A silk making device

A technology for making silk and sliver, which is applied in the fields of silk reeling, silk fiber production, and chemical post-treatment of fibers, etc. It can solve the problems of reducing correlation and affecting efficiency, etc., and achieves the goals of reducing broken silk, high production efficiency, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below.

[0026] Unless otherwise specified, the raw materials used in the present invention can be purchased from the market or commonly used in the field. If not specified, the methods in the following examples are all conventional methods in the field.

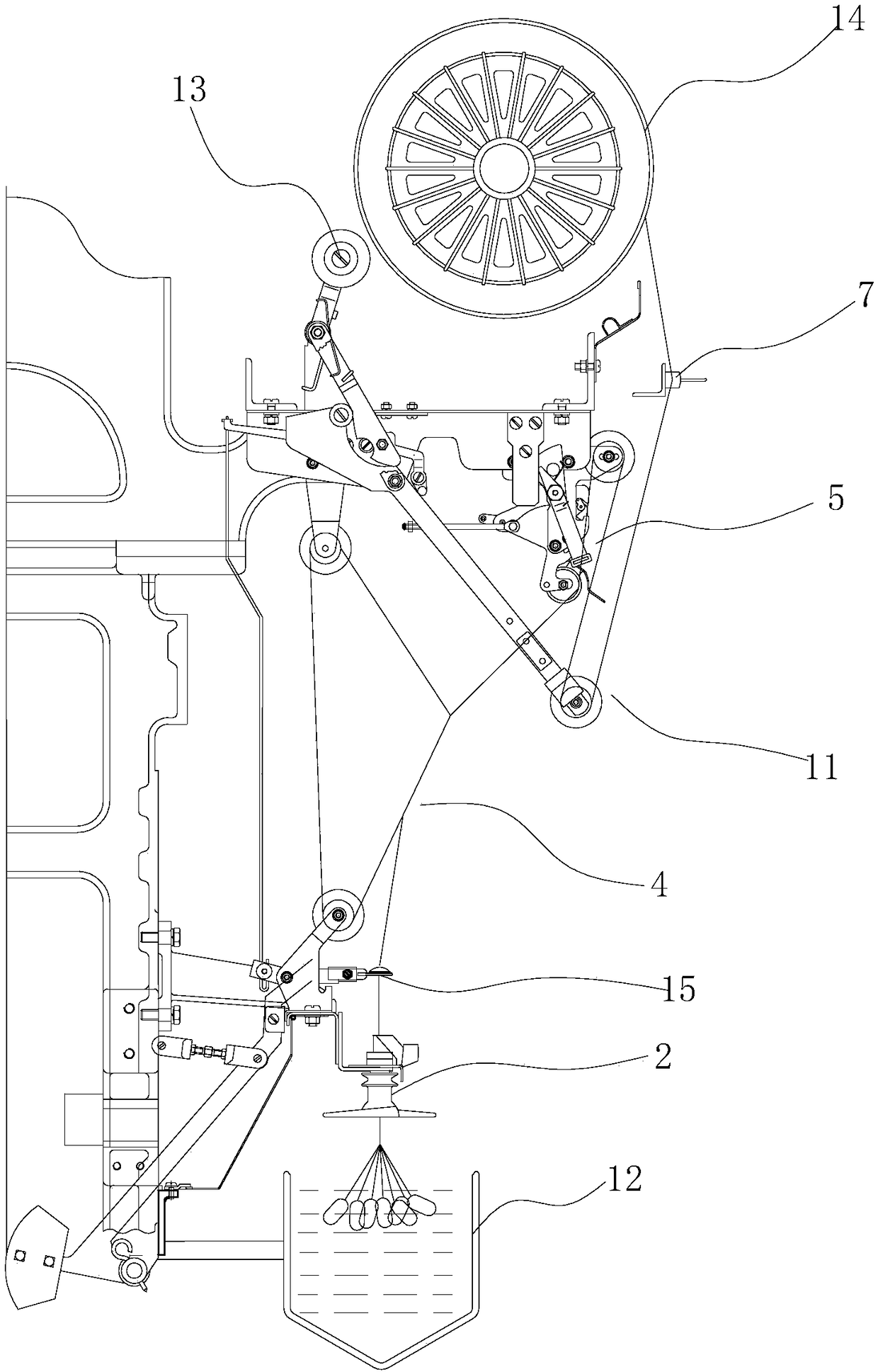

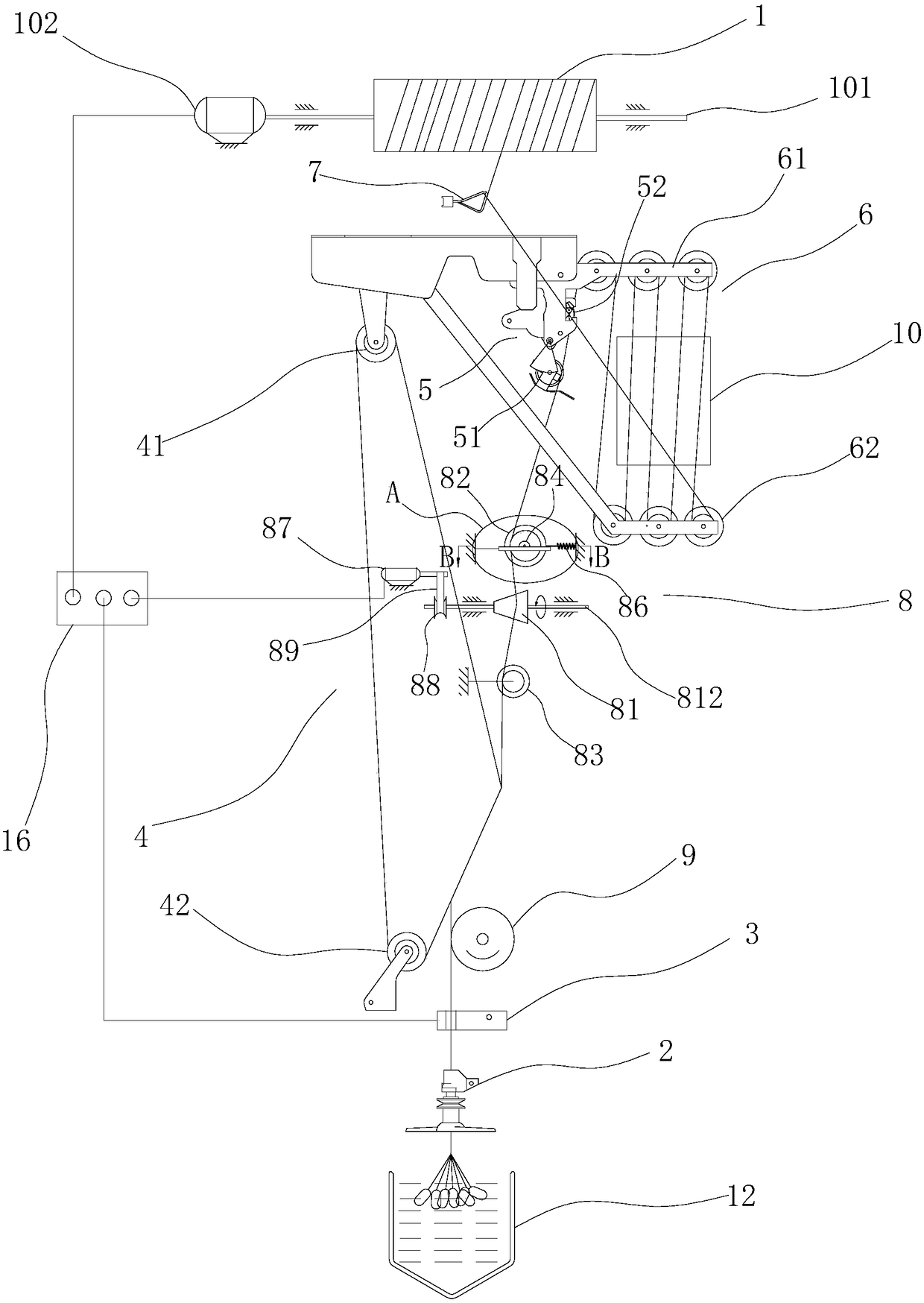

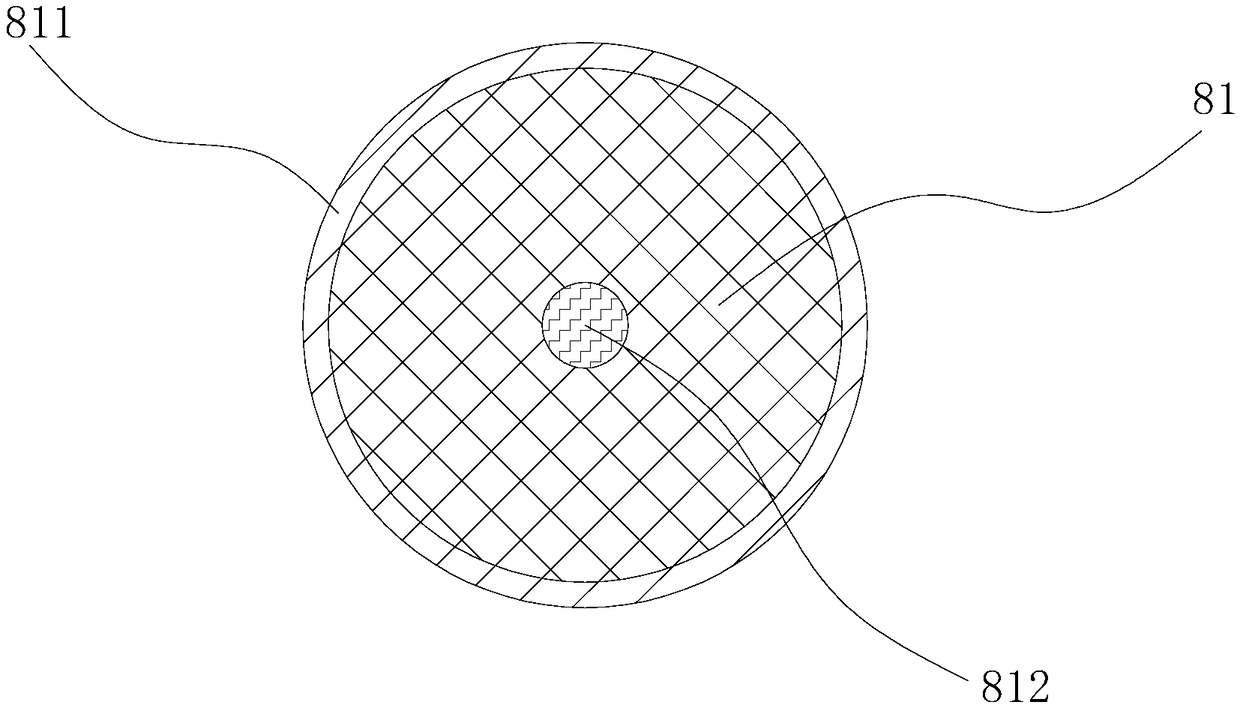

[0027] Such as figure 2 As shown, a silk making device includes a number of thread making units independent of each other, and each thread making unit is sequentially provided with a thread connector 2 and an electronic roughening device from front to back in the conveying direction of cocoon silk or silk strips. 3. The twist sheath structure 4, the exploration structure 5, the intertwining ring 7 and the unit cylinder 1 for winding the thread sliver, the winding motor 102 and the controller 16 for driving the rotation of the unit cylinder are also provided in the silk making unit, and the controllers are respectively It is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com