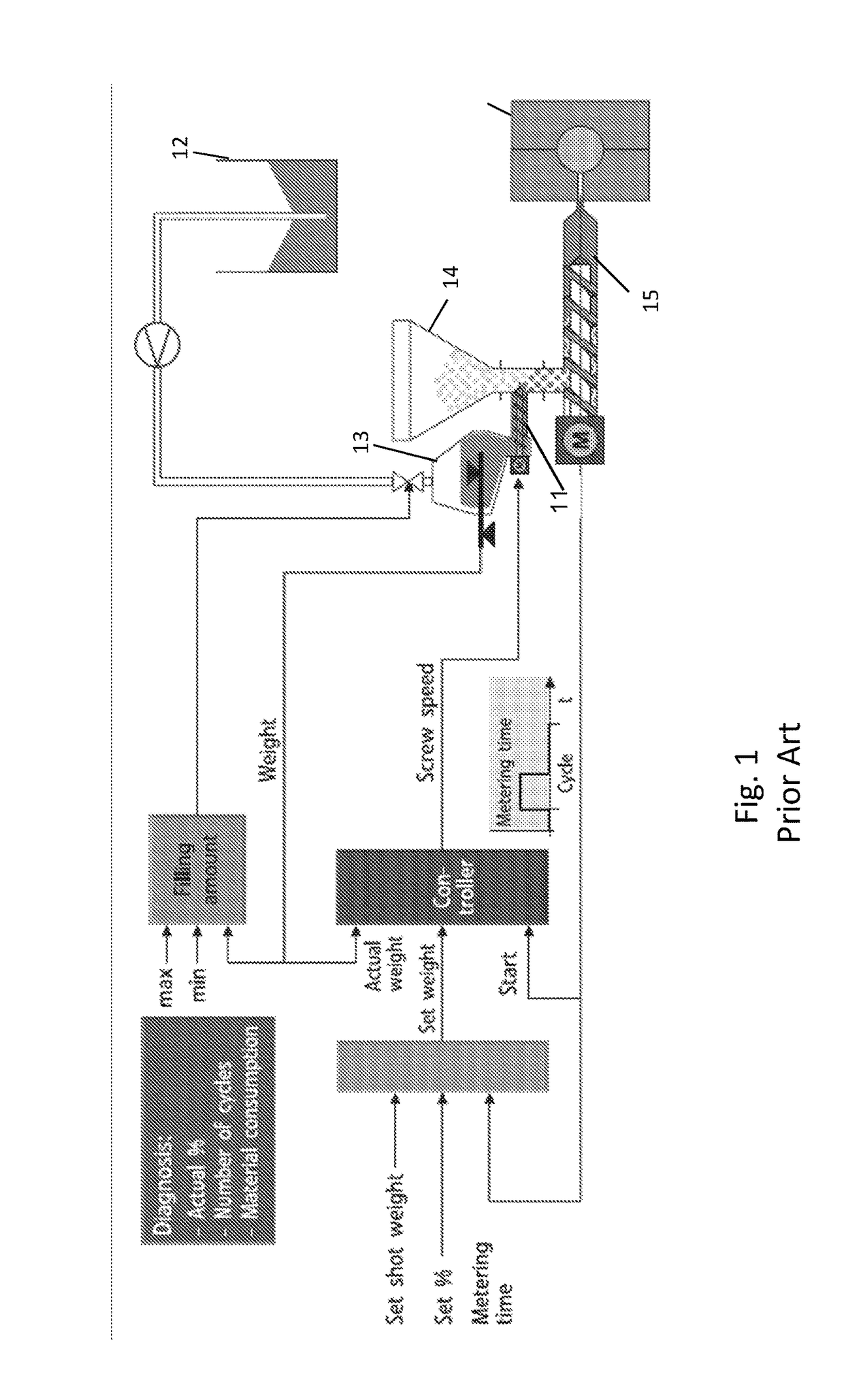

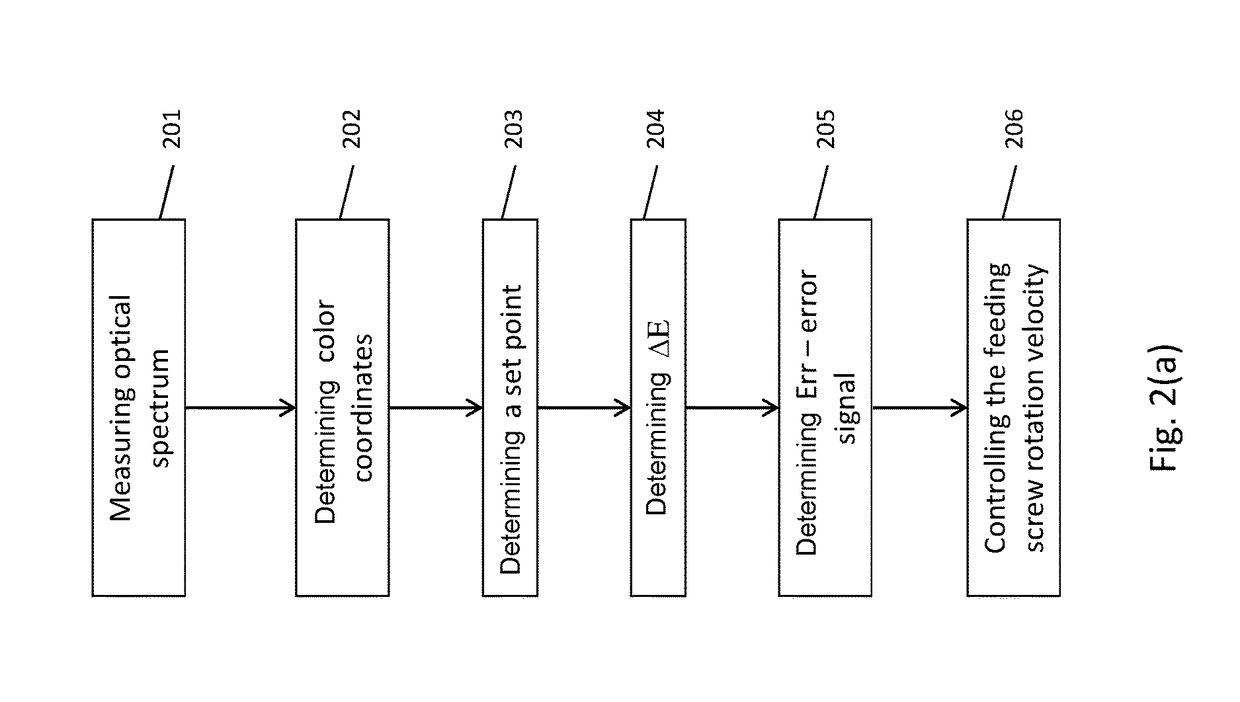

Spectral properties-based system and method for feeding masterbatches into a plastic processing machine

ActiveUS20170165873A1Improve accuracyEliminate requirementsTransportation and packagingMixer accessoriesMechanical engineeringPlastics processor

A method and system for optimizing a match between the color of an in-line part manufactured by a plastic product production machine and the color of a reference part by adjusting the concentration of masterbatch in the mixture of raw material fed to the plastic product production machine. The optimization of the color is based on spectra of the in-line part and reference part obtained within a short time interval using the same spectrometer, thereby eliminating the requirement for high accuracy spectrometer calibration and allowing the method, which determines the rates at which the base masterbatches are added to the raw material, to be carried out in real time on the manufacturing floor while the plastic product production machine is being operated to manufacture in-line parts.

Owner:AMPACET CORP

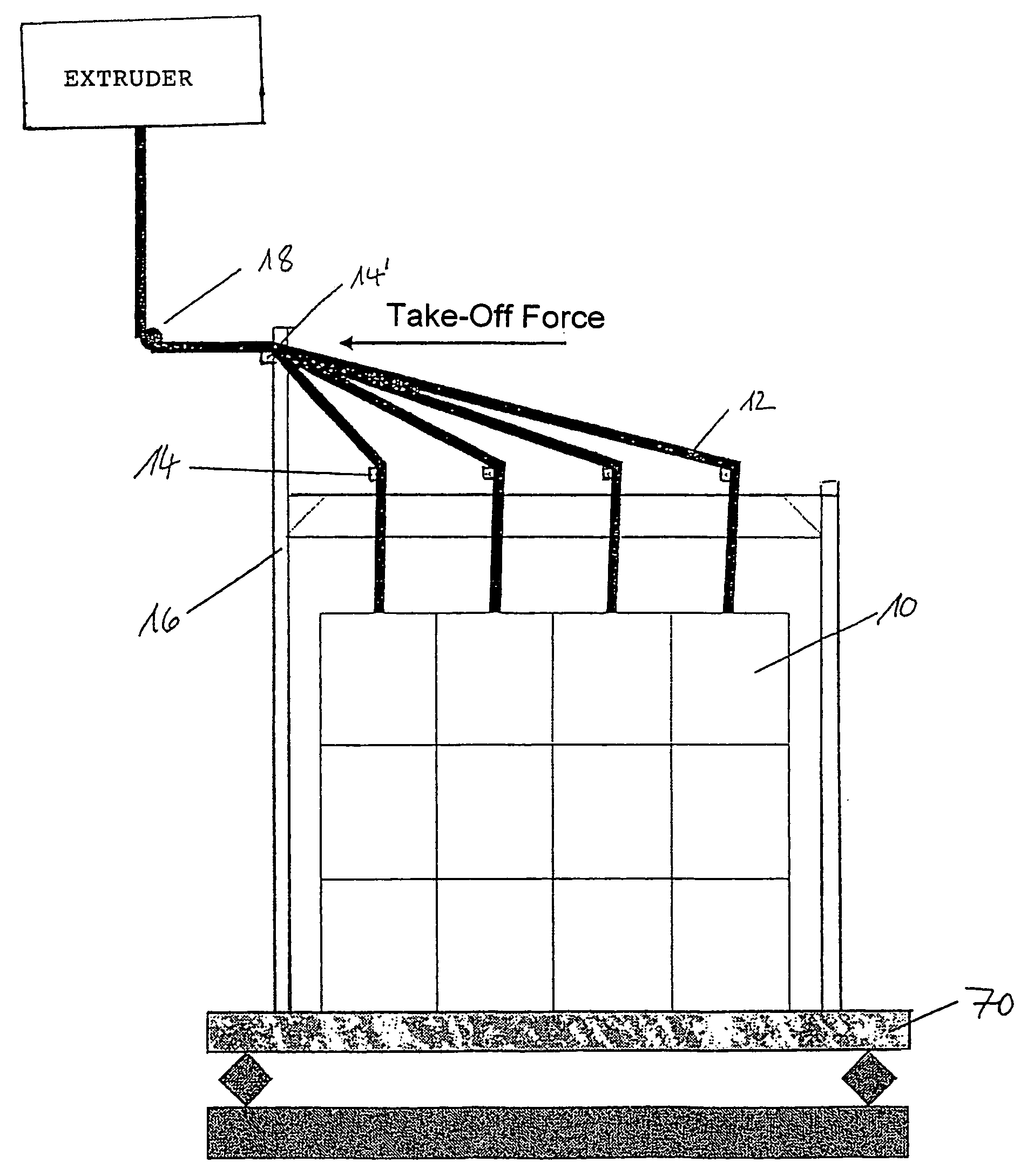

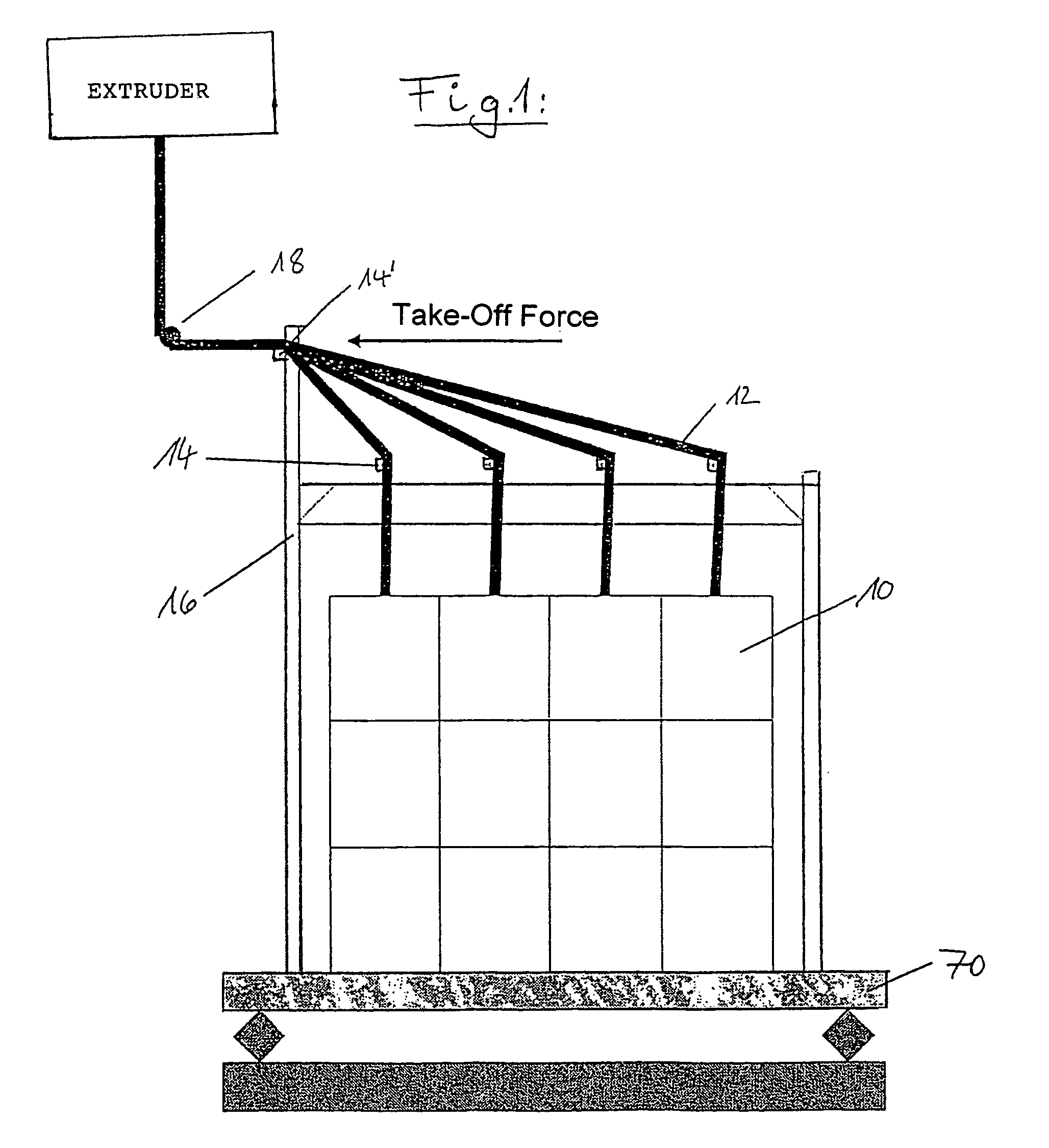

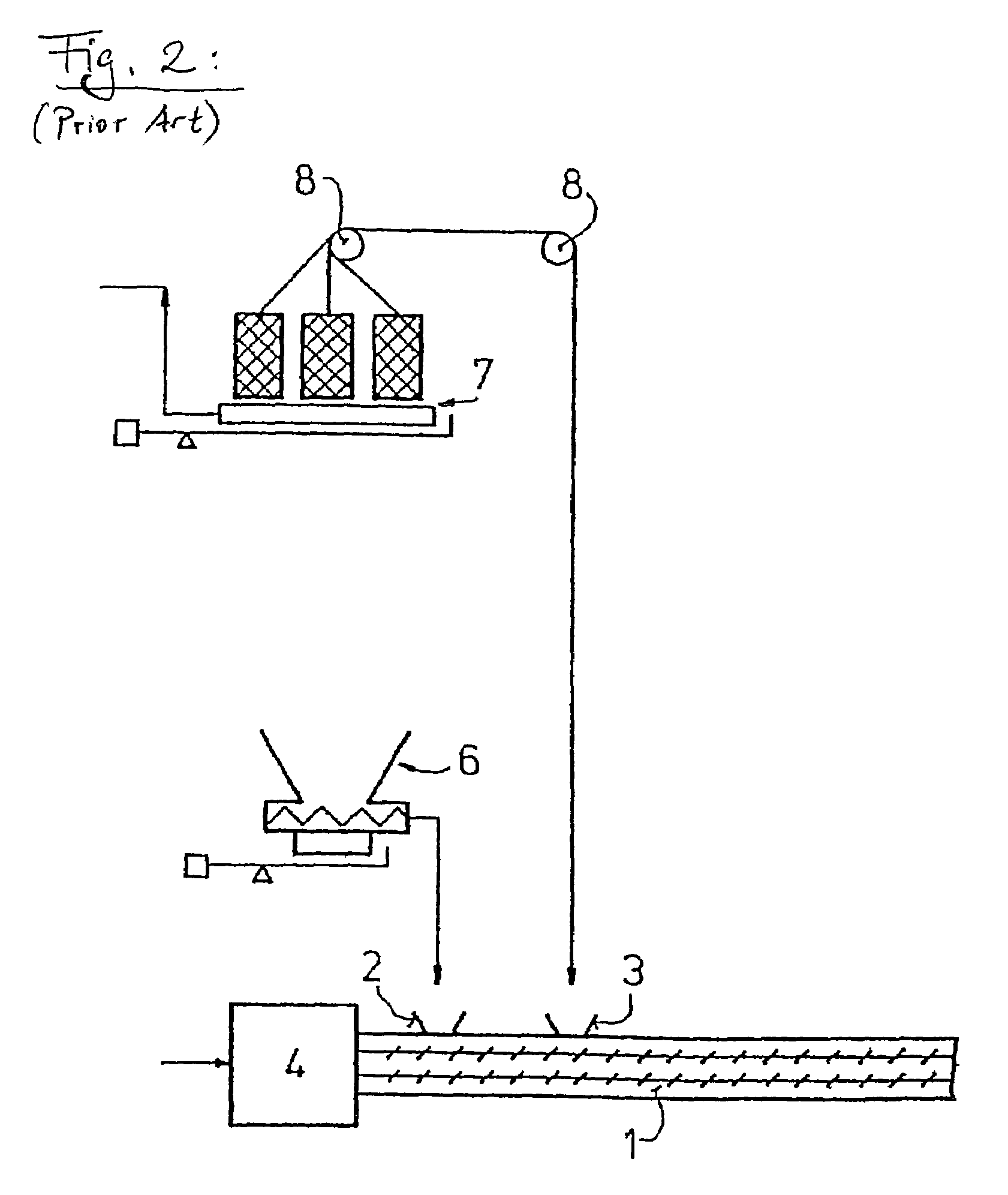

Plastic processing machine for producing fiber-containing thermoplastics

A plastics processing machine for producing fiber-containing thermoplastics includes an extruder, and a scale assembly having a weighing plate for determining an amount of fiber to be supplied to the extruder. A fiber feeding device supplies fibers from a take-off unit into the extruder and includes a first fiber guide unit, which is securely fixed to the weighing plate, for removing the fibers from the take-off unit, and a second fiber guide unit which is decoupled from the weighing plate and so constructed as to route the fibers between the first and second guide units in a substantially perpendicular relationship to a gravitational force.

Owner:KRAUSSMAFFEI TECH GMBH

Conical double screw extruder special for wood plastic composite material

The present invention belongs to a special cone-shaped double-screw extruding machine for a wood-plastic composite material of the plastic processing machine, including a power source, a reduction gear box, a screw-machine barrel accessory, a machine frame and a feeding bucket. The power source is connected with a screw inside the screw-machine barrel accessory through the reduction gear box. The feeding bucket communicates with a machine barrel inside the screw-machine barrel accessory. The screw is installed inside the machine barrel. Cooling and temperature-reducing device are installed at the lower part of a feeding opening of the machine barrel and at a closely adjacent section to make the two sections as cooling sections, the sections after which are provided with heating devices which make the rest sections as the heating sections. Only one vent is arranged at the machine barrel. The screw, which is installed inside the machine barrel, is the cone-shaped screw and is provided with a mixing section, and the same time the length-diameter ratio of the machine barrel and the screw is more than 30. Before the vent, the present invention can convey, compress, heat and plastify the wood-plastic composite material under the quite low temperature; after being completely plastified, the plastic can complete enwrap the heated wooden powder before the vent and mix with the wooden powder uniformly; a double-screw vacuum exhausting and flash-preventing device which continuously rotates downwards can exhaust as well as never flash.

Owner:BAOJI QINCHUAN FUTURE PLASTIC MECHINE

Plastics processing machine

InactiveUS7539547B2Easy to operateLow costProgramme controlComputer controlOperating pointMachine control

A plastics processing machine, particularly an injection molding machine, with an operating unit, a machine controller, and a subsystem having its own dedicated control unit is described. The machine controller and control device each generate a screen display and can be operated via the screen display. The operating unit is connected or can be connected for data transmission to both the machine controller and the control unit. Both of the machine controller and the control unit can be monitored and controlled by reproducing the original screen output from the machine controller and the control unit on the display screen of the operating unit, where new information can be entered. The information entered on the display screen of the operating unit is then transmitted back to the corresponding controller or unit associated with the reproduced screen display where the information was entered.

Owner:SUMITOMO SHI DEMAG PLASTICS MACHINERY

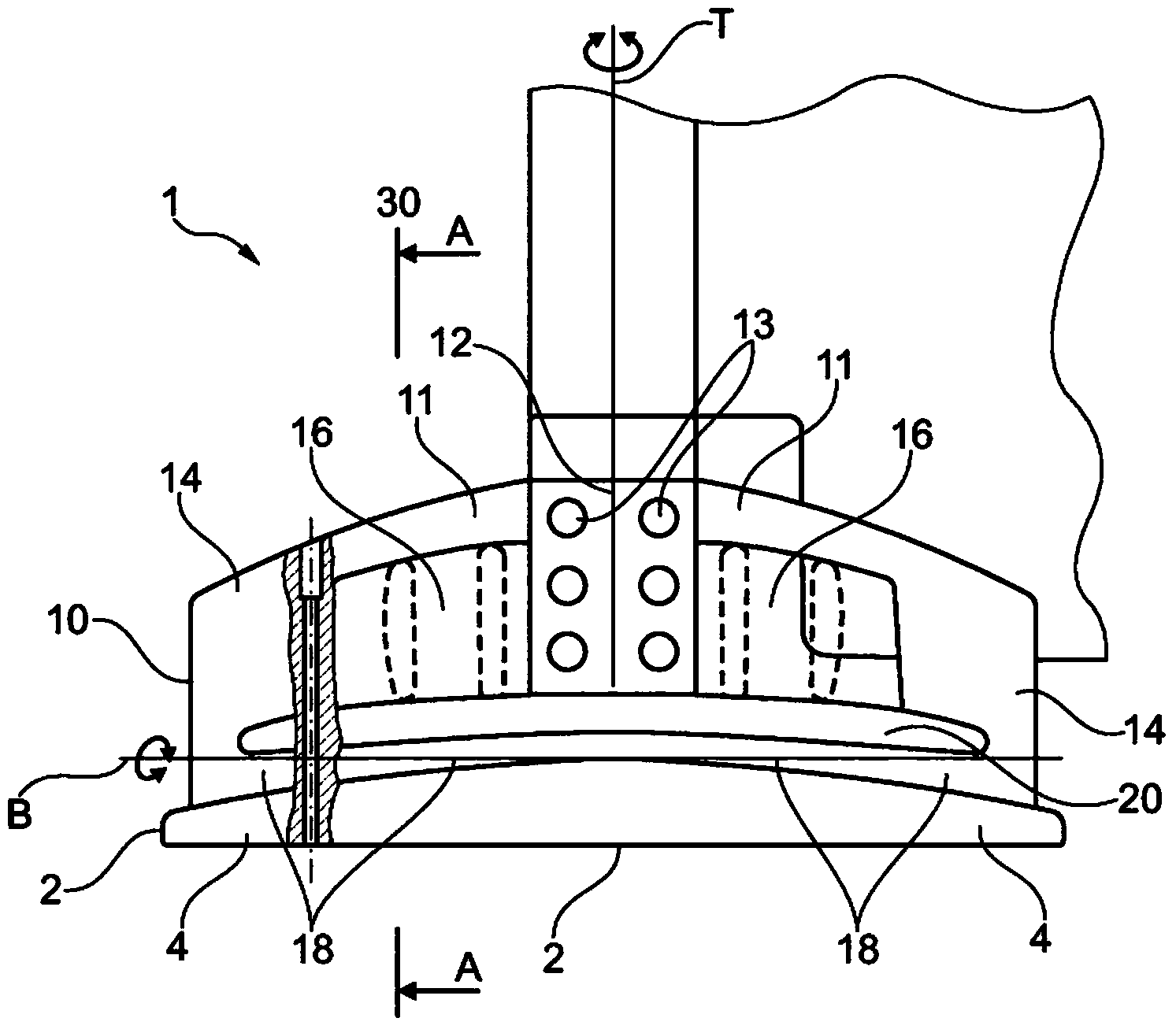

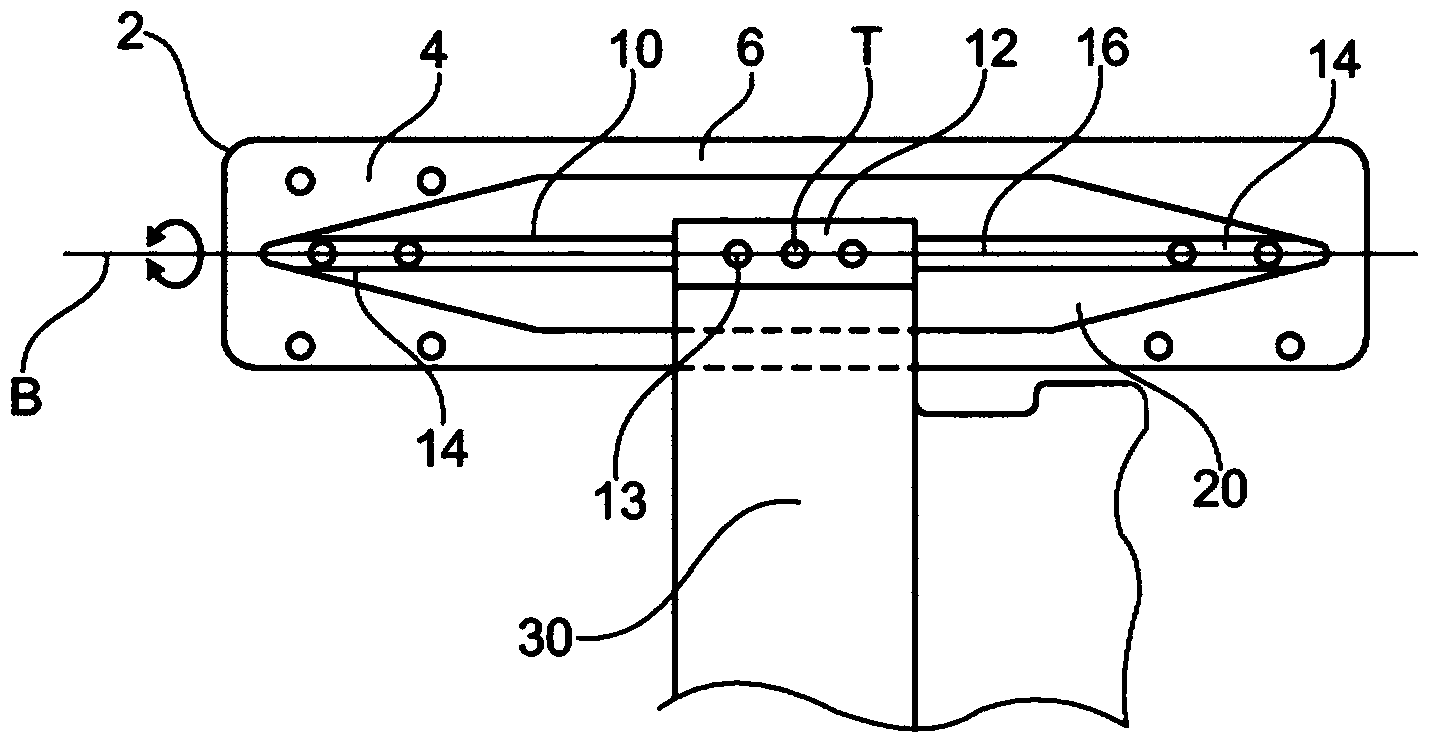

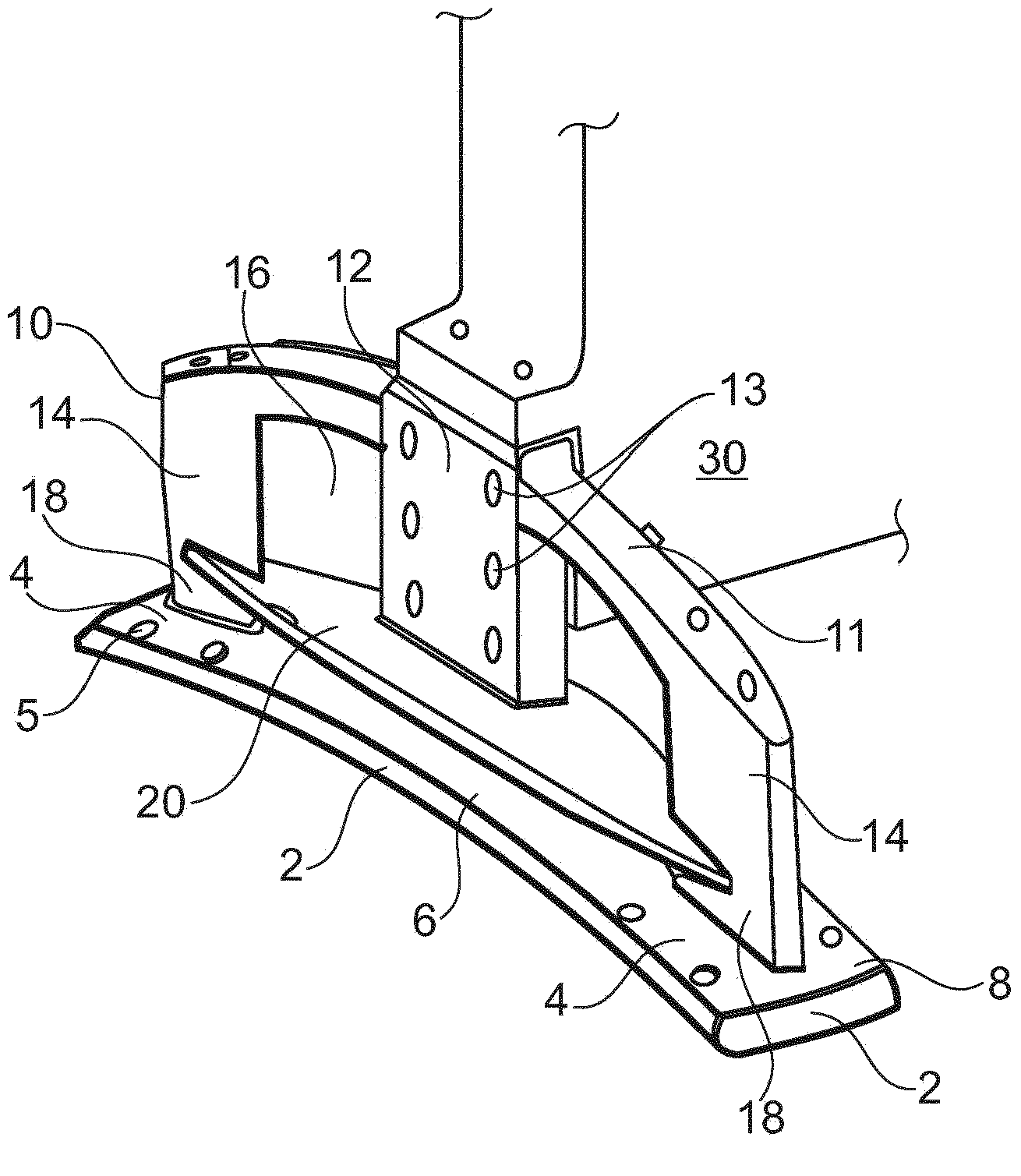

Guide shoe for a guiding device of a plastic processing machine clamping unit

The invention relates to a guide shoe (1) of a guiding device of a plastic processing machine clamping unit for supporting and guiding a moving mold platen (30) in the clamping direction of the plastic processing machine. The guide shoe (1) has a main part (2) which is elongated in the clamping direction and on which sliding and / or rolling elements can be fixed, and the guide shoe has a connecting element (10) which is spaced from the main part (2), which runs in a substantially vertical manner in the clamping direction (x direction), and which has a fixing region (12) for fixing the guide shoe (1) to a moving mold platen (30), wherein - the moving mold platen (30) can be fixed solely to the fixing region (12) of the connecting element (10) in a decoupled manner from the main part (2), - the connecting element (10) is designed as a deformation element (10), and - the deformation element (10) is fixed to the main part (2) via a connecting region (18) that forms a target bending zone with respect to a bend about a bending axis (B), which is substantially parallel to the clamping direction, such that the deformation element (10) additionally forms a target torsion zone about a torsion axis (T), which is substantially perpendicular to the clamping direction. (Figure 3)

Owner:KRAUSSMAFFEI TECH GMBH

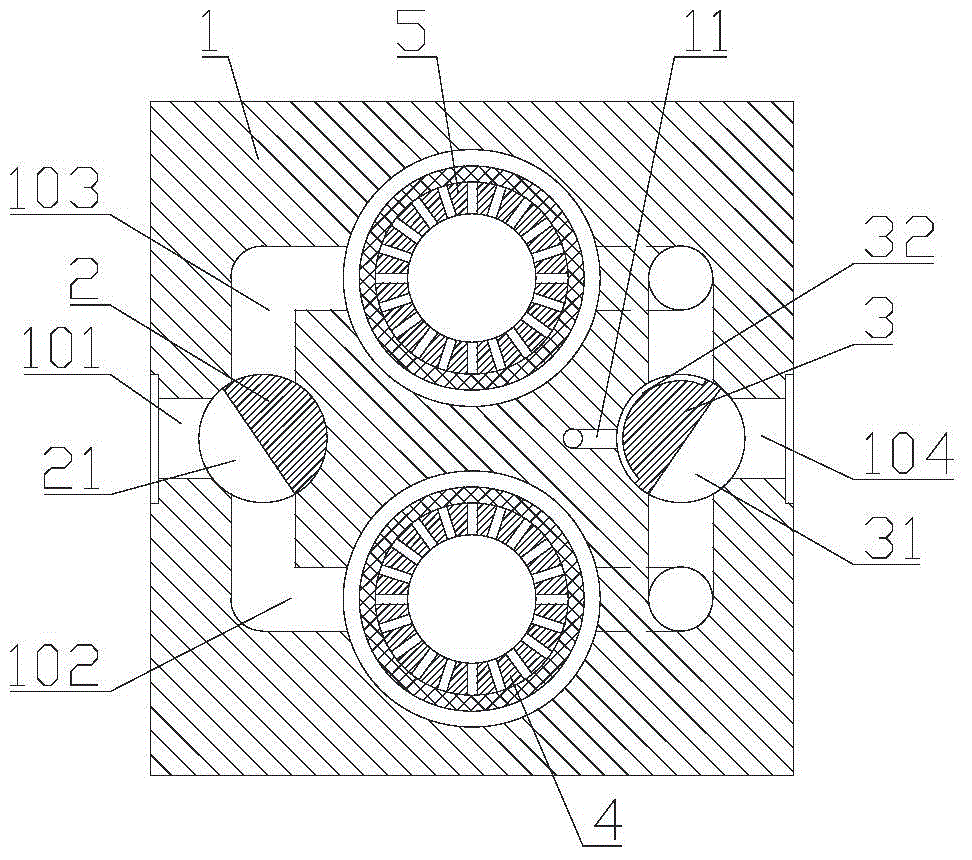

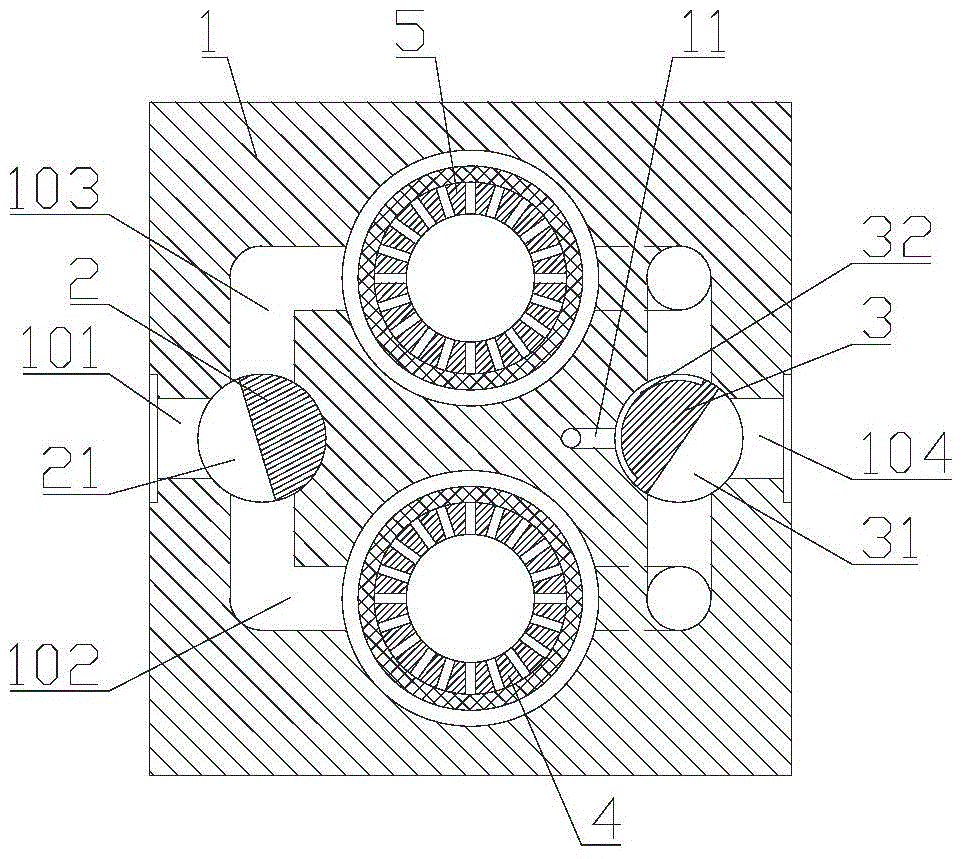

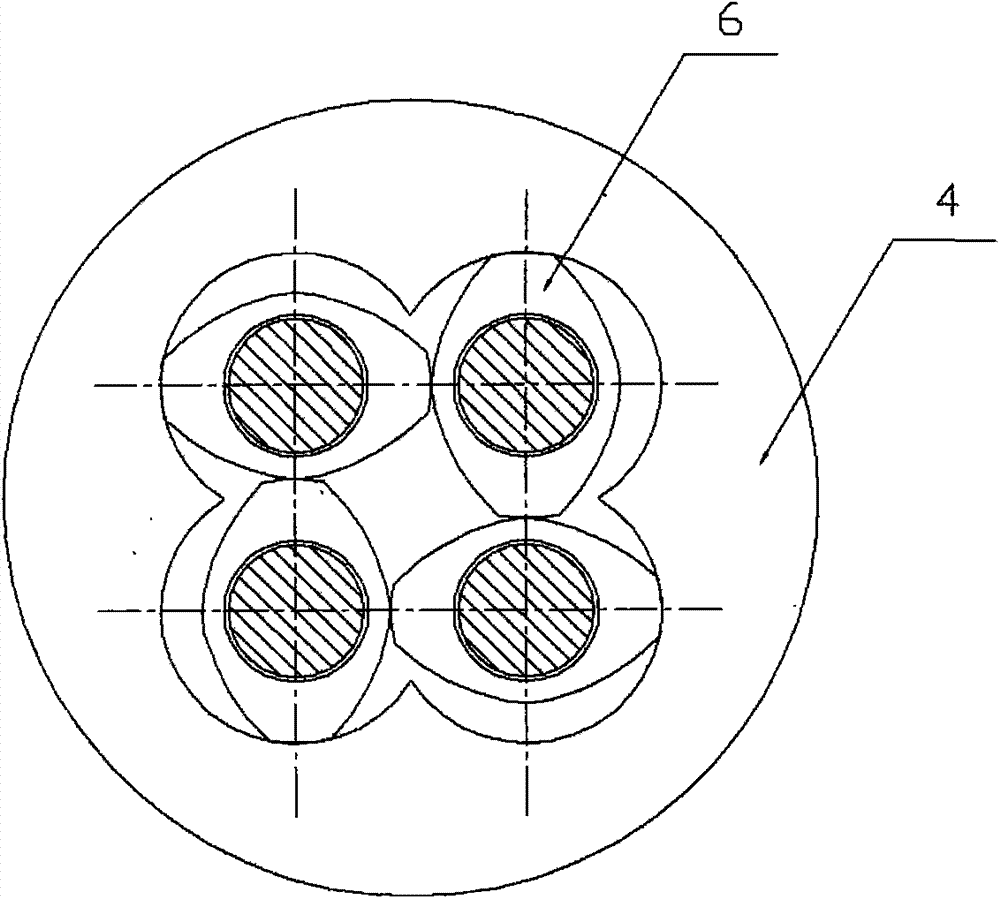

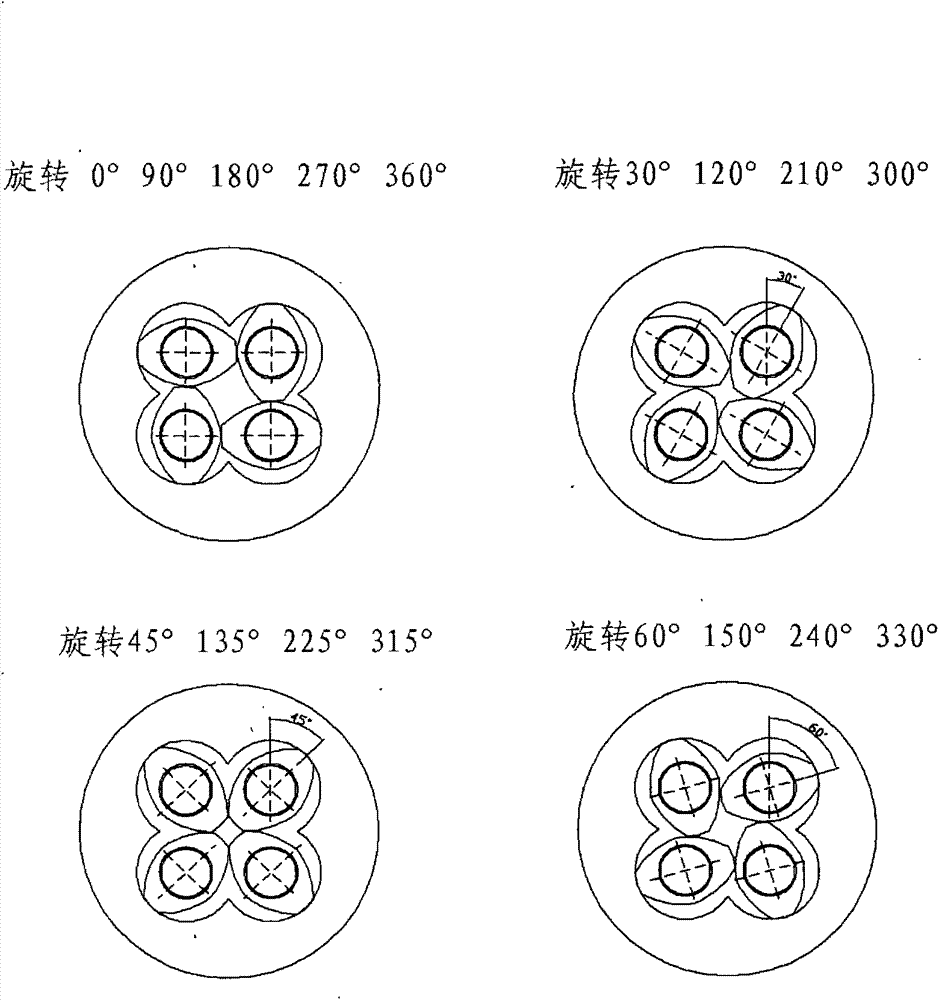

Four-screw mixing extruder

The invention relates to a novel plastic processing machine, in particular relates to a four-screw mixing extruder which is characterized in that a mixing device and an extruding device as well as a mixing working procedure and an extruding working procedure which are needed in the plastic processing process are respectively integrated. The four-screw mixing extruder consists of four screws, wherein the axes of the four screws are parallel to one another, the center distances of the four screws are equal, and a square shape is formed by connecting lines of four central points of the four screws in a vertical cross section. The four screws are respectively in a block combination type; all screw elements are meshed with one another, and a closed central area which is a mixing area can be formed. The four screws can rotate along the same direction, the area of the central area is changed for four times when the four screws turn a circle, and a period is defined by 90 degrees. The material is kneaded and extruded powerfully for tens of thousands of times every minute in the central area and is fully plastified, and all the components are evenly dispersed. The productivity of the four-screw mixing extruder is twice that of a common twin-screw extruder, and the energy consumption of the four-screw mixing extruder is reduced by 50%.

Owner:许汉辰 +2

Highly effective plastic-steel belt processing device

The invention discloses a high efficient manufacturing device of plastic-steel band in the plastic manufacturing machine domain, which comprises the following parts: spiral extrusion device, drawing device and driving device in connection with the spiral extrusion device, wherein the stabilized cylinder and separatory die are connected between spiral extrusion device and drawing device sequently; the feed inlet of stabilized cylinder connects the feed inlet of separatory die within 4-8 feed inlets; the pressure sensor is set in the stabilized cylinder to control the rotary speed of actuating device. The invention can produce several PET bands simultaneously, which improves the productive efficiency and reduces the manufacturing cost.

Owner:谢志江

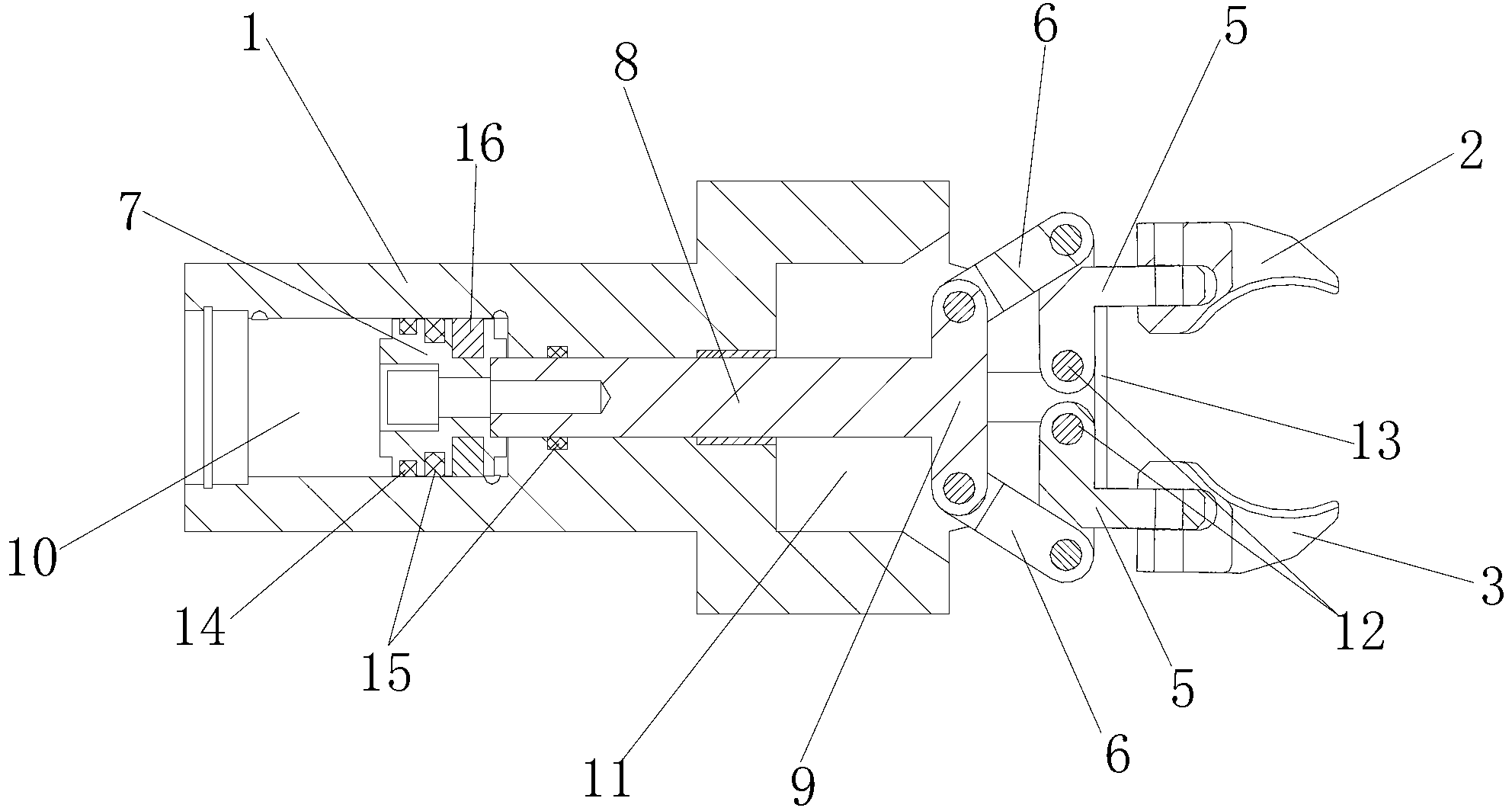

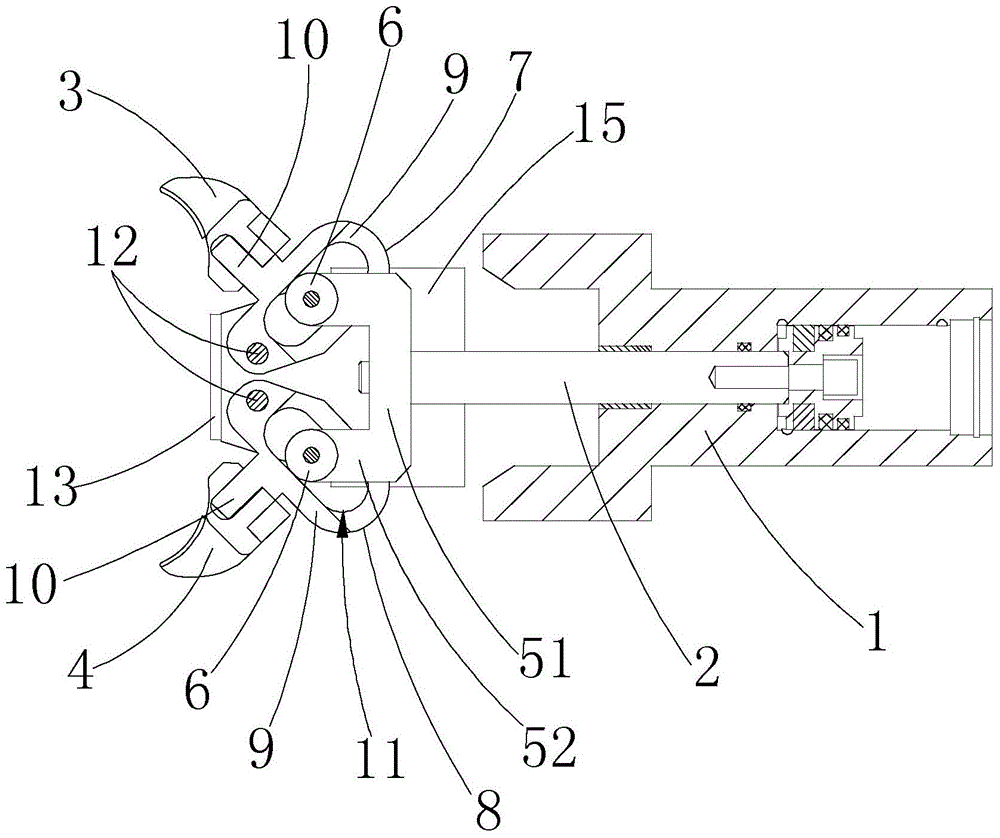

Pneumatic pawl manipulator

The invention discloses a pneumatic pawl manipulator and belongs to the field of plastic processing machinery technology. The manipulator comprises a cylinder body, a piston, a cylinder rod and a pair of clamp arms connected to the cylinder rod and capable of gathering together and opening relatively. The manipulator is characterized in that one end of the cylinder rod connected to the clamp arms is provided with a U-shape rack; a transverse arm of the U-shape rack is connected to the cylinder rod; end portions of two vertical arms of the U-shape rack are respectively provided with a bearing; the pair of clamp arms are respectively slidably connected to the two vertical arms of the U-shape rack through a support with a bearing groove; the bearing runs in the bearing groove; and the support is connected to the cylinder body through a support pin. The invention has the advantages of simple structure, compactness, small volume and low energy consumption, etc.

Owner:台州迈格机械模具有限公司

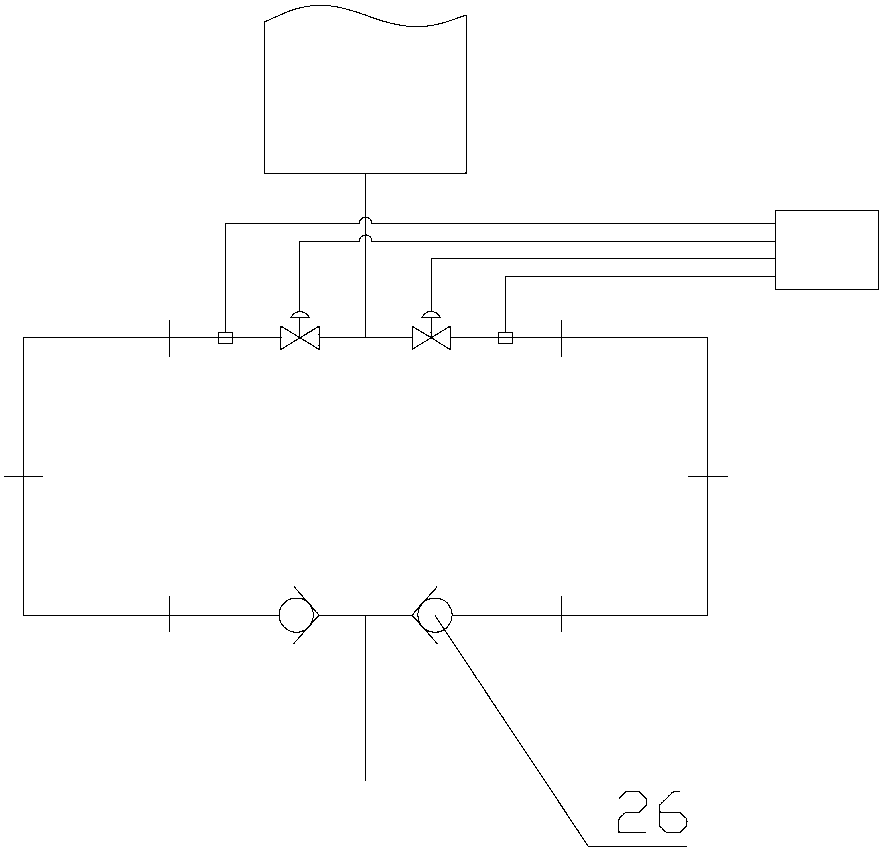

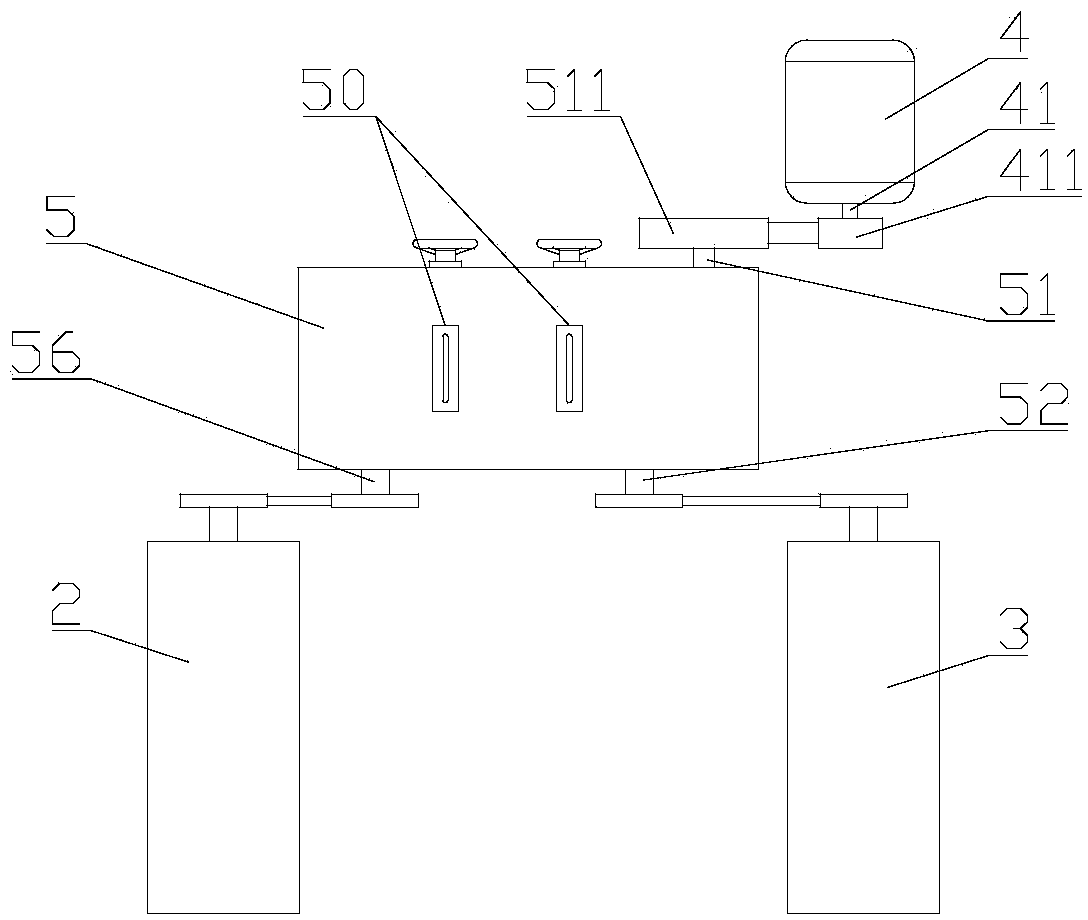

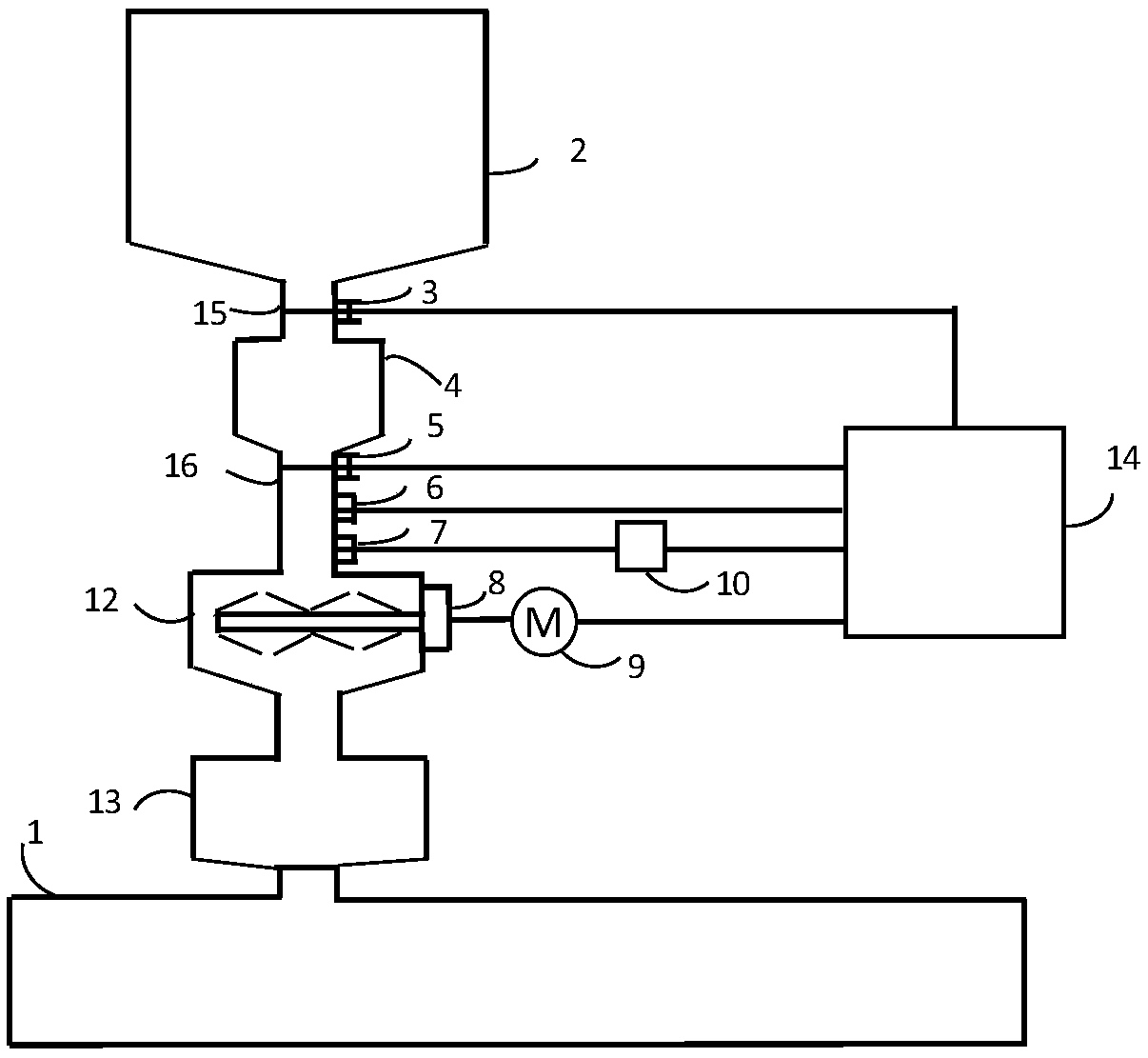

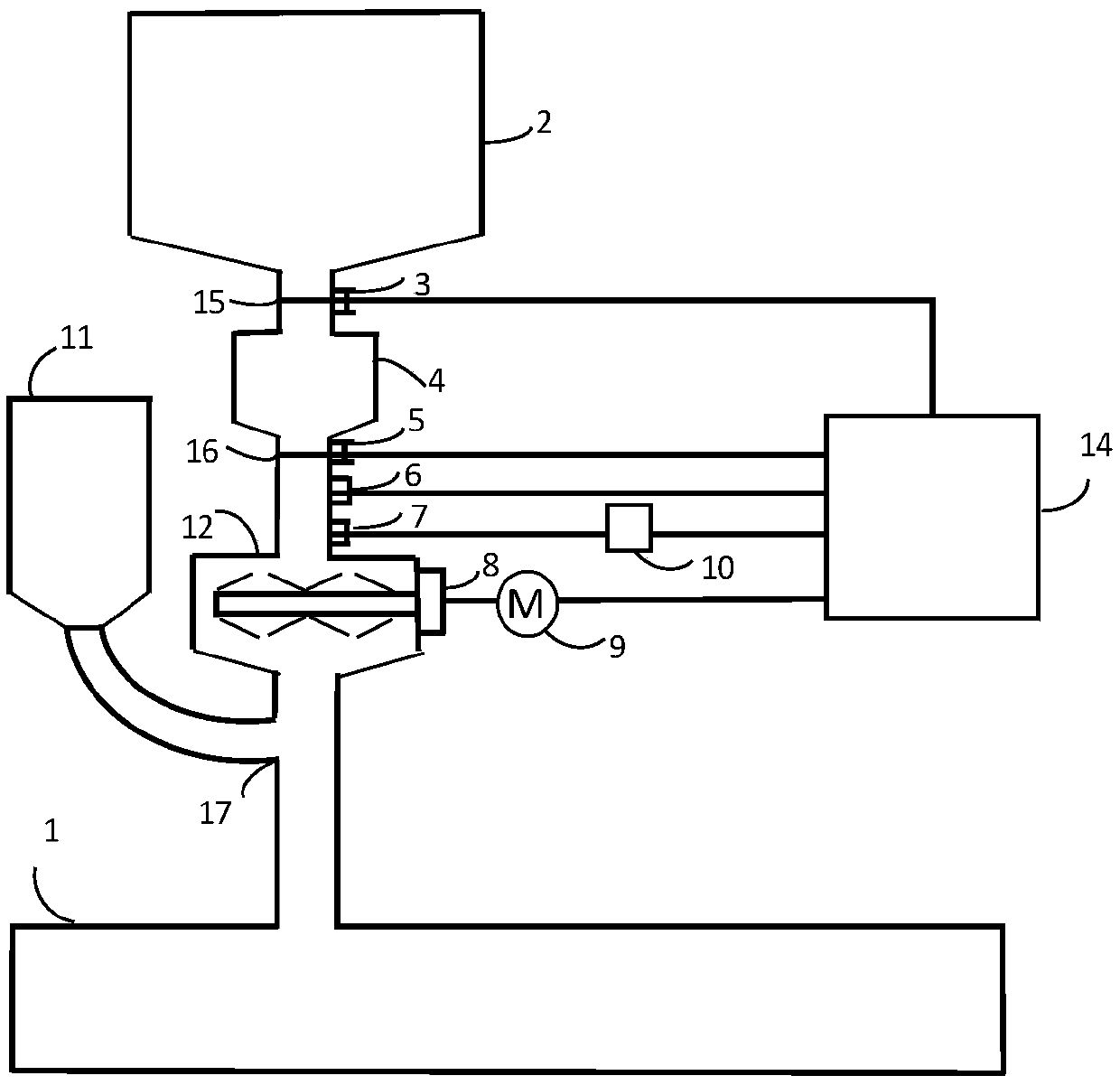

Automatic feeding device for plastic processing machinery

The invention provides an automatic feeding device for plastic processing machinery. The automatic feeding device comprises a plastic raw material cylinder, a constant-volume material cylinder, a mixer, a liquid color master machine and a control system; the bottom of the raw material cylinder is connected with the constant-volume material cylinder through a pipeline; the bottom of the constant-volume material cylinder is connected with the mixer through a pipeline; a liquid color master feeding opening is formed at the upper portion of the mixer; liquid color master is automatically added bythe liquid color master machine; the constant-volume material cylinder is provided with a material level sensor; the lower end of the mixer is connected with the plastic processing machinery through apipeline; and the automatic feeding device is controlled by an automatic program, thereby realizing timed and quantitative addition of the liquid color master and plastic particles, guaranteeing thequality of a product and guaranteeing that different batches of products are consistent in color shade. Meanwhile, the automatic feeding device realizes recycling of the two materials, also realizes that the plastic material is used just after being colored and stirred, reduces waste of the raw materials and lowers the production cost.

Owner:福建约克新材料科技有限公司

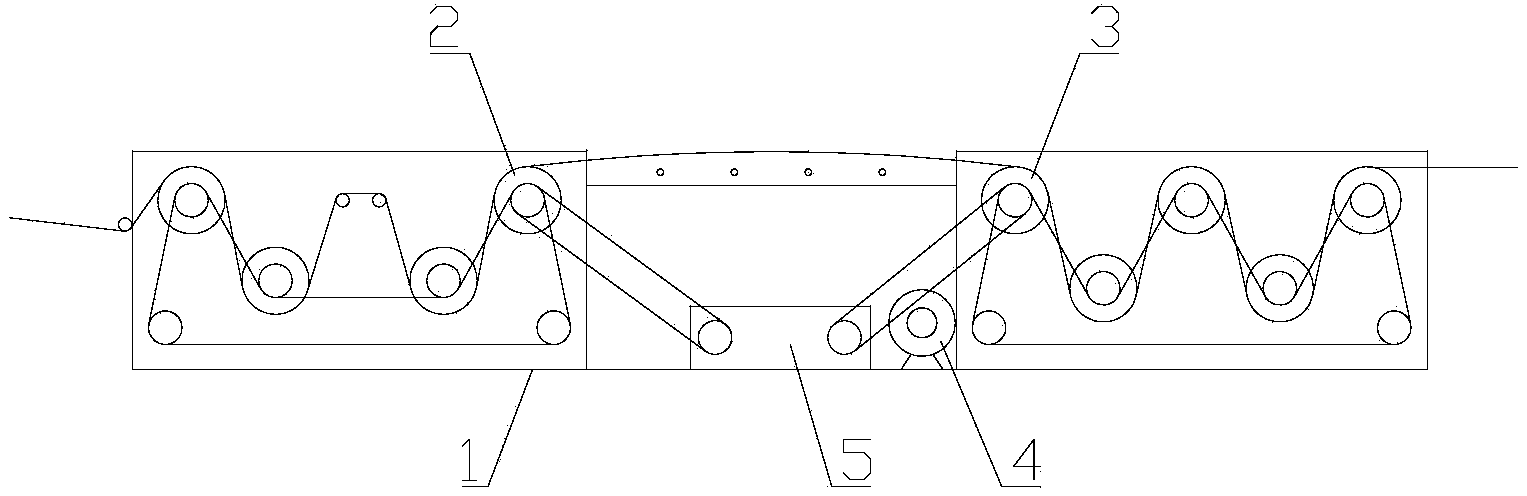

Self-shaping device of film blowing machine set of thermal shrinkage films

The invention discloses a self-shaping device of a film blowing machine set of thermal shrinkage films and relates to a plastic processing machine. The self-shaping device comprises a rack and shaping rollers which are mounted on the rack and arranged in parallel; at least five shaping rollers are arranged; the second shaping roller counting from left to right is a driven roller; other shaping rollers are driving rollers; gears are arranged on the driving rollers and meshed with a motor, so that the driving rollers are driven by the motor; spiral grooves are formed in roller bodies of the shaping rollers; water inlet holes and water outlet holes are formed in the sealed ends; the inner parts of the water inlet holes and the water outlet holes are communicated with a spiral runner which is formed by the spiral grooves; the outer parts of the water inlet holes and the water outlet holes are connected with rotary joints and flexible pipes. The blown thermal shrinkage films subjected to on-line shaping are low in natural shrinkage and high in shrinkage starting temperature; in particular, the blown thermal shrinkage films have the balanced shrinkage performance and do not need to be shaped by a drying chamber again, so that the blown thermal shrinkage films can be cut and subsequently can be subjected to printing and the like or directly used.

Owner:JIANGSU GUANGHUI PACKAGE +2

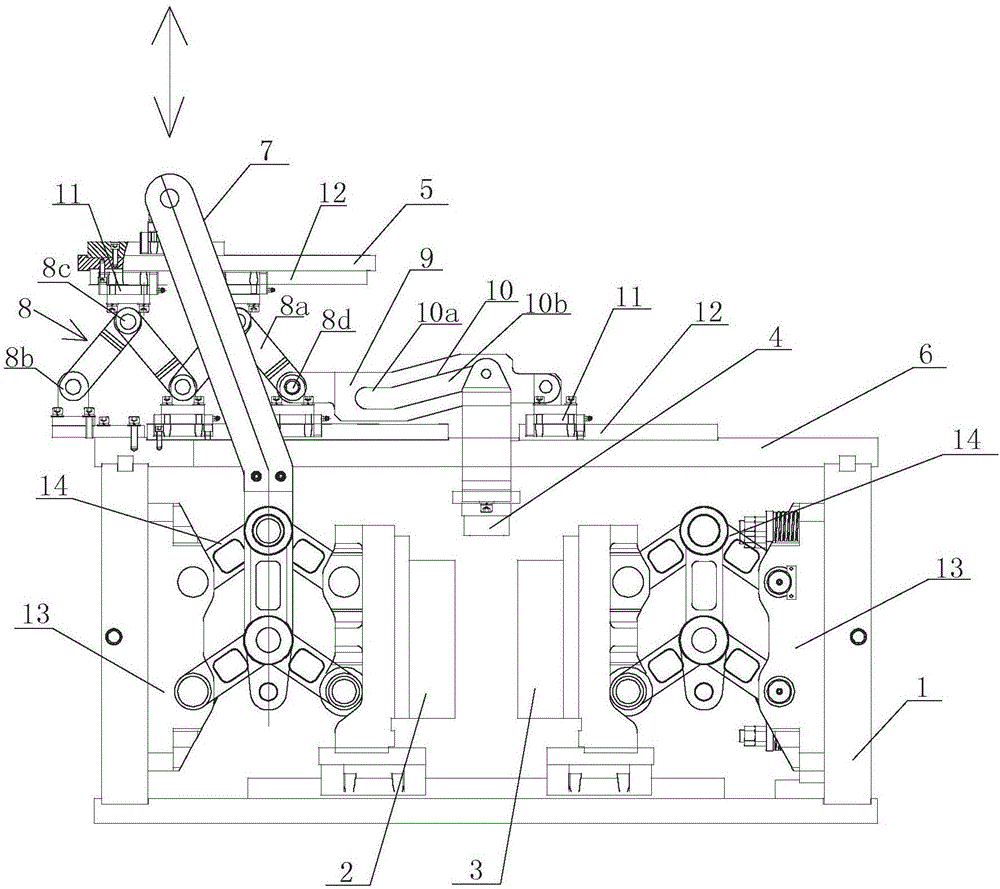

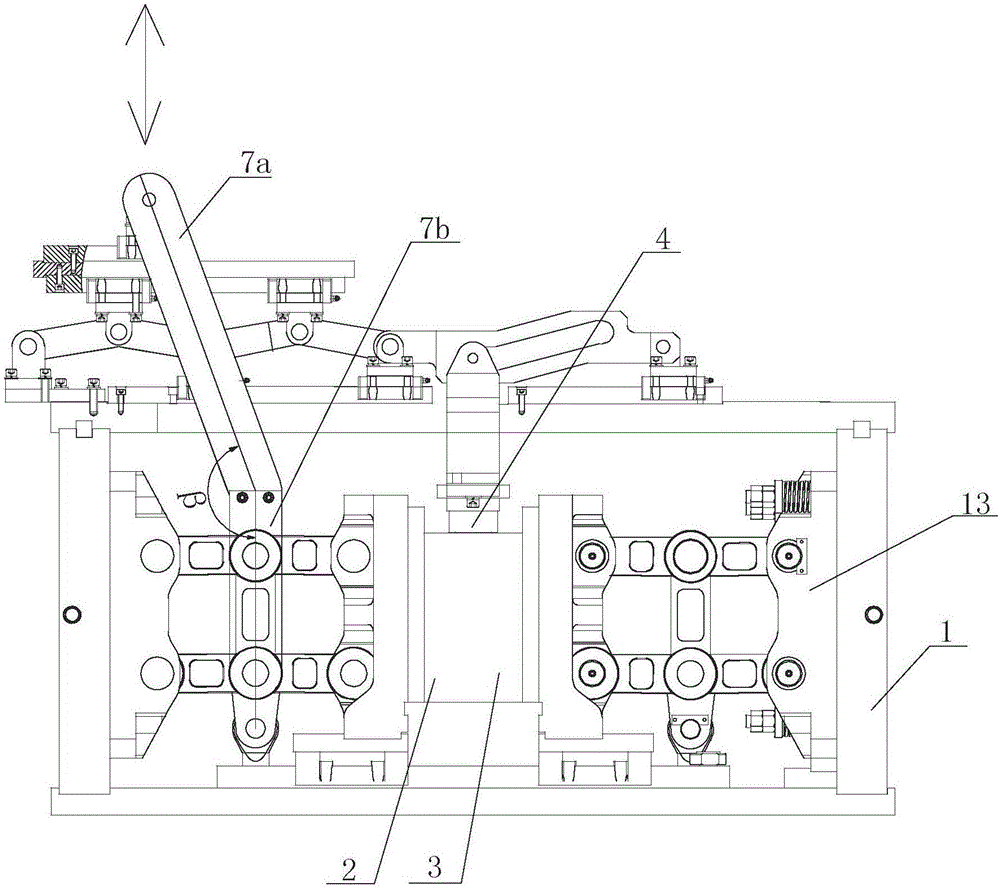

Mold opening and closing device of bottle blowing machine

The invention discloses a mold opening and closing device of a bottle blowing machine and belongs to the technical field of plastic processing machinery. According to the mold opening and closing device, by arranging a supporting rod transmitting power, a link mechanism and a variable-distance guide groove, the power from a power source is resolved into the force in the perpendicular direction and the force in the horizontal direction, and therefore the power is synchronously supplied to a front mold plate, a back mold plate and a bottom mold plate; and in this way, synchronous drive of all the mold plates is achieved, and the time of the processes of opening and closing the mold is shortened. Meanwhile, the power is saved, and the production efficiency is improved.

Owner:台州迈格机械模具有限公司

Plastic Biaxial Tensile Grid Mesh Clamp

The invention relates to the technical field of plastic processing machinery, in particular to a plastic biaxially stretched grid net clamp. Including clamp body, high temperature pressure spring, spring sleeve, cylindrical pin, upper clamp and lower clamp, each of the upper part of the clamp body and the middle part of the upper clamp is equipped with a cylindrical pin, and a spring sleeve is installed between the cylindrical pins, high temperature resistant pressure type The spring is installed in the spring casing, and the jaw surfaces of the upper and lower jaws are stamped into fish scale inverted teeth. Compared with the prior art, the present invention can keep the fixture with a long-lasting and large clamping force. During the stretching process, the fixture does not change shape, the spring does not fall off, the plastic sheet does not come off the clamp, and does not swim. According to products of different thicknesses, It is very convenient to replace the spring.

Owner:JIANGSU SAIDE MACHINERY

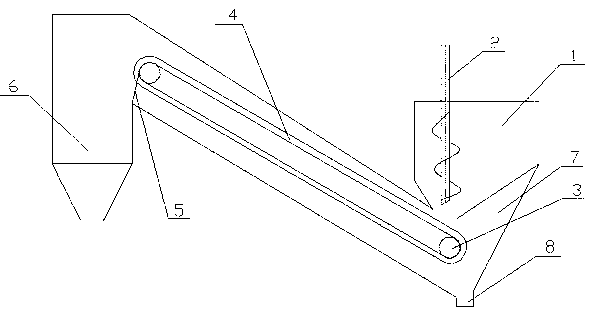

Multifunctional feeding device for extruder

The invention relates to a feeding device and especially relates to a multifunctional feeding device for an extruder and belongs to the technical field of plastic processing machinery auxiliary equipment. The multifunctional feeding device comprises a material storage bin, a material conveyer belt and a hopper. A screw rod is arranged in the material storage bin. The screw rod is located right above an outlet of the material storage bin. The material conveyer belt is supported by two belt wheels. One end of the material conveyer belt is located under the outlet of the material storage bin and the other end of the material conveyer belt is located obliquely above the hopper. The periphery of the material conveyer belt is provided with a spilled material belt for receiving spilled materials in conveying. The outlet is arranged below the spilled material belt. The multifunctional feeding device has a simple structure. Compacted materials in the material storage bin are loosed by the screw rod, then fall on the material conveyer belt, then are conveyed to the hopper by material conveyer belt circulating rotation, and then enter into the hopper under the action of a scraper blade. The multifunctional feeding device can be used for powder and for feeding granules and short threads, and has complete functions.

Owner:SHENYANG CHUANGDA TECH TRADE MARKET

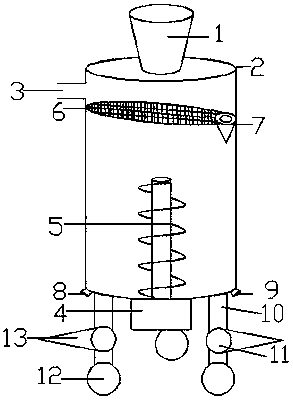

Plastic mixing mechanism for plastic processing machine

The invention discloses a plastic mixing mechanism for a plastic processing machine. The plastic mixing mechanism comprises a feeding hopper, a box, a water inlet, an axial motor, a spiral blade, an adjustable screen mesh, a cone crusher, a discharging hopper, a water outlet, supporting frames, bearings, rollers and a conical support. When raw material components in the feeding hopper enter the box, the small-particle components fall onto the bottom of the box, and the large-particle components fall onto the adjustable screen mesh. Due to the fact that the adjustable screen mesh has a certaininclination angle, the large-particle components can roll down along the inclined face of the adjustable screen mesh into the cone crusher connected with the tail end of the adjustable screen mesh, and the large-particle components can be ground into small-particle components through the cone crusher. The ground components flow out of the bottom of the cone crusher, and the ground components and other component raw materials are mixed and stirred together by being mixed by the spiral blade. The plastic mixing mechanism is reasonable in design, easy to operate and high in practicality.

Owner:刘辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com