Non-stop screen exchanger and plastic extruder

A technology of screen changer and discharge port, applied in the field of plastic processing machinery, can solve the problems of inability to discharge air, inclusion of bubbles in plastic melt, affecting the quality of plastic products, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

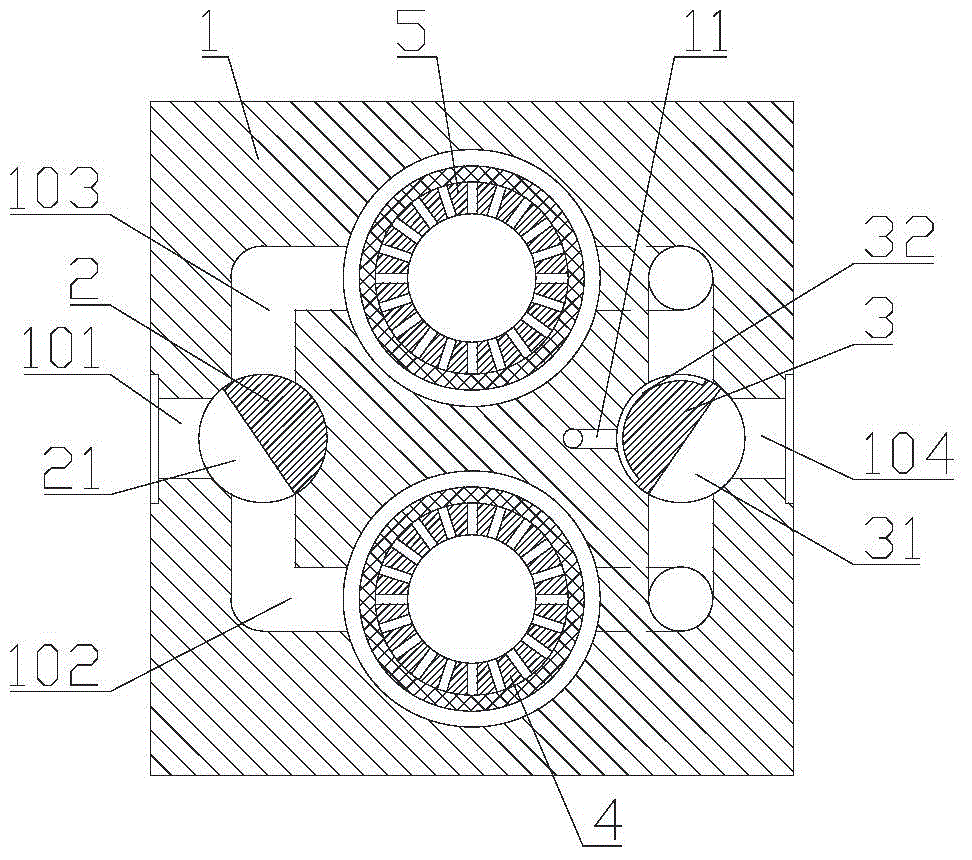

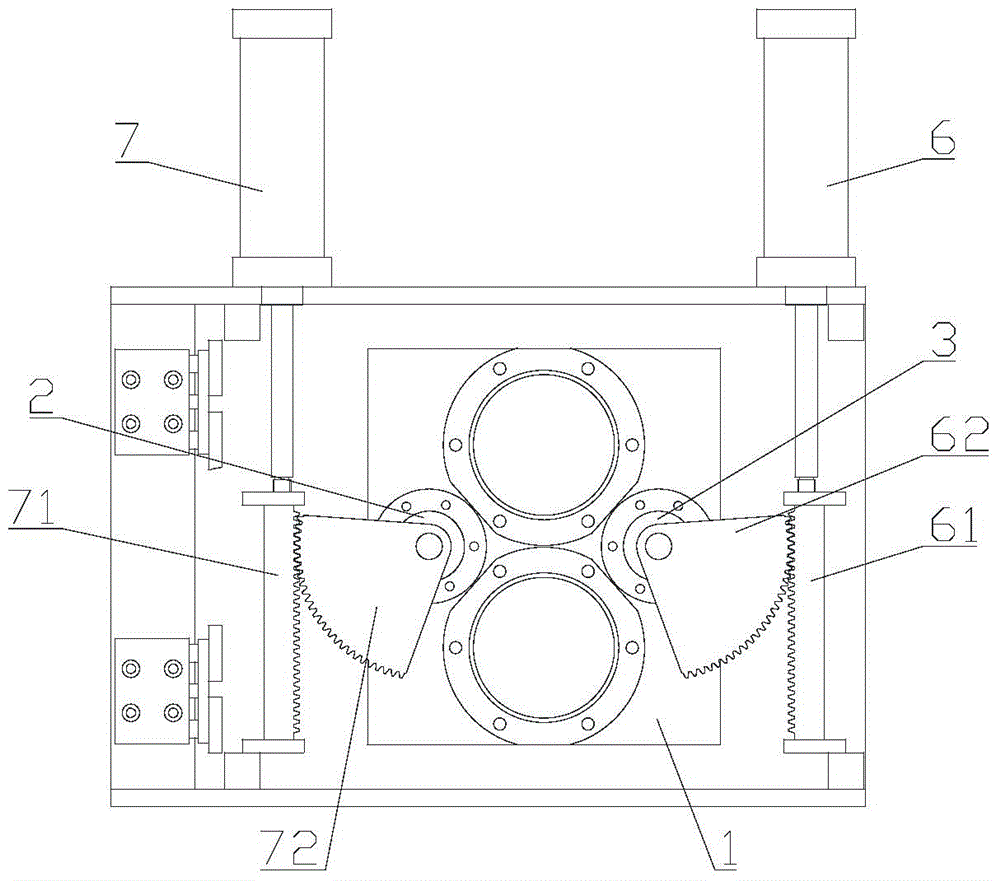

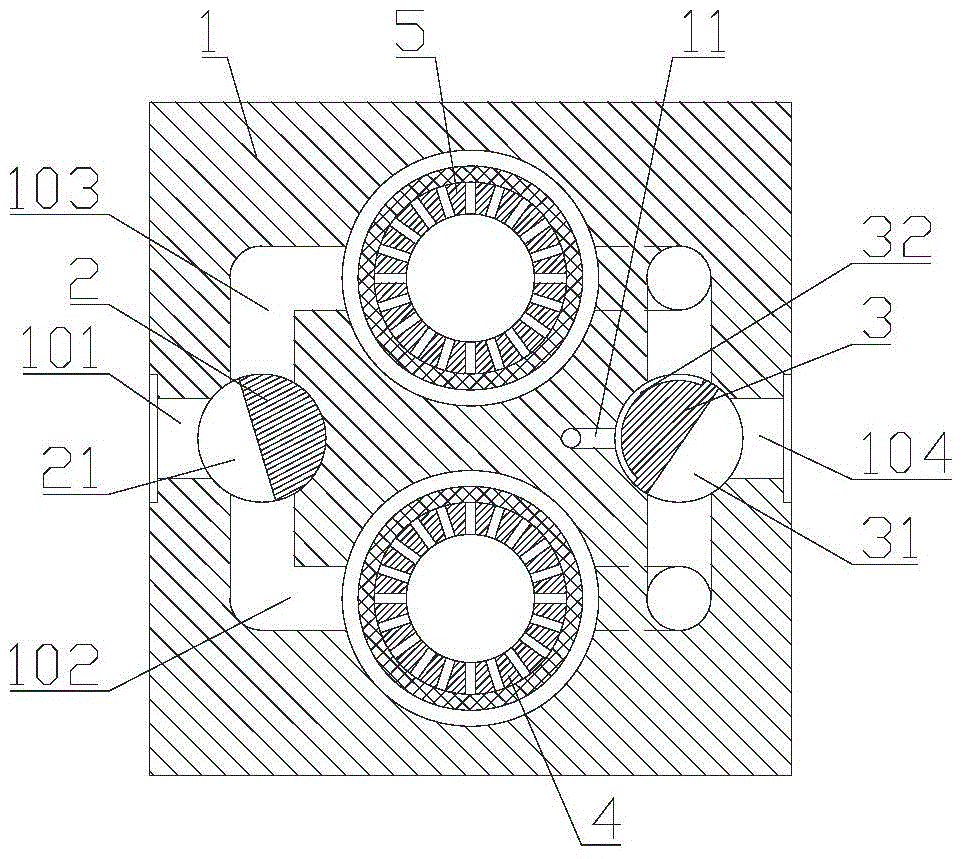

[0023] This embodiment provides a non-stop screen changer, such as figure 1 Shown, comprise main body 1, be provided with feed inlet 101, first passage 102, second passage 103 and discharge outlet 104 in main body 1, the inlet of first passage 102 and the inlet of second passage 103 are all connected with feed inlet 101 connection, the outlet of the first channel 102 and the outlet of the second channel 103 are connected with the discharge port 104, the connection between the feed port 101 and the first channel 102, the second channel 103 is provided with a feed valve core 2, and the outlet A discharge valve core 3 is provided at the connection between the feed port 104 and the first channel 102 and the second channel 103, the first filter element 4 is provided in the first channel 102, the second filter element 5 is provided in the second channel 103, and the feeding The outer peripheral side wall of the spool 2 is provided with a feed flow groove 21, and the feed valve core ...

Embodiment 2

[0034] This embodiment provides a plastic extruder, including an extrusion tube and an extrusion screw, and also includes the non-stop screen changer in the above embodiment, the extrusion port of the extrusion tube communicates with the feed port of the non-stop screen changer . Through the application of non-stop screen changer, the working effect of the extruder can be greatly improved, and the product quality of the extruder is also improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com