Environment protection high-efficiency energy-saving heating ring for TMD electric heating membrane

A high-efficiency, energy-saving, electric heating film technology, applied in the direction of heating element material, heating element shape, etc., can solve the problems of shortening the service life, increasing the resistance, and hindering the flow of the original current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

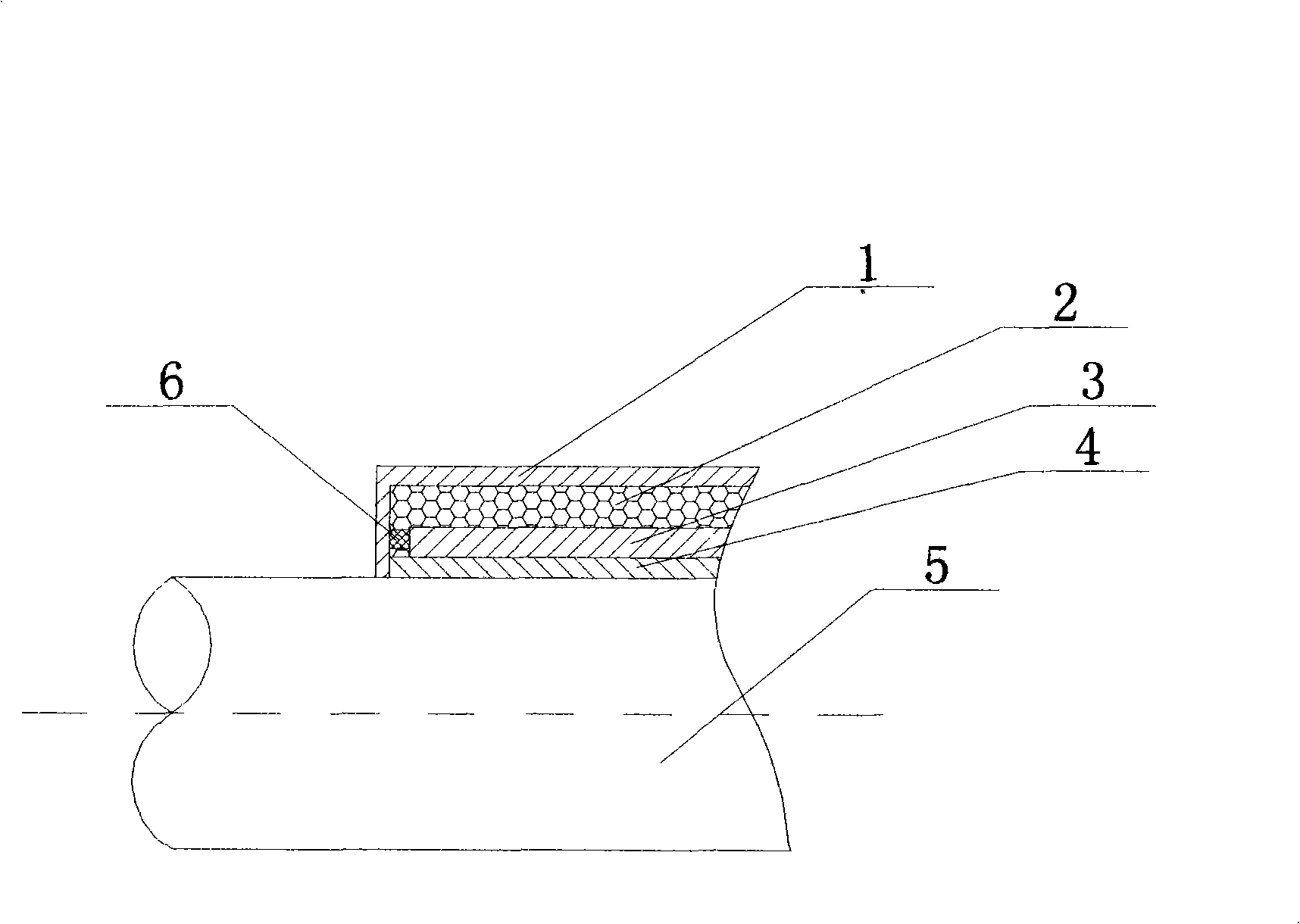

[0005] see figure 1 , this specific embodiment is composed of a metal shell 1, an aluminum silicate cotton insulation layer 2, an electric heating diaphragm layer 3, and an aluminum liner layer 4. The aluminum liner layer 4 is wrapped on the outside of the injection molding machine barrel 5, and the electric heating The diaphragm layer 3 is covered on the outside of the aluminum liner layer 4 , the aluminum silicate cotton insulation layer 2 is arranged on the outside of the electrothermal diaphragm layer 3 , and the metal shell 1 is wrapped on the outside of the aluminum silicate cotton insulation layer 2 . The connection between the metal shell 1 and the aluminum inner tank adopts heat-insulating ceramic parts to cut off the heat transfer between the two. The electrothermal diaphragm layer 3 adopts various high-temperature-resistant insulating dielectric materials such as glass-ceramics, ceramics, and quartz glass, and is made into a planar or cylindrical substrate as requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com