Technology for machining spreader plate of hot runner system

A processing technology and manifold technology, which is applied in the field of manifold processing technology, can solve problems such as the smoothness of the runner hole of the manifold and the difficulty of color change, and achieve the effects of high hardness, avoiding easy glue leakage, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

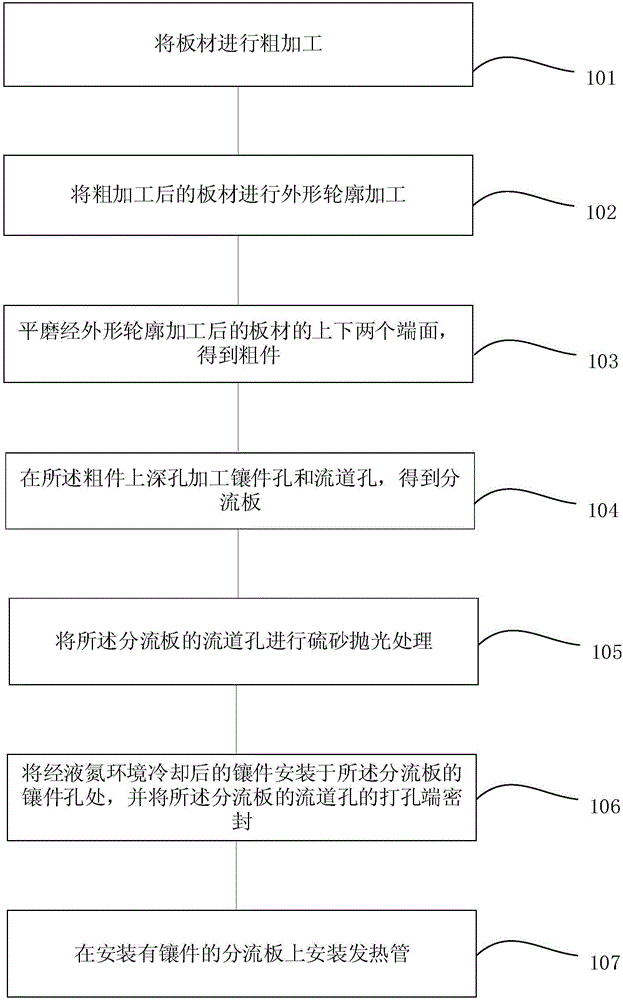

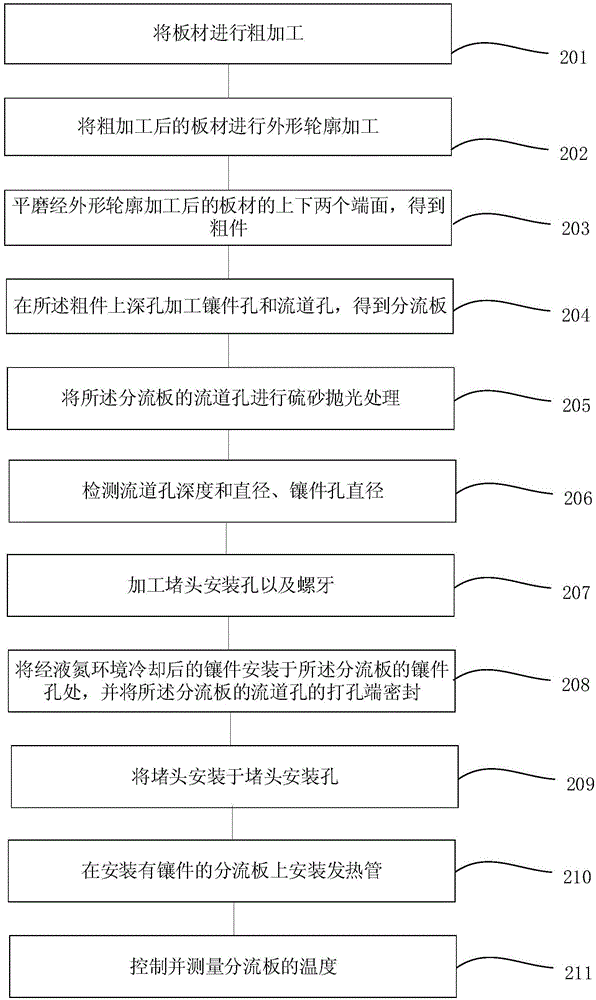

[0031] An embodiment of the present invention proposes a process for processing a distributor plate of a hot runner system. refer to figure 1 , the process includes the following steps:

[0032] Step 101, performing rough machining on the plate.

[0033] Specifically, the heat pipe groove, the outlet groove, the main nozzle, the screw hole, the temperature-sensing line hole, the glue inlet and the glue outlet are processed by the CNC center, leaving a margin of 0.3mm.

[0034] Step 102 , processing the outline of the roughly machined board.

[0035] Specifically, the outline of the roughly processed plate is processed by water cutting, so that the outline of the plate is the same as the outline of the target splitter plate with a certa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com