Glove making machine

A technology of glove machine and unloading rack, which is applied in the field of glove machine, can solve the problems such as difficult to achieve, and achieve the effect of improving quality, less elongation, and less pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

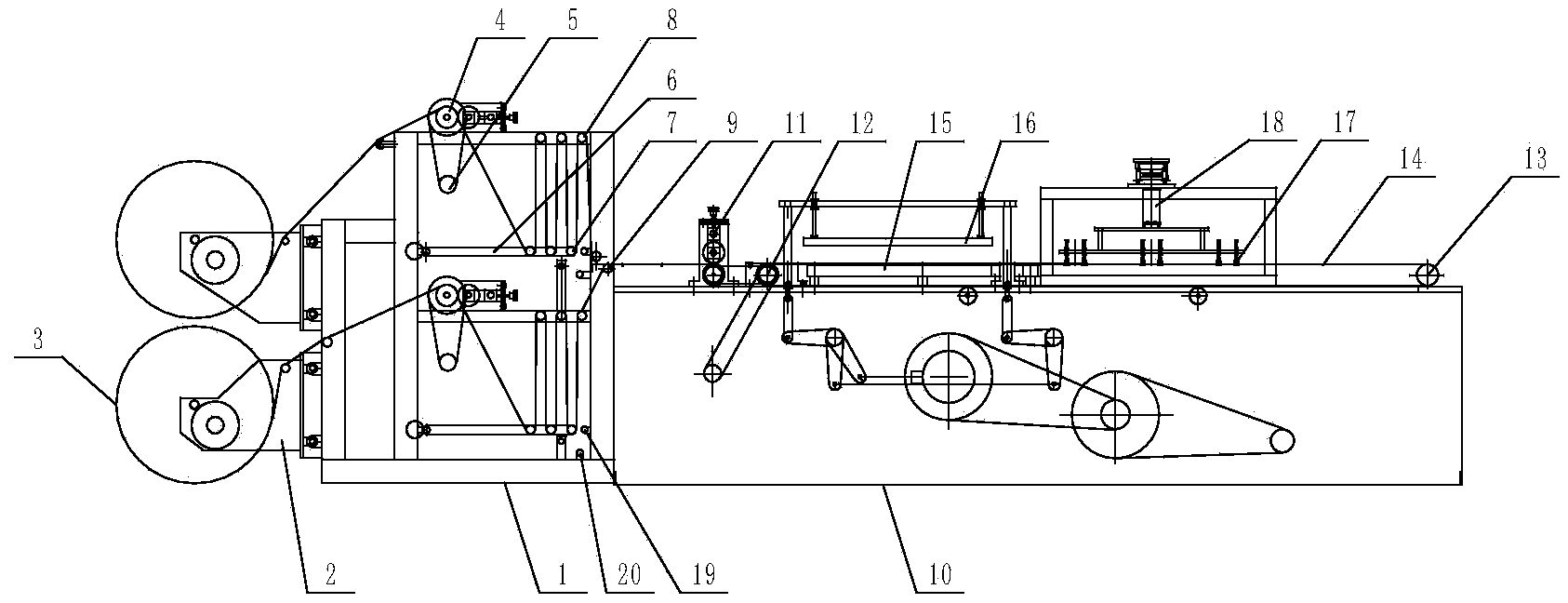

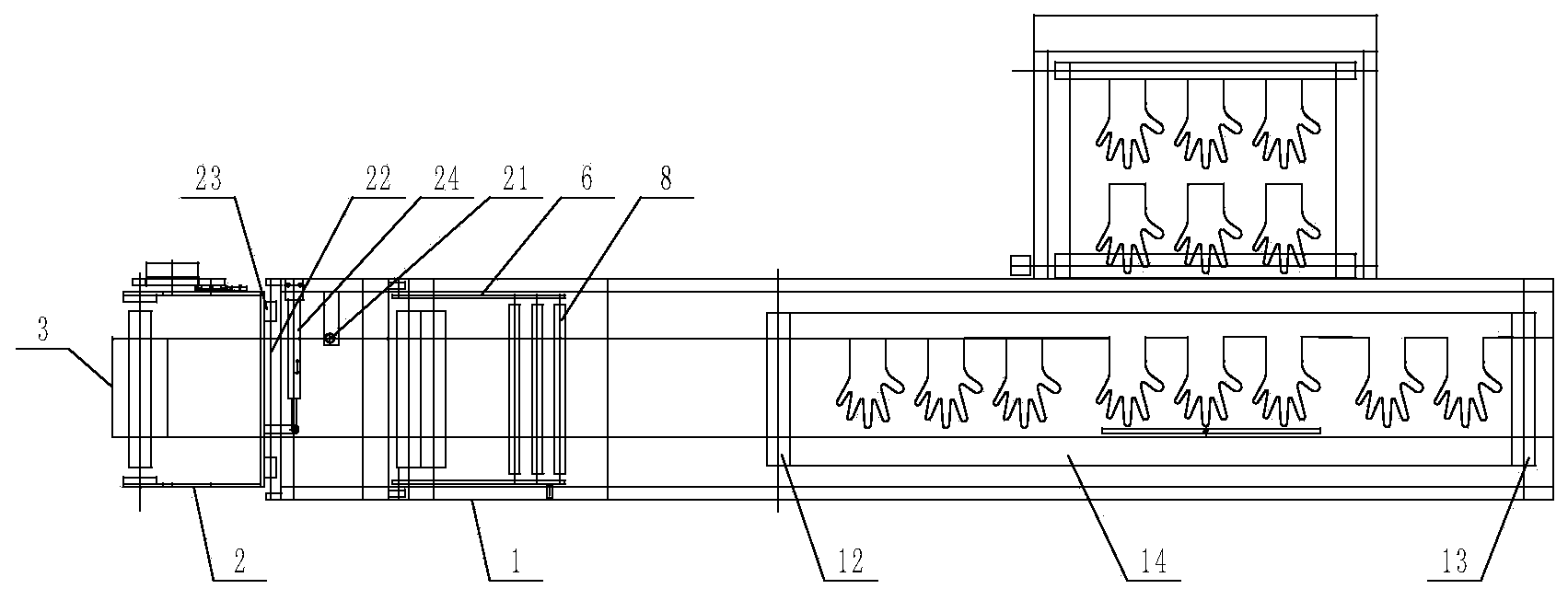

[0016] A glove machine according to the present invention will be further described in detail through specific examples below.

[0017] As shown in Figure l, figure 2 As shown, a glove machine includes a discharging device, a forming mold and a receiving device arranged in sequence. The discharging device includes a discharging rack 1, and the discharging rack 1 is provided with two sets of discharging equipment up and down. The structure of the two sets of unwinding equipment is the same, each set of unwinding equipment includes a roll rack 2 arranged at the front end of the unwinding rack 1, the roll rack 2 is provided with a roll 3, and the unwinding rack 1 is provided with a feeding rubber roller 4 And drive the discharge motor 5 of the discharge rubber roller 4, the discharge rack 1 is also provided with two swing rods 6 on the same plane that are hinged with the discharge rack 1, and several swing rods 6 are arranged between the two swing rods 6. The lower support rod 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com