Wire drawing machine

A wire drawing machine and frame technology, applied in the field of plastic processing machinery, can solve problems affecting production progress, drawing ratio errors, and high labor intensity, and achieve reduced labor intensity, reduced production costs and use costs, and high transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

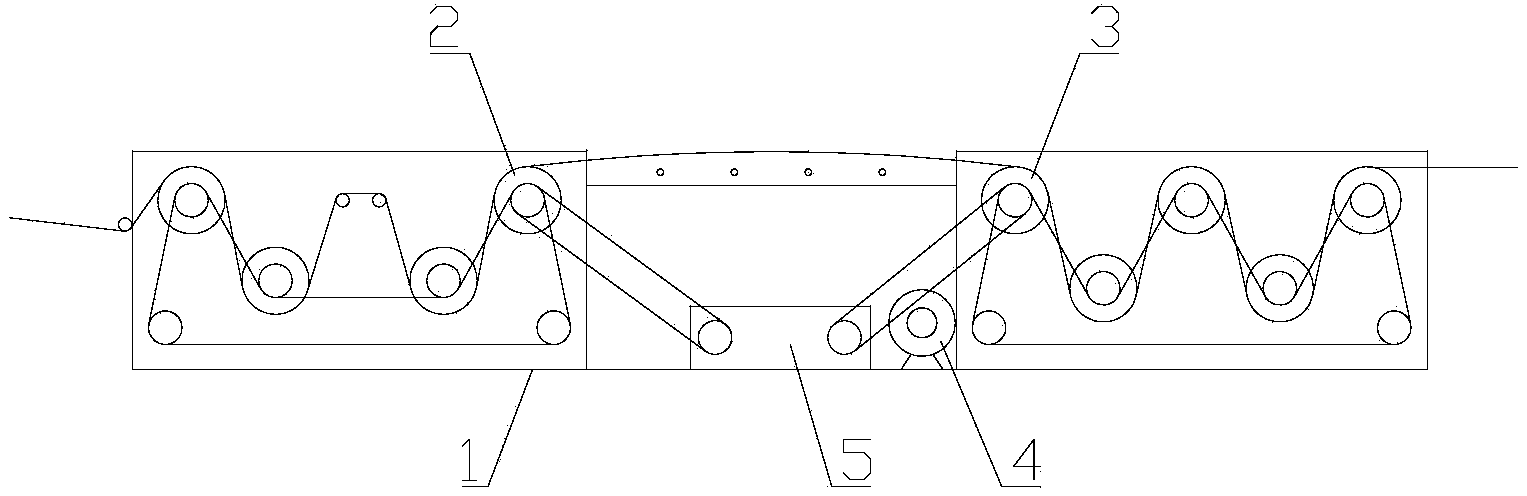

[0028] Such as figure 1 As shown, the present embodiment provides a wire drawing machine, including a frame 1, a traction roller 2, a stretching roller 3, a drive motor 4 and a gearbox 5, and the traction roller 2 and the stretching roller 3 are all positioned on the machine. On frame 1, after the extruder extrudes the plastic filament, it is pulled forward by the pulling roller 2 after being cooled, and stretched by the drawing roller 3 after heating. 3. When the rotating speed is slow, the plastic filament can be elongated and thinned to increase the strength.

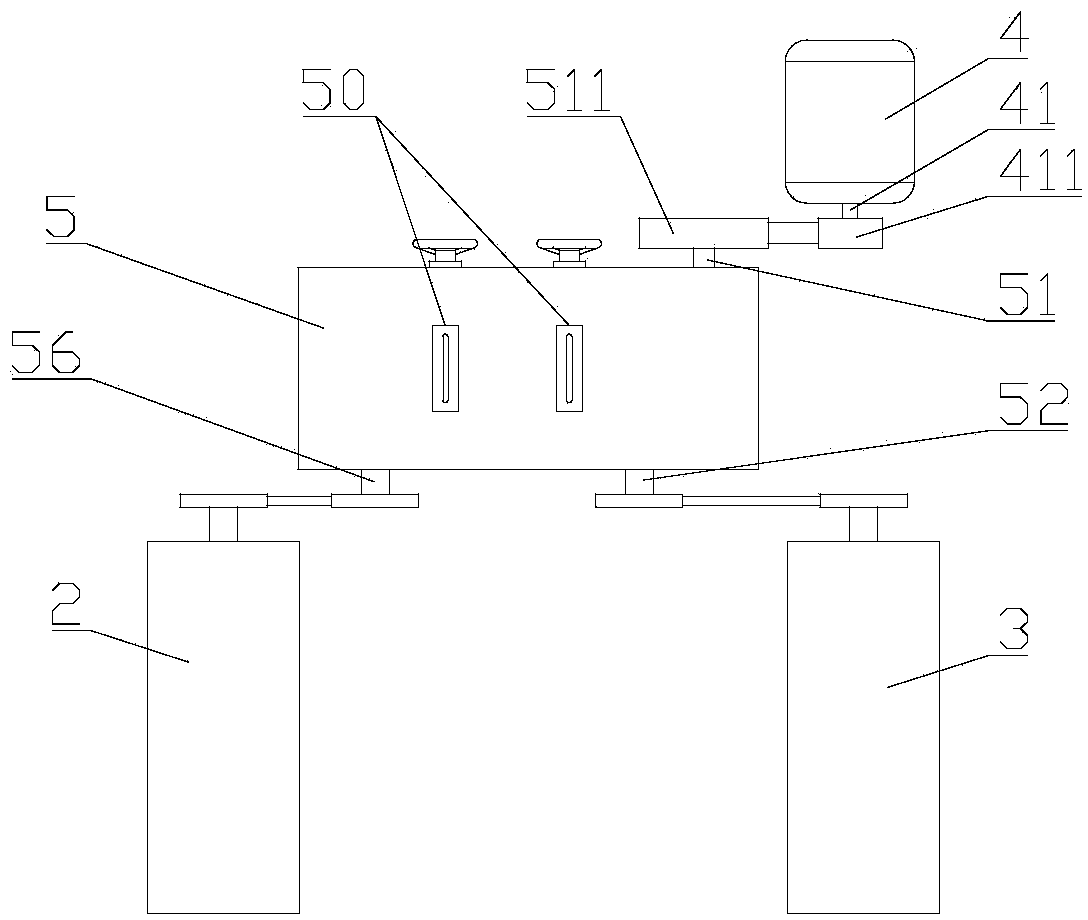

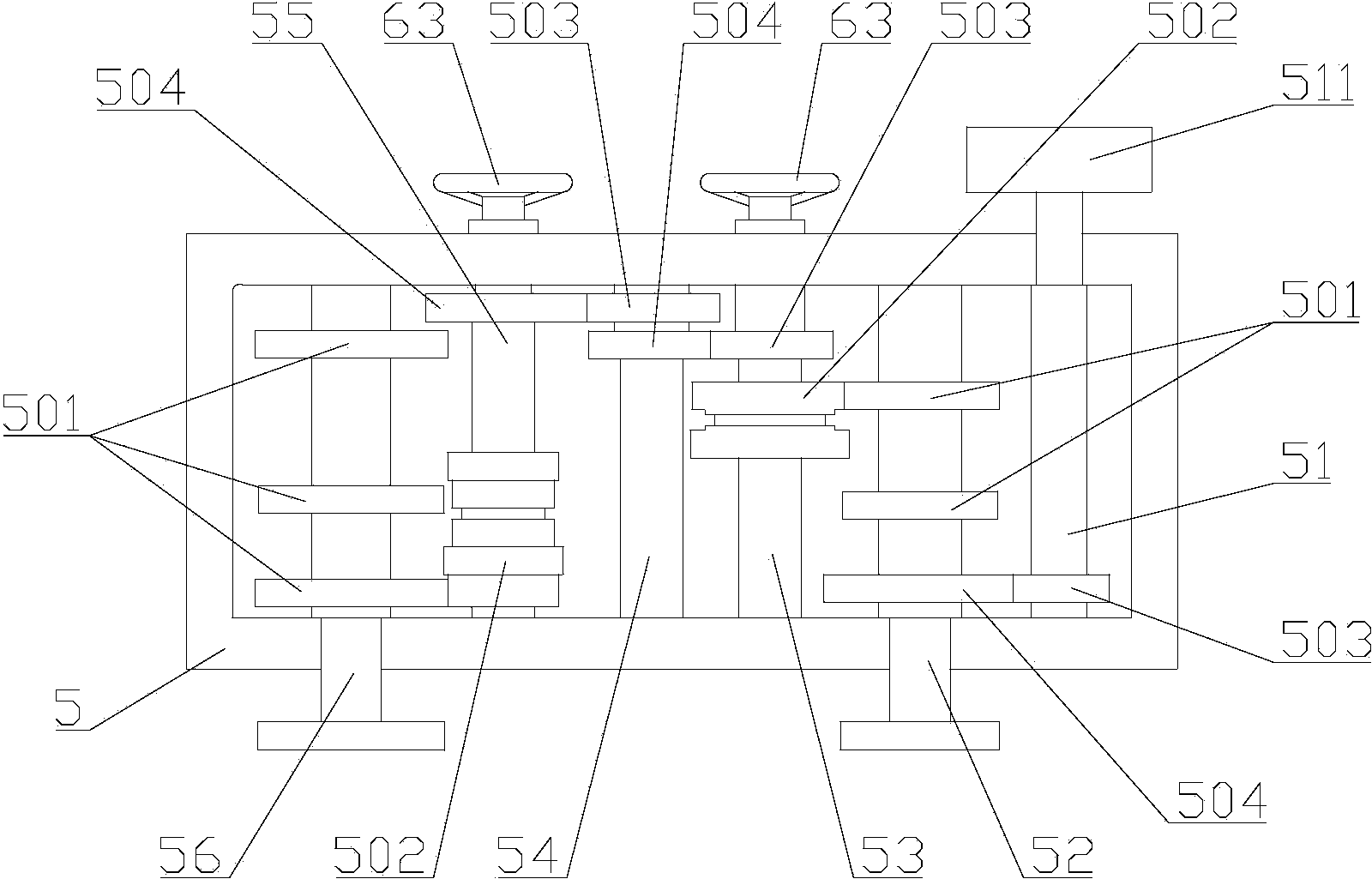

[0029] Combine below figure 2 and image 3 To illustrate the specific structure of the gearbox 5.

[0030] In the gearbox 5, an input shaft 51, a first output shaft 52, a first transition shaft 53, a second transition shaft 54, a third transition shaft 55 and a second output shaft 56 are sequentially arranged in parallel, and the driving motor 4 and the input shaft 51 drive The connection, preferably gear meshin...

Embodiment 2

[0038] See Figure 6 , The difference between this embodiment and Embodiment 1 is mainly in two points: First, the input shaft 51 and the first output shaft 52 are coaxial structures. In this embodiment, "coaxial structure" means that the input shaft 51 and the first output shaft 52 are completely composed of one shaft, one end of which is connected to the drive motor, and the other end is connected to the stretching roller. barrel drive connection. In this way, the transmission structure between the input shaft 51 and the first output shaft 52 can be omitted, and the first output shaft 52 can obtain a preset rotating speed through the input shaft 51 and the drive motor to reduce speed; secondly, on the second transition shaft Only one transition gear 505 is provided, the first transition shaft 53 is provided with a driving gear 503 meshing with the transition gear 505 on the second transition shaft 54, and the third transition shaft 55 is provided with a transition gear 503 ...

Embodiment 3

[0041] See Figure 7 , the difference between this embodiment and the first embodiment is that the slip gear 502 originally arranged on the third transition shaft 55 in the first embodiment is set on the second output shaft 56, while the first The three transmission gears 501 on the second output shaft 56 are arranged on the third transition shaft 55, and the principle of shifting is the same as that of the first embodiment, so it will not be repeated here.

[0042] The relationship between the input shaft 51 and the first output shaft 52 in this embodiment can also adopt the "coaxial structure" mentioned in the second embodiment.

[0043] Similar to this embodiment, the slip gear 502 on the first transition shaft 53 and the two transmission gears 501 on the first output shaft 52 can also be exchanged, that is, the two transmission gears 501 are located in the first transition On the shaft 53 , a slip gear 502 is provided on the first output shaft 52 . Therefore in addition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com