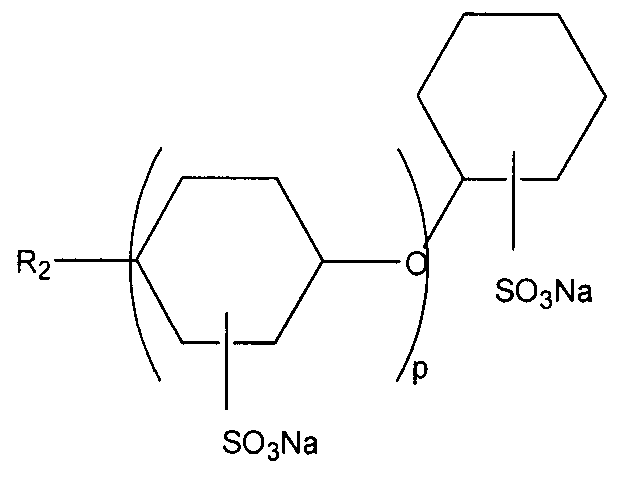

Preparation method of stable oil-in-water emulsion with high solid content

An oil-in-water emulsion, high solid content technology, applied in the field of fine chemicals, can solve the problems of narrow application range, one-sided process application range, poor stability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

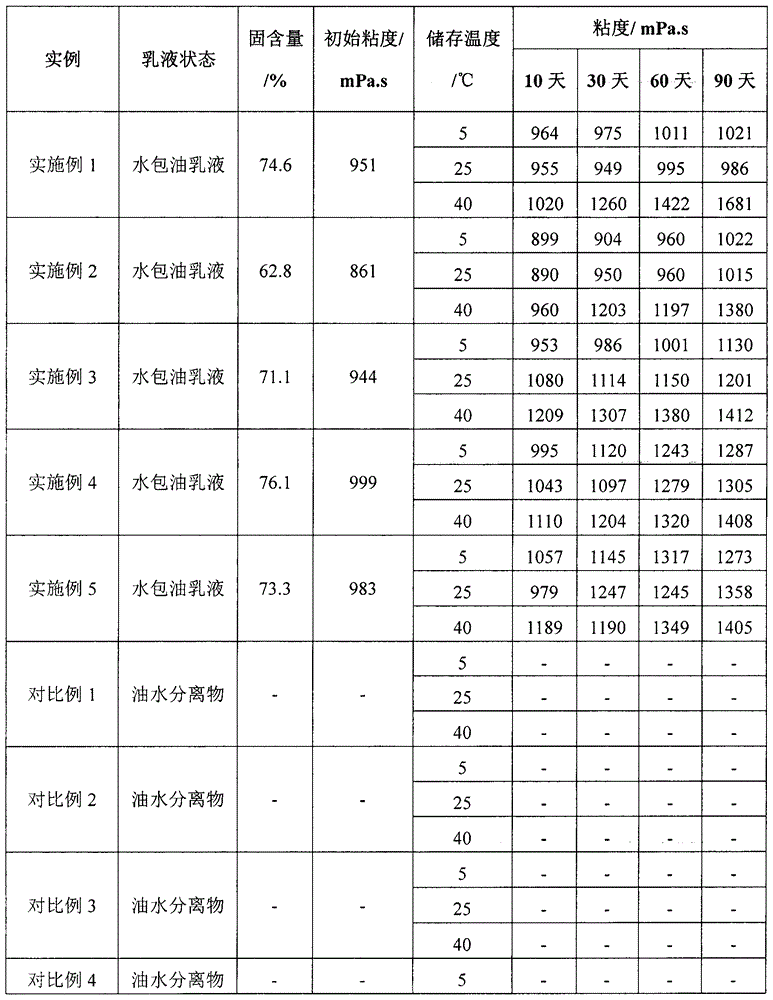

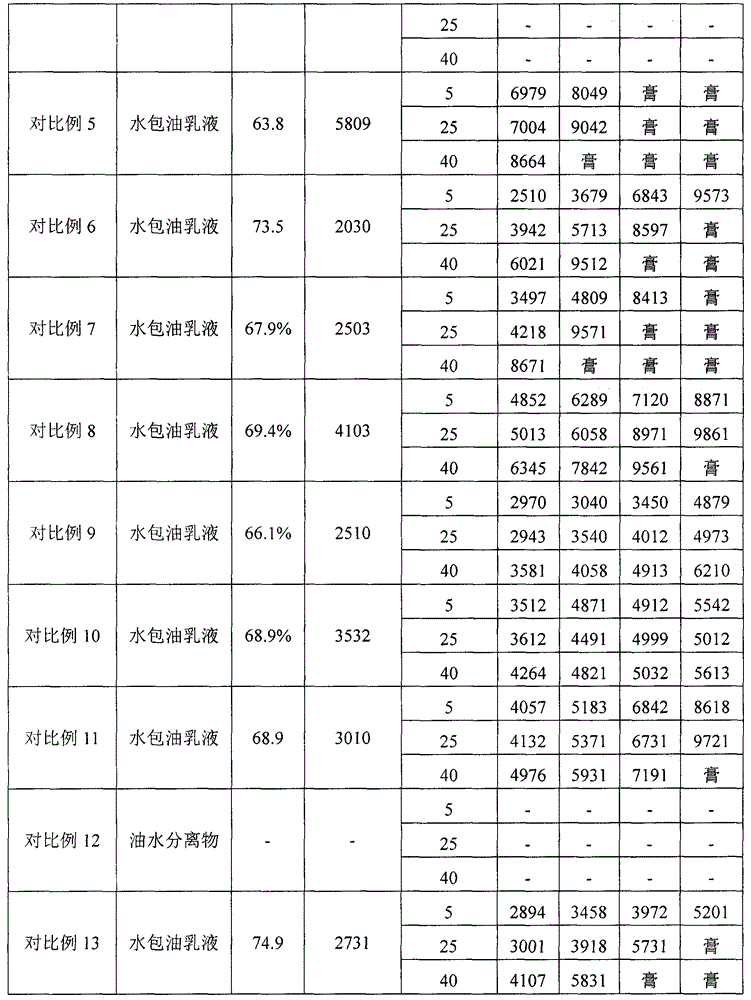

Examples

Embodiment 1

[0040] 13g of white oil, 17g of C10 alcohol, 29.69g of Garopa wax, and 0.1g of ethylene glycol laurate were added to the beaker, and the temperature was slowly raised to 90°C. 5g disodium hydrogen phosphate-citric acid buffer solution (0.01mol / L) is mixed as the pretreatment phase inversion liquid X, and 1 / 3 of the mass of the pretreatment phase inversion liquid X is reserved as X-I for use, and in the remaining pretreatment phase inversion liquid X Add 5g of sodium ethylbenzenesulfonate as the phase inversion liquid Y for use, both are heated to 85°C, the stirring speed is 50r / min, and the temperature is kept for use; the oil phase stirring speed is maintained at 50r / min, and the oil phase is slowly stirred at 0.1mL / s. Add pretreatment phase inversion liquid X-I; continue to stir at a stirring speed of 350r / min, quickly add phase inversion liquid Y at 20mL / min, stop stirring after the addition of liquid, let stand for 1min, during which 0.1g of polyoxyethylene (20 ) sorbitan ...

Embodiment 2

[0042] Add 32g of C14-C16 alcohol, 13g of beeswax, and 0.5g of sorbitan monostearate to the beaker, slowly heat up to 120°C, after all melted, keep warm for 20min; then add 24.7g of deionized water and 0.1g of Phthalic acid-hydrochloric acid buffer solution (0.1mol / L) is mixed as the pretreatment phase inversion liquid X, and 1 / 3 of the mass of the pretreatment phase inversion liquid X is reserved as X-I for use, and 0.1 0.1 of the remaining pretreatment phase inversion liquid X is added. g Sodium dodecyl benzene sulfonate was used as the phase inversion liquid Y, and both were heated to 75 °C, the stirring speed was 300 r / min, and the temperature was kept for use; Add pretreatment phase inversion liquid X-I; continue stirring at a stirring speed of 500 r / min, quickly add phase inversion liquid Y at 50 mL / min, stop stirring after the addition of liquid, and let stand for 5 minutes, during which 0.5 g of triethanolamine sodium oleate is added dropwise , and then quickly turn on...

Embodiment 3

[0044] Add 20g of liquid wax, 28.45g of rubber protective wax, and 3.5g of glycerol monolaurate to the beaker, slowly heat up to 100°C, and keep warm for 15min after all melted; then add 14g of deionized water and 3.5g of borax-hydroxide The sodium buffer solution (0.01mol / L) was mixed as the pretreatment phase inversion liquid X, and 1 / 3 of the mass of the pretreatment phase inversion liquid X was reserved as X-I for later use, and 2.5g of hexadecyl was added to the remaining pretreatment phase inversion liquid X. Sodium diphenyl ether disulfonate was used as phase inversion liquid Y, both of which were heated to 80°C, and the stirring speed was 100 r / min. Process phase inversion liquid X-I; continue stirring at a stirring speed of 1000 r / min, quickly add phase inversion liquid Y at 40 mL / min, stop stirring after adding liquid, let stand for 3 min, and add 2.5 g of stearyl alcohol polyoxyethylene dropwise during this period. (20), then quickly open and stir to the original sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com