Self-shaping device of film blowing machine set of thermal shrinkage films

A technology of heat shrinkable film and setting device, which is applied in the field of plastic processing machinery, can solve problems such as film deformation, and achieve the effects of balanced shrinkage performance, high shrinkage initiation temperature, and low natural shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

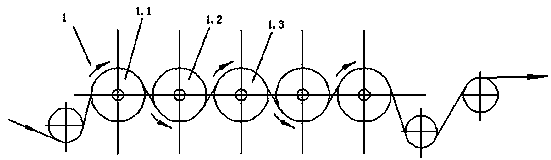

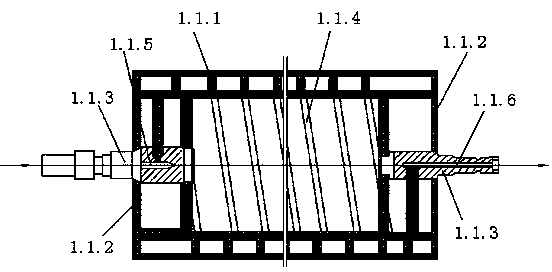

[0019] The self-setting device of the heat-shrinkable film blowing machine includes a frame, and setting rollers 1 installed side by side on the frame. There are at least five setting rollers 1, and the second one from left to right is a driven roller 1.2. The rest are driving rollers 1.1, 1.3, 1.4..., driving rollers 1.1, 1.3, 1.4... are driven by gears meshed with motors, and the shaping roller 1 includes a roller body 1.1.1 and two side sealing end plates 1.1.2 , the end plates 1.1.2 on both sides are respectively provided with a water inlet hole 1.1.5 and a water outlet hole 1.1.6, which communicate with the spiral groove 1.1.4 provided inside the roller body 1.1.1 to form a spiral flow channel. The water inlet 1.1.5 and the water outlet 1.1.6 are connected to the shaft head 1.1.3 with a central hole, and the shaft head 1.1.3 is connected to the rotary joint and the hose.

[0020] The shaping roller 1 is the roller body 1.1.1 is Q235 steel plate, the surface is plated with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com