Highly effective plastic-steel belt processing device

A processing device and a technology for plastic steel belts, which are applied to belts, other household appliances, household appliances, etc., can solve the problems of high production cost, small production capacity, and large floor space, and achieve the effect of reducing production cost and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

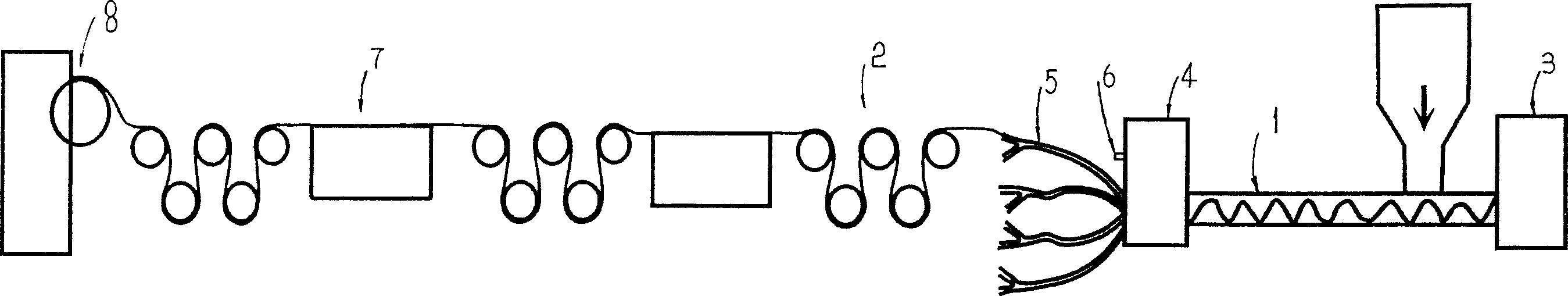

[0010] refer to figure 1 As shown, a high-efficiency plastic-steel strip processing device of the present invention is composed of a screw extruding device 1, a stretching device 2, a driving device 3 connected to the screw extruding device 1, a shaping device 7, and a winding device 8. The extrusion device 1 and the stretching device 2 are also connected in turn with a pressure-stabilizing cylinder 4 and a distribution mold 5. The feed port of the pressure-stabilizing cylinder 4 is connected with the outlet of the screw extrusion device 1, and the output of the pressure-stabilizing cylinder 4 The mouth is connected with the feeding port of the material distribution mold 5, and the material distribution mold 5 is provided with eight discharge ports; the pressure stabilizing cylinder 4 is provided with a pressure sensor 6 that controls the output speed of the drive device 3; the material distribution pipeline in the material distribution mold 5 Adopt arc shape and arrange symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com