High fill polyolefin composite film masterbatch and preparation method thereof

A composite film and polyolefin technology, applied in the field of high-filled polyolefin composite film masterbatch and its preparation, can solve the problems of complex process control conditions, inability to use blow molding, large equipment investment cost, etc., and achieves excellent physical properties, Low cost and lower settlement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

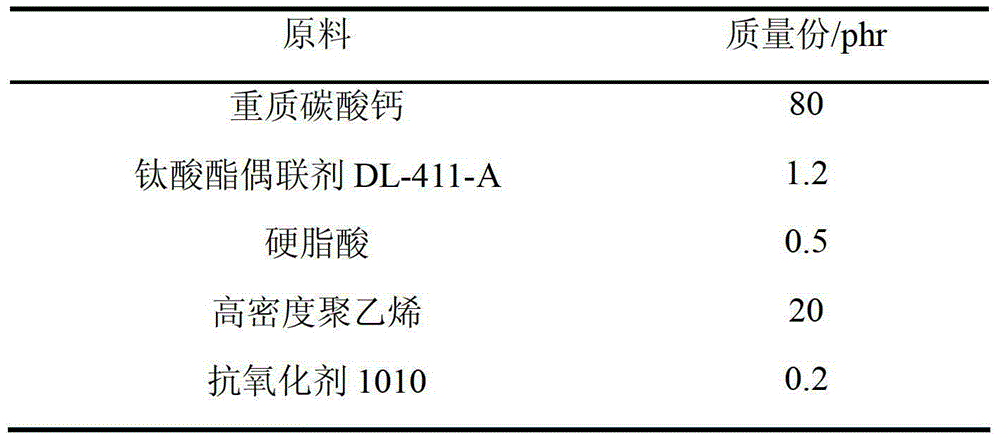

[0035] 1. Ingredients:

[0036]

[0037] 2. Preparation

[0038] 1) Add heavy calcium carbonate to a high-speed mixer, dry at 110°C for 5 minutes, add titanate coupling agent DL-411-A for activation for 5 minutes, add stearic acid and mix for 5 minutes, raise the temperature to 130°C and add 12 parts High-density polyethylene, mixed evenly to obtain a mixture, after the temperature of the material is cooled to below 80°C, the material is discharged.

[0039] 2) Mix the above-mentioned mixture, 8 parts of high-density polyethylene and antioxidant 1010 with a high-speed mixer at 100 ° C to uniformly discharge the material, extrude and granulate through a twin-screw extruder, and set the temperature of the twin-screw extruder to 130 -190°C, the screw speed is 100-200rpm, and the high-filling polyolefin composite film masterbatch is prepared after water cooling and air drying.

[0040] The masterbatch prepared in this example can be directly used for extrusion blow molding, e...

Embodiment 2

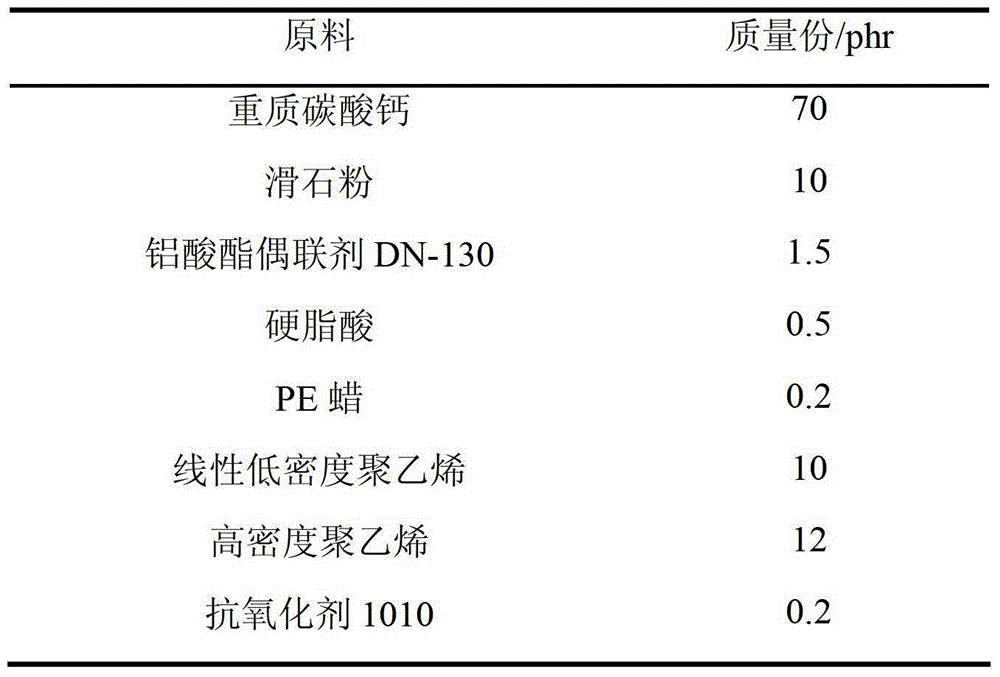

[0042] 1. Ingredients:

[0043]

[0044] 2. Preparation:

[0045] 1) Add heavy calcium carbonate and talcum powder to a high-speed mixer, dry at 110°C for 5 minutes, add titanate coupling agent DN-130 to activate for 8 minutes, add stearic acid and polyethylene wax to mix for 5 minutes, and raise the temperature to 130°C After ℃, add 12 parts of high-density polyethylene, mix evenly to obtain a mixture, and wait until the temperature of the material is cooled to below 80°C to discharge.

[0046] 2) Mix the above mixture, linear low density polyethylene, and antioxidant 1010 with a high-speed mixer at 100°C, and then extrude and granulate through a twin-screw extruder. The temperature of the twin-screw extruder is set at 130-190°C °C, the screw speed is 100-200rpm, and the high-filling polyolefin composite film masterbatch is prepared after water cooling and air drying.

[0047] The masterbatch prepared in this example can be directly used for extrusion blow molding, extru...

Embodiment 3

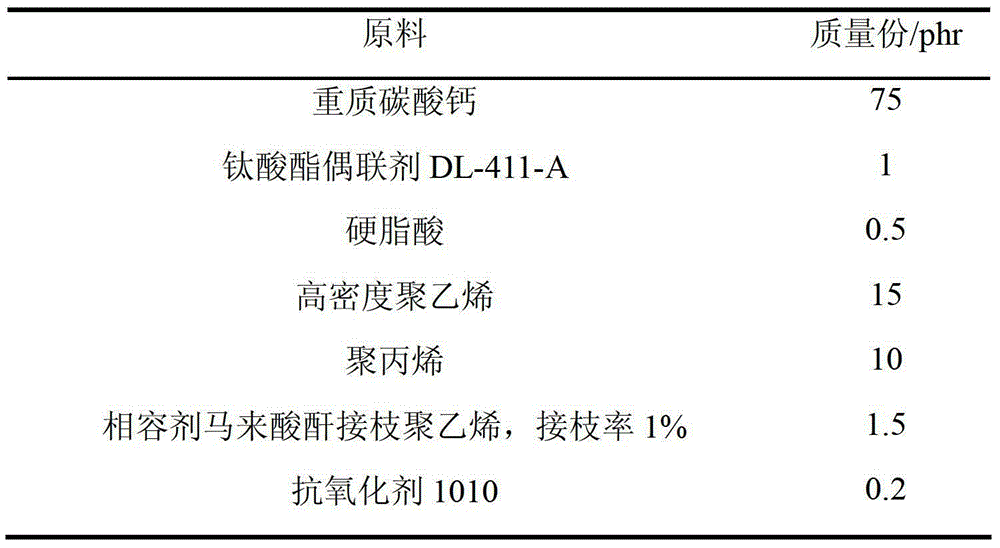

[0049] 1. Ingredients:

[0050]

[0051] 2. Preparation:

[0052] 1) Add heavy calcium carbonate to a high-speed mixer, dry at 110°C for 5 minutes, add titanate coupling agent DL-411-A to activate for 8 minutes, add stearic acid and mix for 5 minutes, raise the temperature to 130°C and add 15 parts High-density polyethylene, mixed uniformly to obtain a mixed material, the material temperature is cooled to below 80 ° C and discharged.

[0053] 2) Mix the above-mentioned mixture, polypropylene, compatibilizer, and antioxidant with a high-speed mixer at 100°C to uniformly discharge the material, extrude and granulate through a twin-screw extruder, and set the temperature of the twin-screw extruder to 150- 220 ℃, the screw speed is 100-200rpm, after water cooling and air drying, the highly filled polyolefin composite film masterbatch is prepared.

[0054] The masterbatch prepared in this example can be directly used for extrusion blow molding, extrusion tape casting and extrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com