Guide shoe for a guiding device of a plastic processing machine clamping unit

A technology of guide device and guide seat, which is applied in the field of closed units, can solve the problems of high manufacturing cost of injection molding machines, poor energy balance, large and expensive structure of mold clamping plates, etc., and achieve high parallelism and good linear guidance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

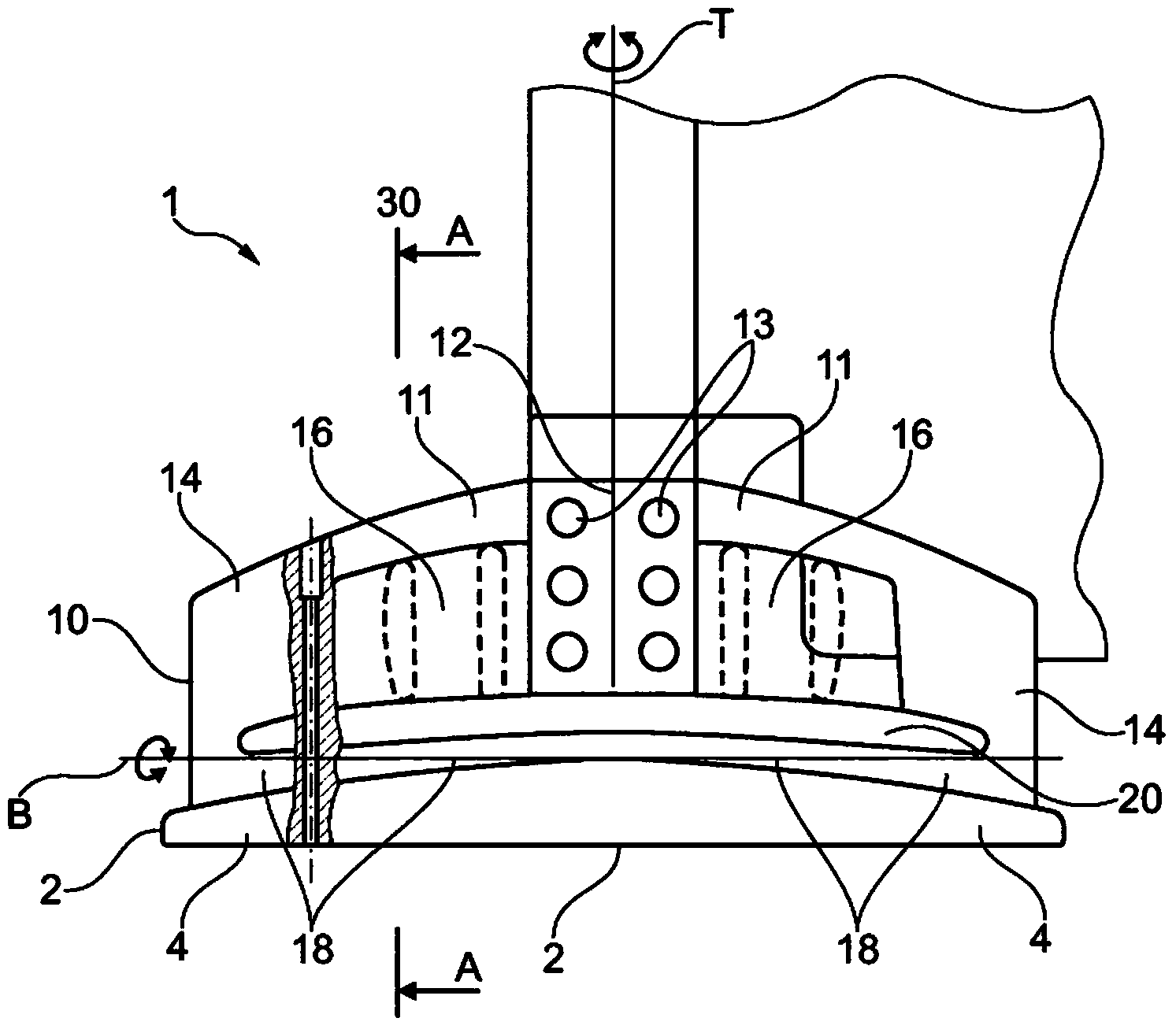

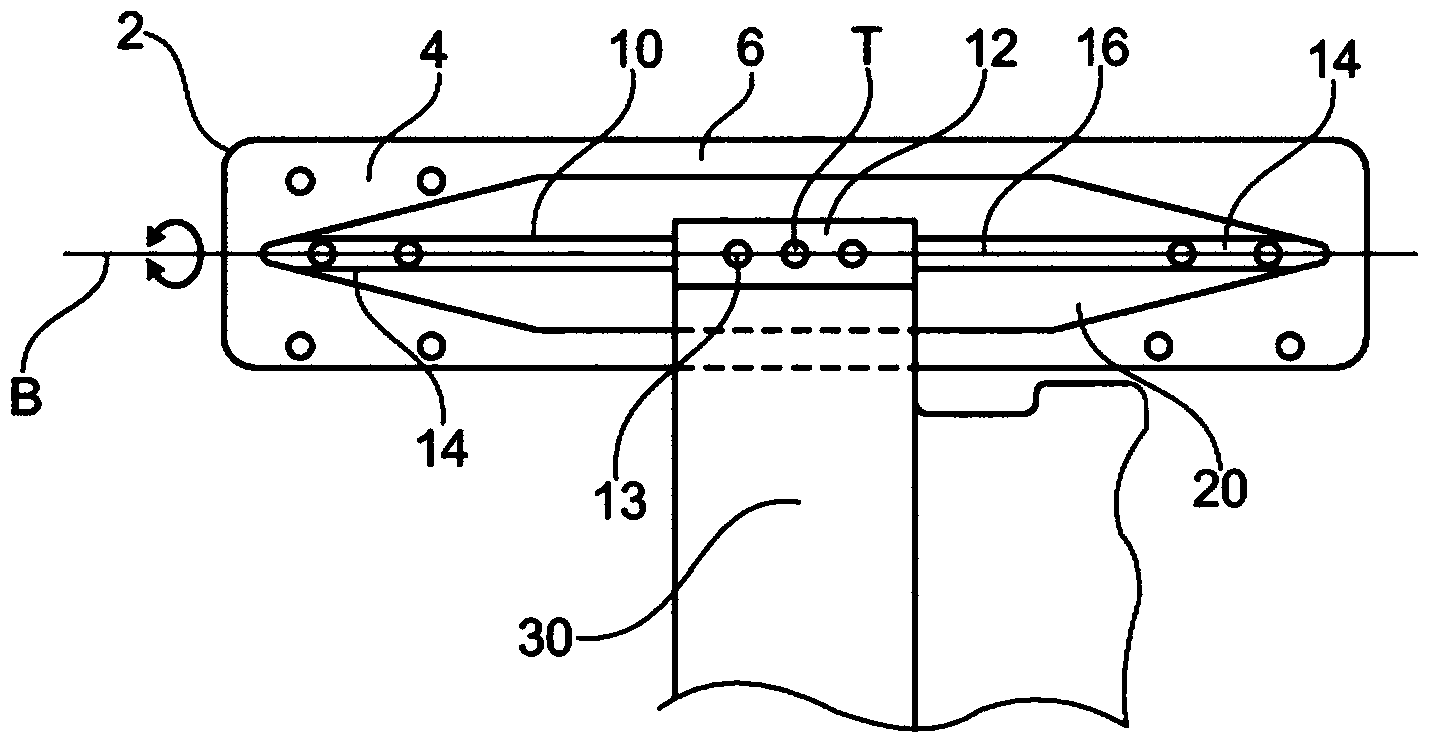

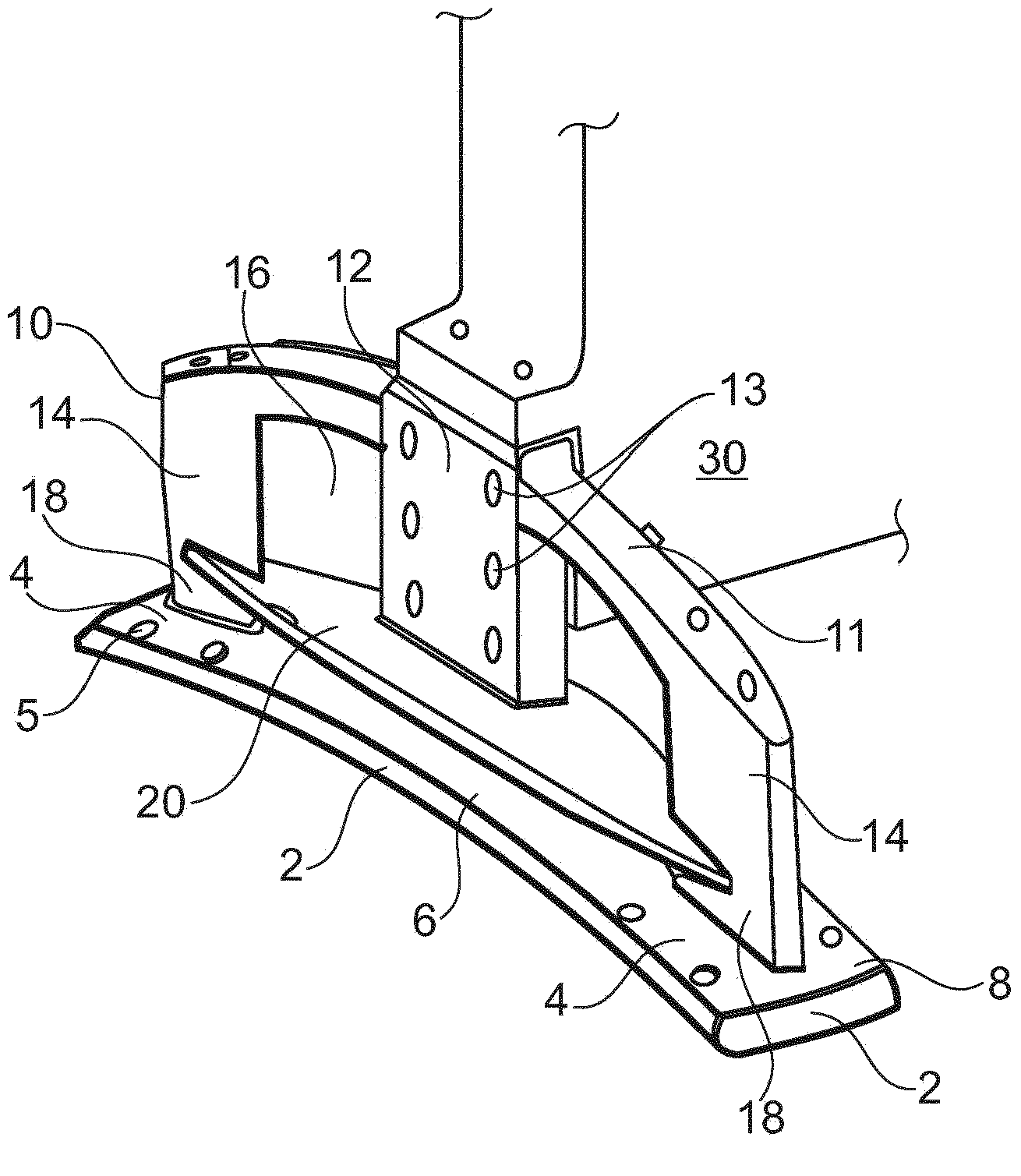

[0066] figure 1 A side view shows a guide seat 1 according to the invention, wherein the longitudinal extension corresponds to the longitudinal direction (X direction) of an injection molding machine. in figure 1 The guide seat shown in has a basic body 2 which is located in the area below the guide seat 1 in the application state of the guide seat 1 and is provided with a deformation element 10 on the basic body spaced upward in the vertical direction. The deformation element is connected to the end area 4 of the base body 2 via the end area 14. By way of example, fastening holes 5 for sliding elements / rolling elements (not shown) are shown in the end region 4 of the base body. The middle region 6 of the base body 2 is located between the end regions 4 of the base body 2, and the base body is connected to the middle region 16 of the deformation element 10 by a connecting region 18. The connecting area 18 is formed as a target bending area for the deformation element to bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com