Multifunctional feeding device for extruder

A feeding device and multi-functional technology, applied in the field of feeding devices and multi-functional feeding devices for extruders, can solve the problems of inapplicability, inconvenient material addition, high labor intensity, etc., and achieve the effect of simple structure and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

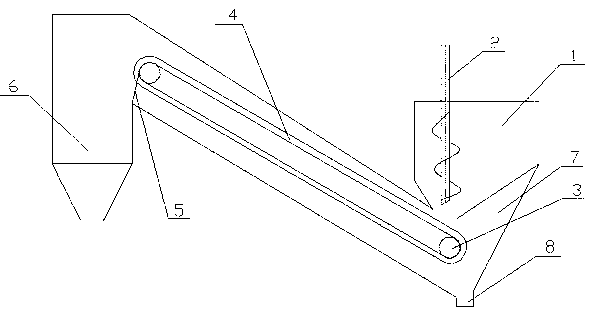

[0013] Such as figure 1 The multifunctional feeding device for the extruder shown includes a storage bin 1, a conveyor belt 4, and a hopper 6. A screw 2 is arranged inside the storage bin 1, and the screw rod 2 is at the outlet of the storage bin 1. Directly above, the conveyor belt 4 is supported by two pulleys 3, one end of which is arranged below the outlet of the storage bin 1, and the other end is arranged obliquely above the hopper 6, and a bulk material belt 7 is arranged around the conveyor belt 4 , used to receive the materials scattered outside during the conveying process, and a discharge port 8 is set under the bulk material belt 7 .

[0014] The conveyor belt 4 is composed of two layers, the lower layer is made of ordinary conveyor belt material, and the upper layer is adhered with a layer of stainless steel.

[0015] The outer edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com