Iron filing collection device for machining

A collection device and machining technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of low recycling efficiency and inability to achieve cooling flood treatment of iron filings, so as to facilitate centralized processing and improve follow-up Processing efficiency, the effect of promoting rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

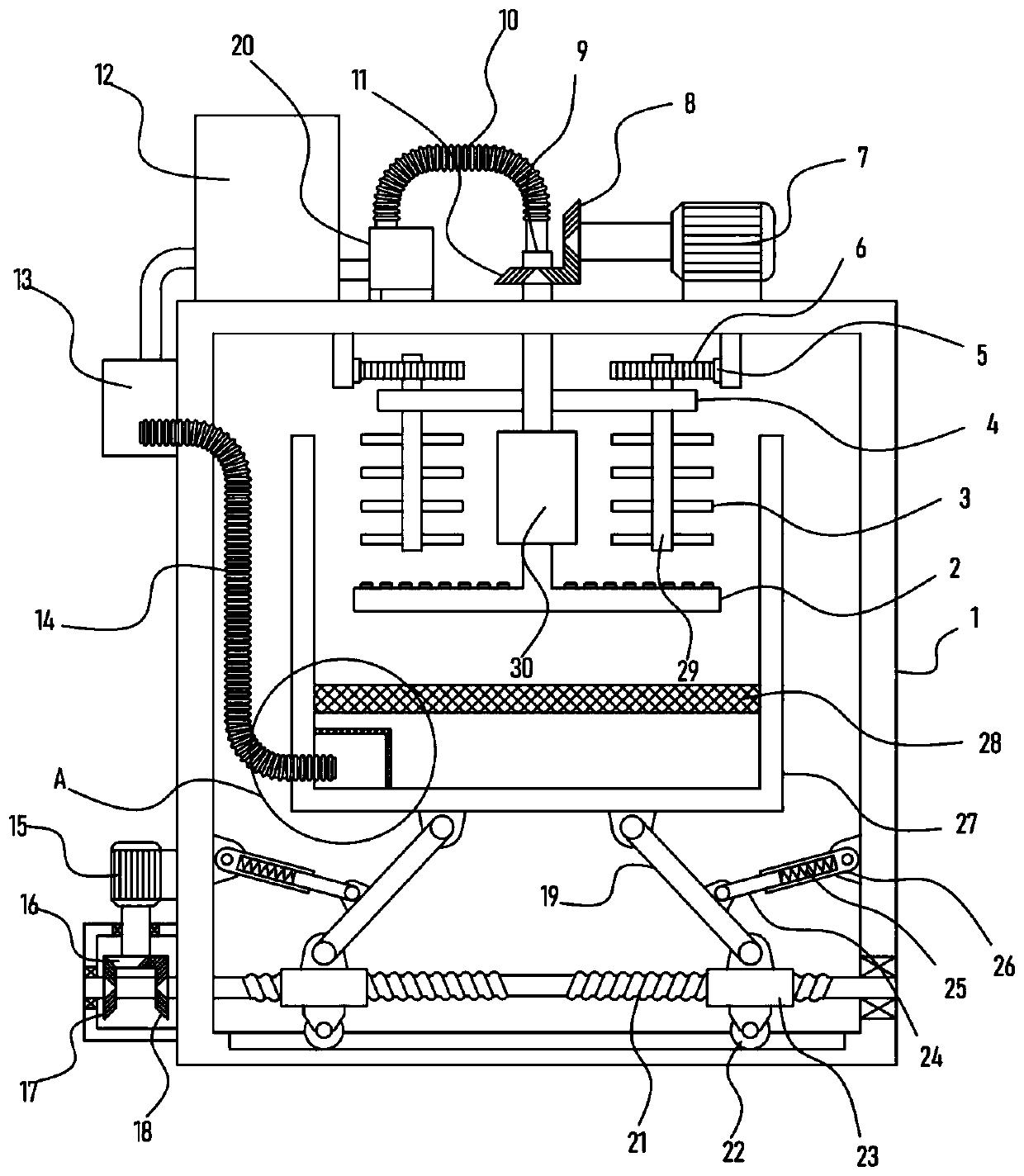

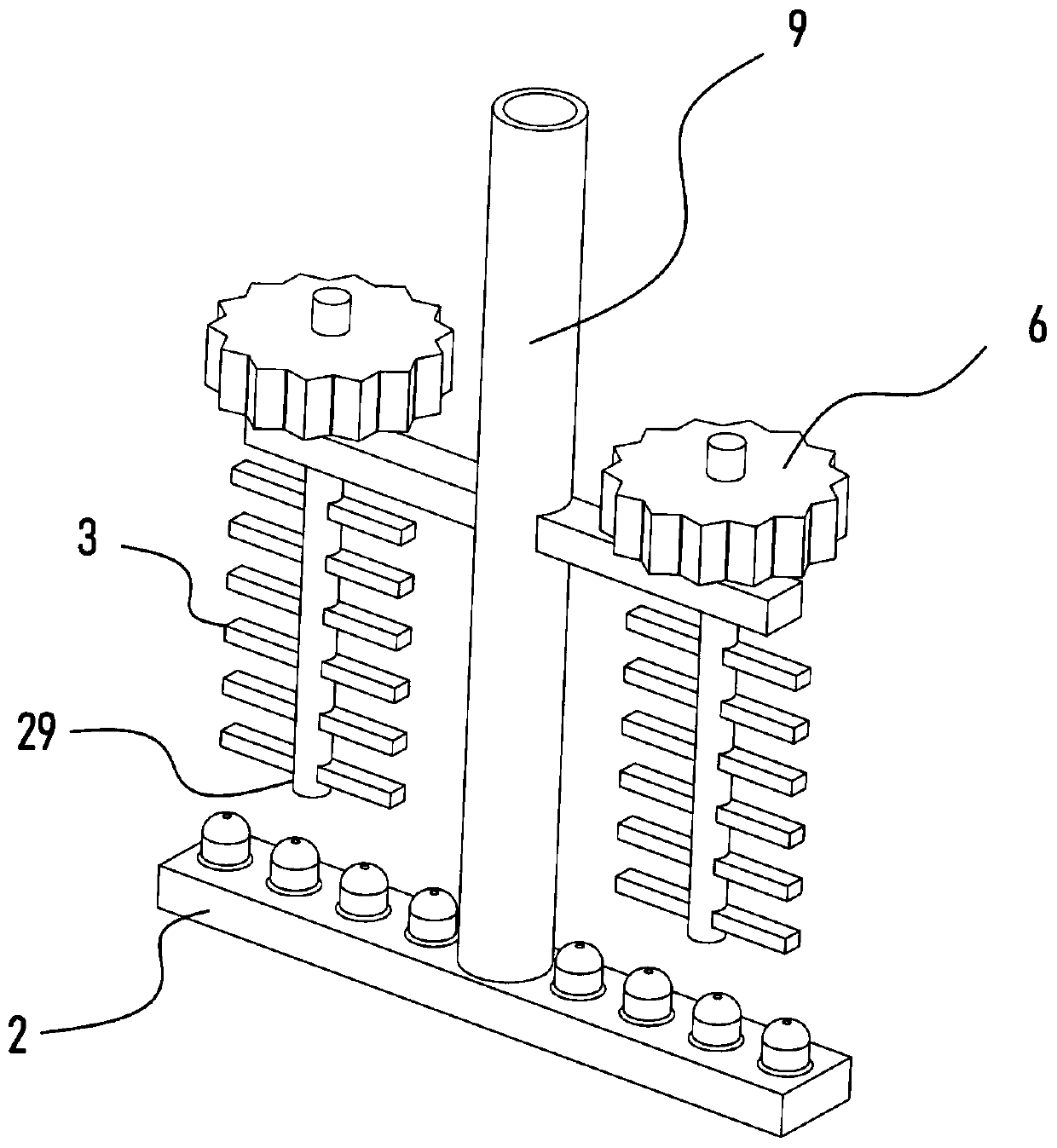

[0024] see Figure 1-3 , a chip collecting device for machining, comprising a support frame 1, a coolant tank 12 is fixed on the support frame 1, a storage tank 27 is provided in the support frame 1, a driving mechanism is provided on the support frame 1, and the The mechanism drives and rotates a rotating tube 9 extending into the storage tank 27. A dispersing mechanism is provided on the rotating tube 9. An electromagnet 30 is fixed on the rotating tube 9. The bottom of the rotating tube 9 is installed with a coolant tank. 12 communicates with the cooling mechanism provided, the side wall of the support frame 1 is fixed with a driving motor II15, a reversing mechanism is connected to the driving motor II15, and a lifting mechanism is connected between the reversing mechanism and the storage tank 27.

[0025] The inside of the storage tank 27 in this device is used to store the iron filings produced in the machining process. The electromagnet 30 is energized to absorb the iro...

Embodiment 2

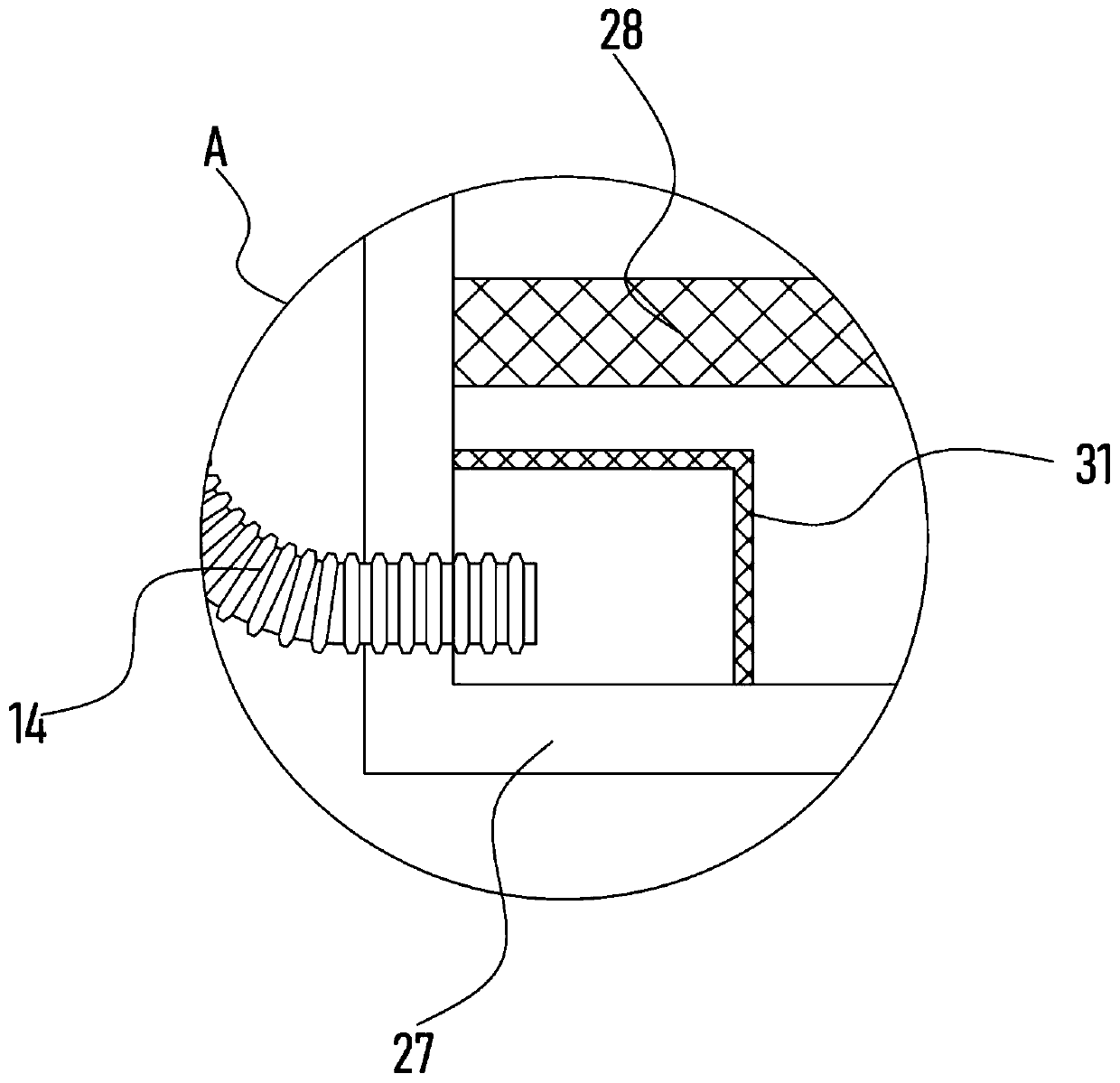

[0031] On the basis of Embodiment 1, in addition, the side wall of the support frame 1 is fixed with a lift pump 13 communicating with the coolant tank 12, and the inlet end of the lift pump 13 communicates with the storage tank 27 through the bellows II14, and the storage tank 27 is horizontally fixed with The mesh plate 28 above the bellows II14 is located at one end of the bellows II14 in the storage tank 27 and is provided with a filter screen cover 31 .

[0032] The cooling liquid sprayed from the spray plate 2 can pass through the mesh of the mesh plate 28 and drop to the bottom of the storage tank 27, and the lift pump 13 is set to extract and recover the cooling liquid in the storage tank 27 through the bellows II14 to the cooling liquid Inside the box 12, the circulation effect is realized, the circulation utilization of the coolant is guaranteed, and the sufficient cooling of the high-temperature iron filings is promoted.

[0033] Further, the device is also provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com