Four-screw mixing extruder

A technology of extruder and screw, which is applied in the field of new style machines, can solve the problems of high energy consumption, low output, environmental pollution, etc., and achieve the effect of increasing plasticizing and dispersing capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

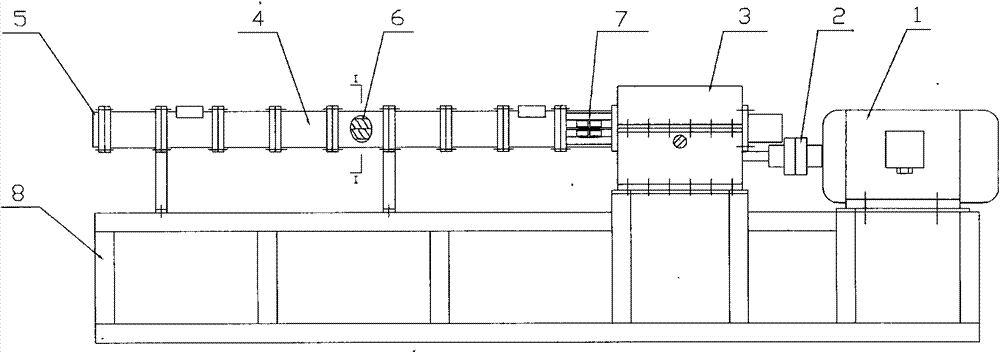

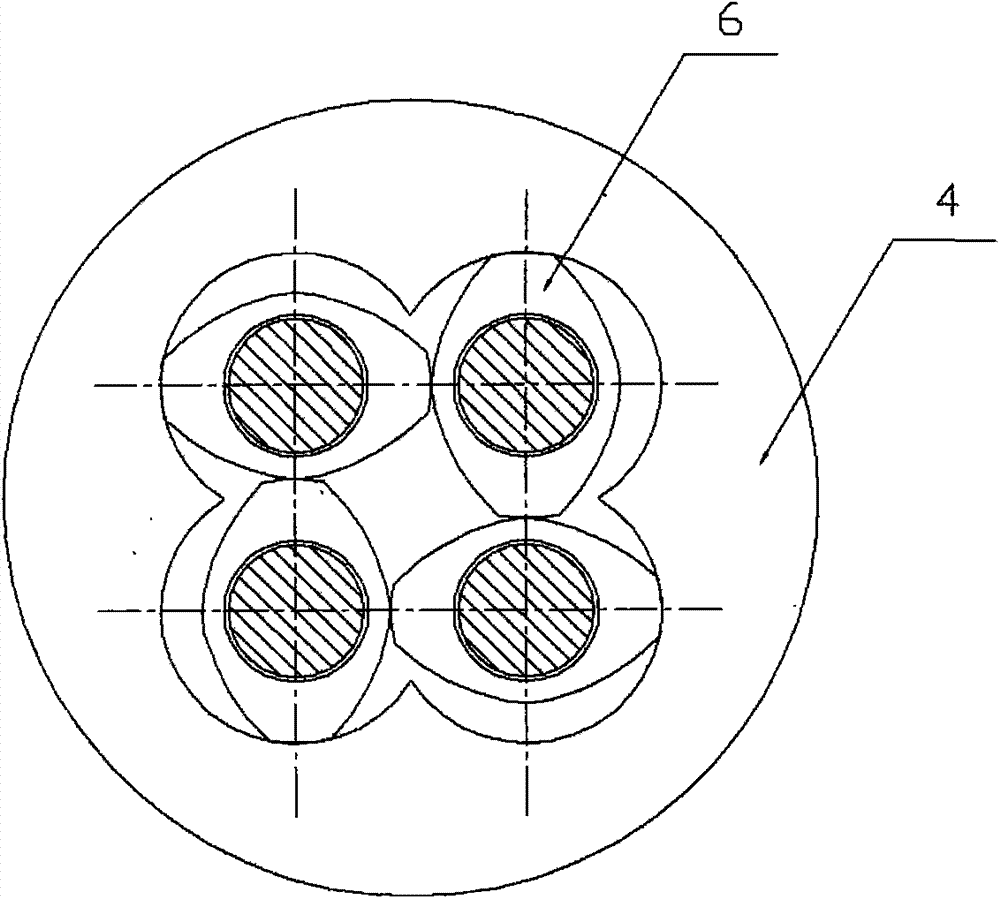

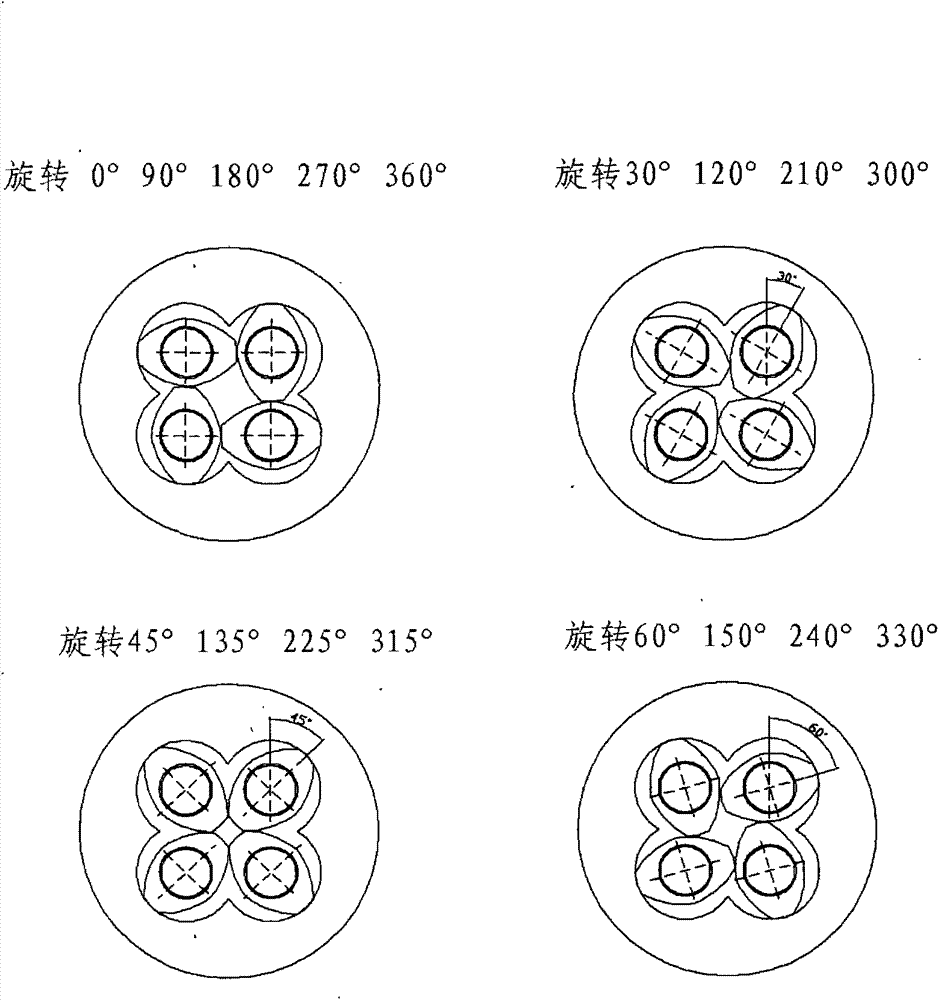

[0014] see figure 1 with figure 2 , the four-screw banbury extruder of the present invention comprises a motor 1, a shaft coupling 2, a speed change gearbox 3, a group of closed cylinders 4, a machine head 5, a group of four screws 6 and a machine rack 8.

[0015] see Figure 4 with Figure 5 , The transmission gearbox 3 of the present invention includes an input shaft 10 , an intermediate shaft 20 and a first output shaft 30 , a second output shaft 40 , a third output shaft 50 and a fourth output shaft 60 .

[0016] The input shaft is supported in the casing (not shown) of the transmission gearbox 3 through two bearings 11, and a driving pinion 12 is fixedly installed on the input shaft 10.

[0017] The countershaft 20 is supported in the case of the transmission gearbox through two bearings 21, and a driven bull gear 22 and two identical countershaft first pinion gears 23 and second countershaft pinion gears 24 are fixedly installed on the countershaft 20 , the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com