Batching device for uniformly and continuously measuring microscale solid powder and particles

A technology for solids and powders, which is applied in the field of continuous and uniform metering and batching devices for trace solid powders and particles, can solve the problems of poor feeding continuity and accuracy, impact on product quality and performance, and difficulty in ensuring accuracy. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

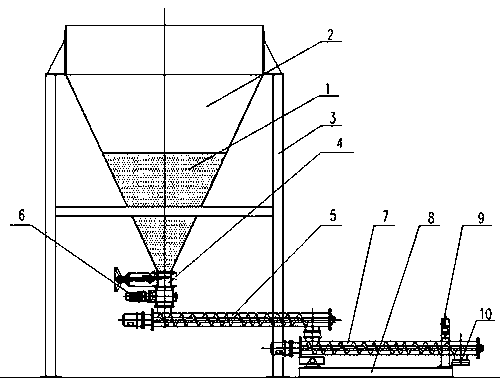

[0017] A device for continuously and uniformly metering and distributing trace amounts of solid powder and granules, the structure of which includes: a feeding box 2, the feeding box may be a conical feeding box, and the feeding box is fixed on the foundation by a support frame 3 There is a discharge pipe at the bottom of the feed box; the discharge pipe is provided with a screw gate 4; a variable speed screw conveyor 5, the feed port of the conveyor is connected with the discharge pipe of the feed box, and the conveyor consists of Driven by a variable frequency speed regulating motor; the frequency conversion speed regulating motor variable frequency controller 6 is fixed on the feeding tube of the feeding box. The frequency conversion speed regulating motor can be fixed on the feeding box feeding tube; The screw conveyor is fixed on the foundation by the support seat; the feed port of the conveyor is connected with the discharge port of the variable speed screw conveyor, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com