Pneumatic gripper mechanical arm

A manipulator and air gripper technology, which is applied in the field of plastic processing machinery, can solve the problems of small number of manipulators, increase the size of the machine and occupy space, and achieve the effects of compact structure, convenient maintenance and replacement, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

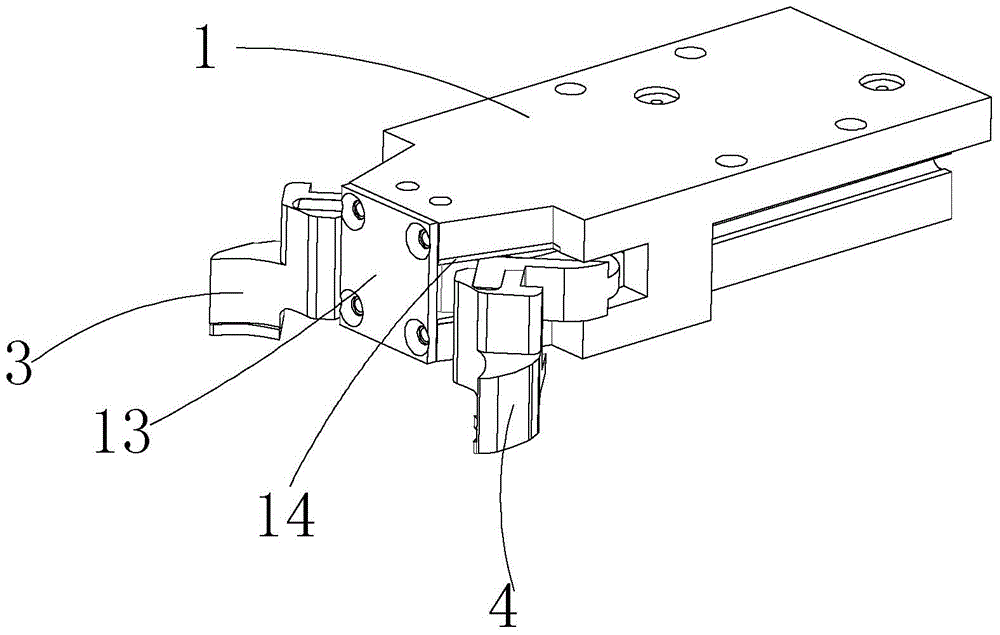

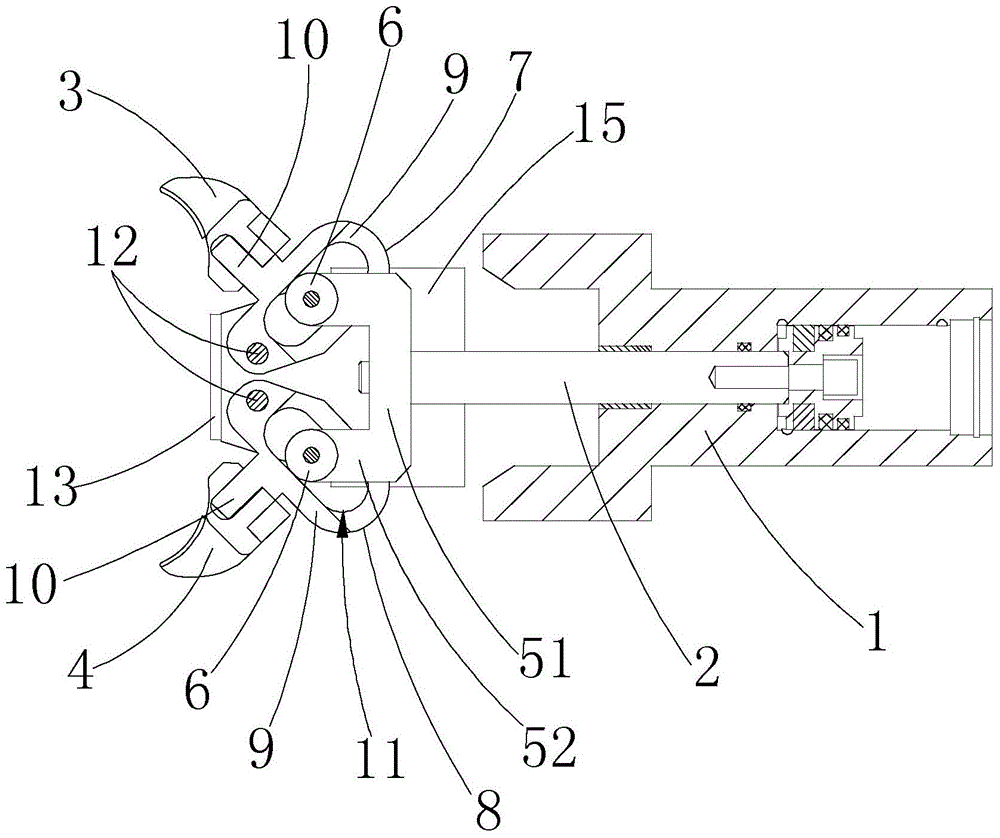

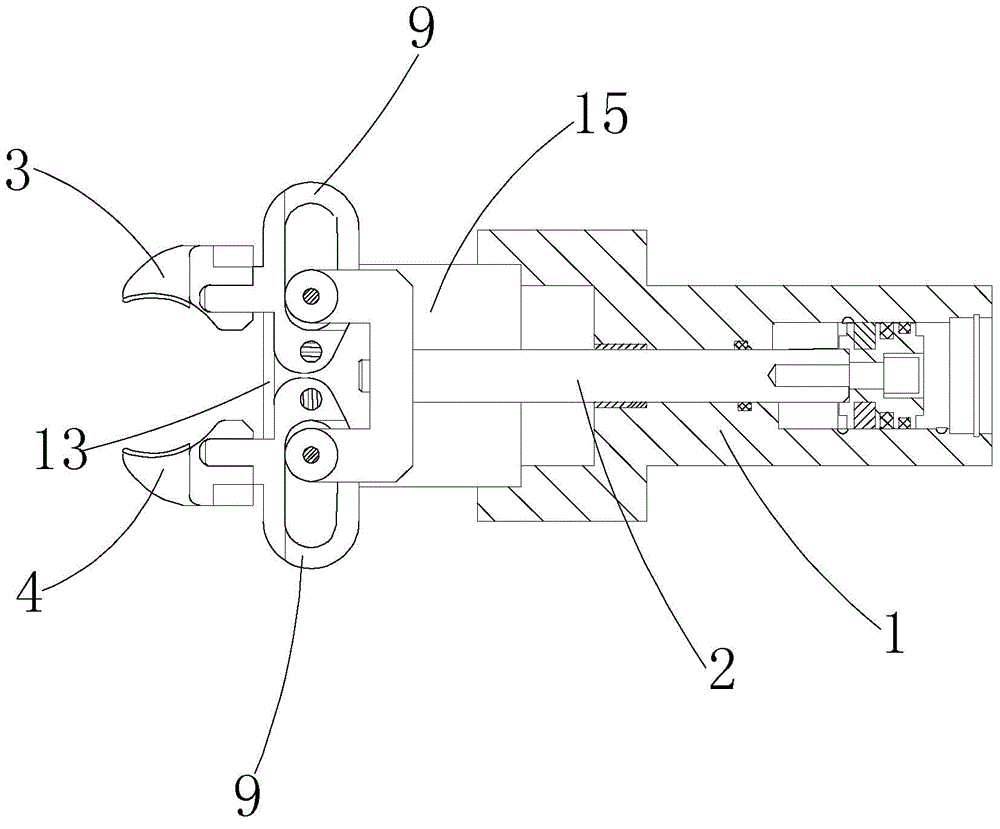

[0024] like Figure 1-5 As shown, the air claw manipulator includes a cylinder body 1, a piston, a cylinder rod 2, and a pair of clamping arms connected to the cylinder rod 2 that can be relatively gathered and opened, which are called the left clamping arm 3 and the right clamping arm 4 herein. One end of the cylinder rod 2 is connected with the piston, and the other end is connected with the clamp arm. One end of the cylinder rod 2 connected with the clamp arm is provided with a U-shaped frame 5. The U-shaped frame 5 has a transverse arm 51 in a horizontal direction and two vertical arms. The vertical arm 52 and the cross arm 51 are connected to the cylinder rod 2, and the ends of the two vertical arms 52 are respectively provided with a bearing 6, and the left and right clamping arms 3 and 4 respectively pass through a bracket, which are referred to as the left bracket 7 and the right bracket here. 8. Slidably connected to the two vertical arms 52. Both the left and right b...

Embodiment 2

[0027] The difference between this embodiment and embodiment 1 is:

[0028] like Figure 6-9 As shown, the left bracket 7 and the right bracket 8 are rotatably connected to the cylinder block 1 through a common support pin 12. The second connecting part 10 is provided with a bearing groove 11 on the first connecting part 9, and the acute angle β between the long axis direction of the first connecting part 9 and the long axis direction of the second connecting part 10 is 50-80°. In this embodiment The middle is about 65°. The left support 7 and the right support 8 are rotatably connected to the cylinder block 1 through a common support pin 12, which makes the structure of the manipulator more compact, and at the same time, reduces the machining accuracy of the manipulator, making the process more convenient and accurate.

[0029] The air claw manipulator of the invention has the advantages of compact structure, small volume, low energy consumption, good effect and wide applic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com