Conveying device

A technology of conveying device and driving device, applied in the field of plastic processing machinery, can solve the problems of low efficiency, slow change of spacing, complicated control, etc., and achieve the effect of accurate spacing, changing power mode and reducing overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

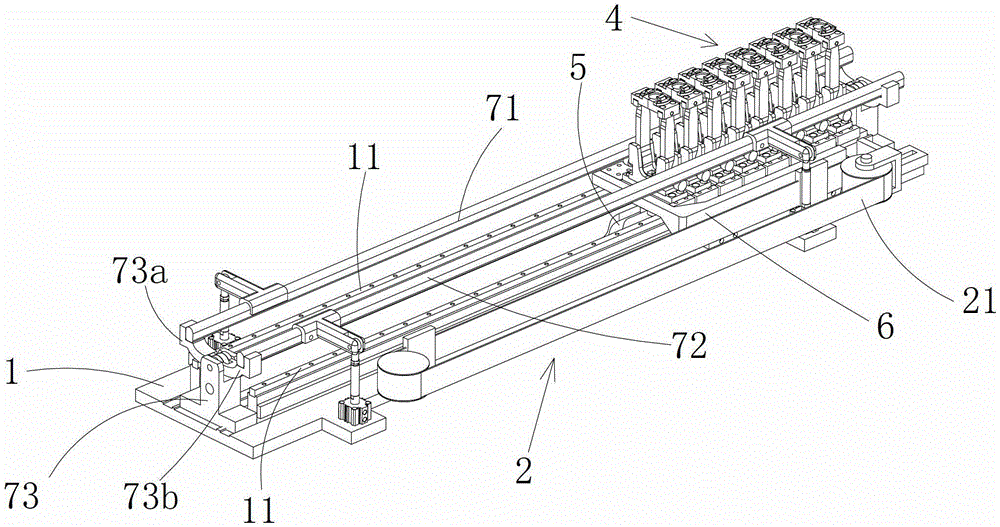

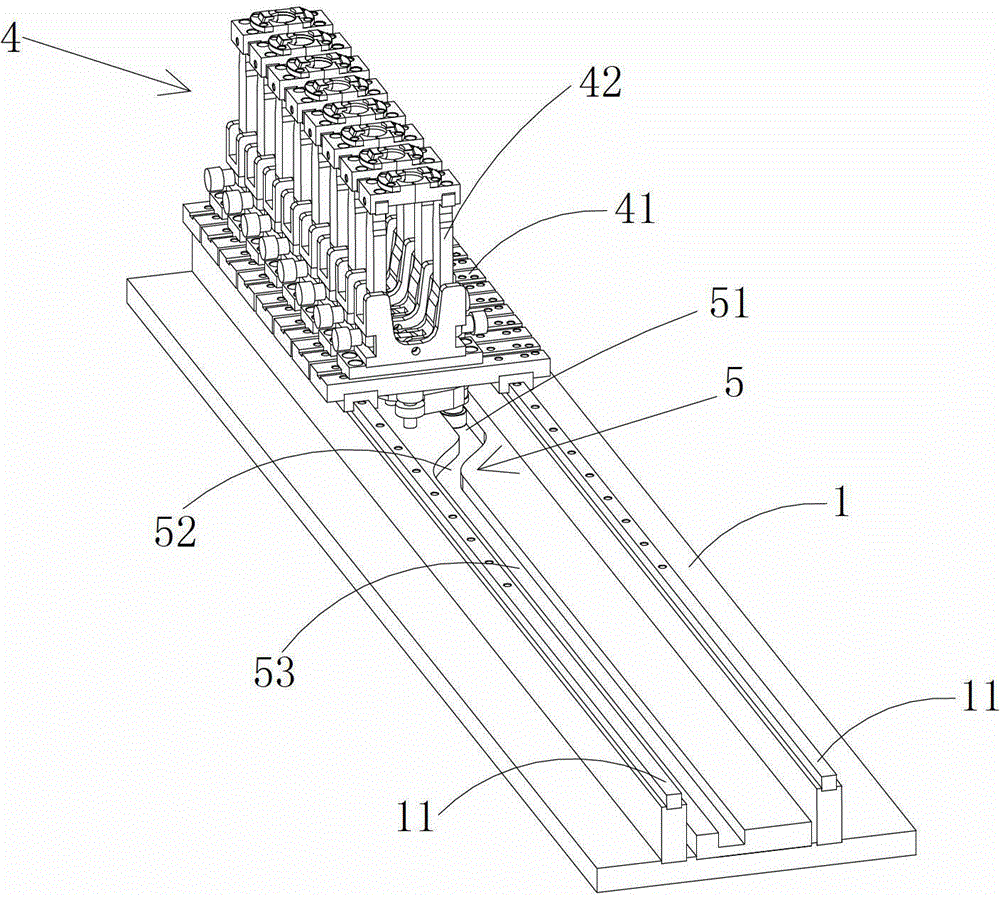

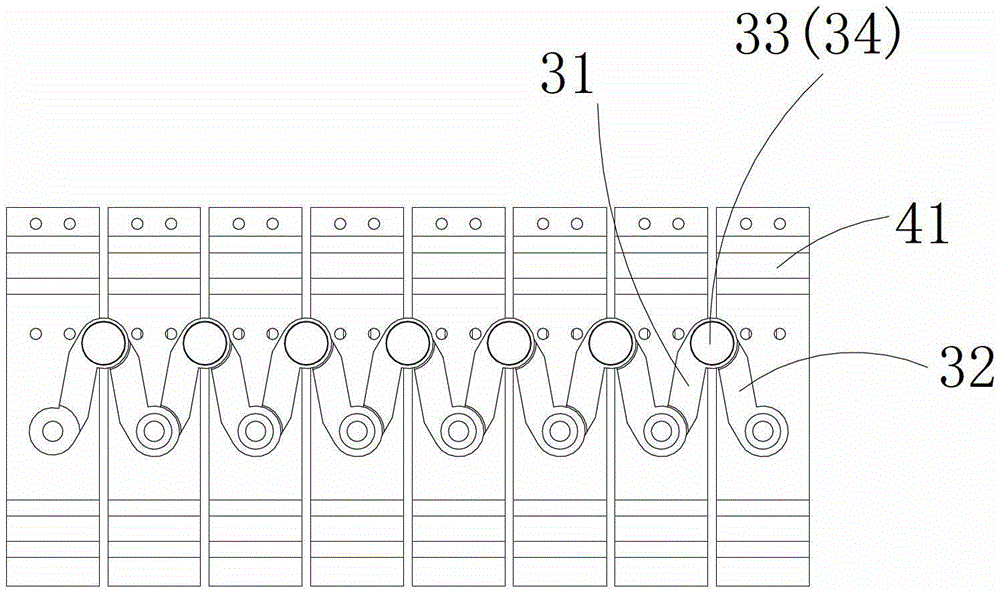

[0030] Such as Figure 1-8 As shown, a conveying device includes a base 1, a group of manipulators mounted on the base 1 that can reciprocate along the transmission path, a driving device 2 that drives the reciprocating movement of the manipulator group, and each manipulator 4 includes a manipulator seat 41 and the clamping portion 42 installed on the manipulator base 41, the adjacent two manipulator bases 41 are connected by the linkage mechanism 3, as image 3 , 4 As shown, the linkage mechanism 3 is two connecting rods 31 and 32, one end of the two connecting rods 31 and 32 are respectively pivotally connected to the bottoms of two adjacent manipulator seats 41, and the other ends are pivotally connected together to form a movable hinge point 33, A first bearing 34 is provided at the movable hinge point 33, and a displacement track 5 is provided on the base 1 and below the manipulator seat 41 to move the movable hinge point 33 so that two adjacent manipulators move relativ...

Embodiment 2

[0037] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the displacement track is a linear track 8 arranged below the manipulator seat 41, and the linear track 8 is connected to the base 1 through a cylinder and can be moved in the cylinder. Driven to move perpendicular to the transmission direction, a first bearing 34 is arranged at the living hinge point 33, and the first bearing 34 runs in the linear track 8.

[0038] The working process of this embodiment differs from that of Embodiment 1 in that: when the heating is completed, several manipulators (generally determined according to the number of cavities in the mould) hold the preform and enter the linear track 8, the cylinder moves, Pull the linear track 8 to move perpendicular to the transmission direction, drive the first bearing 34 inside to move, the connecting rods between several manipulators are opened at the same time, and a group of plastic container preforms realize pi...

Embodiment 3

[0040] The difference between this embodiment and Embodiment 1 is that it further includes a moving base 9 on which a group of manipulators 4 are arranged and connected with the driving device 2 through the moving base 9 . The upper surface of the moving seat 9 has a pair of second linear guide rails 91 arranged in parallel, and the lower surface has a pair of second slide blocks 92 corresponding to the pair of linear guide rails. A slider 41a is slidably connected to the second linear guide rail 91, and the moving base 9 is slidably connected to the first linear guide rail 11 on the base through the second slider 92. The bottom of the moving base 9 has an opening, and the linkage The mechanism 3 is connected to the shifting track 5 through the opening, and the shifting track 5 includes a first straight line segment 51, a shifting segment 52 and a second straight line segment 53 in sequence, and the first straight line segment 51 and the second straight line segment 53 are abse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com