Full-automatic precise film cutting machine

A fully automatic, film-cutting technology, applied in layered products, lamination auxiliary operations, lamination, etc., can solve problems such as large demand, achieve the effect of improving production efficiency and improving industrial competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

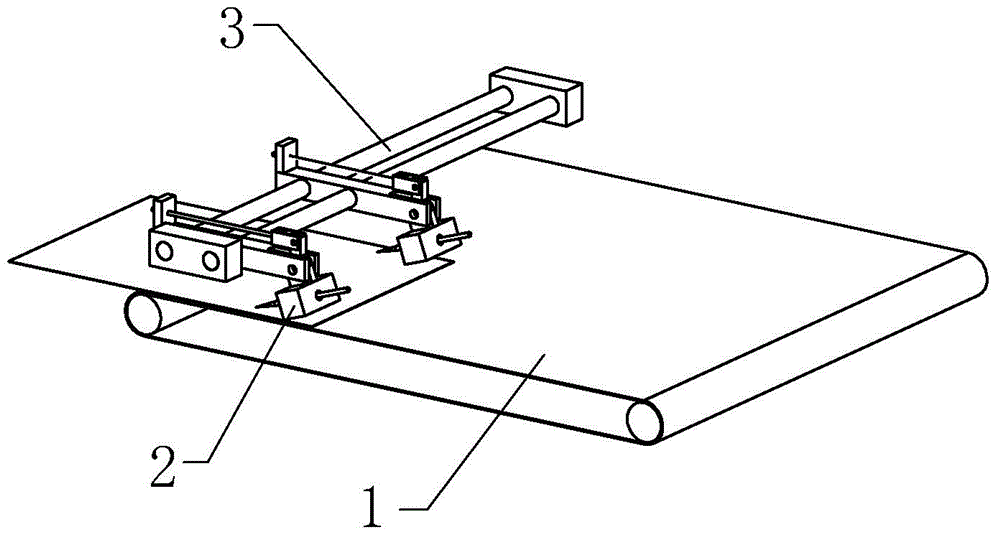

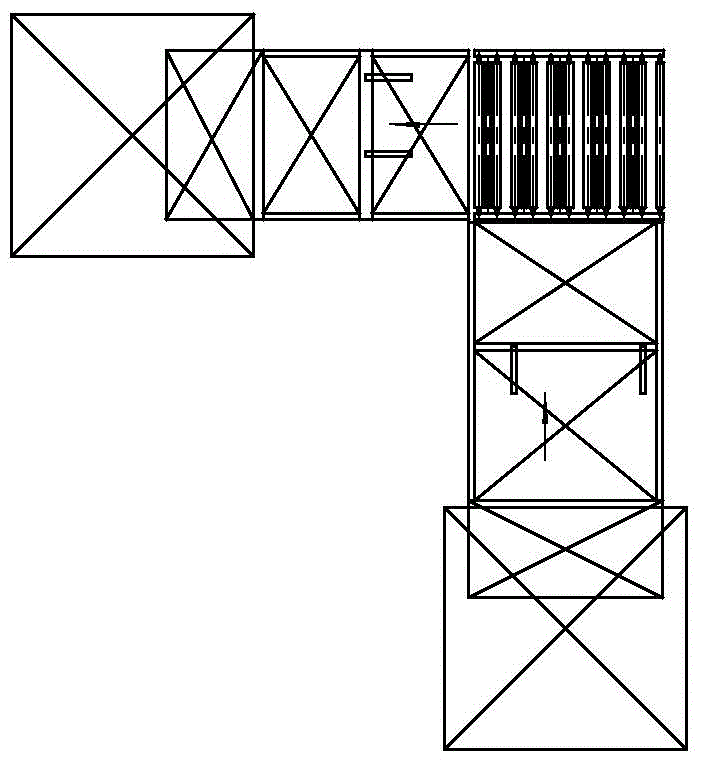

[0016] Refer to attached figure 1 and attached figure 2 , the present invention is a fully automatic precision film cutting machine, which includes a mounting frame, in which a sheet material conveyor belt 1 and a plurality of pairs of film cutting knives suspended above the sheet material conveyor belt 1 are arranged. 2. The knife distance of any group of film cutting knives 2 is fixed and adjustable, and the sheet conveyor belt 1 also includes constant tension devices arranged on both sides.

[0017] Specifically, the constant tension device includes a programmable controller and a magnetic brake, which calculates the tension of the protective film attached to the sheet through the programmable controller in real time, and controls the magnetic brake to generate a braking torque through the current to make the protective film reach a suitable level. The tension ensures that the protective film does not stretch or wrinkle during cutting.

[0018] In order to solve the floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com