Cold shaping machine for vehicle oil pipe end squeeze pack

A cold forming machine and oil pipe technology, which is applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of the size, position and shape and appearance of the cold extrusion package, and achieve accurate extrusion position, easy adjustment, and shape. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

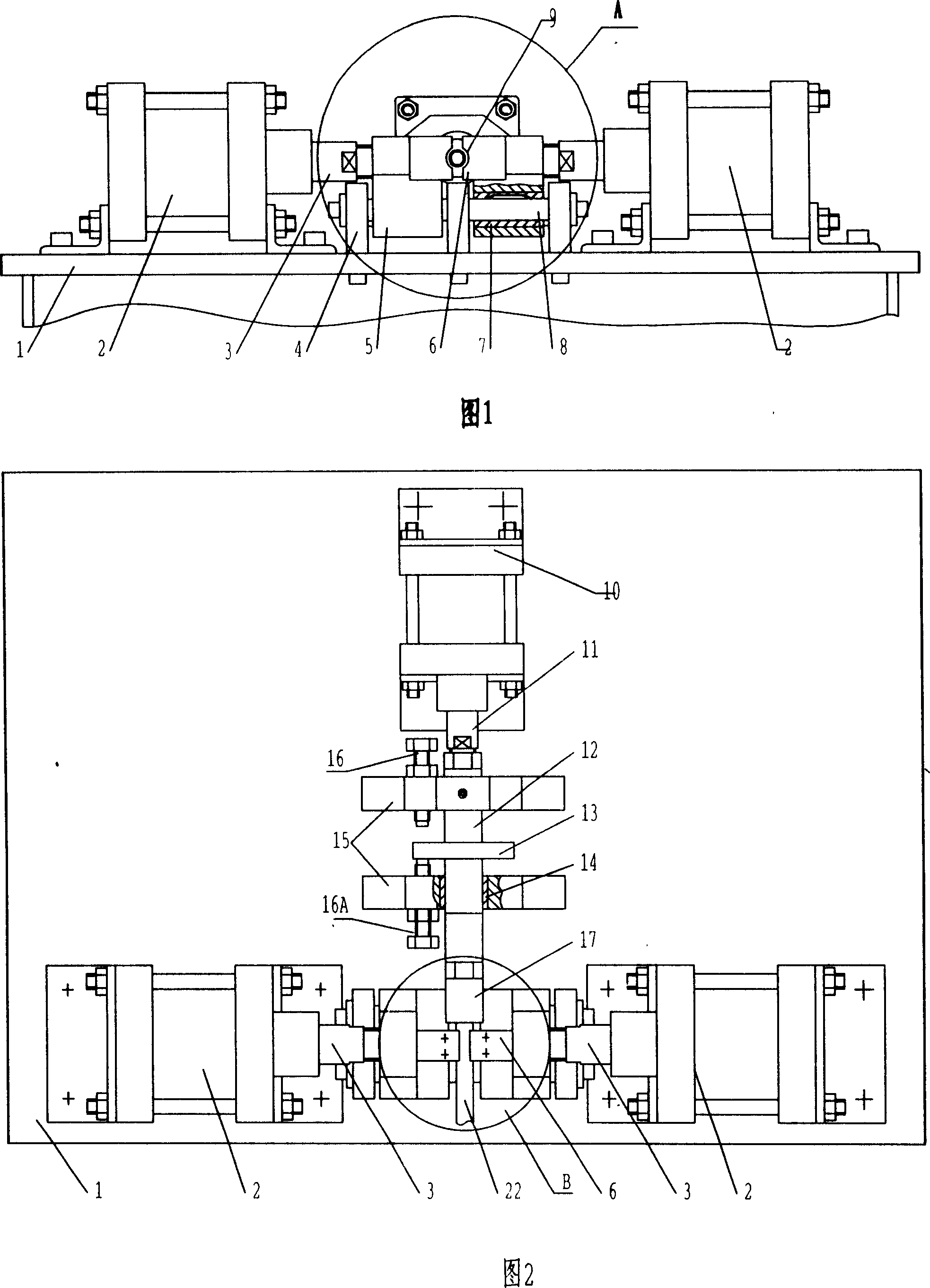

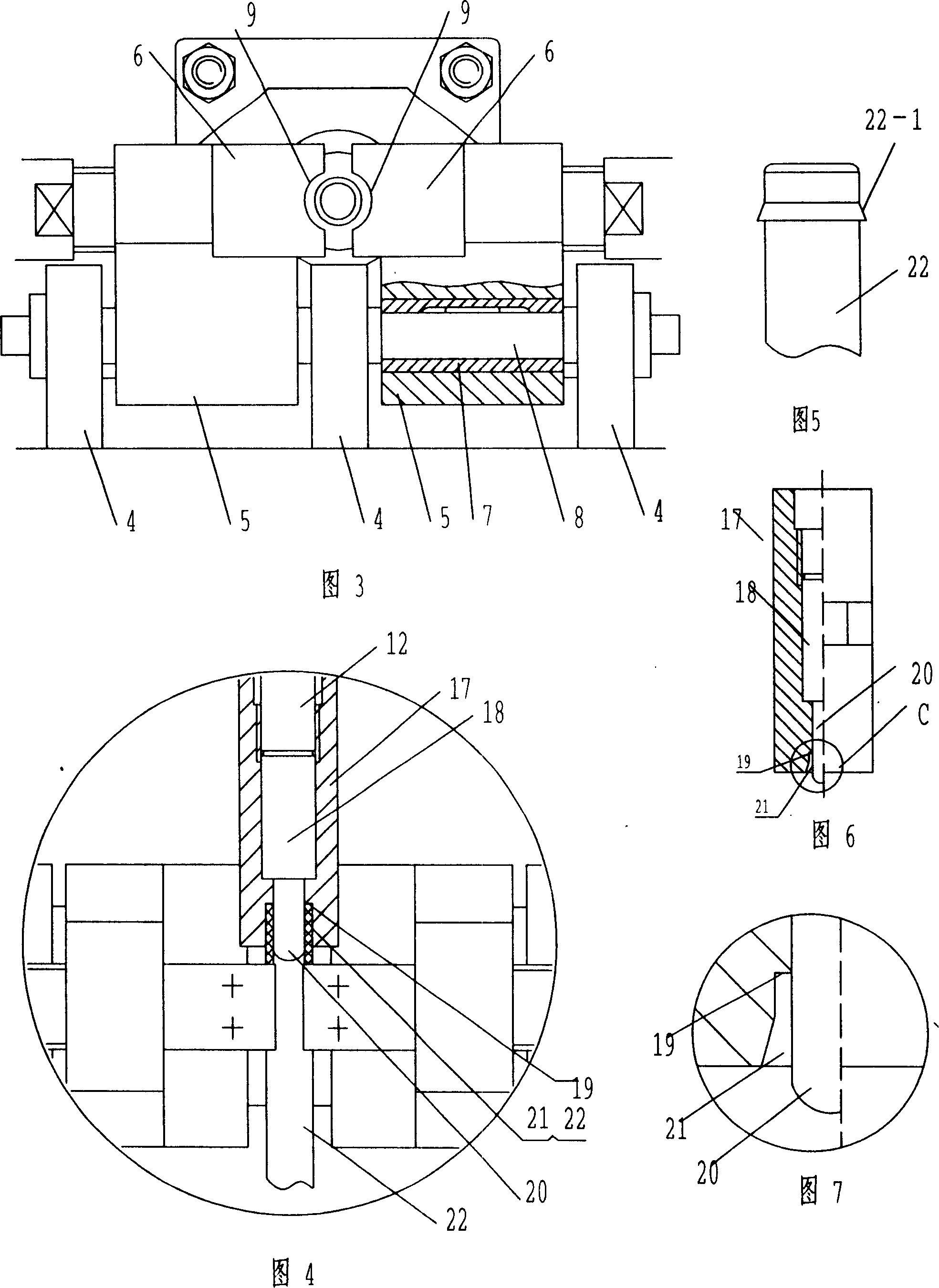

[0019] The main components of the present invention include a tubing clamping device, a punching device and a frame 1. Both the tubing clamping device and the punching device use air source as the power source, the cylinder as the executive component, and the tubing clamping device and the punching device are both located in the machine. Shelf. Refer to Figure 2 and Figure 4, the punching device is composed of a punching cylinder 10, a guide stroke adjustment mechanism and a punch 17. The guide stroke adjustment mechanism is composed of a guide rod 12, a guide seat 15, a stroke adjustment bolt 16, 16A and a stopper 13. One end of the rod is fixedly connected to the punching cylinder rod 11, and the other end is threadedly connected to the punch 17. This connection method facilitates the replacement of the punch and is suitable for press processing of different specifications of tubing. The punch is provided with a tube core 18, the end of the tube core is a guide section 20 whose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com