Plastic extrusion flat film wire drawing machine

A wire drawing machine and flat film technology, which is applied in the field of plastic extrusion flat film wire drawing machine, can solve the problems of reduced safety factor, uneven film thickness, material deformation, etc., achieve reduced strength requirements, improve production efficiency, and reduce power requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

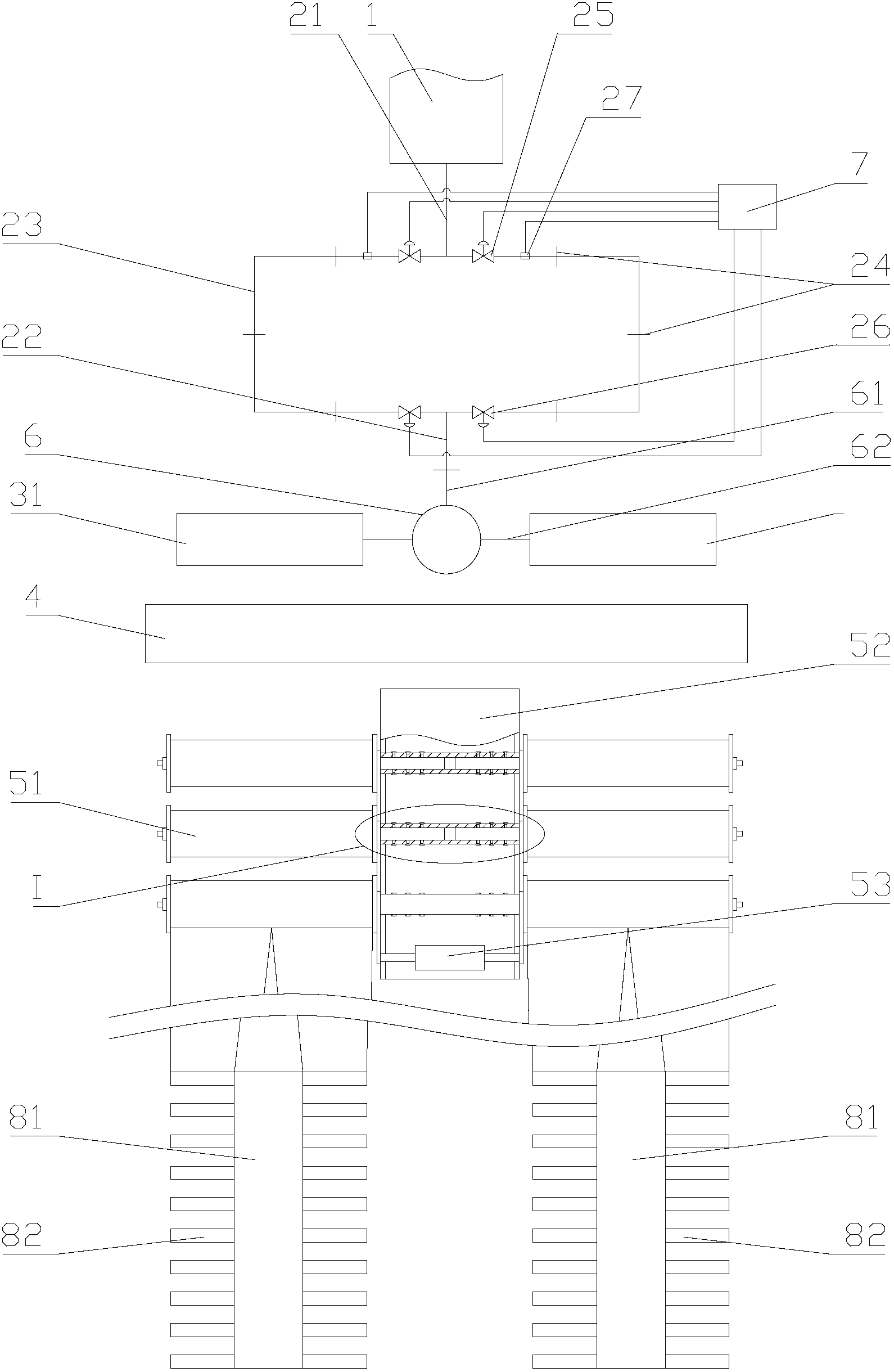

[0021] Such as figure 1 with 2 Shown is the first embodiment of the present invention, a plastic extrusion flat film wire drawing machine, including an extrusion mechanism and a film discharge mechanism, the extrusion mechanism includes a screw barrel 1 and a filter device, and the film discharge mechanism includes a molding die , a cooling water tank 4, a drum assembly and a winding assembly, the screw barrel communicates with the filter device, the filter device communicates with the molding die, and the filter device communicates with the molding die through a three-way splitter 6, the The forming mold includes two die heads 31, the feed port 61 of the three-way splitter communicates with the filter device, and the two discharge ports 62 communicate with the two die heads respectively.

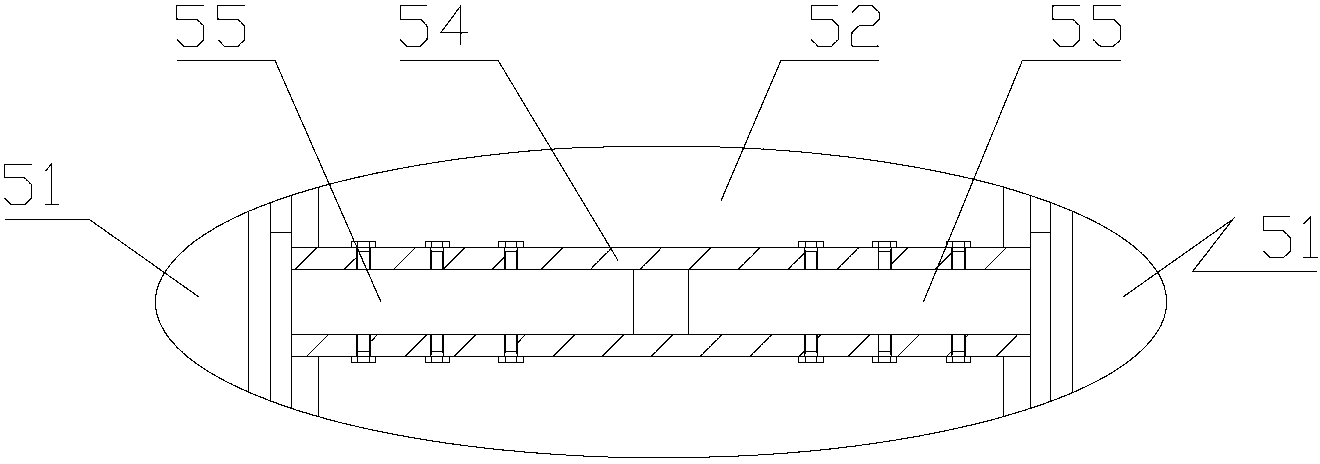

[0022] The roller assembly includes a roller 51 and a traction unit driving the roller. The rollers are arranged on both sides of the traction unit and correspond to the two die heads resp...

Embodiment 2

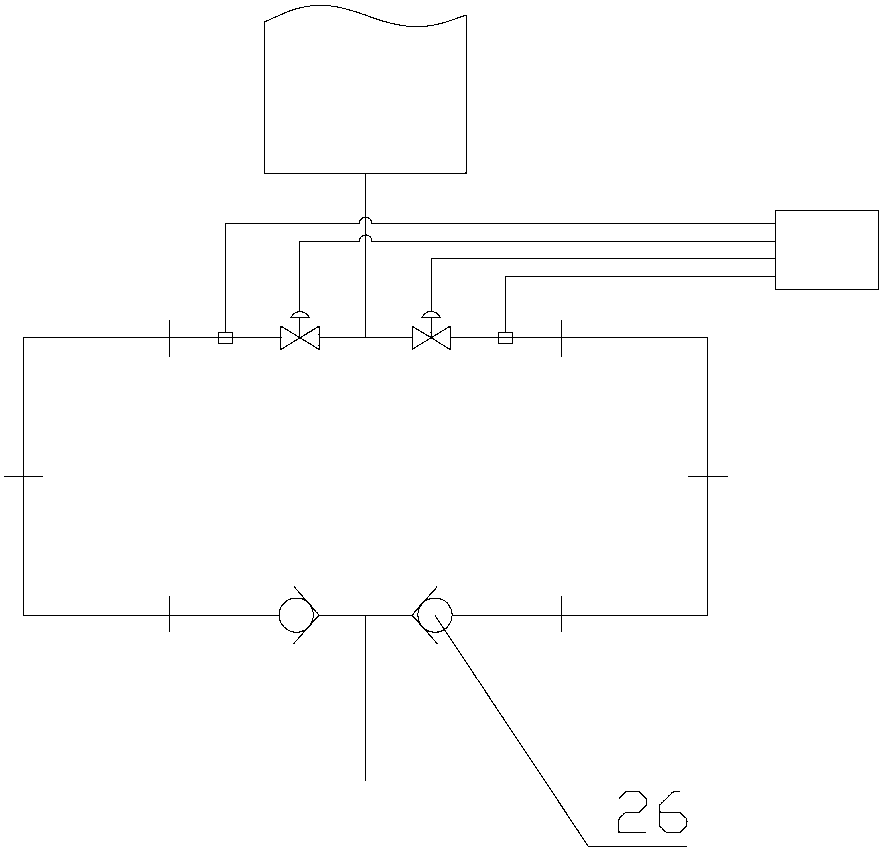

[0029] Such as image 3 Shown is the second embodiment of the present invention, this embodiment is similar to the first embodiment, the difference is that the second control valve 26 is a check valve that allows the material to flow from the middle flow channel to the discharge pipe in one direction, and the stop valve The blow-off valve need not be controlled by the controller. Of course, a shut-off valve and a check valve can also be selected among the two second control valves. The number of the second control valves is increased. In all the second control valves, there is at least one shut-off valve and a check valve. The principle is the same and will not be repeated here.

Embodiment 3

[0031] Such as Figure 4 Shown is the third embodiment of the present invention, this embodiment is similar to the first embodiment, the difference is that the motor is provided with two and respectively drives the rollers on both sides of the traction unit, so that according to the actual production needs, by changing The speed of the two motors adjusts the traction speed, which can realize two products of the same or different models produced by one machine. There are two cooling water tanks corresponding to the two die heads respectively. In addition, flow control valves can be set on the two outlets of the three-way diverter, which can match the speed of the two motors to adjust the corresponding flow. This embodiment can also be implemented in combination with Embodiment 2.

[0032]The working principle of the present invention to realize non-stop screen change is explained as follows by taking the first and two intermediate channels of the embodiment as examples: when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com