Intelligent management system for construction hoist

A technology for construction elevators and management systems, applied in elevators, transportation and packaging, etc., can solve problems such as safety accidents, hidden dangers, affecting workers' life and property safety, and achieve the effect of reducing overstaffing, low cost and improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

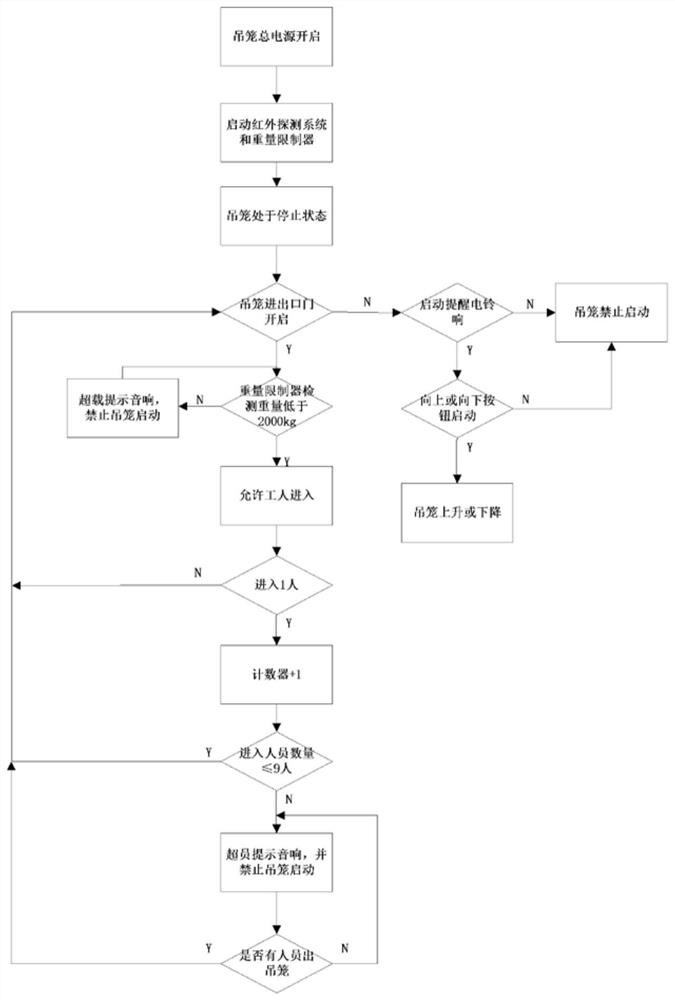

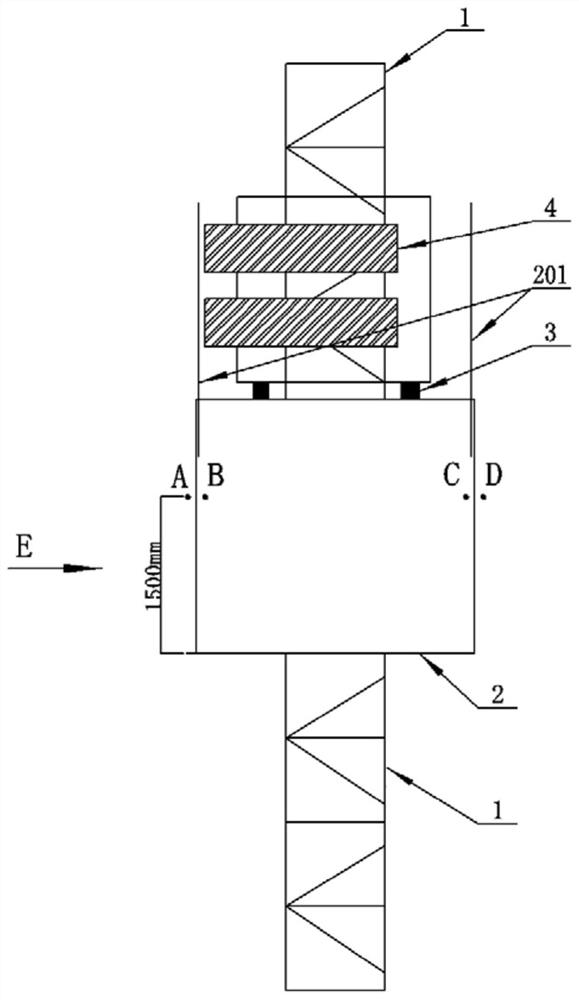

[0036] Such as Figure 1-4 As shown, an intelligent management system for a construction hoist includes a hanging cage 2, which is provided with a load-carrying cavity, and two opposite sides of the hanging cage 2 are respectively provided with inlets and outlets, and the inlets and outlets are vertically slidably connected with Closed door 201, that is, the quantity that the worker can enter from the entrance and exit and the closed door 201 is two, and the worker can enter the hanging cage 2 from one entrance and exit, and then go out from the hanging cage 2 from another entrance and exit.

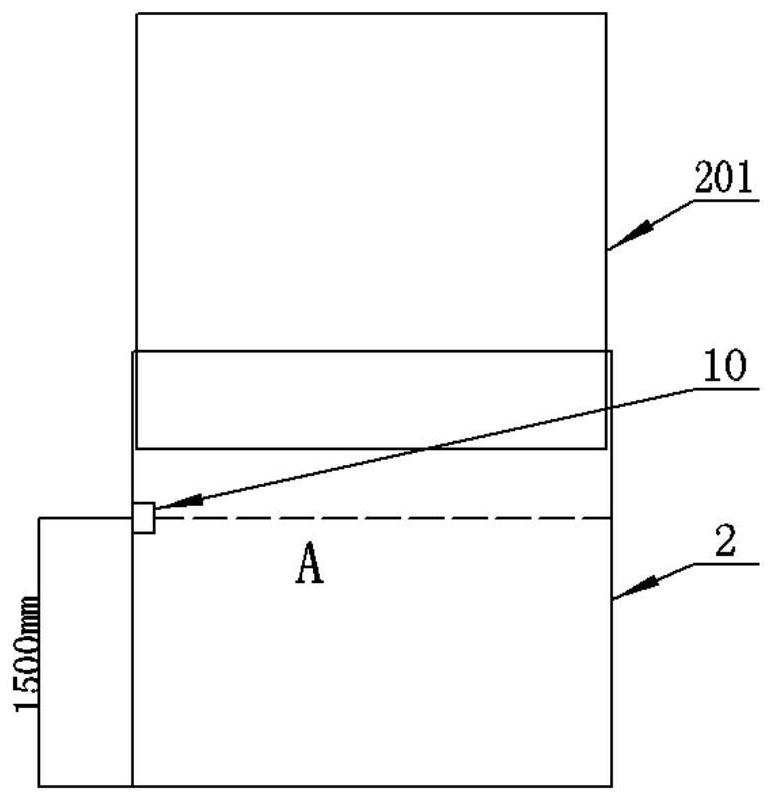

[0037] The management system also includes the first infrared counter 10 ( figure 2 In the detection line A), the second infrared counter ( figure 2 In the detection line B), the third infrared counter ( figure 2 The detection line C) and the fourth infrared counter ( figure 2 In the detection line D), the first infrared counter 10, the second infrared counter, the third infrared ...

Embodiment 2

[0051] The difference between this embodiment and embodiment 1 is only: as Figure 5 with Image 6 As shown, the two ends of the first rotating shaft 503 pass through both sides of the closed door 201 respectively, one end of the first rotating shaft 503 is fixedly connected with the vertical part 501 by bolts, and the other end of the first rotating shaft 503 is fixedly connected by bolts The limiting block 7 is provided with a limiting hole 701 on the limiting block 7 .

[0052] The inner side wall of the hanging cage 2 is welded with a receiving pipe 9, and the receiving pipe 9 is provided with a sliding chamber opening towards the stop block 7, and the sliding chamber is horizontally slidably connected with a second stop pin 901, one end of the second stop pin 901 The tension spring 902 is fixedly connected with the sliding chamber (by bolts).

[0053] The inner side wall of the cage 2 is embedded with an electromagnet 8, and the second limit pin 901 is embedded with an ...

Embodiment 3

[0056] The difference between this embodiment and embodiment 2 is only: as Figure 7 with Figure 8 As shown, the second limit pin 901 is provided with an anti-swing through hole communicating with the limit hole 701, and a wedge 1101 is slidably connected in the anti-swing through hole, and the sliding direction of the wedge 1101 is aligned with the centerline of the limit hole 701 Vertically, there are two wedges 1101 , and one of the wedges 1101 is on the side of the limiting block 7 close to the second limiting pin 901 . The closing plate is provided with a slot 202 for inserting one end of the wedge 1101. When the second limiting pin 901 is inserted into the limiting hole 701, the wedge 1101 is inserted into the slot 202 under the action of the second limiting pin 901. .

[0057] The management system also includes a compression spring 1102 capable of driving one end of the wedge 1101 away from the slot 202 . The wedge 1101 can effectively prevent the limit block 7 fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com