Yarn tension adjusting mechanism

A technology for adjusting mechanism and yarn tension, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of unadjusted yarn tension, high breakage rate, uneven surface of fabrics, etc. To achieve the effect of soft and stable speed, appropriate yarn tension, uniform and stable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

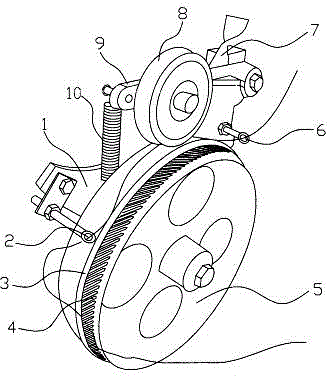

[0012] Below in conjunction with accompanying drawing, the present invention will be further described:

[0013] The present invention includes a main body 1, an outlet guide hole 2 fixedly installed on one side of the main body 1, an incoming wire guide hole 6 fixedly installed on the other side of the main body 1, a yarn bearing wheel 5 rotatably installed on the main body 1, and a yarn bearing wheel 5 sleeved on the yarn bearing A ratchet sleeve 3 with a plurality of ratchets 4 on the periphery of the wheel 5, an adjustment lever 7 rotatably mounted on the body 1, an adjustment arm 9 rotatably installed on the body 1, a compression wheel 8 rotatably mounted on the free end of the adjustment arm 9, and The spring 10 between the main body 1 and the adjusting arm 9 is tightened, and a yarn breakage detection device is arranged on the yarn receiving wheel 5. The yarn breakage detection device is a sensor. The light sensor is arranged on the yarn bearing wheel 5, and the light re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com