Automatic feeding device for plastic processing machinery

A processing machine and automatic feeding technology, which is applied in the field of plastic processing and manufacturing, can solve the problems that the liquid color masterbatch cannot be poured clean, will pollute the subsequent conveying pipeline, and affect the coloring of plastics, so as to save labor and time and not pollute the working environment , The effect of reducing waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

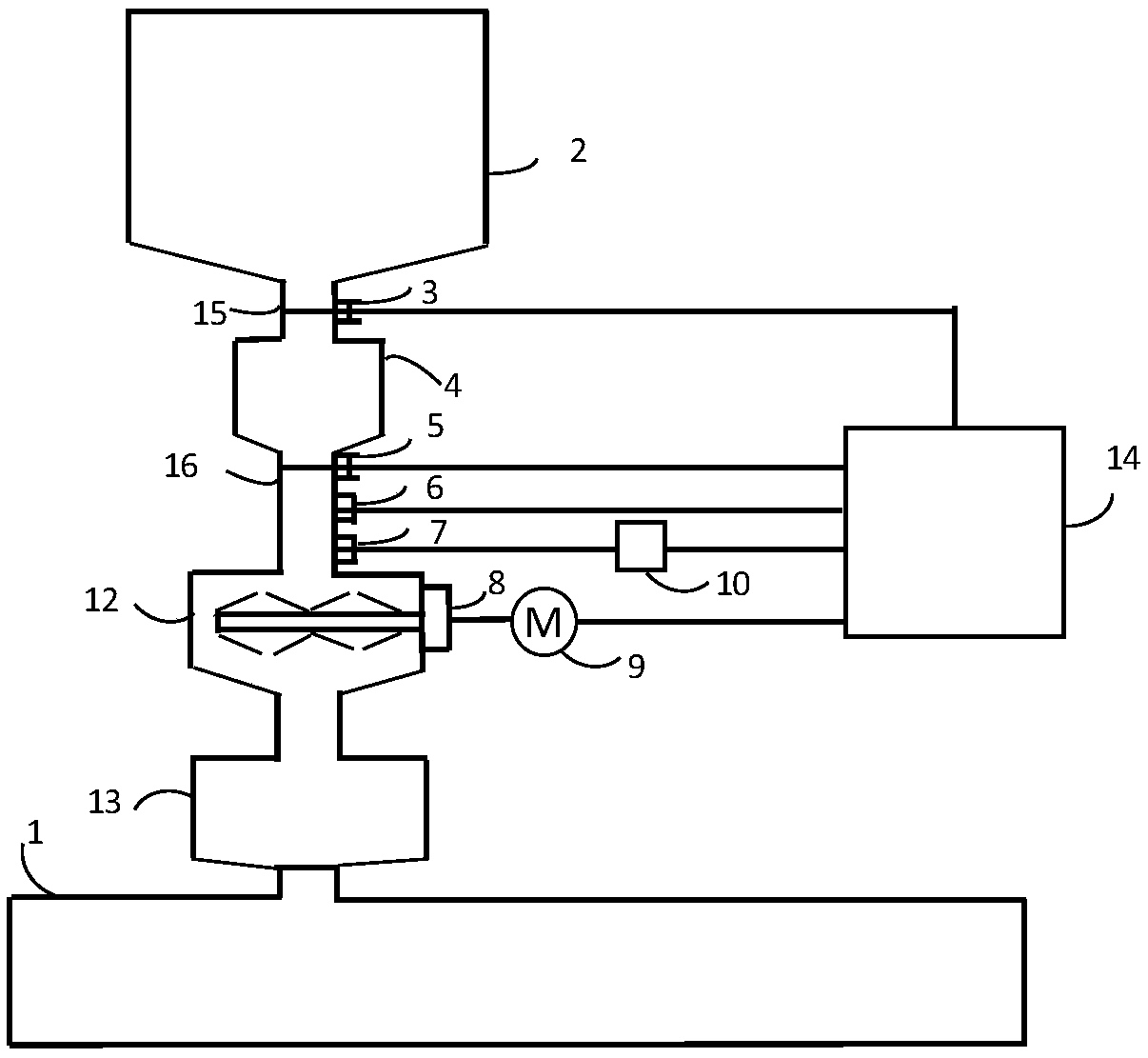

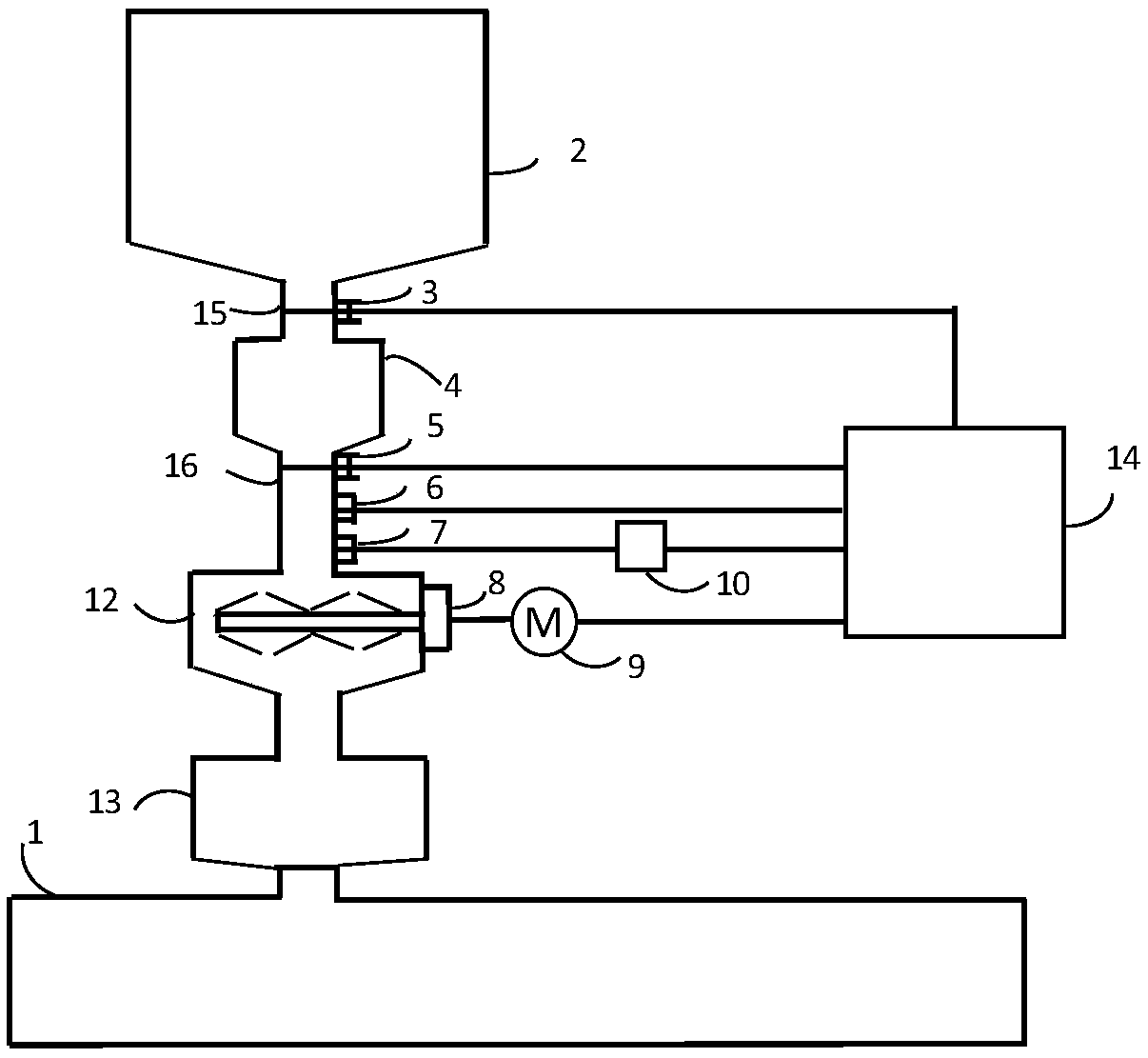

[0029] figure 1 It is an automatic feeding device for a plastic processing machine, including a plastic raw material barrel 2, a fixed volume barrel 4, a mixer 12, a liquid color masterbatch machine 10 and a control system, and the plastic raw material barrel 2 is located in the fixed volume barrel 4 Above, the fixed volume barrel 4 is positioned above the mixer 12 again, the bottom of the plastic raw material barrel 2 is connected with the fixed volume barrel 4 through a pipeline, the bottom of the fixed volume barrel 4 is connected with the mixer 12 through a pipeline, and the plastic raw material barrel 2 is connected with the mixer 12 through a pipeline. An upper valve 15 is arranged on the pipeline between the fixed-volume barrels 4, a lower valve 16 is arranged on the pipeline between the fixed-volume barrel 4 and the mixer 12, and a liquid masterbatch inlet 7 is arranged above the mixer 12. The automatic addition of the liquid color masterbatch is completed by the liqui...

Embodiment 2

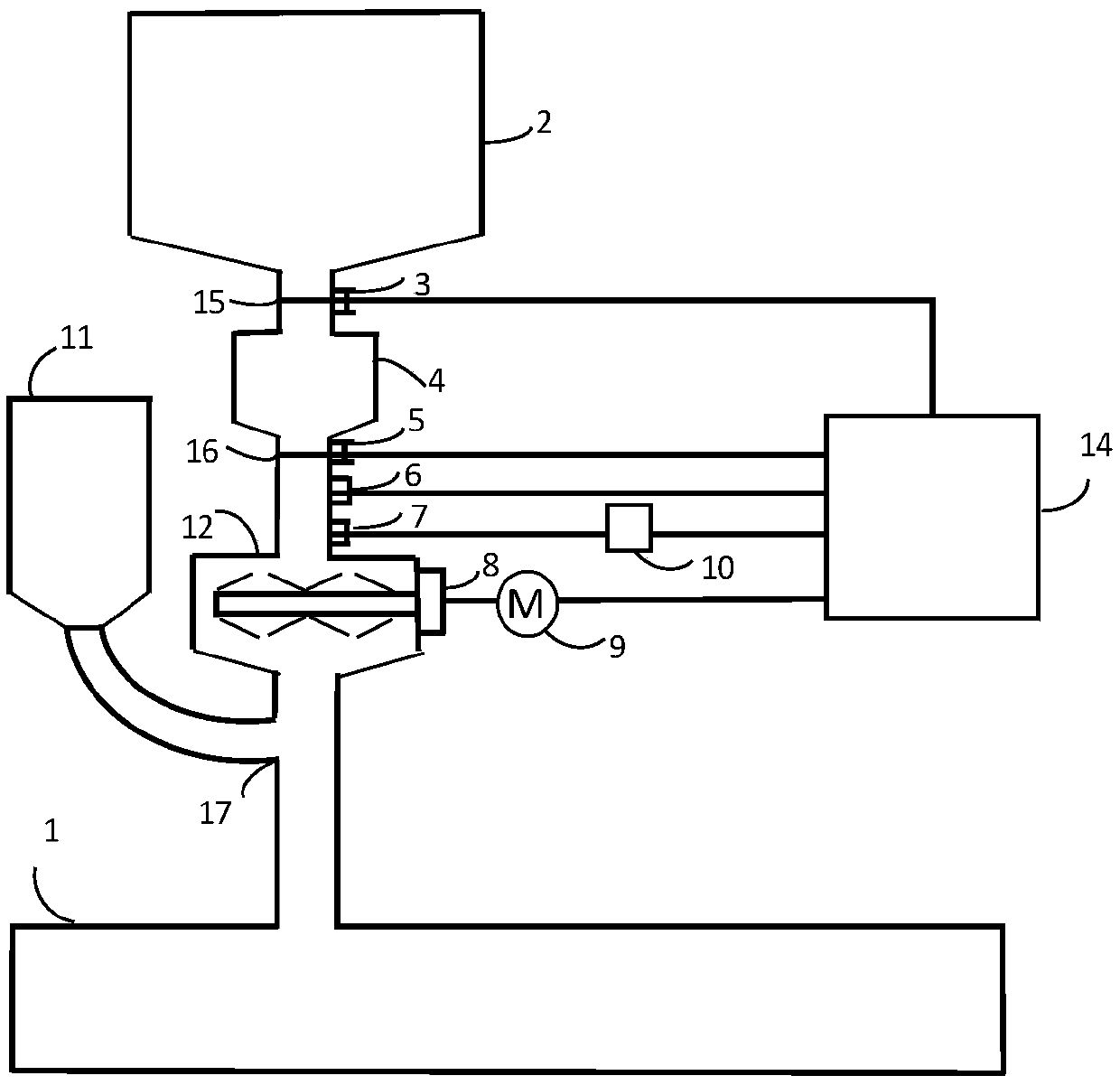

[0041] figure 2 It is an automatic feeding device for a plastic processing machine, including a plastic raw material barrel 2, a fixed volume barrel 4, a mixer 12, a liquid color masterbatch machine 10 and a control system, and the plastic raw material barrel 2 is located in the fixed volume barrel 4 Above, the fixed volume barrel 4 is positioned above the mixer 12 again, the bottom of the plastic raw material barrel 2 is connected with the fixed volume barrel 4 through a pipeline, the bottom of the fixed volume barrel 4 is connected with the mixer 12 through a pipeline, and the plastic raw material barrel 2 is connected with the mixer 12 through a pipeline. An upper valve 15 is arranged on the pipeline between the fixed-volume barrels 4, a lower valve 16 is arranged on the pipeline between the fixed-volume barrel 4 and the mixer 12, and a liquid masterbatch inlet 7 is arranged above the mixer 12. The automatic addition of the liquid color masterbatch is completed by the liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com