Plastic Biaxial Tensile Grid Mesh Clamp

A technology of two-way stretching and grid mesh, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of plastic sheet unclamping, inability to adapt to products of different thicknesses, complex structure, etc., and achieve the effect of convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in detail below with reference to the drawings and specific embodiments.

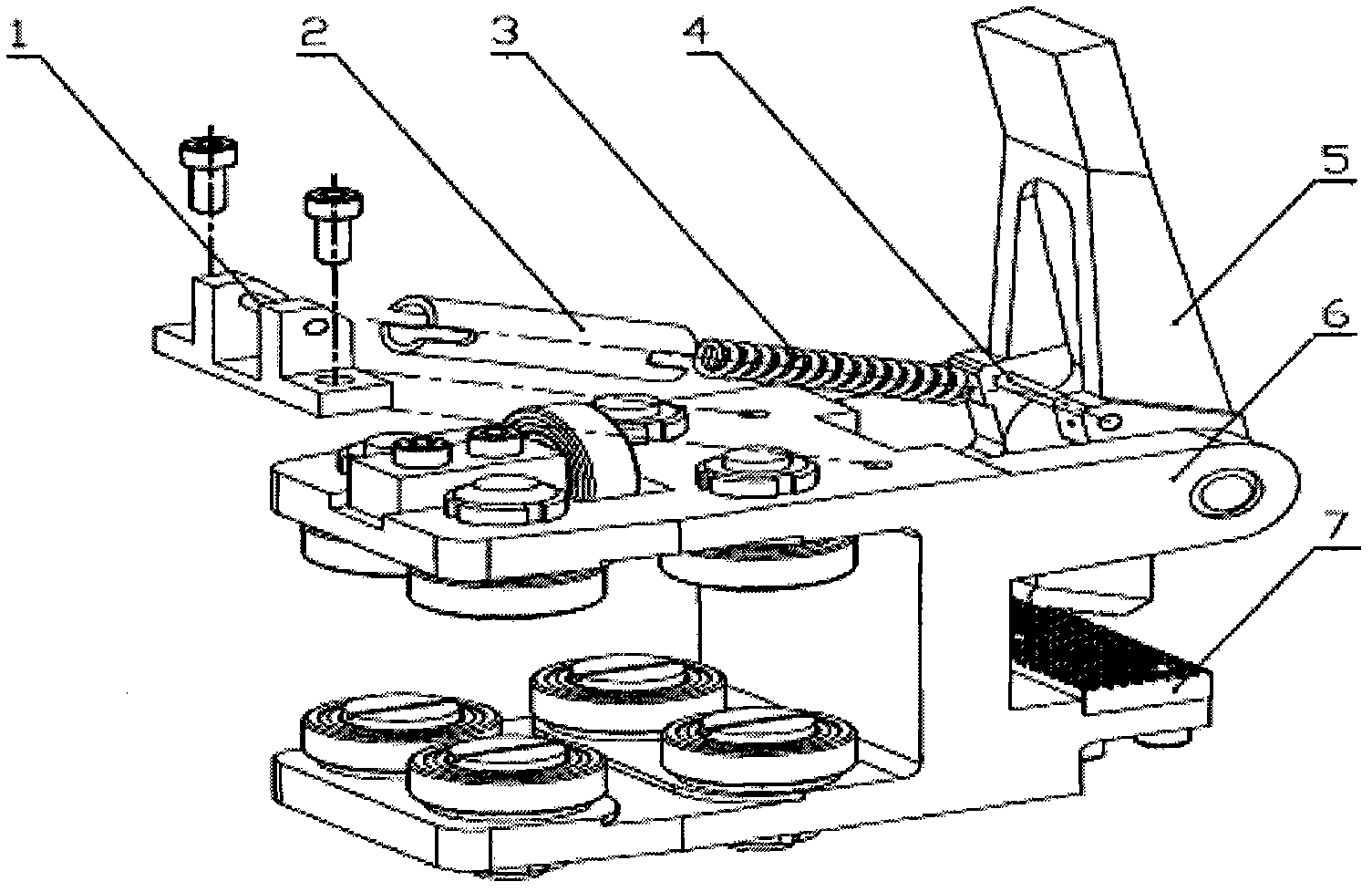

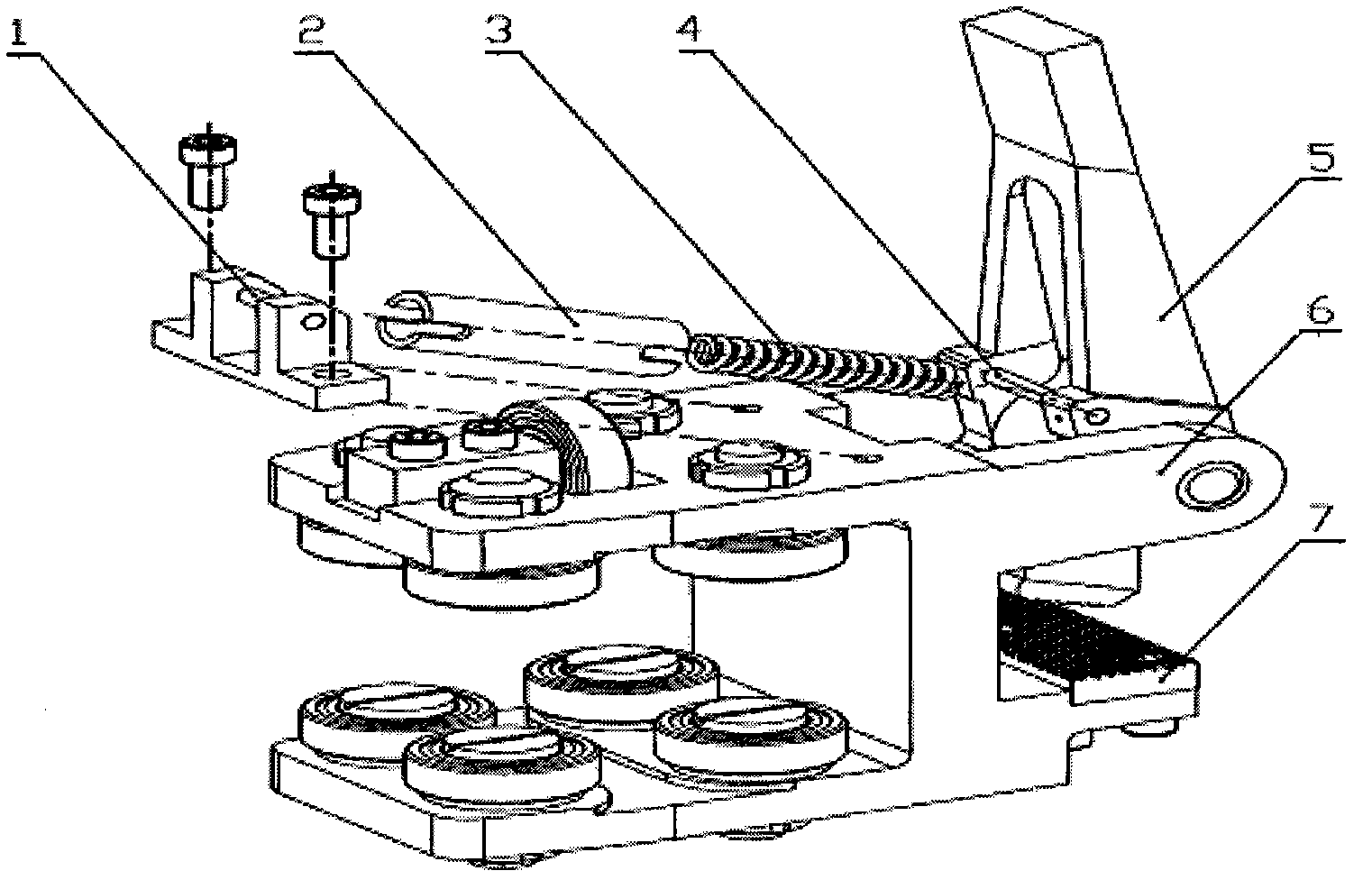

[0009] in figure 1 In, the plastic two-way stretch grid mesh fixture, including the clamp body 6, the high temperature compression spring 3, the spring sleeve 2, the upper clamp 5, the lower clamp 7, the cylindrical pin 1 and the cylindrical pin 4, the upper part of the clamp body 6 is equipped with a cylindrical pin 1. The middle part of the upper jaw is equipped with a cylindrical pin 4, a spring sleeve 2 is installed between the cylindrical pin 1 and the cylindrical pin 4, and a high temperature resistant compression spring 3 is installed in the spring sleeve 2.

[0010] The jaw faces of the upper pliers 5 and the lower pliers 7 are stamped into fish-scale inverted teeth.

[0011] The specific working principle. When clamping the plastic sheet, use the clamp to gently press the upper pliers 5, the upper pliers 5 of the clamp will automatically close with the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com