Low floating fiber glass fiber enhanced flame resistant polypropylene material

A flame-retardant polypropylene and low-floating fiber technology, which is applied in the field of low-floating fiber glass fiber reinforced flame-retardant polypropylene materials, can solve the problems of low strength of weld lines, poor dispersion of flame retardants, and influence on surface appearance, etc., to achieve increased plasticity and disperse, improve the exhaust effect, improve the effect of poor appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

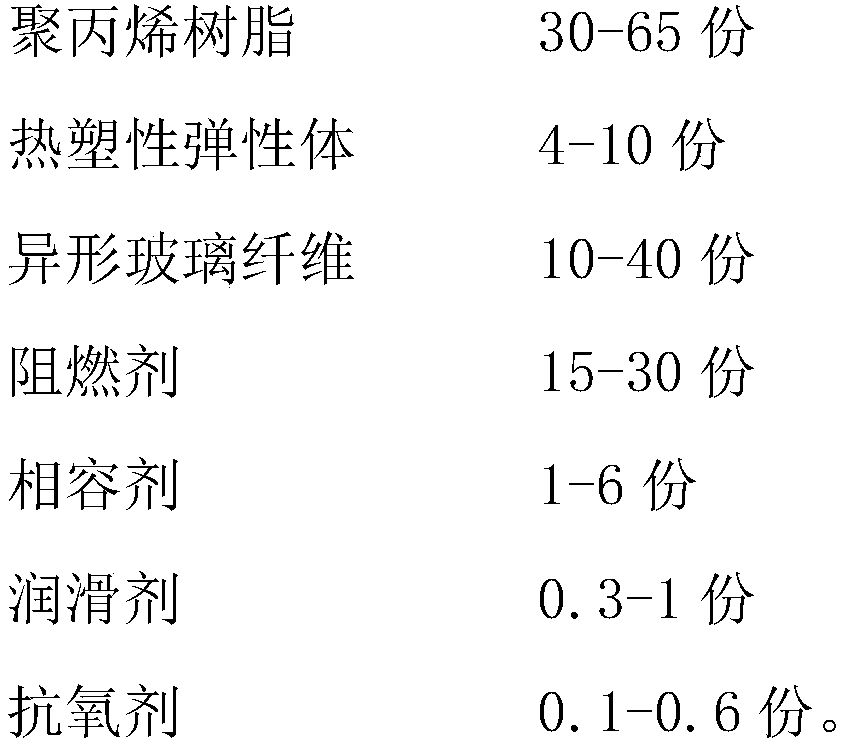

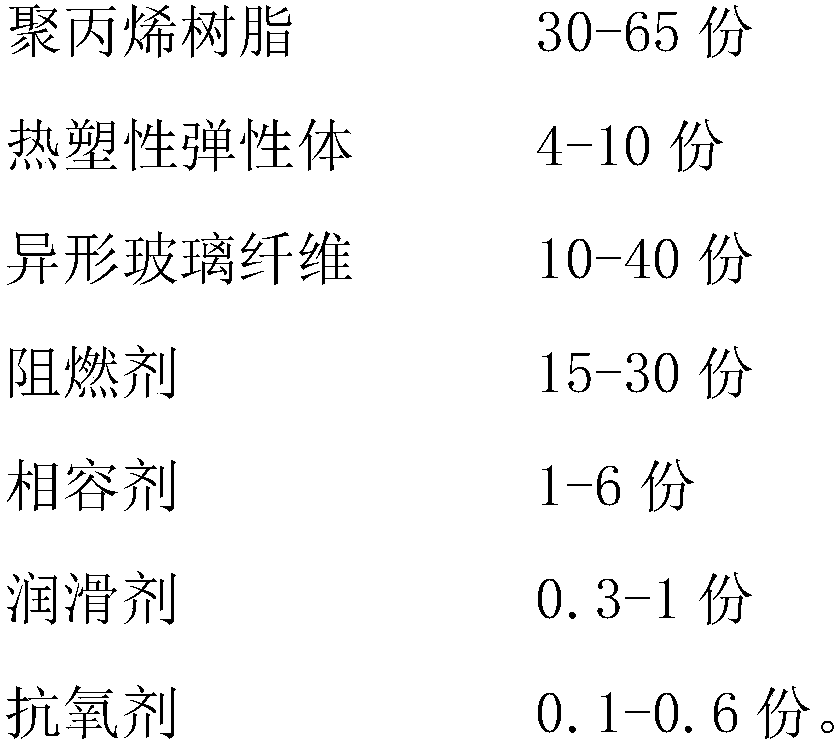

[0020] A low-floating glass fiber reinforced flame-retardant polypropylene material in this embodiment includes the following components in parts by weight: 40 parts of polypropylene resin, 6 parts of thermoplastic elastomer, 30 parts of special-shaped glass fiber, and 20 parts of flame retardant part, 3 parts of compatibilizer, 0.6 part of lubricant and 0.4 part of antioxidant.

[0021] Among them, the polypropylene resin is block copolymerized PP with a melt index of 80g / 10min; the thermoplastic elastomer is POE; the special-shaped glass fiber is chopped glass fiber, the cross-section of the special-shaped glass fiber is elliptical, and the special shape ratio is 4; the flame retardant is A mixture of decabromodiphenylethane and antimony trioxide at a mass ratio of 3:1; the compatibilizer is PP-g-MAH; the lubricant is EBS; the antioxidant is antioxidant 1010 and antioxidant 168 by mass Mixture ratio 1:2.

[0022] A method for preparing the above-mentioned low-floating fiber...

Embodiment 2

[0024] A low-float glass fiber reinforced flame-retardant polypropylene material in this embodiment comprises the following components in parts by weight: 45 parts of polypropylene resin, 4 parts of thermoplastic elastomer, 20 parts of special-shaped glass fiber, and 25 parts of flame retardant 5 parts, 5 parts of compatibilizer, 0.5 parts of lubricant and 0.5 parts of antioxidant.

[0025] Among them, the polypropylene resin is block copolymerized PP with a melt index of 100g / 10min; the thermoplastic elastomer is EPDM; the special-shaped glass fiber is chopped glass fiber, the cross-section of the special-shaped glass fiber is elliptical, and the special shape ratio is 5; the flame retardant is A mixture of decabromodiphenylethane and antimony trioxide at a mass ratio of 4:1; the compatibilizer is POE-g-MAH; the lubricant is oxidized polyethylene wax; the antioxidant is antioxidant 1076, antioxidant DSTP is a mixture of 1:1 by mass ratio.

[0026] A method for preparing the ...

Embodiment 3

[0028] A low-floating glass fiber reinforced flame-retardant polypropylene material in this embodiment includes the following components in parts by weight: 35.6 parts of polypropylene resin, 8 parts of thermoplastic elastomer, 25 parts of special-shaped glass fiber, and 28 parts of flame retardant 4 parts, 4 parts of compatibilizer, 0.8 part of lubricant and 0.6 part of antioxidant.

[0029] Among them, the polypropylene resin is homopolymer PP with a melt index of 65g / 10min; the thermoplastic elastomer is EVA; A mixture of brominated diphenylethane and antimony trioxide in a mass ratio of 4:1; the compatibilizer is PE-g-MAH; the lubricant is stearic acid; the antioxidant is antioxidant 1010, antioxidant 168 and DSTP is a mixture of 1:1:1 by mass.

[0030] A method for preparing the above-mentioned low-floating fiber glass fiber reinforced flame-retardant polypropylene material, comprising the following steps: firstly mixing polypropylene resin, thermoplastic elastomer, flam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com