Waste tyre rubber powder plasticizing reaction modifying method

A technology for waste tire rubber and waste tires, used in plastic recycling, reagents, educts, etc., can solve the problems of unstable dynamic performance, poor physical and mechanical properties of reclaimed rubber, and pollute the environment. Physical and mechanical properties, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

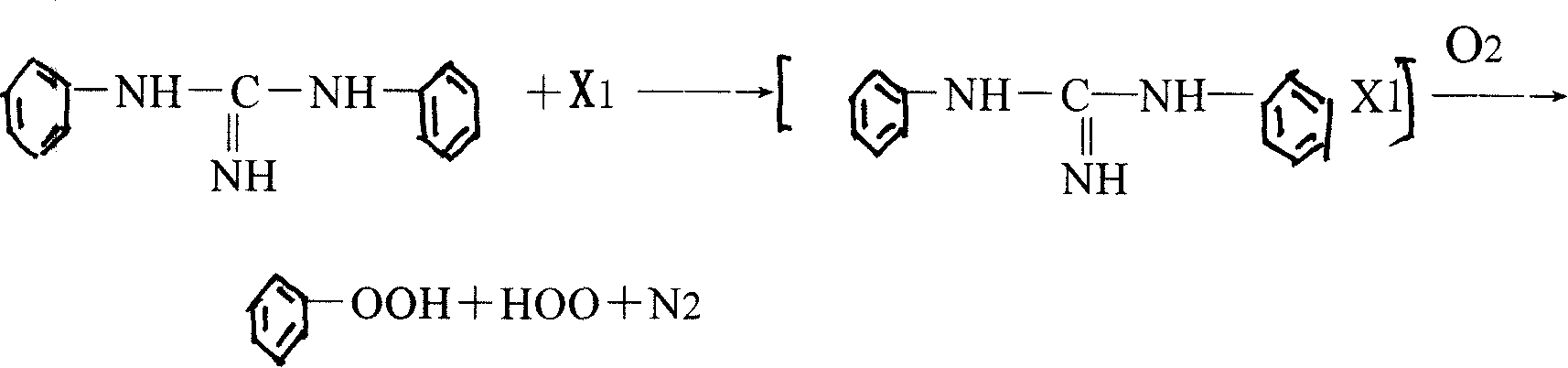

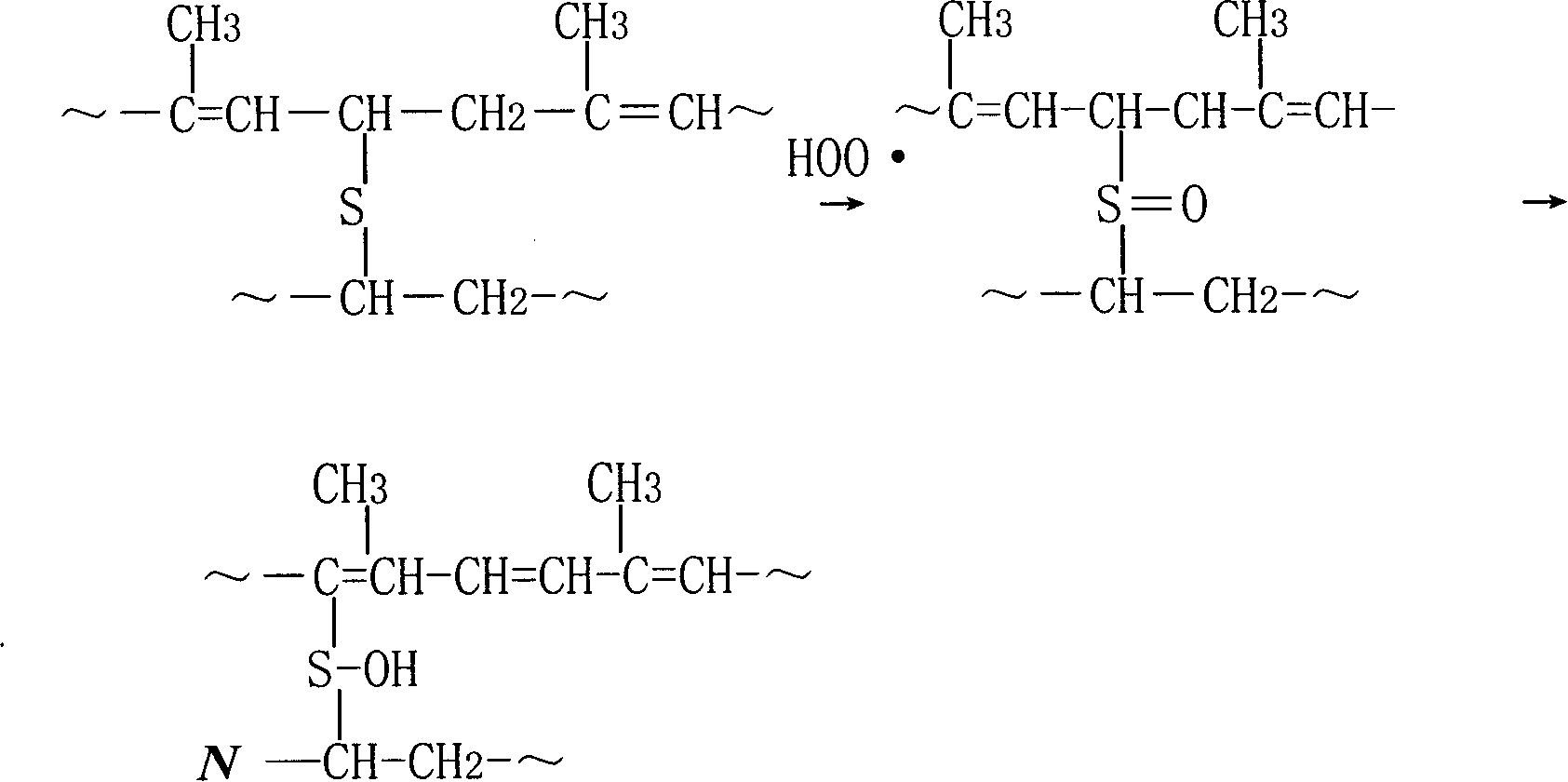

Method used

Image

Examples

Embodiment 1

[0030] Formula: Based on 40-60 mesh waste tire rubber powder, the weight of each component is:

[0031] 40-60 mesh waste tire rubber powder 100kg

[0032] Plasticizer A-dipentene 2kg

[0033] Plasticizer B-oxidized tall oil 8kg

[0034] Plasticizer - Tributylamine 1.5kg

[0035] Plasticizing aid - cuprous chloride solution 0.5kg

[0036] Dilute dispersant-ethanol 5kg

[0037] A total of 117kg.

[0038] Processing technology:

[0039] Put the waste tire rubber powder of 40-60 mesh in the above ratio into the high-speed shearing equipment, raise the temperature to 60°C, add plasticizing aid-tributylamine, plasticizing aid-cuprous chloride solution in turn, and plasticize Agent-dipentene, plasticizer-oxidized tall oil, adopt 900 rpm high-speed shear, control the temperature at 110°C, and the reaction time is 15 minutes. rubber powder.

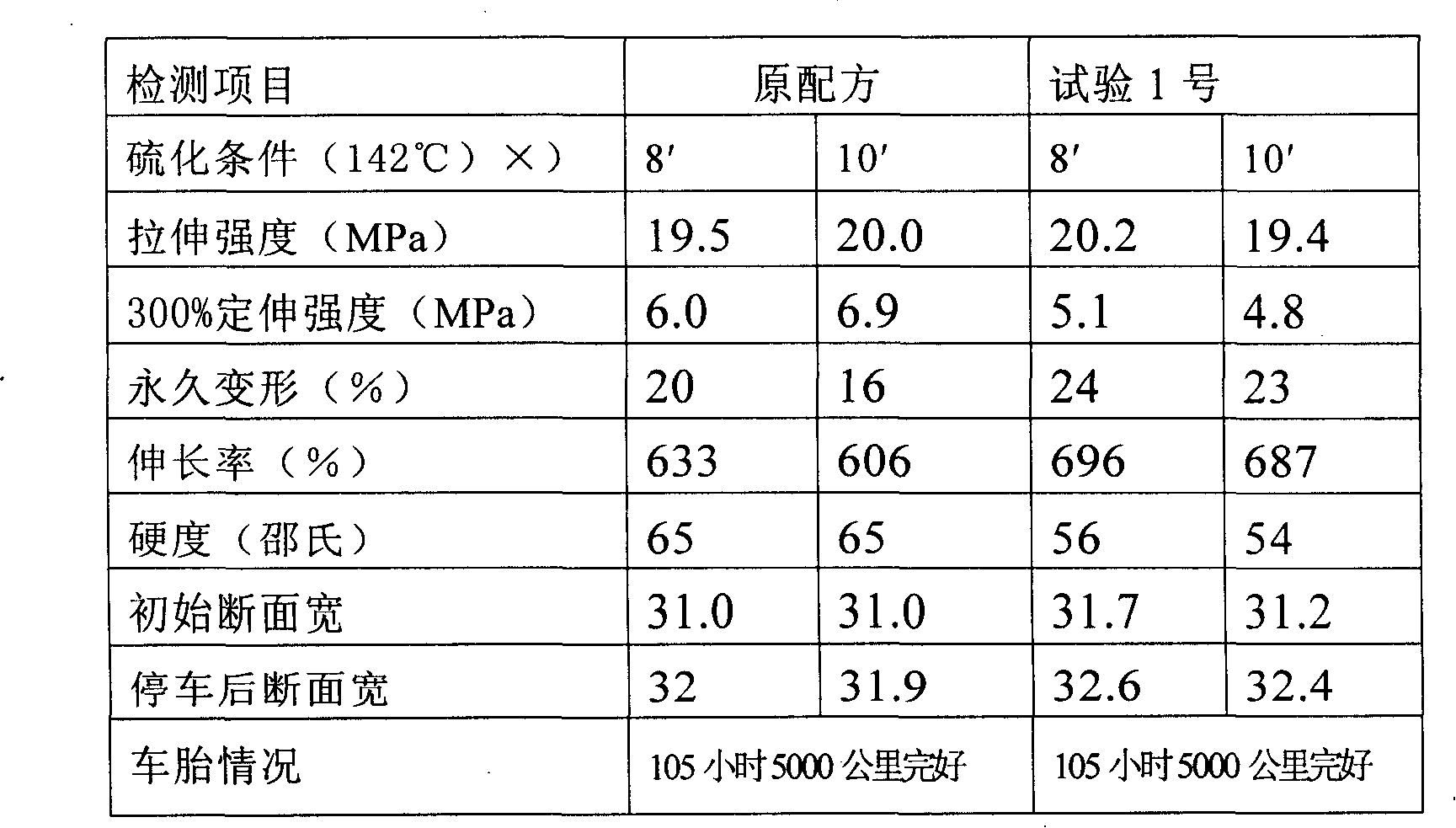

[0040] The obtained modified rubber powder is added to bicycle tires in a weight ratio of 5 parts instead of 5 parts of raw rubber. Compa...

Embodiment 2

[0044] Formula: Based on 40-60 mesh waste tire rubber powder, the weight of each component is:

[0045] 40-60 mesh waste tire rubber powder 100kg

[0046] Plasticizer A-dipentene 4kg

[0047] Plasticizer B-oxidized tall oil 6kg

[0048] Plasticizer - Tributylamine 1.4kg

[0049] Plasticizing aid - cuprous chloride solution 0.6kg

[0050] Dilute dispersant-ethanol 5kg

[0051] A total of 117kg.

[0052] Processing technology:

[0053] Put the waste tire rubber powder of 40-60 mesh in the above ratio into the high-speed shearing equipment, raise the temperature to 80°C, add plasticizing aid-tributylamine, plasticizing aid-cuprous chloride solution in turn, and plasticize Agent - dipentene, plasticizer - oxidized tall oil, using 500 rpm high-speed shear, controlling temperature at 100 ° C, reaction time is 15 minutes, the reaction is completed, cooling and discharging, to obtain plasticizing reaction modification rubber powder.

[0054] The obtained modified rubber powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com