Sponge foaming rubber for car door sealing strip and preparation method thereof, car door sealing strip and preparation method thereof

A technology of sealing strip sponge and foam rubber, which is applied to sealing devices, engine sealing, mechanical equipment, etc., can solve the problems of affecting the aesthetics of sealing strip products, low quality of sealing strip products, and unfavorable lightweight design. Effects of lightweight design, good compounding processability, and good extrusion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

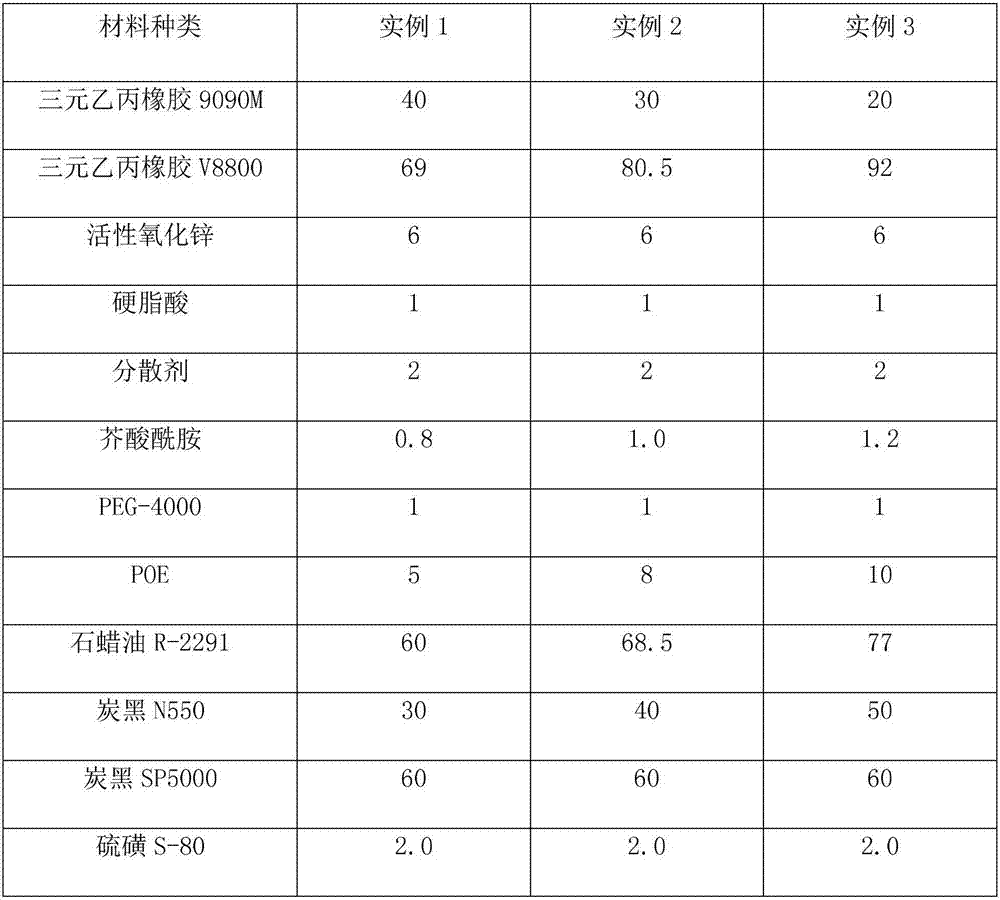

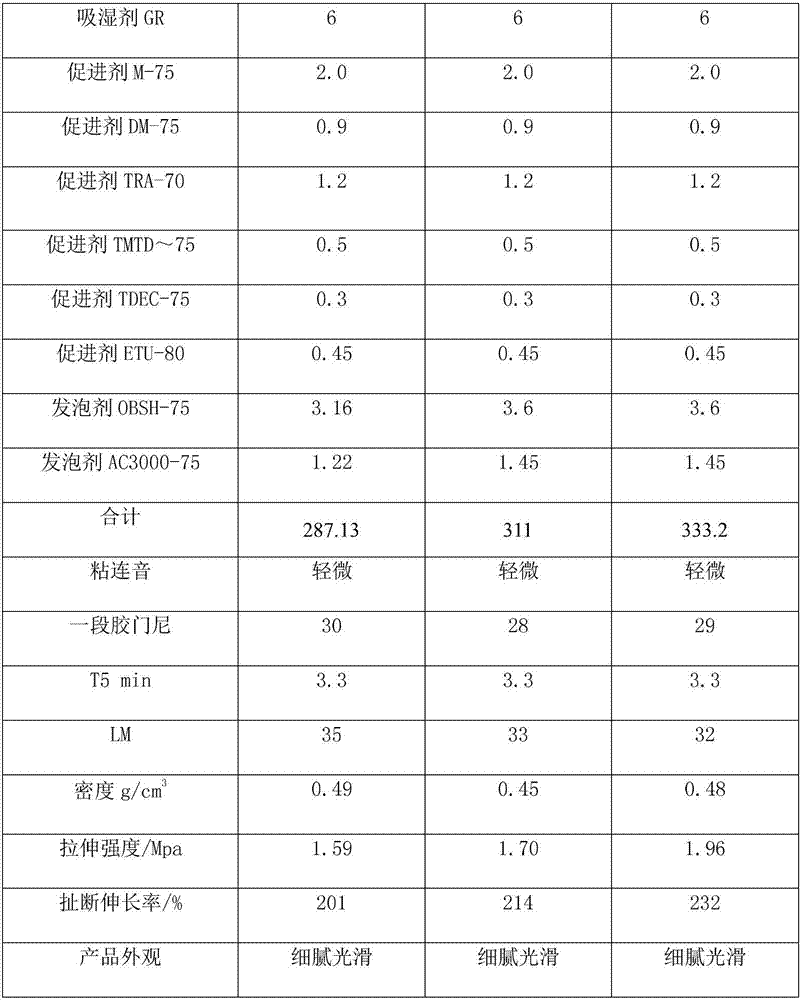

[0045] This embodiment relates to a sponge foam rubber material for car door seals, which is specifically made of the following components by weight ratio: EPDM 9090M: 20-40 parts, EPDM V8800: 69-92 active zinc oxide: 5-7 parts, stearic acid: 1-2 parts, dispersant: 1-3 parts, erucamide: 0.8-1.4 parts, PEG-4000: 1-2 parts, POE: 5-2 parts 10 parts, paraffin oil R-2291: 60-77 parts, carbon black N550: 30-50 parts, carbon black SP5000: 50-70 parts, sulfur S-80: 1.5-2.5 parts, hygroscopic agent GR: 6-10 parts , accelerator: 3-6.4 parts, foaming agent OBSH-75: 3-3.6 parts, foaming agent AC3000-75: 1.1-1.5 parts.

[0046] Among them, the accelerator includes the following components by weight: accelerator M-75: 1.5-2.5 parts, accelerator DM-75: 0.3-0.9 parts, accelerator TRA-70: 0.5-1.5 parts, accelerator TMTD- 75: 0.2-0.6 parts, Accelerator TDEC-75: 0.2-0.4 parts, Accelerator ETU-80: 0.3-0.5 parts.

[0047] When preparing the foamed rubber material for door seal strips in this emb...

Embodiment 2

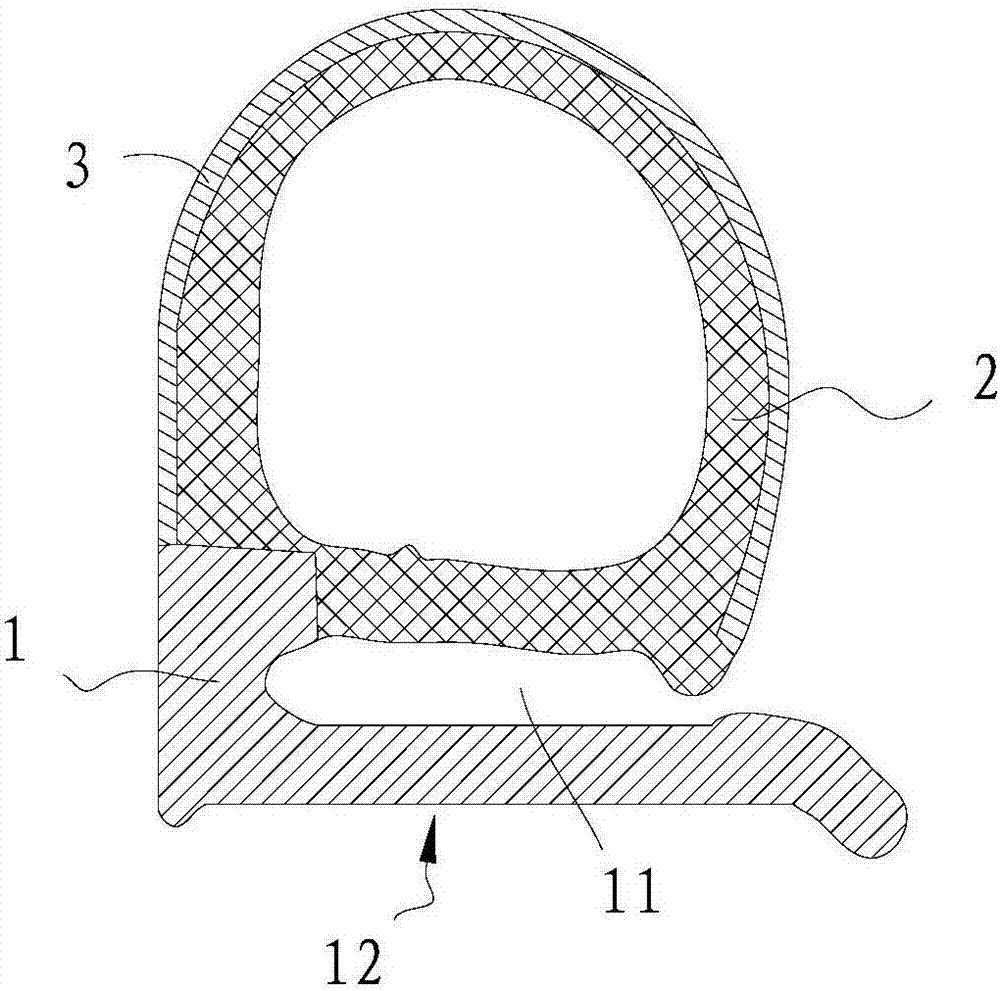

[0054] This embodiment relates to a kind of door sealing strip, such as figure 1 As shown in , it includes a mounting part 1 made of compact glue, and a tape bonding surface 12 is formed on one side of the mounting part 1, and is integrally fixed on the other side of the mounting part 1 relative to the tape bonding surface 12. There is a sealing part 2 made of the foamed rubber material of the door weather strip described in Embodiment 1, and a decorative part 3 made of compact rubber is also covered on the outer surface of the sealing part 2 . In this embodiment, the mounting part 1 is also provided with a bayonet 11 that opens to one side of the mounting part 1. The bayonet 11 can make the door guard The plate is inserted into the bayonet 11 to facilitate the stable arrangement of the sealing strip. In addition, in this embodiment, the thickness of the decorative part 3 covering the sealing part 2 is 0.2-0.4 mm, for example, it may be 0.3 mm.

[0055] The door sealing stri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com