Engine fuel injection control device

A technology of fuel injection and control device, which is applied in the directions of fuel injection control, engine control, machine/engine, etc., can solve problems such as feedback control can not keep up, the air-fuel ratio is too rich, and the too rich becomes larger, etc., to improve the startability, The effect of preventing engine speed fluctuations and expanding the feedback control area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

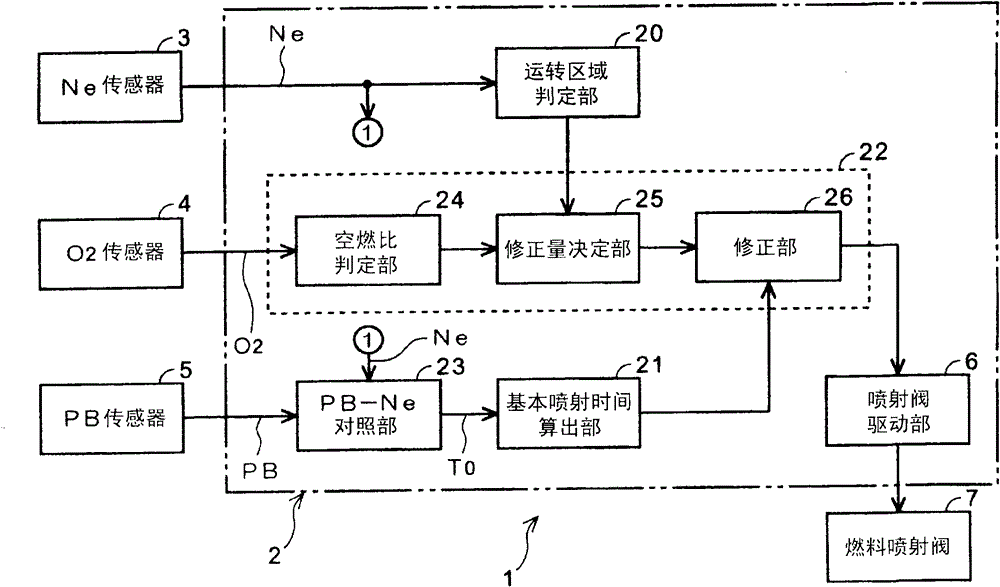

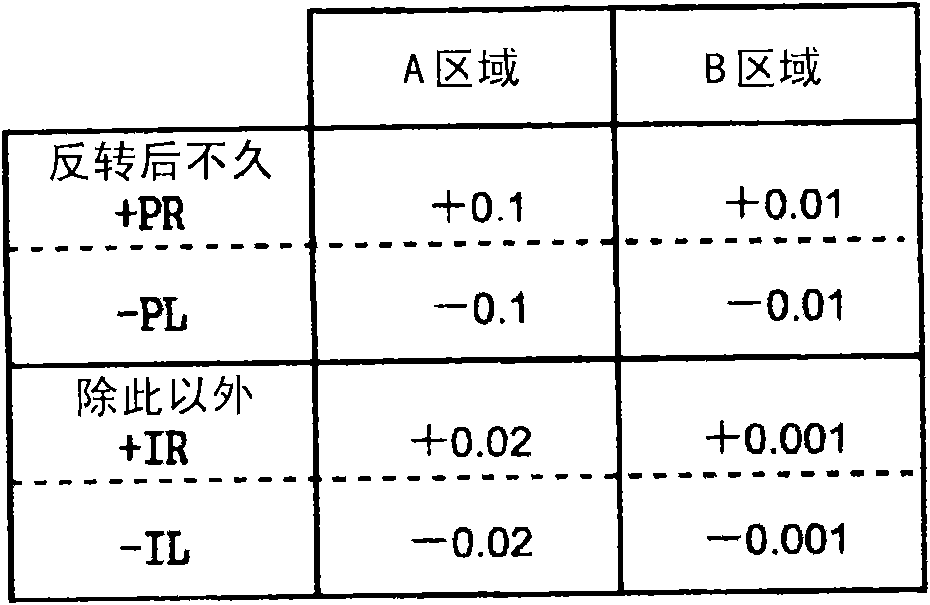

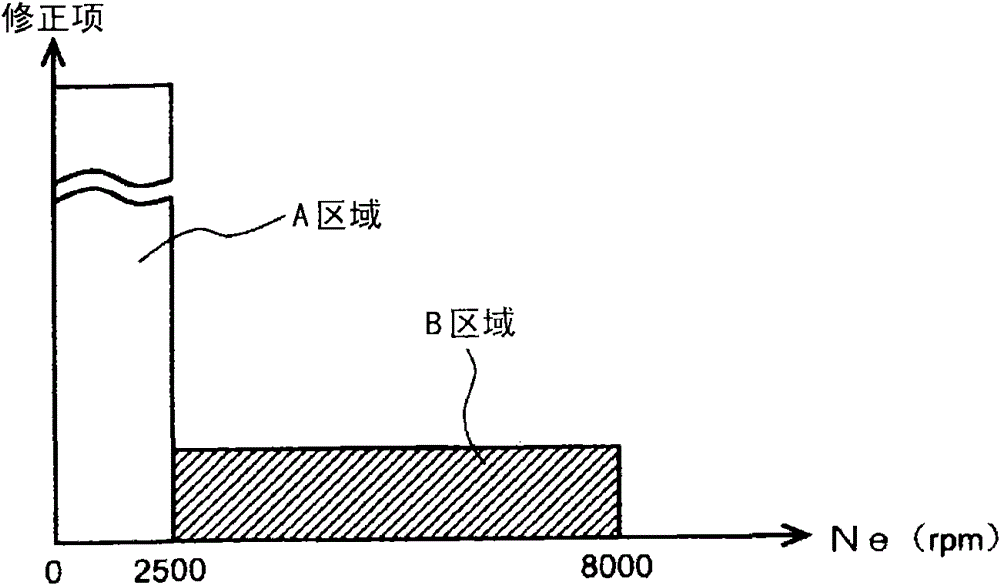

[0035] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. figure 1 It is a block diagram showing a system configuration of a fuel injection control device according to an embodiment of the present invention, and particularly a configuration diagram showing control in an idling region that is a low rotation speed region. In this figure, the fuel injection control device 1 is installed in an internal combustion mechanism, ie, an engine, which is a drive source of a motorcycle or the like. The fuel injection control device 1 includes: a control unit 2 functioning as a fuel injection amount determination unit; an engine speed sensor (hereinafter referred to as “Ne sensor”) 3 for detecting an engine speed Ne; An oxygen concentration sensor (hereinafter referred to as "O2 sensor") 4 functioning as a concentration detecting means, and a negative pressure sensor (hereinafter referred to as "PB sensor") 5 for detecting an intake negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com