An aluminum alloy door frame, a door panel using the aluminum alloy door frame, and a method of use thereof

An aluminum alloy and door frame technology, which is applied in the field of door panels and aluminum alloy door frames, can solve the problems of not being beautiful and tidy, not suitable for transparent core boards, etc., to improve stability and airtightness, ensure structural strength and safety, and avoid loosening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

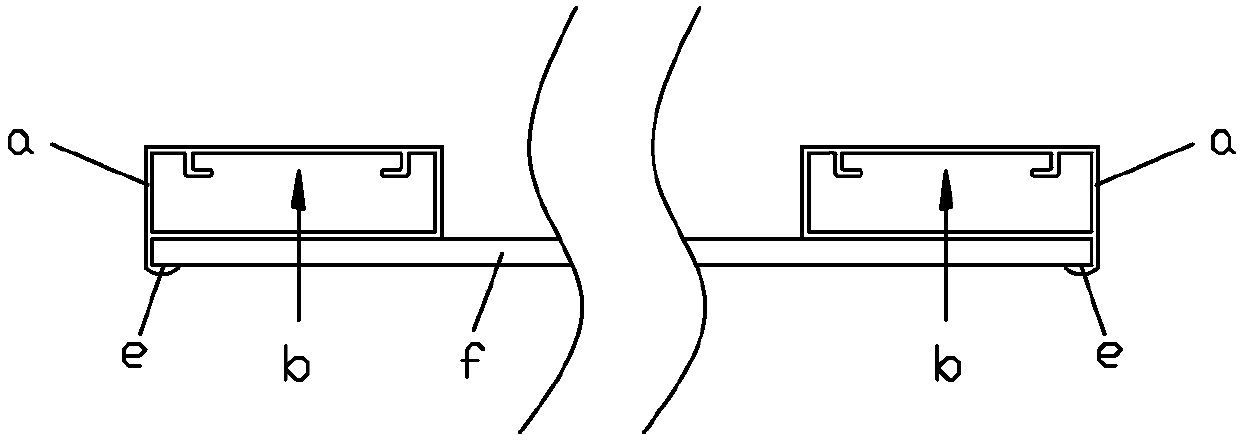

[0061] Such as Figure 5 to Figure 18 As shown, an aluminum alloy door frame includes a polygonal door frame body 10, a polygonal bead 20 corresponding to the door frame body 10, and a polygonal buffer bar 30;

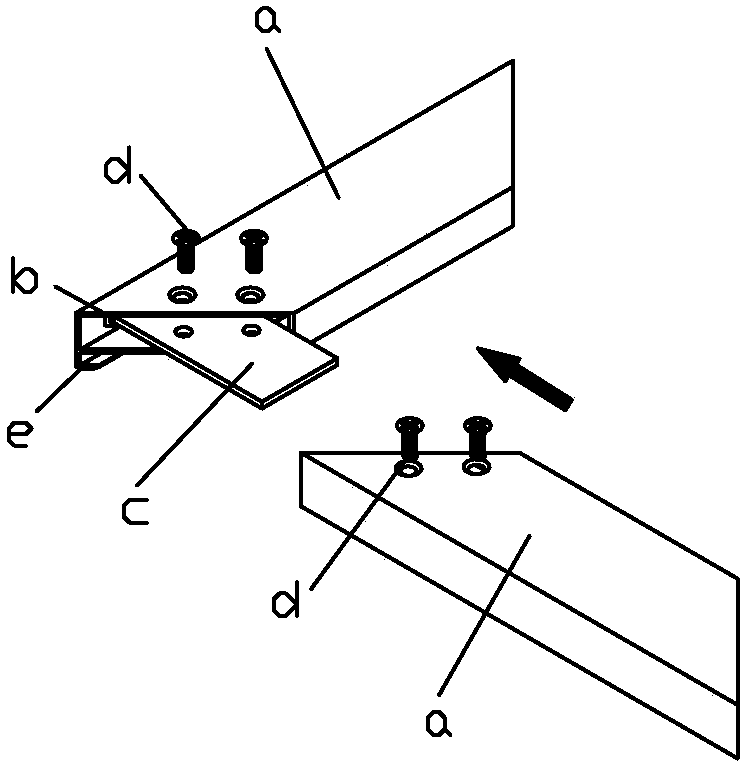

[0062] The door frame main body 10 is composed of a plurality of trapezoidal frames 11 connected end to end and fixed and spliced by corner codes 12 / 13 / 14 and screws 15; the frame 11 is extruded from aluminum profiles, including Arranged corner code matching part 111, bead matching part 112 and core board matching part 113; Figure 8 Among them, the corner code matching part 111, the bead matching part 112 and the core plate matching part 113 are arranged from left to right.

[0063] Such as Figure 8 As shown, the corner code matching part 111 is provided with a first corner code installation groove 1111 arranged in the up and down direction in the right position, and a second corner code installation groove 1112 arranged in the left and right direction is provide...

Embodiment 2

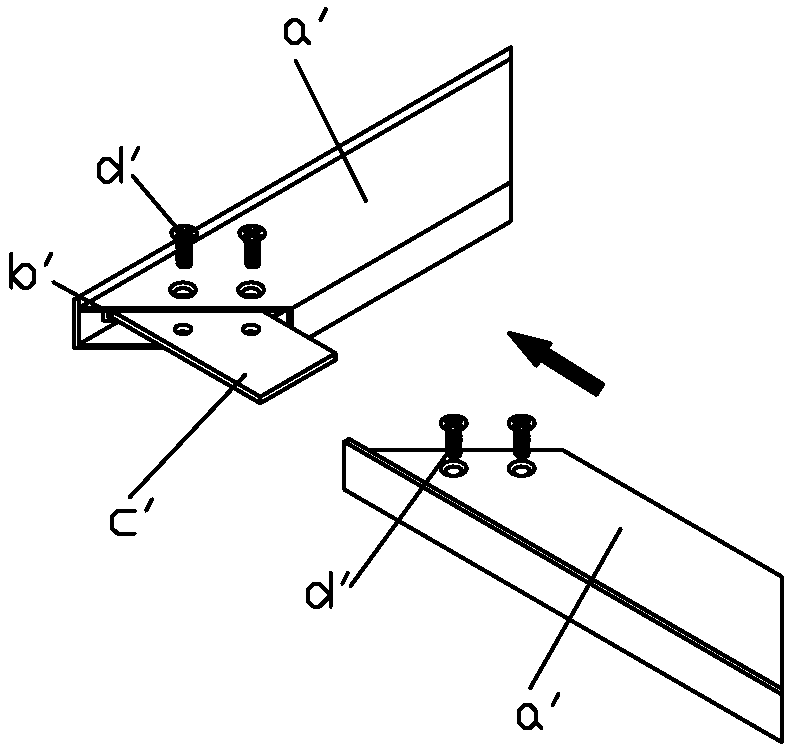

[0079] Such as Figure 19 to Figure 23 As shown, the present embodiment provides a narrow-sided aluminum alloy door frame, including a polygonal door frame body, a polygonal bead 20' corresponding to the door frame body, and a polygonal buffer bar 30';

[0080] The main body of the door frame is composed of a plurality of trapezoidal frames 11' which are connected end to end and are fixed and spliced by corner brackets 12' and screws 15'; the frame 11' is made of extruded aluminum profiles, including beading arranged on the outside and inside Fitting part 112' and corner code fitting part 111'; Figure 19 Among them, the bead matching part 112' and the corner code matching part 111' are arranged left and right.

[0081] Such as Figure 19As shown, the first corner code installation groove 1111' and the second corner code installation groove 1112' are arranged left and right in the corner code matching part 111'; 112' are adjacent to each other and are used to install vert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com