Bismuth tellurate/bismuth oxide heterojunction material as well as preparation method and application thereof

A bismuth oxide, heterojunction technology, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. Effects with low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

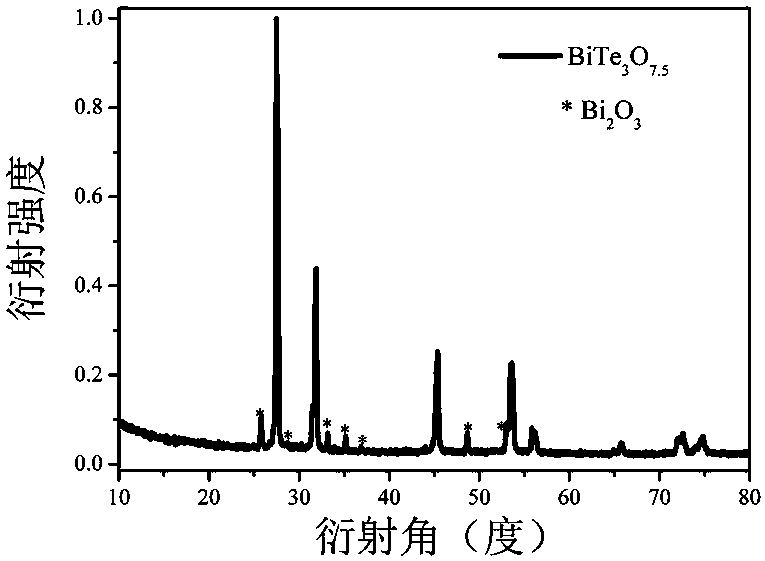

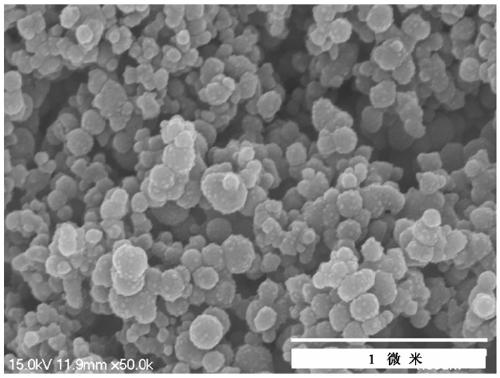

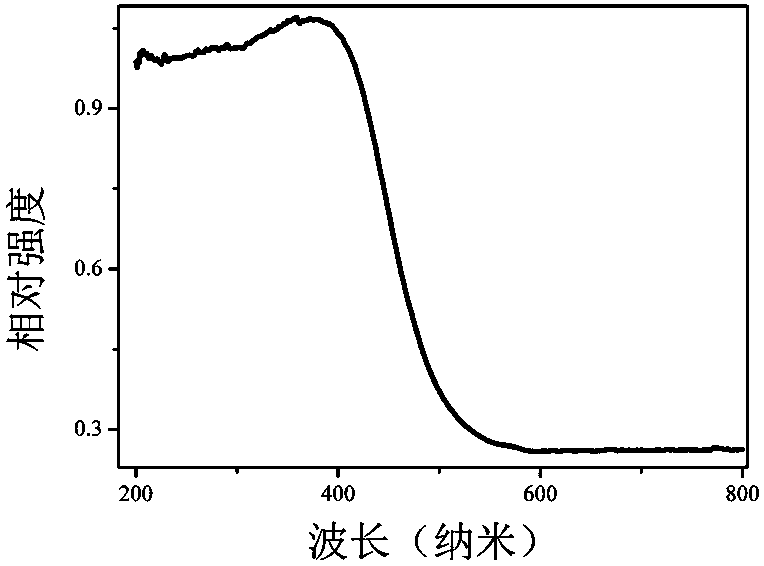

[0027] According to the chemical formula BiTe 3 o 7.5 / Bi 2 o 3 , Bi 2 o 3 with BiTe 3 o 7.5 The molar ratio is 5:100, and the bismuth nitrate Bi(NO 3 ) 3 ·5H 2 O: 1.780 grams, dissolved in dilute nitric acid solution, stirred until completely dissolved to obtain A solution. Then weigh tellurium oxide TeO 2 : 1.596 grams, be dissolved in the citric acid solution that pH value is 1.57, and the solution of gained is B solution.

[0028] Use a dropper to add solution A to solution B drop by drop, stir while adding dropwise, add citric acid or deionized water appropriately, and keep the pH of the mixed solution at about 1.57. Put it into a 60°C water bath and continue to stir for a while until gel appears. After the gel was aged for a period of time, it was placed in an oven and treated at 80°C for 12 hours to obtain a fluffy precursor. Take out the precursor and place it in a clean alumina crucible, calcinate it at 650°C for 8 hours, cool down naturally, take it out...

Embodiment 2

[0034] According to the chemical formula BiTe 3 o 7.5 / Bi 2 o 3 , Bi 2 o 3 with BiTe 3 o 7.5 The molar ratio is 10:100, respectively weigh bismuth oxide Bi 2 o 3 : 0.932 grams, dissolved in nitric acid solution, stirred until fully dissolved to obtain A solution. Then weigh tellurium chloride TeCl 4 : 2.694 grams, be dissolved in the citric acid solution that pH value is 1.5, and the solution of gained is B solution. Use a dropper to add solution A to solution B drop by drop, stir while adding dropwise, add citric acid or deionized water appropriately, and keep the pH of the mixed solution at about 1.5. Put it into an 80°C water bath and continue to stir for a while until gel appears. After aging the gel for a period of time, put it into an oven and bake it at 100°C for 8 hours to obtain a fluffy precursor. Take out the precursor and place it in a clean alumina crucible, calcinate it at 850°C for 4 hours, cool down naturally, take it out and grind it to get BiTe ...

Embodiment 3

[0037] According to the chemical formula BiTe 3 o 7.5 / Bi 2 o 3 , Bi 2 o 3 with BiTe 3 o 7.5 The molar ratio is 1:100, respectively weigh bismuth subcarbonate (BiO) 2 CO 3 : 0.867 gram, be dissolved in dilute nitric acid solution, stir until fully dissolving to obtain A solution. Then weigh tellurium chloride TeCl 4 : 2.694 grams, dissolved in a citric acid solution with a pH value of 2, the resulting solution is B solution. Use a dropper to add solution A to solution B drop by drop, stir while adding dropwise, add citric acid or deionized water appropriately, and keep the pH of the mixed solution at about 2. Put it into a 70°C water bath and continue to stir for a while until gel appears. After the gel was aged for a period of time, it was put into an oven and baked at 90° C. for 10 hours to obtain a fluffy precursor. Take out the precursor and place it in a clean alumina crucible, calcinate at 750°C for 6 hours, cool down naturally, take out and grind to get BiT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com