Patents

Literature

132results about How to "Appropriate tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

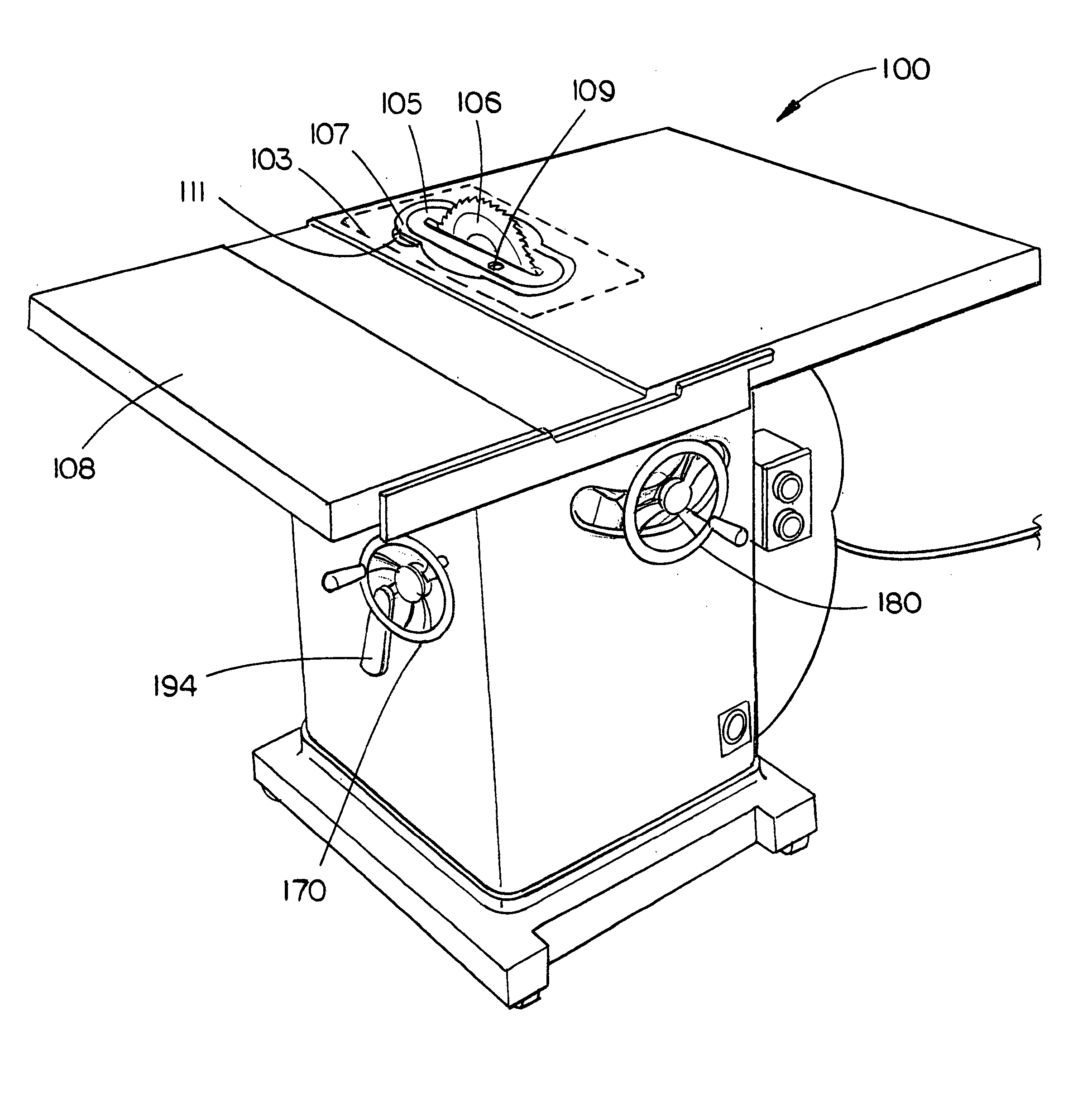

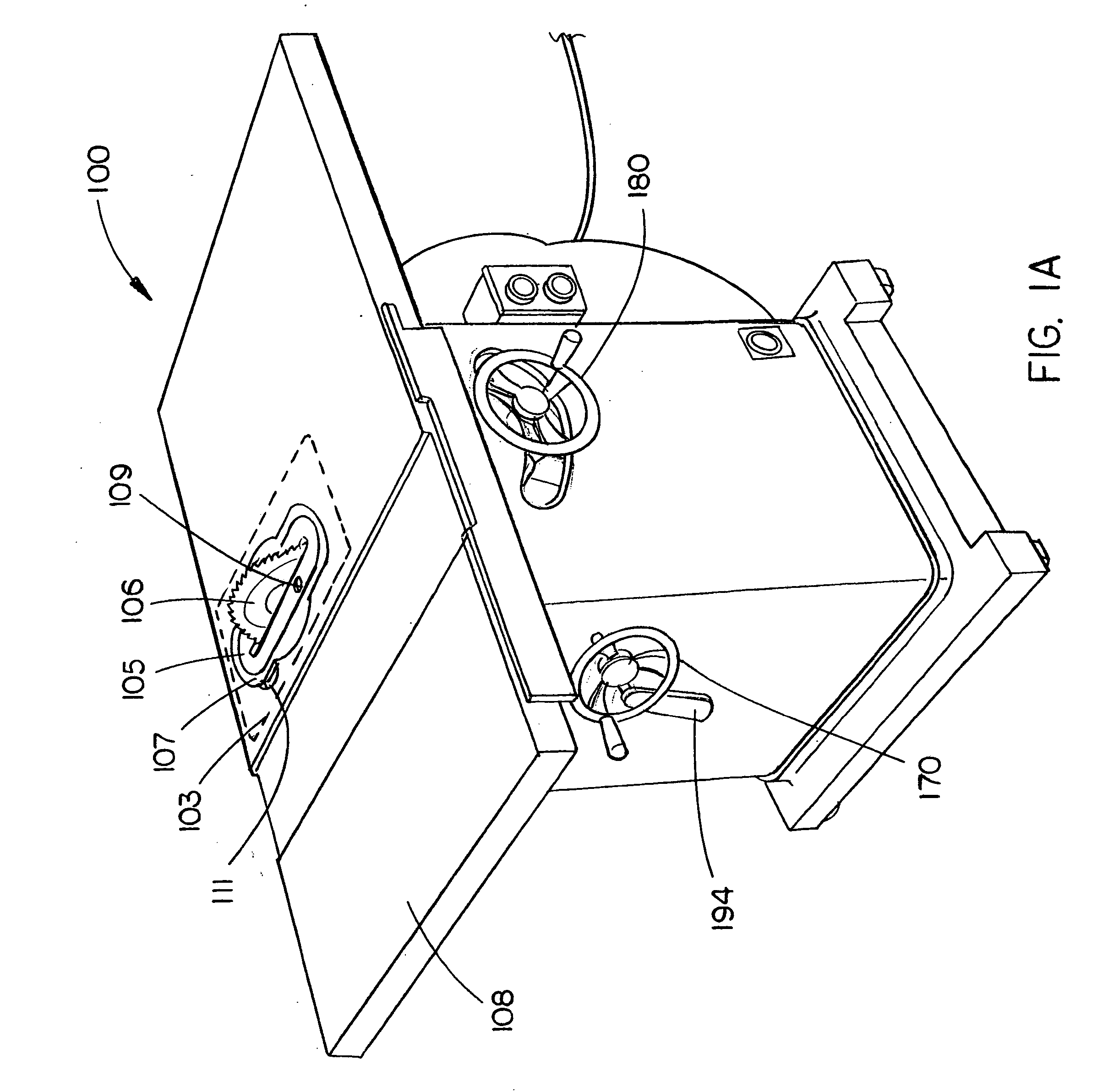

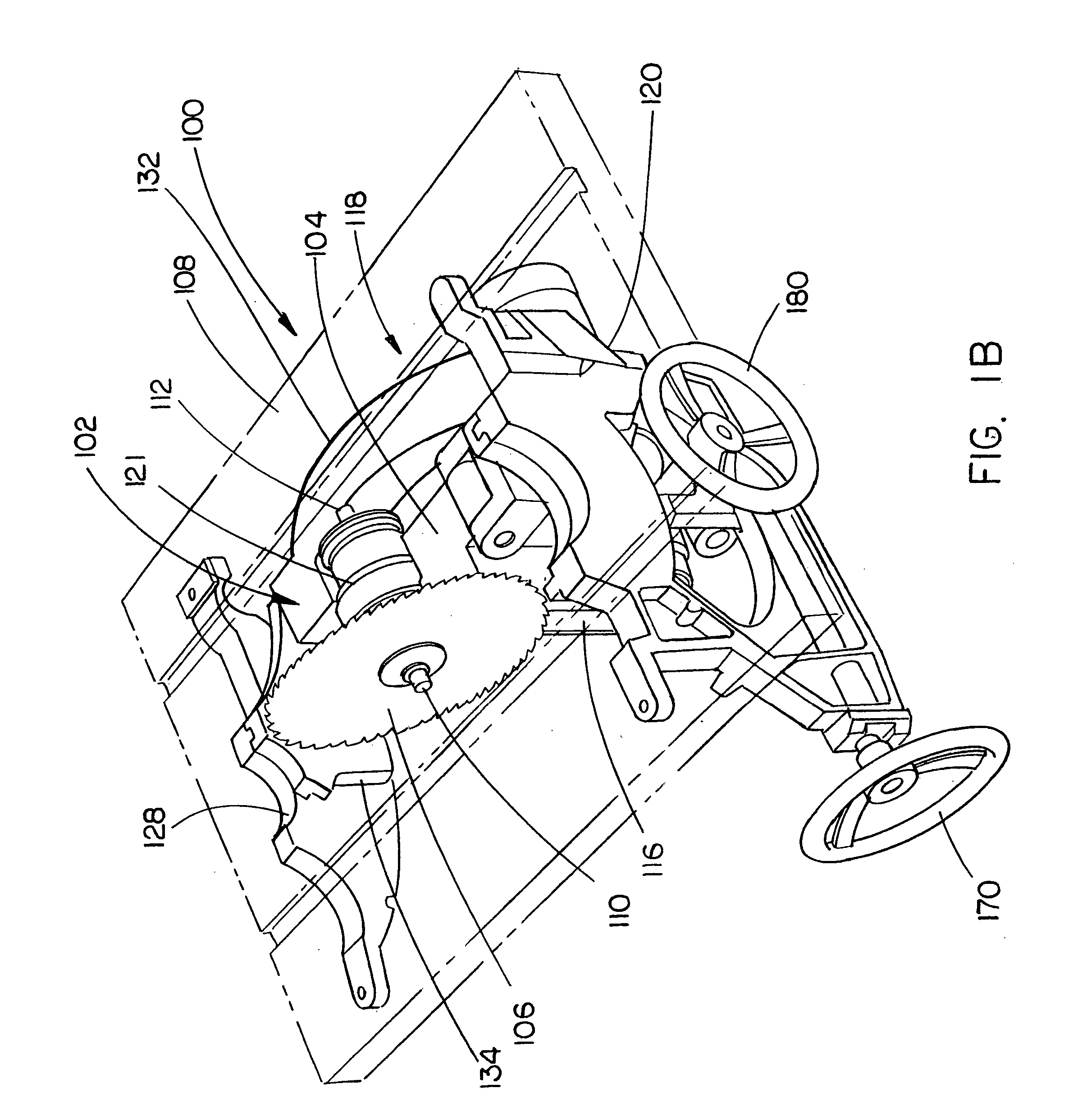

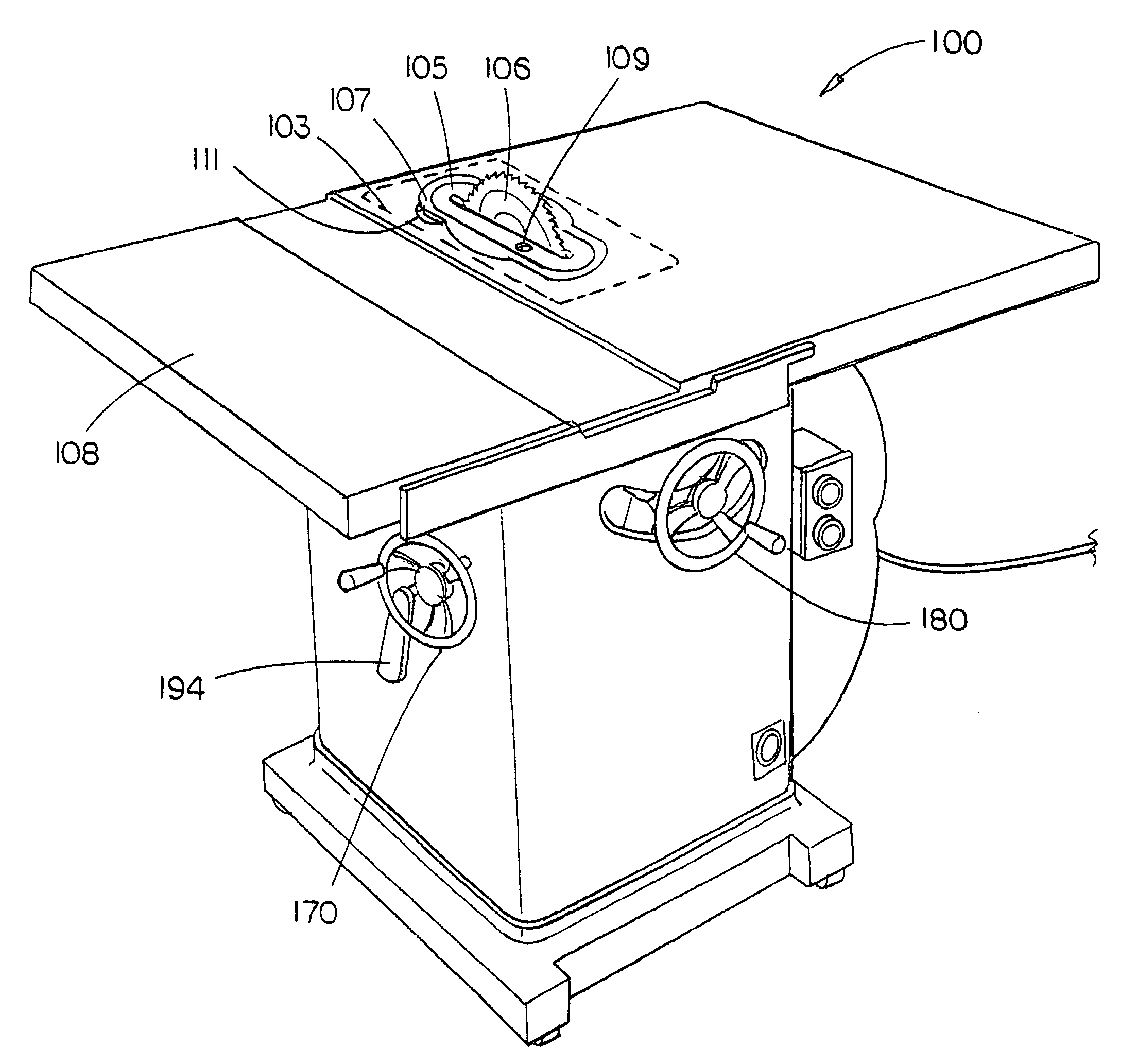

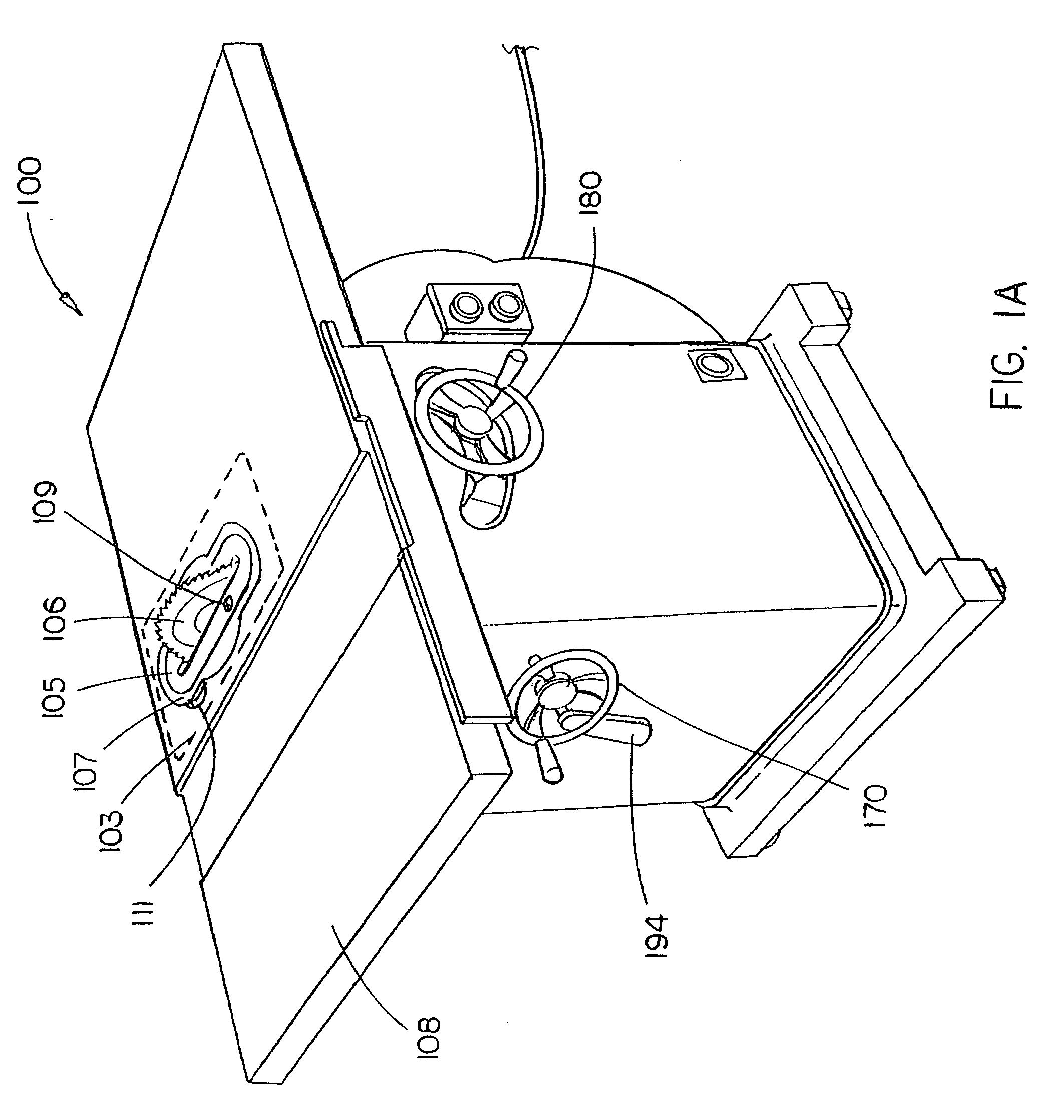

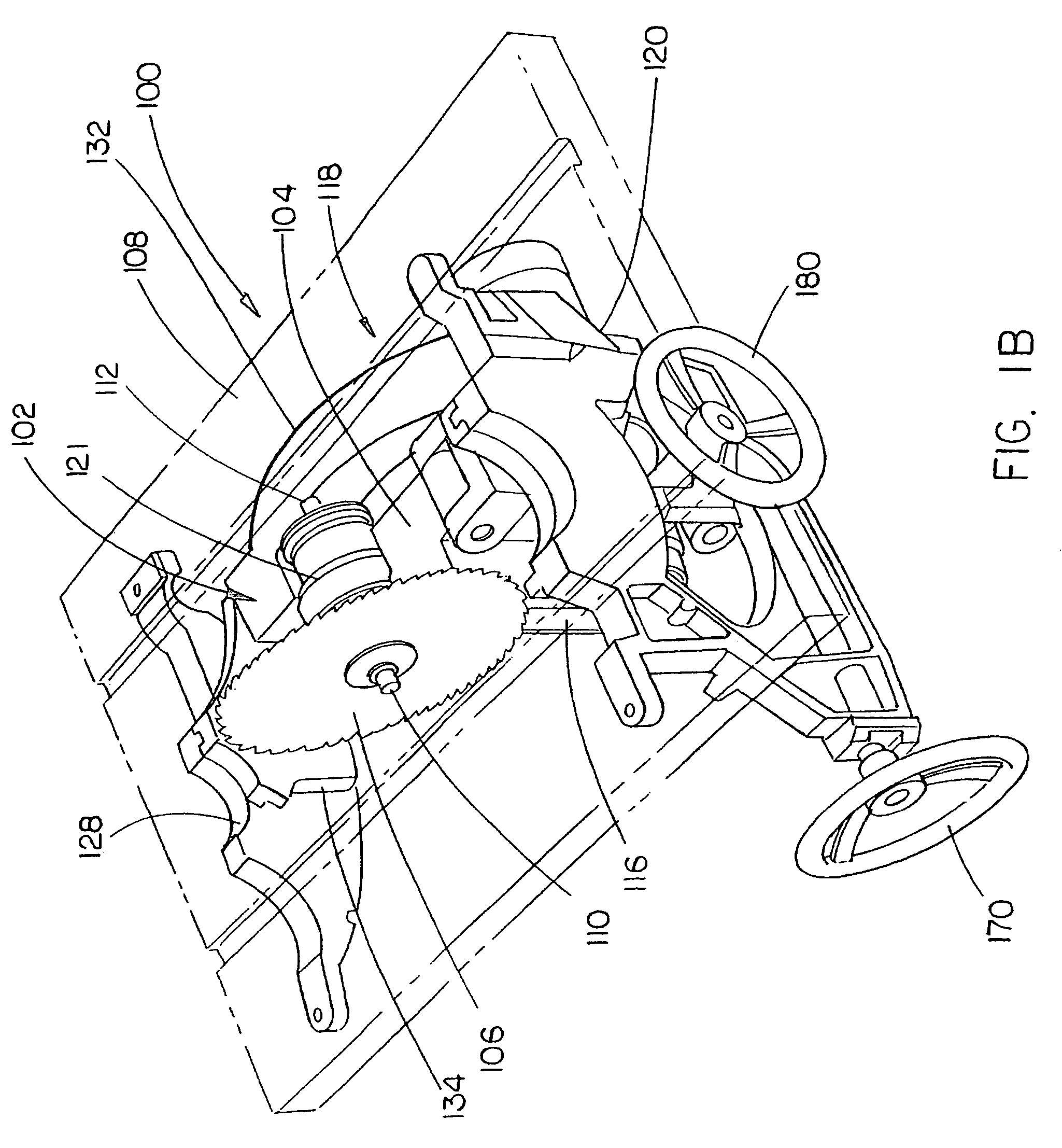

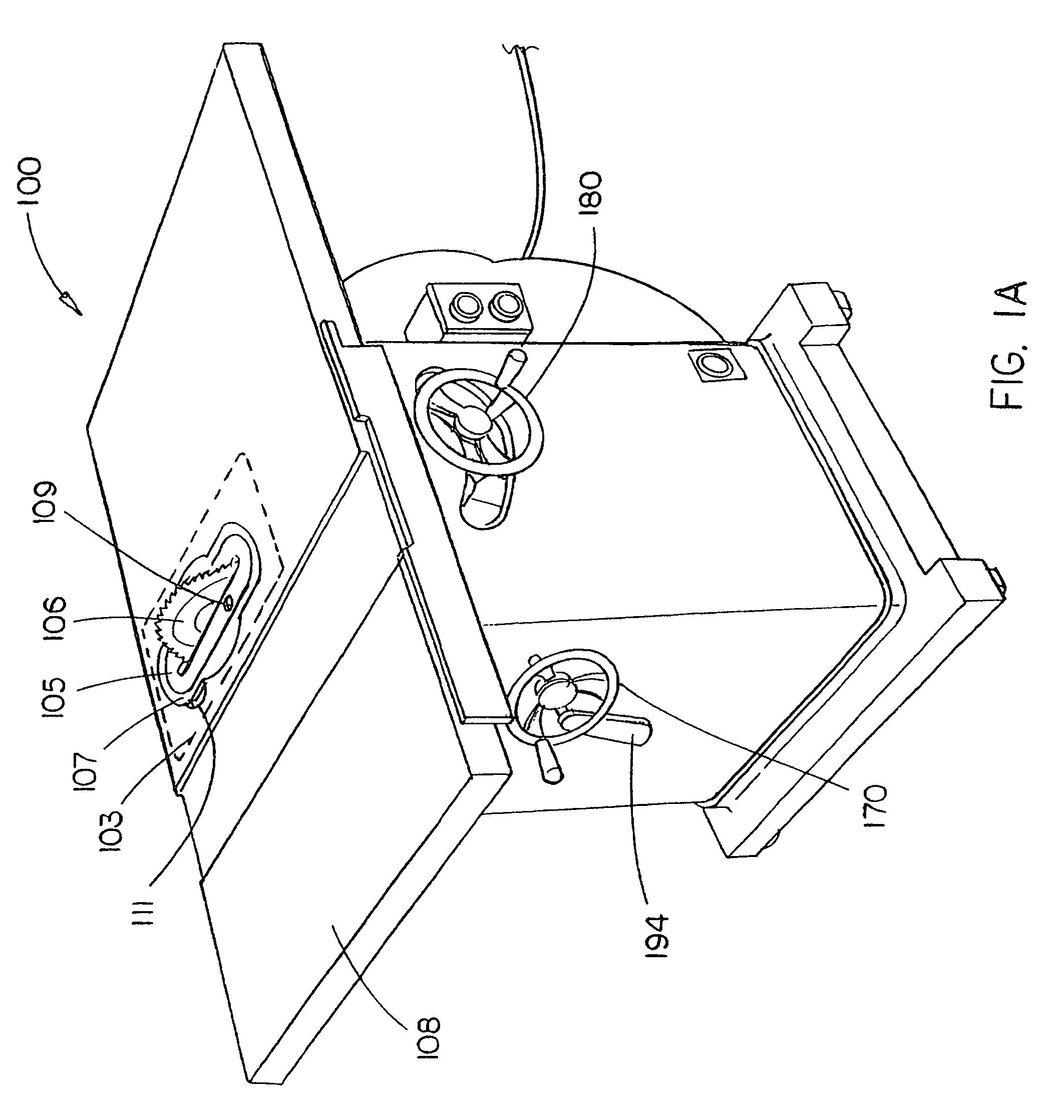

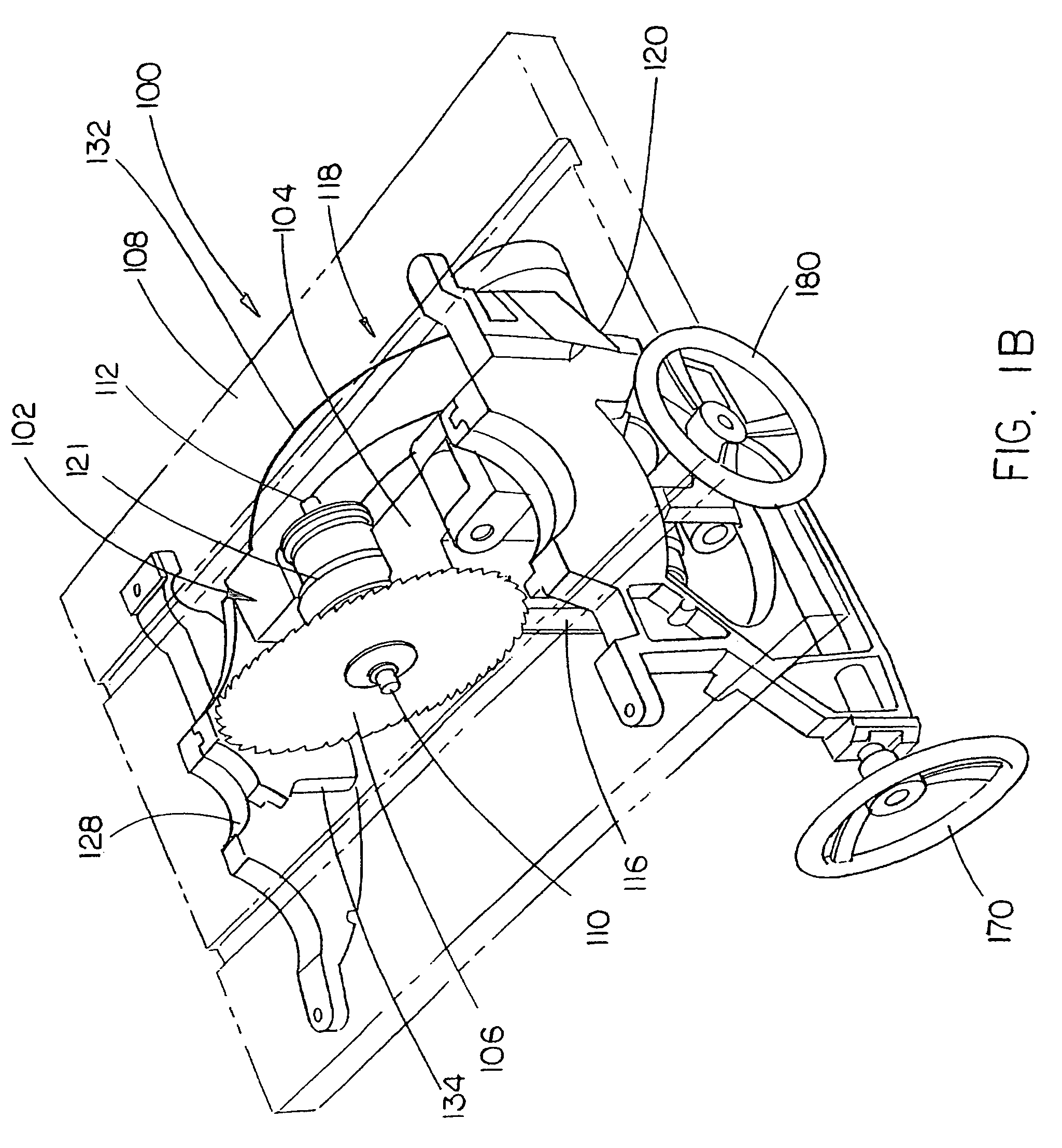

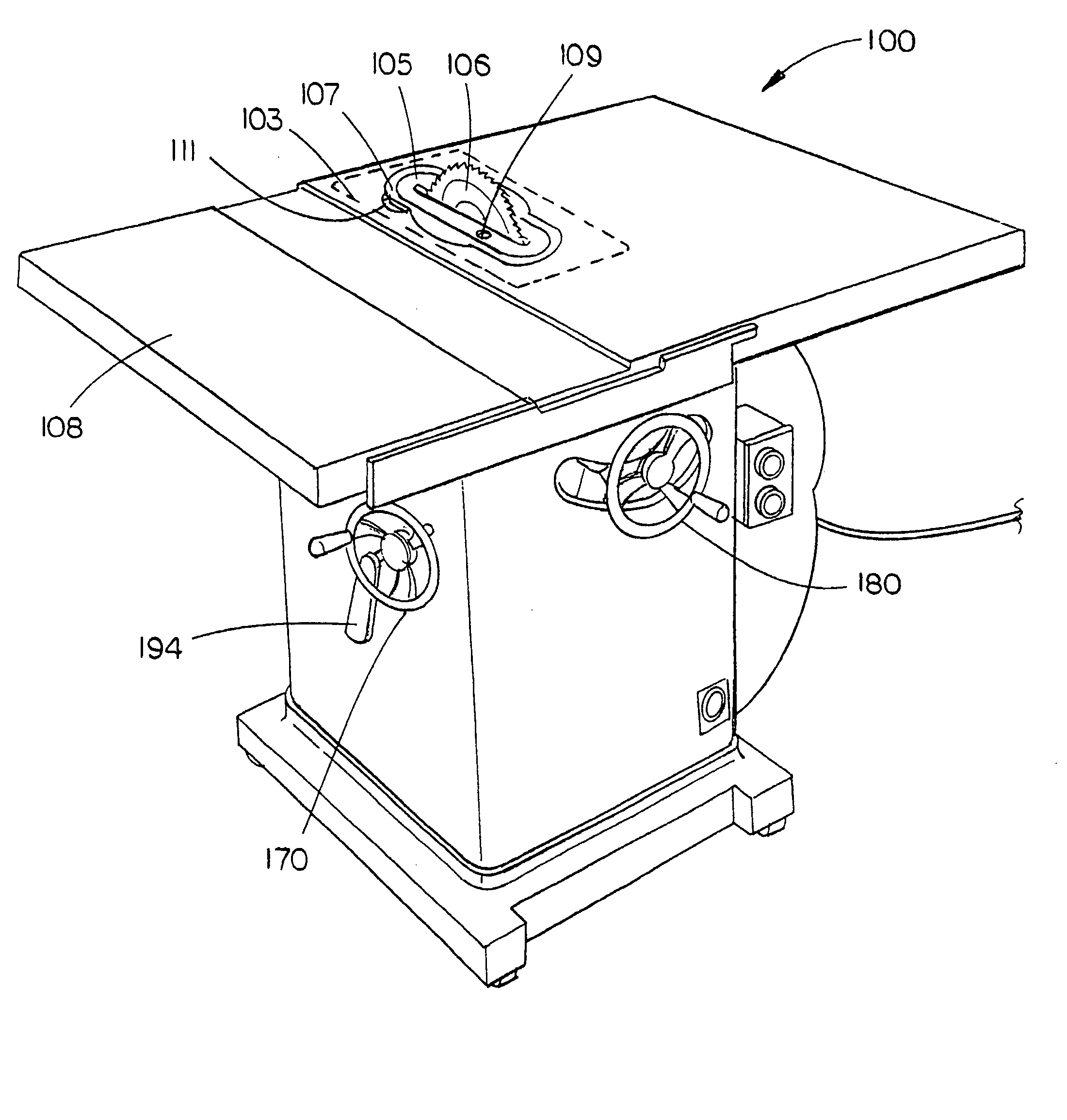

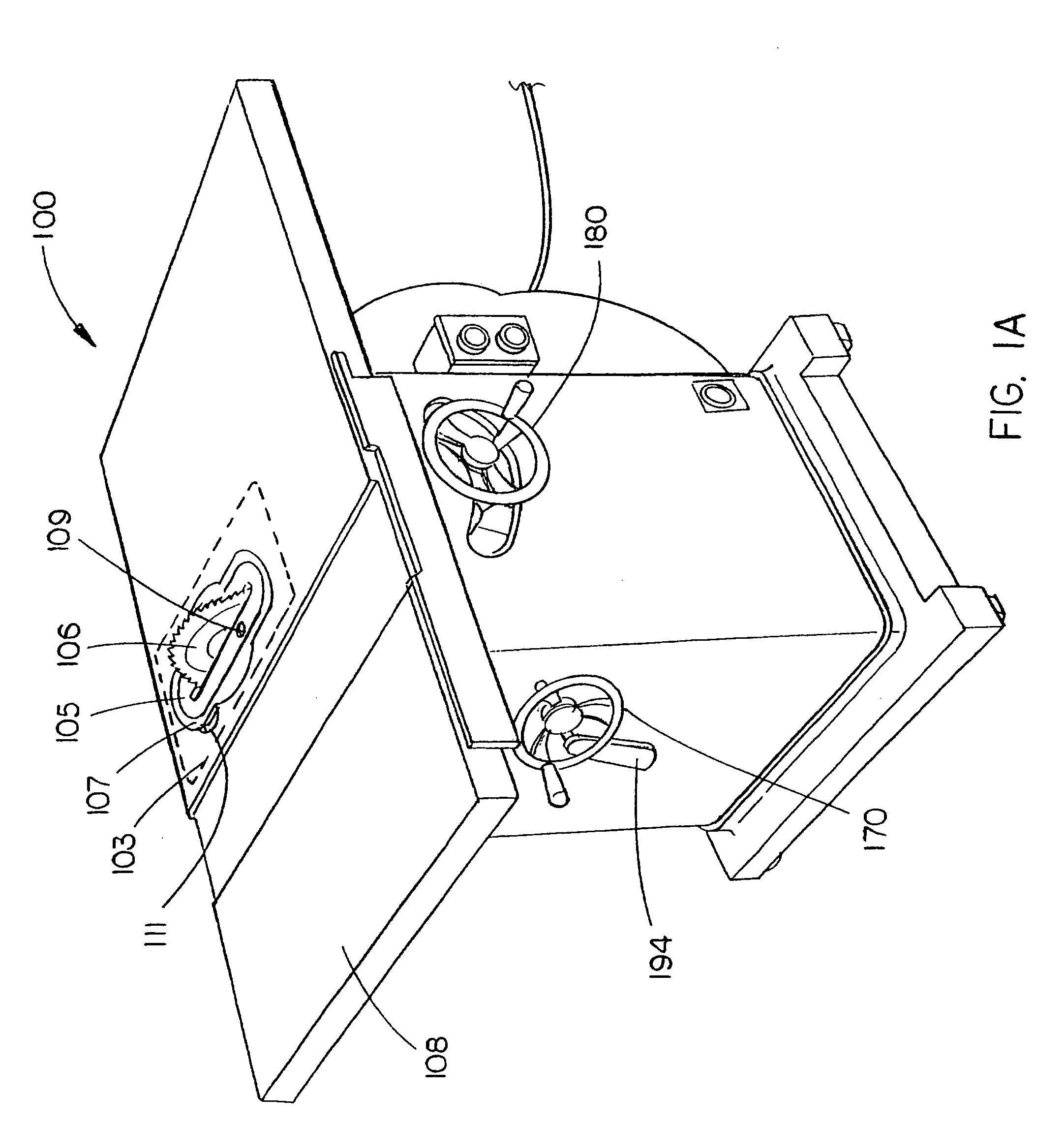

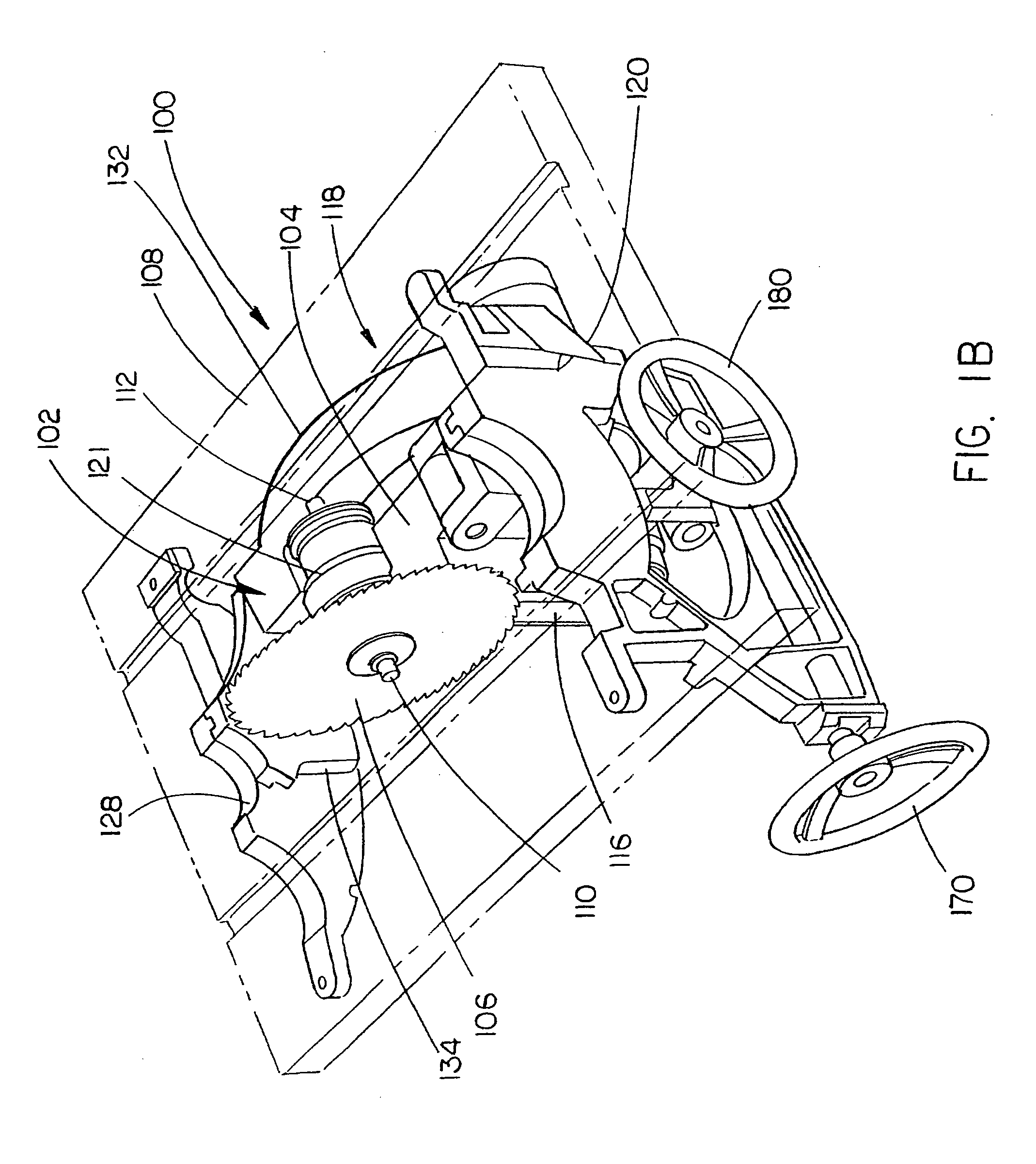

Dual bevel table saw

InactiveUS20040118261A1Efficient use ofMaximizing functional capabilityMetal sawing devicesGuide fencesEngineeringMechanical engineering

A dual bevel table saw provides a table saw enabled with a dual sided arbor assembly and a bi-directional bevel assembly. The dual sided arbor assembly coupled with the bevel assembly further provides for the positioning of a motor and a saw blade to allow for the full range of angular adjustment to be enabled without having to sacrifice any of the cutting features of the saw blade such as depth of cut. The dual bevel table saw may further include a companion saw assembly to provide increased functionality provided by the dual bevel table saw.

Owner:BLACK & DECKER INC

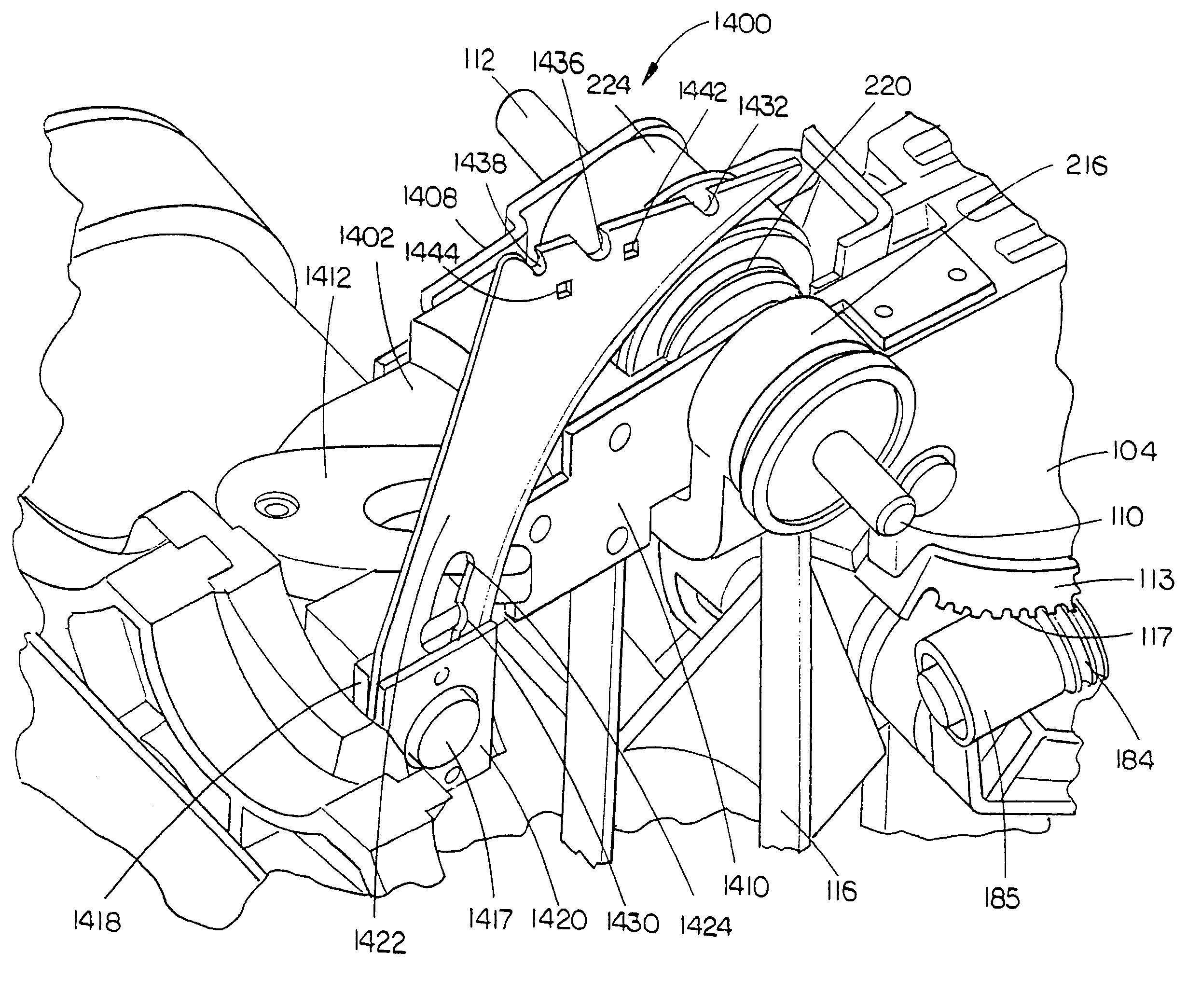

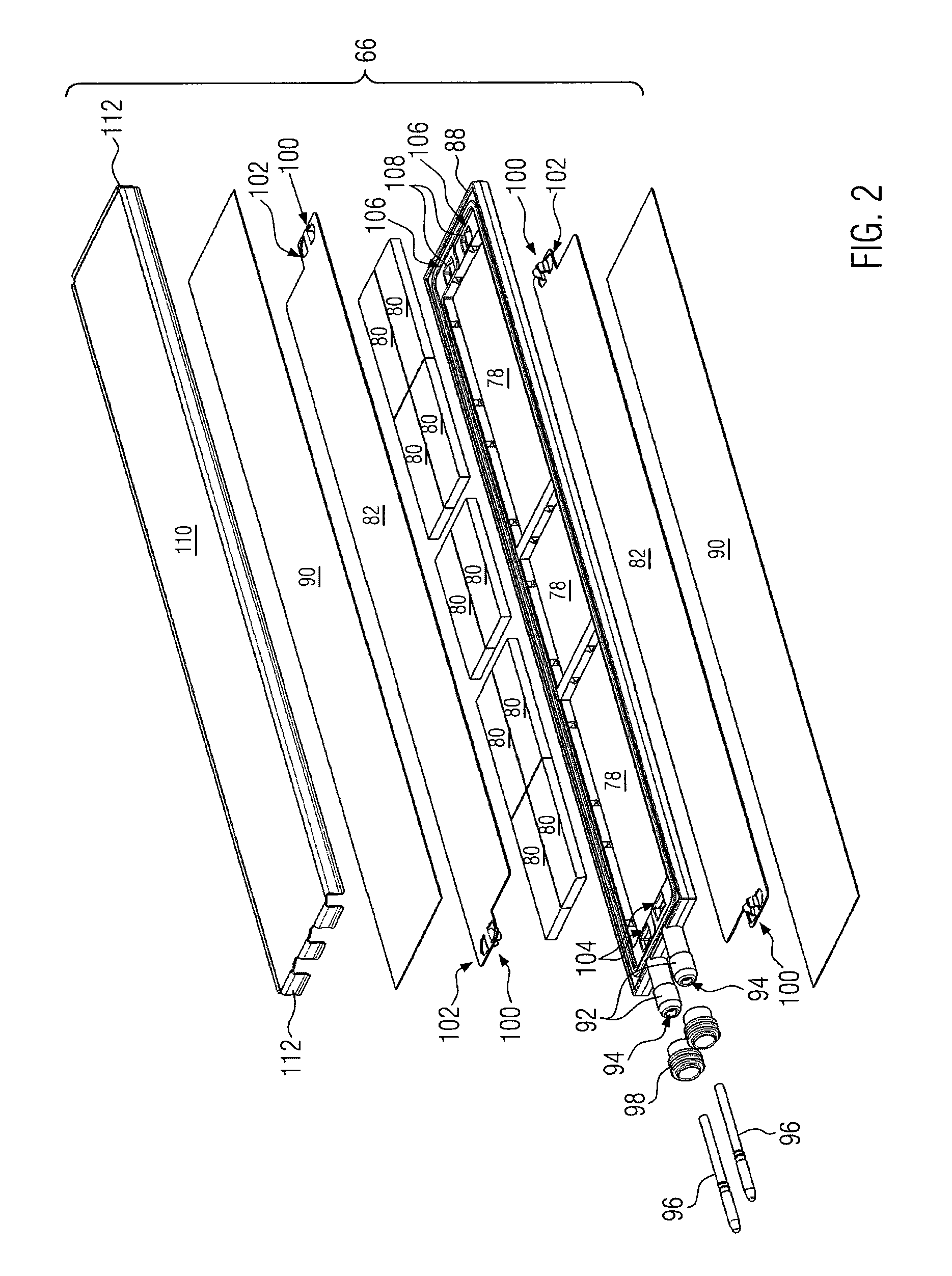

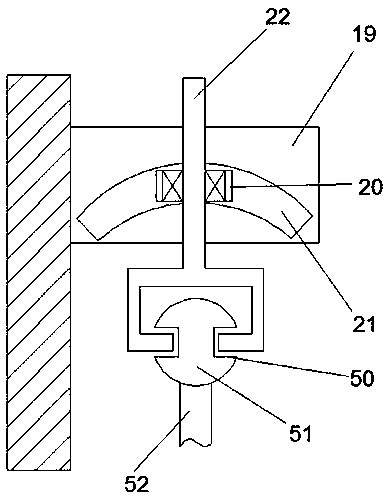

Riving knife assembly for a dual bevel table saw

ActiveUS20050188806A1Efficient use ofFunction maximizationMetal sawing devicesGuide fencesMechanical engineering

An embodiment of the present invention is directed to a riving knife assembly for a dual bevel table saw, comprising: a first armature configured for coupling with a beveling member; a second armature adjustably and rotatably coupled with the first armature; a first mounting member coupled with the second armature; a first riving bracket coupled with the second armature and configured for adjustably coupling with a bearing retaining nut of a dual arbor assembly; a second riving bracket coupled with the first mounting member and configured for adjustably coupling with the inside of a first bore of a first height bracket; a quick release handle disposed upon the first mounting member; an eccentric shaft coupled with the quick release handle; a locking pin having a locking pin body, a second mounting member, a head member coupled with a sheathing member, and a spring loaded assembly, the locking pin operationally coupled with the eccentric shaft; and, a riving knife configured with an engagement assembly for engaging with the locking pin; wherein the spring loaded assembly enables the head member and a circular engagement member disposed on the locking pin body proximal to the head member of the locking pin to be set in a locked position and a release position relative to the second mounting member, the sheathing member and the riving knife; wherein the locked and release positions are established by manipulation of the quick release handle.

Owner:BLACK & DECKER INC

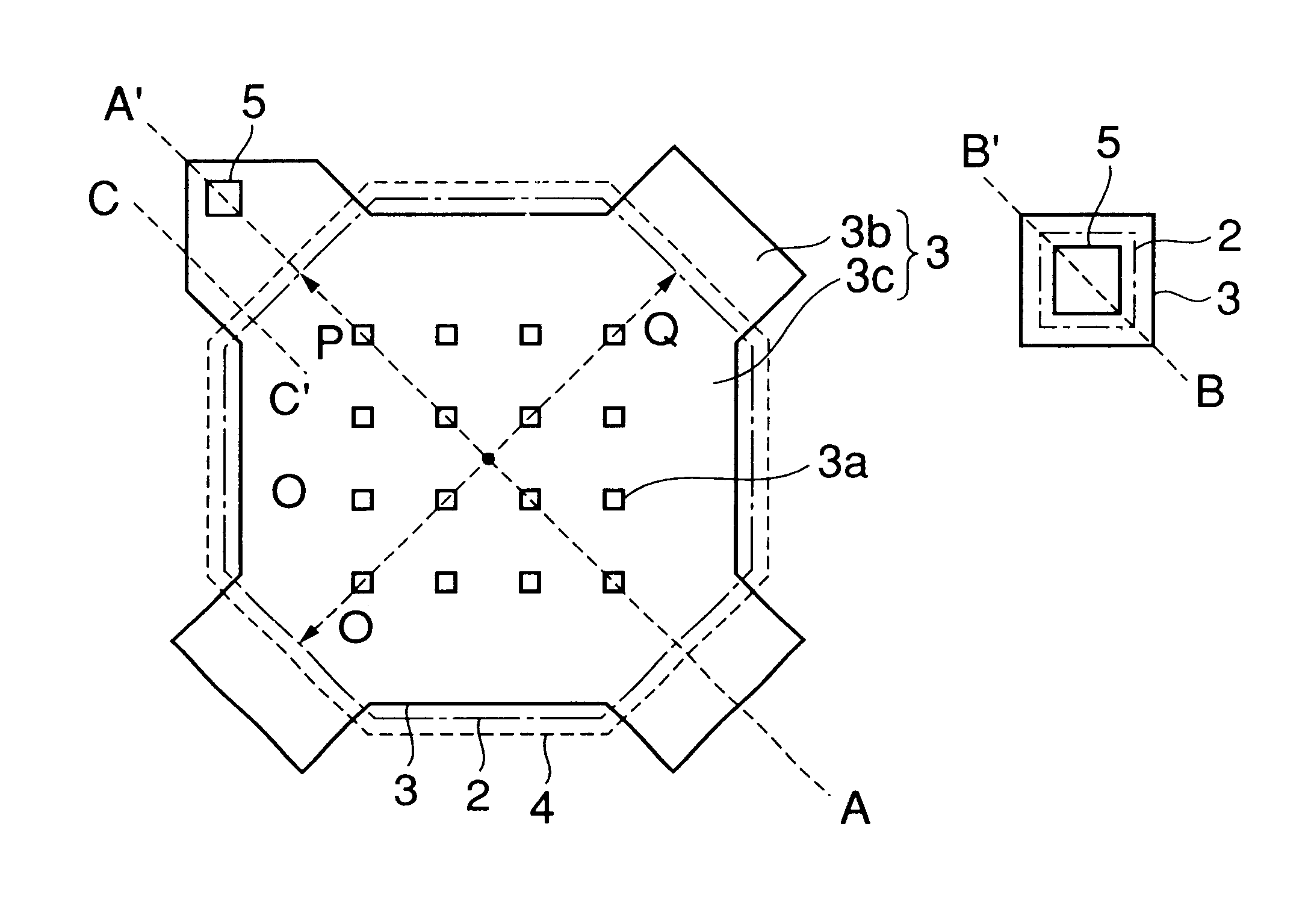

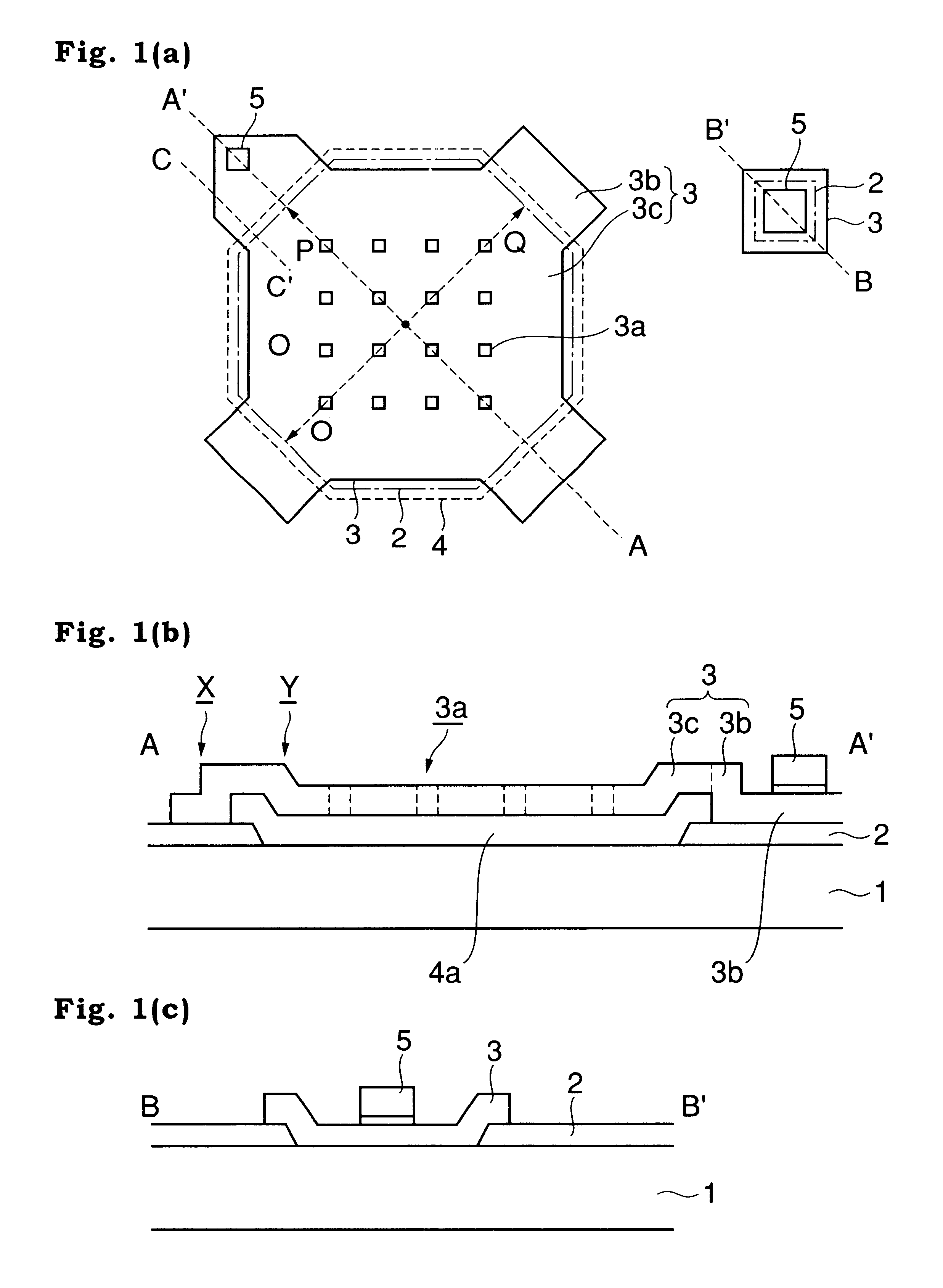

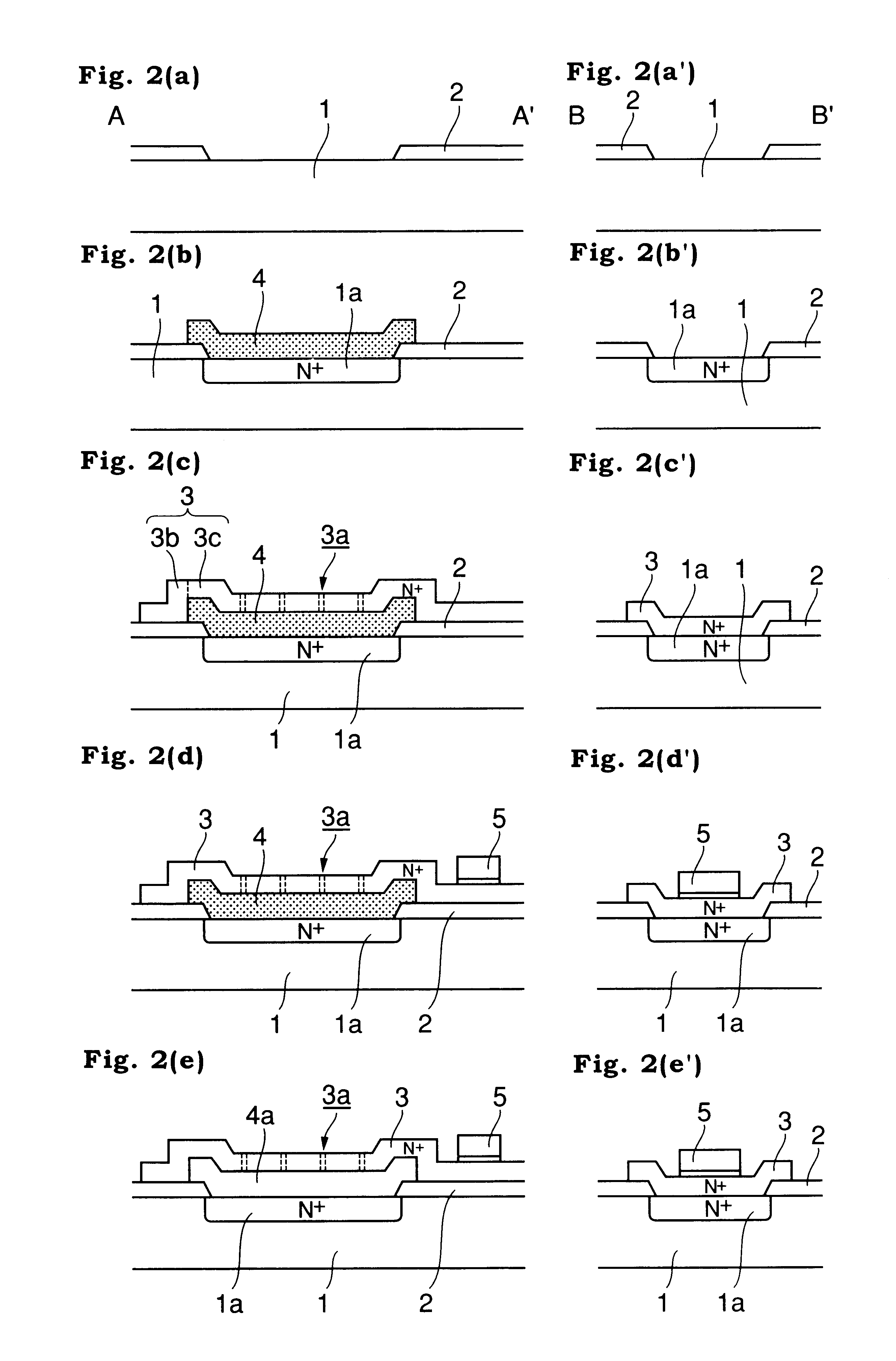

Electroacoustic transducer, process of producing the same and electroacoustic transducing device using the same

InactiveUS6870937B1Improve acoustic propertiesEasy to controlTransducer detailsSemiconductor electrostatic transducersTransducerPhysics

An electroacoustic transducer comprises: a lower electrode; an upper electrode including an oscillation portion and a support portion for supporting the oscillation portion at least at a part of a periphery of the oscillation portion; and an insulating layer for insulating the lower electrode from the upper electrode, wherein the upper electrode has an up and down in the oscillation portion and / or in the support portion to provide a cavity between the upper electrode and the lower electrode.

Owner:SHARP KK

Riving knife assembly for a dual bevel table saw

ActiveUS7137327B2Efficient use ofFunction maximizationMetal sawing devicesGuide fencesEngineeringRivet

An embodiment of the present invention is directed to a riving knife assembly for a dual bevel table saw, comprising: a first armature configured for coupling with a beveling member; a second armature adjustably and rotatably coupled with the first armature; a first mounting member coupled with the second armature; a first riving bracket coupled with the second armature and configured for adjustably coupling with a bearing retaining nut of a dual arbor assembly; a second riving bracket coupled with the first mounting member and configured for adjustably coupling with the inside of a first bore of a first height bracket; a quick release handle disposed upon the first mounting member; an eccentric shaft coupled with the quick release handle; and a riving knife configured with an engaging assembly for engaging with a locking pin or a guard assembly or a kickback finger system.

Owner:BLACK & DECKER INC

Dual bevel table saw

InactiveUS20050160895A1Efficient use ofMaximizing functional capabilityMetal sawing devicesShearing machinesEngineeringMechanical engineering

A dual bevel table saw provides a table saw enabled with a dual sided arbor assembly and a bi-directional bevel assembly. The dual sided arbor assembly coupled with the bevel assembly further provides for the positioning of a motor and a saw blade to allow for the full range of angular adjustment to be enabled without having to sacrifice any of the cutting features of the saw blade such as depth of cut. The dual bevel table saw may further include a companion saw assembly to provide increased functionality provided by the dual bevel table saw.

Owner:BLACK & DECKER INC

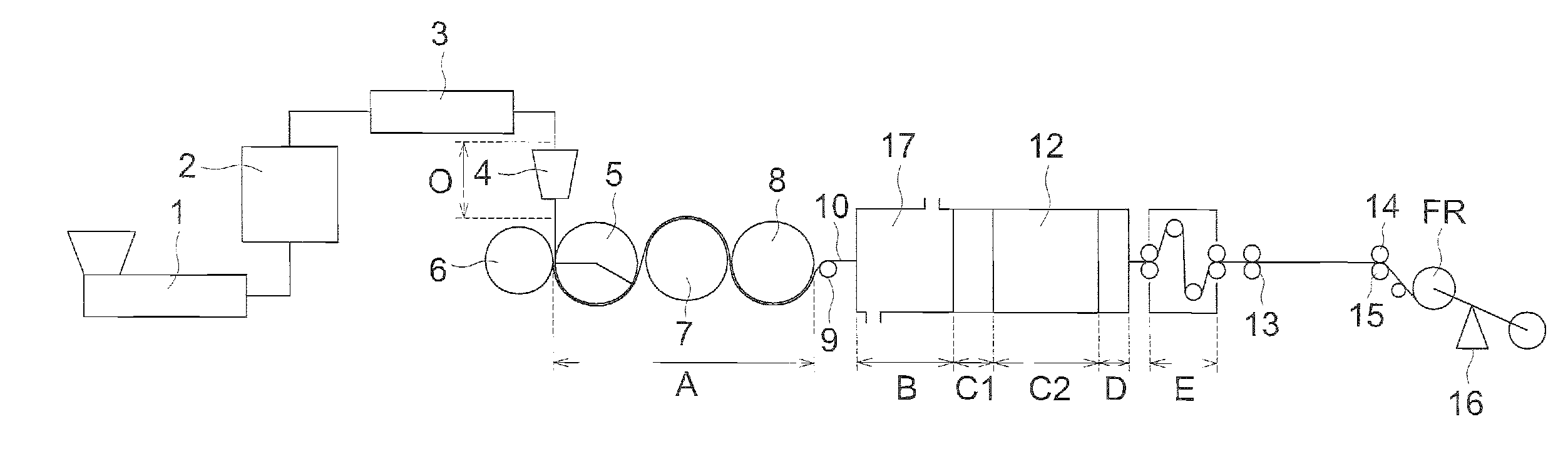

Retardation film, method for producing retardation film, polarizing plate and liquid crystal display

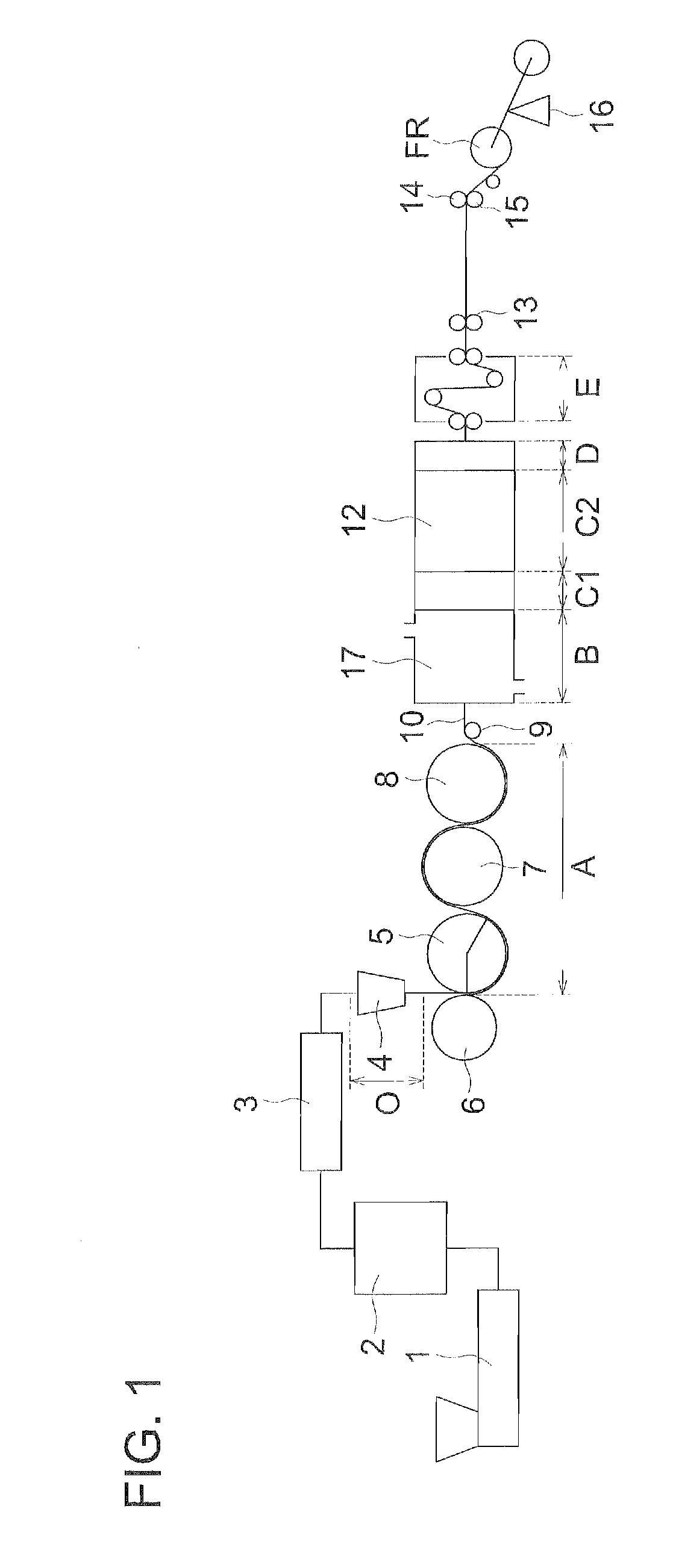

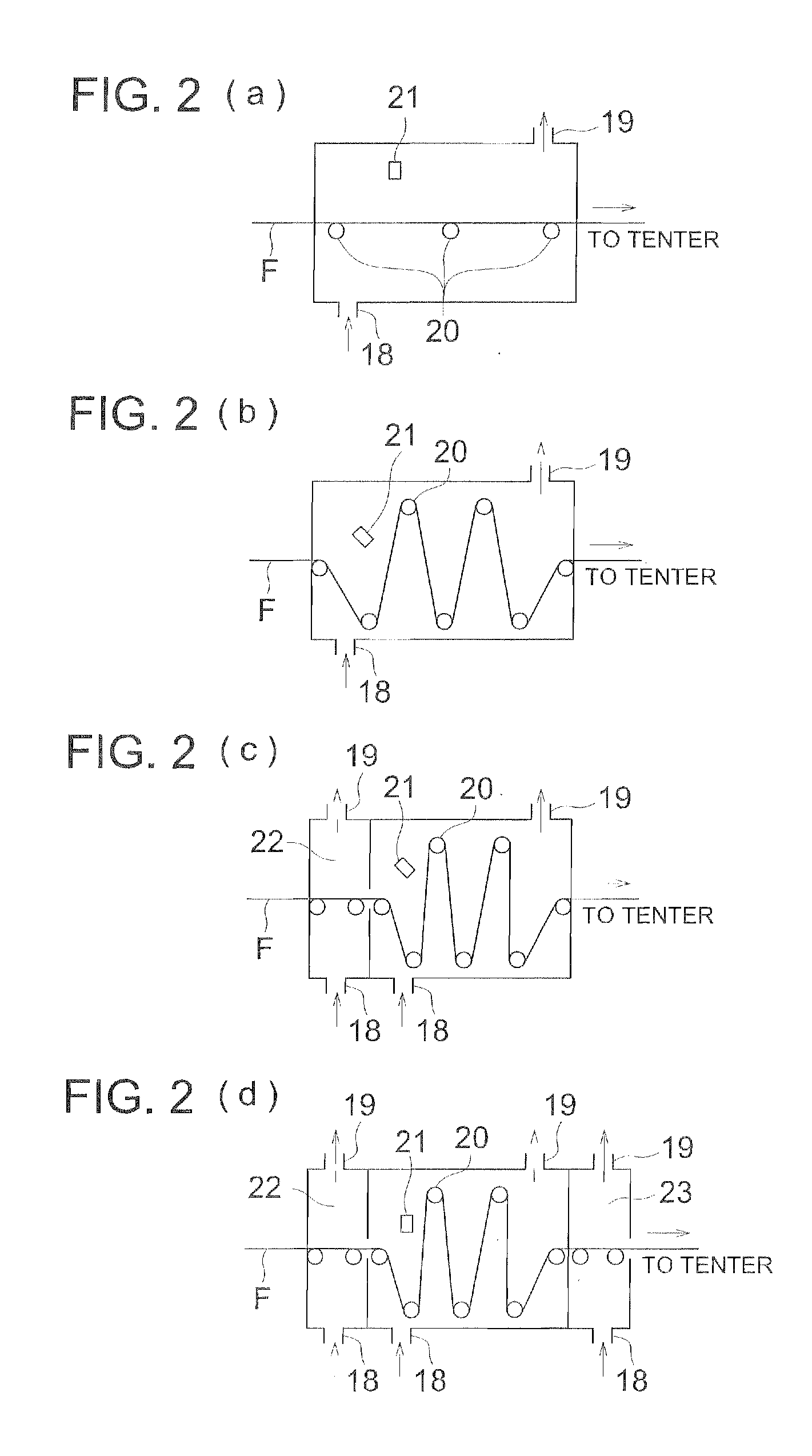

InactiveUS20090169772A1Raised in front-view contrastInhibit coloringLiquid crystal compositionsThin material handlingVitrificationLiquid-crystal display

Disclosed are a retardation film, a method for producing the retardation film, a polarizing plate comprising the retardation film, and a liquid crystal display comprising the polarizing plate. Specifically disclosed is a method for producing a retardation film, which comprises an extrusion step for extruding a composition containing a thermoplastic resin and having a temperature of To [° C.] from a die; a cooling step for cooling a film extruded from the die and having a glass transition temperature of Tg [° C.] to a temperature Ta [° C.]; a heating step for heating the cooled film to a temperature Tb [° C.] at least once; and a stretching step for cooling the heated film to a temperature Tc [° C.] and then stretching the cooled film in the width direction.

Owner:KONICA MINOLTA OPTO

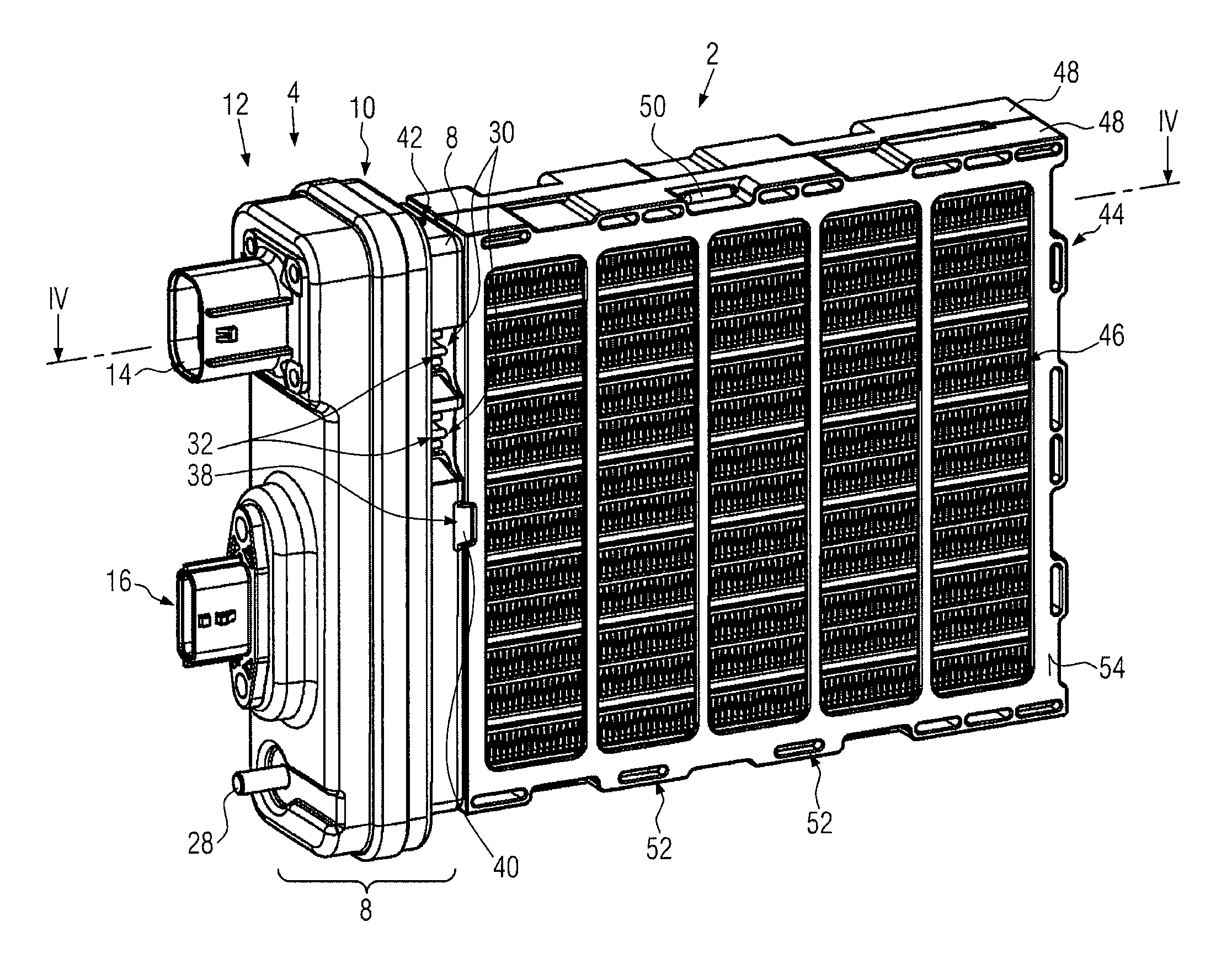

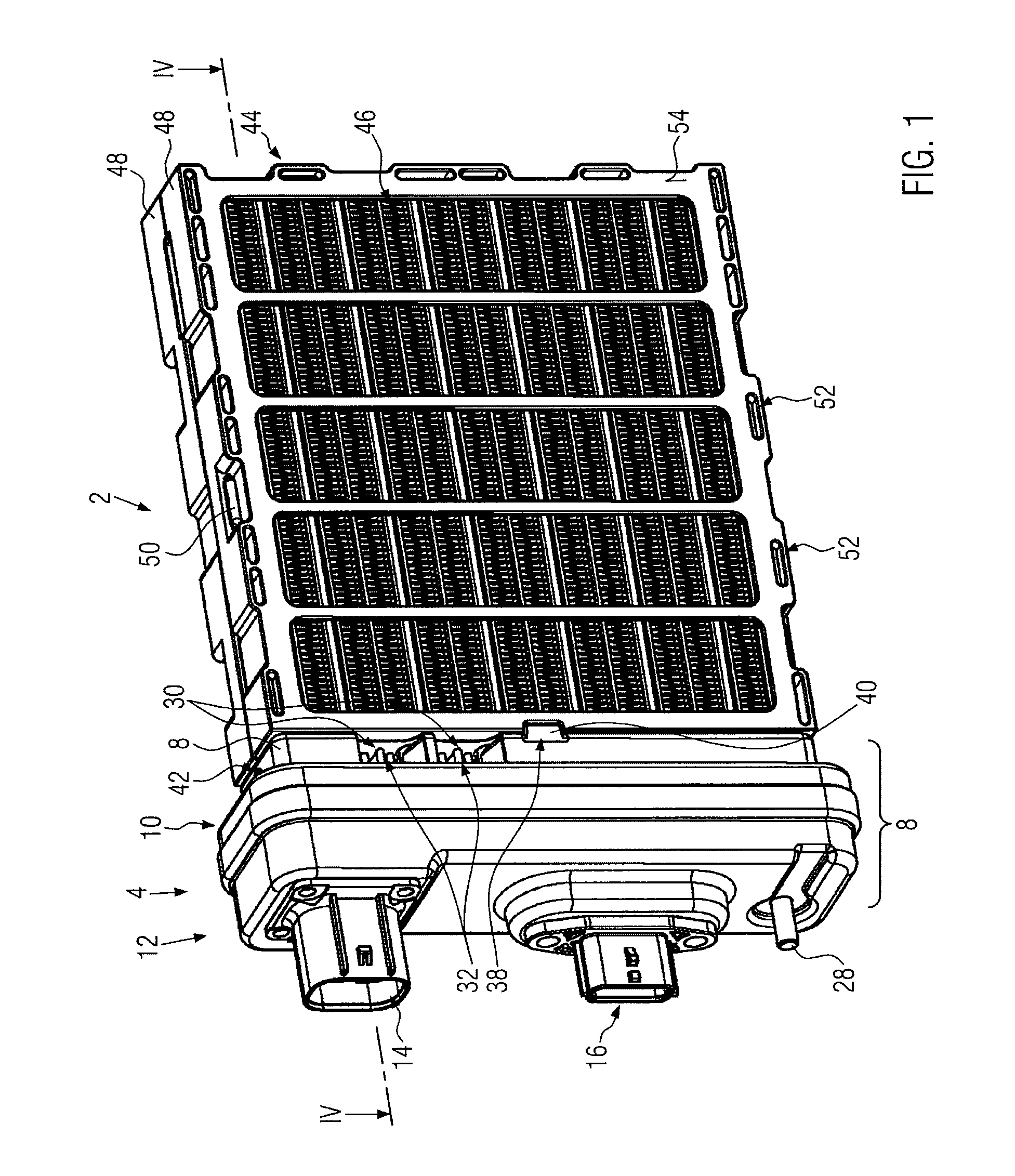

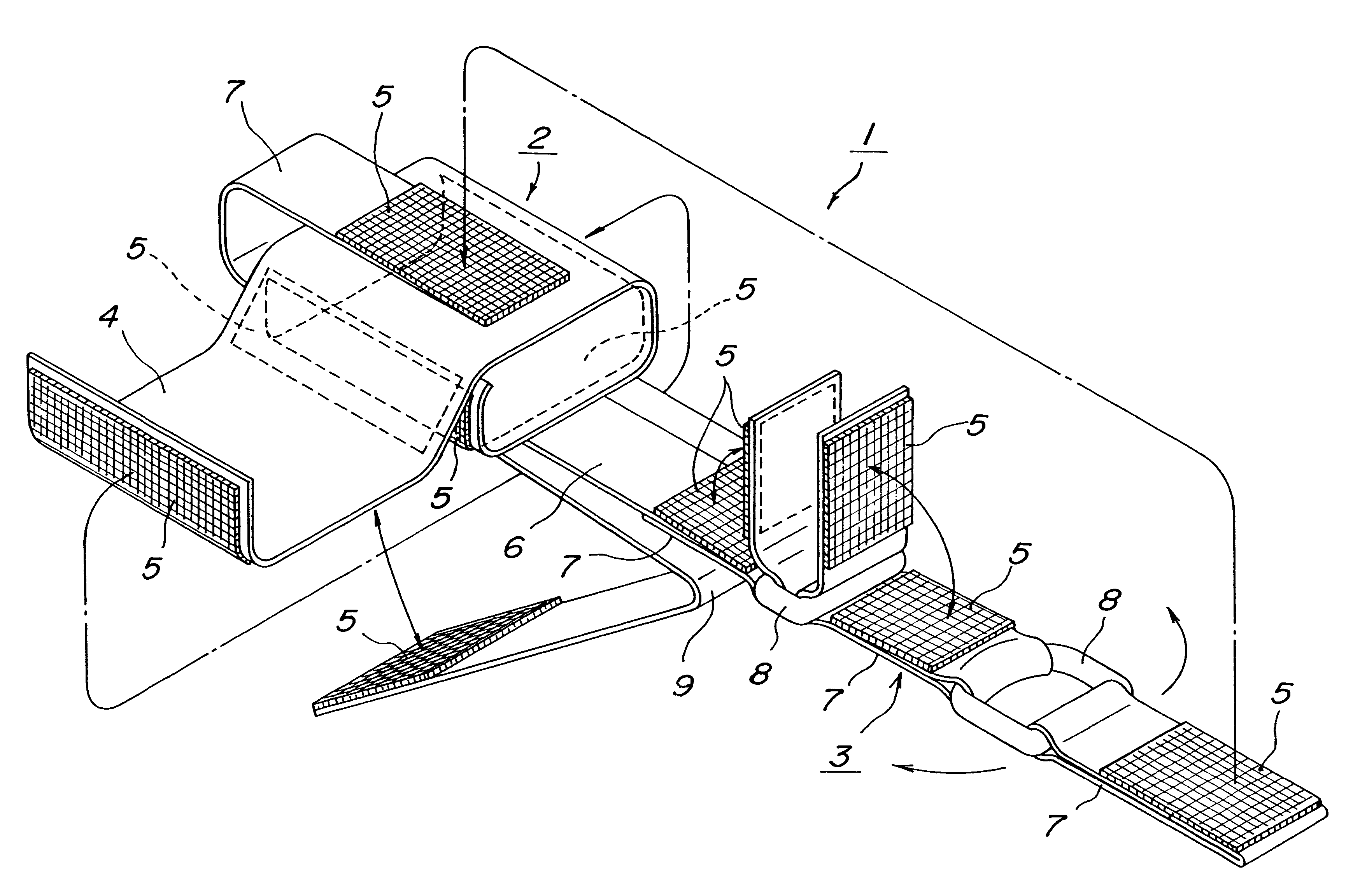

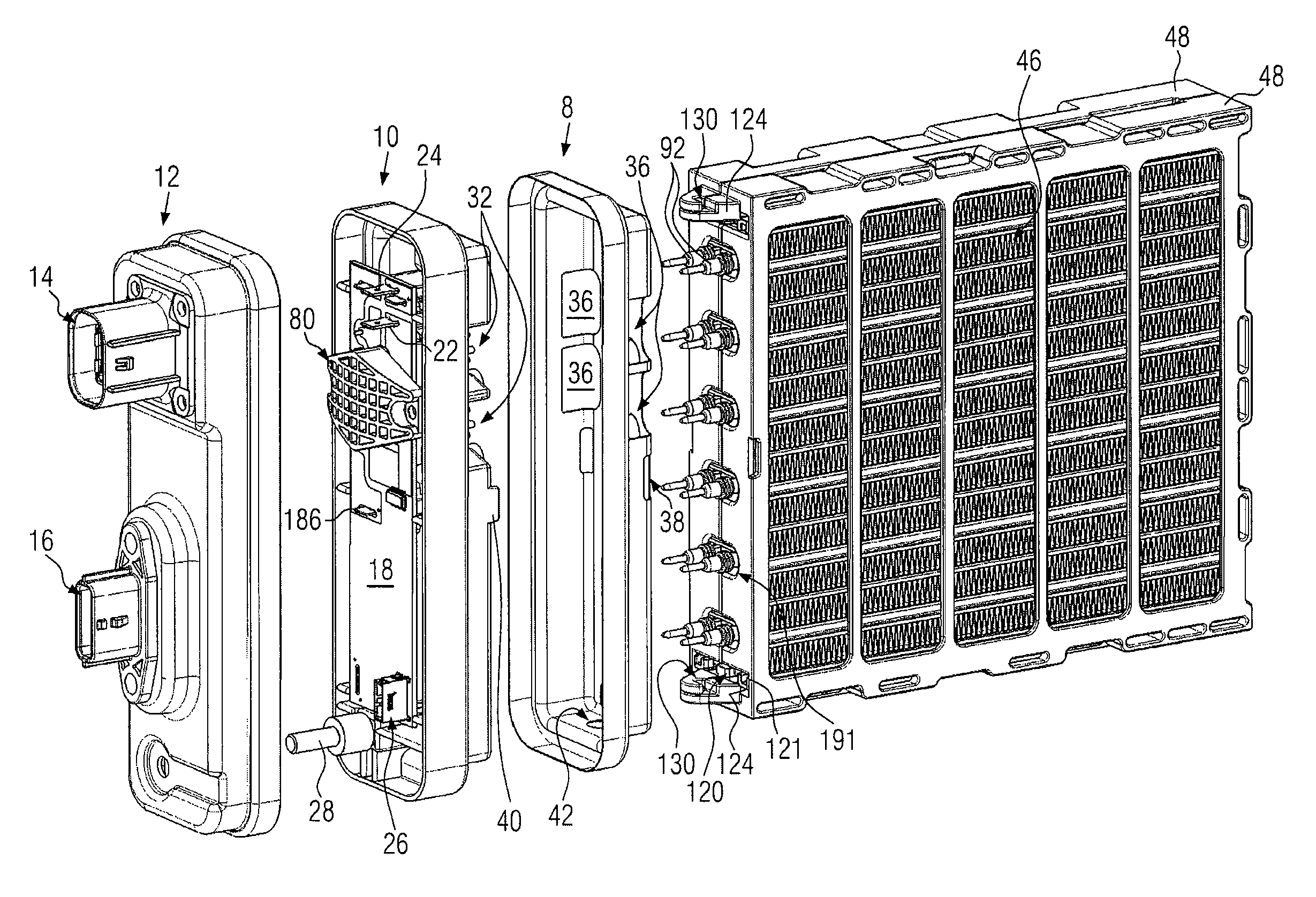

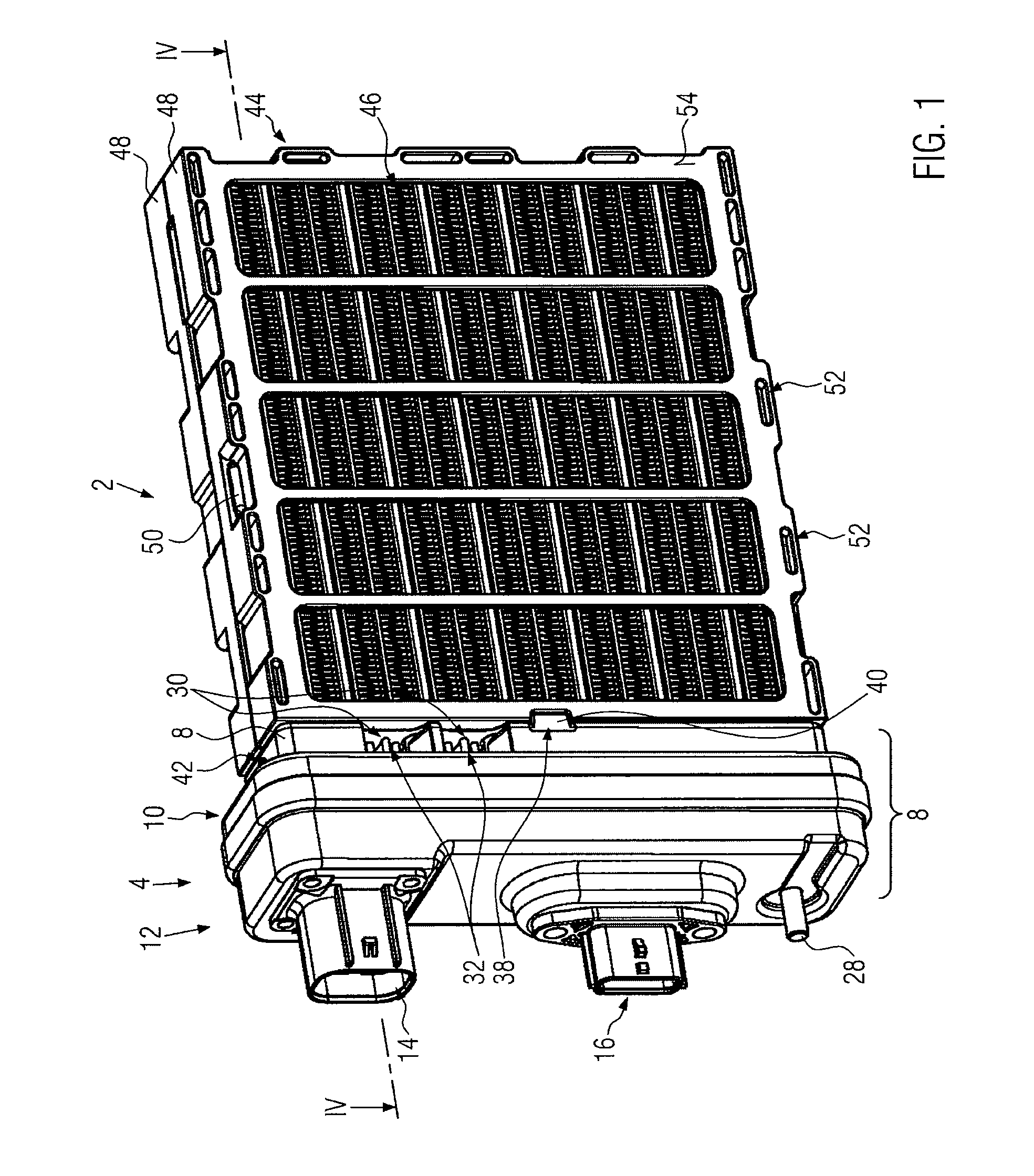

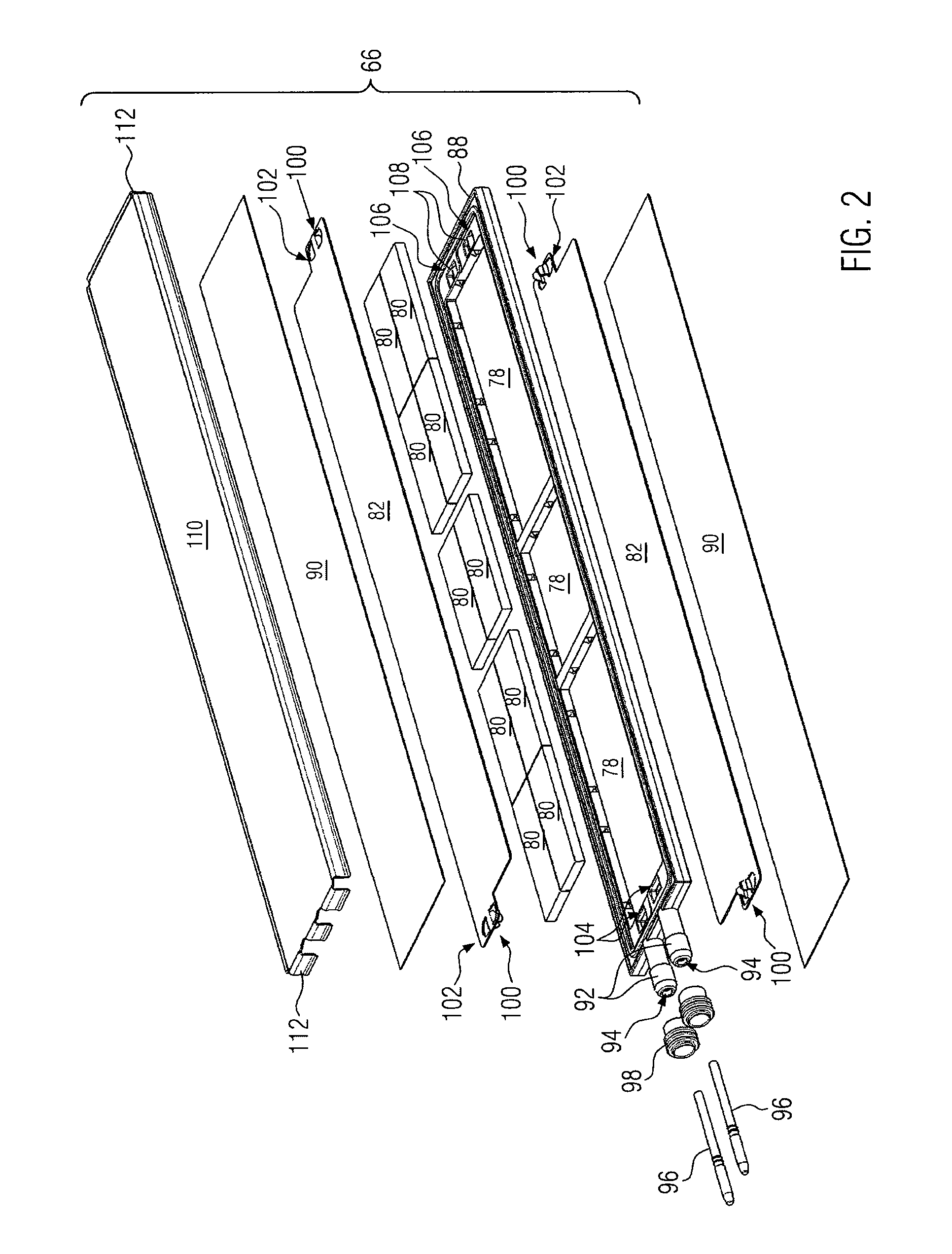

Electrical heating device, particularly for a motor vehicle

ActiveUS20130161308A1Improve cooling effectTolerance on thicknessAir heatersVehicle heating/cooling devicesEngineeringMotorized vehicle

An electrical heating device for a motor vehicle includes a frame that has openings formed on oppositely situated sides for the passage of a medium to be heated, a layer structure, arranged in the frame, and a connecting housing. The layer structure comprises layers of corrugated-rib elements and heat generating elements, and each heat generating element has at least one PTC element arranged between parallel contact plates. At least one power dissipation generating power switch is provided in the connecting housing. A heat sink lies exposed on the outside of the connecting housing. Improved and adequate cooling of the electrical heating device having the power switch is created as a result of the insertion of the heat sink into the connecting housing in a sealing manner.

Owner:EBERSPACHER CATEM

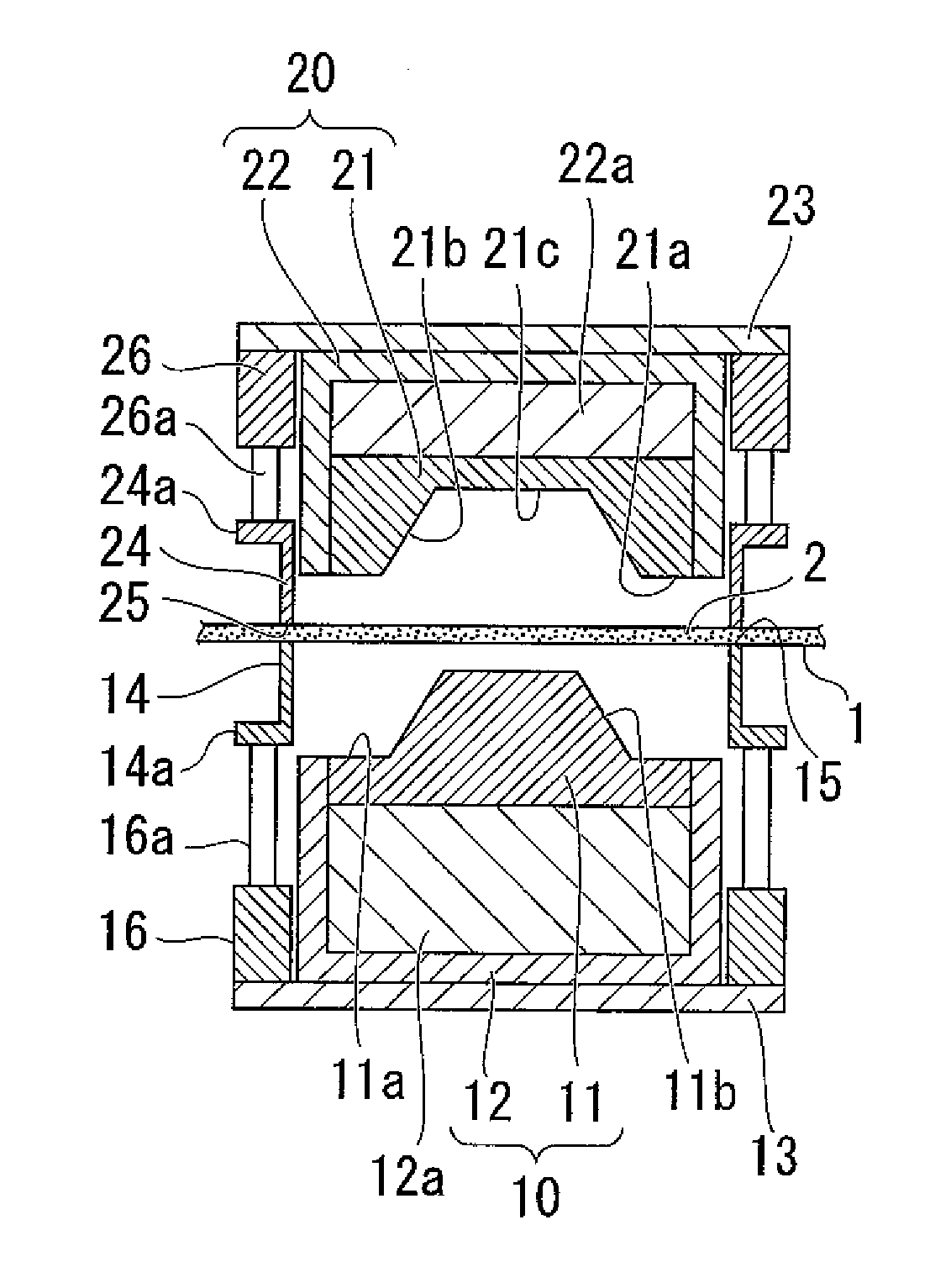

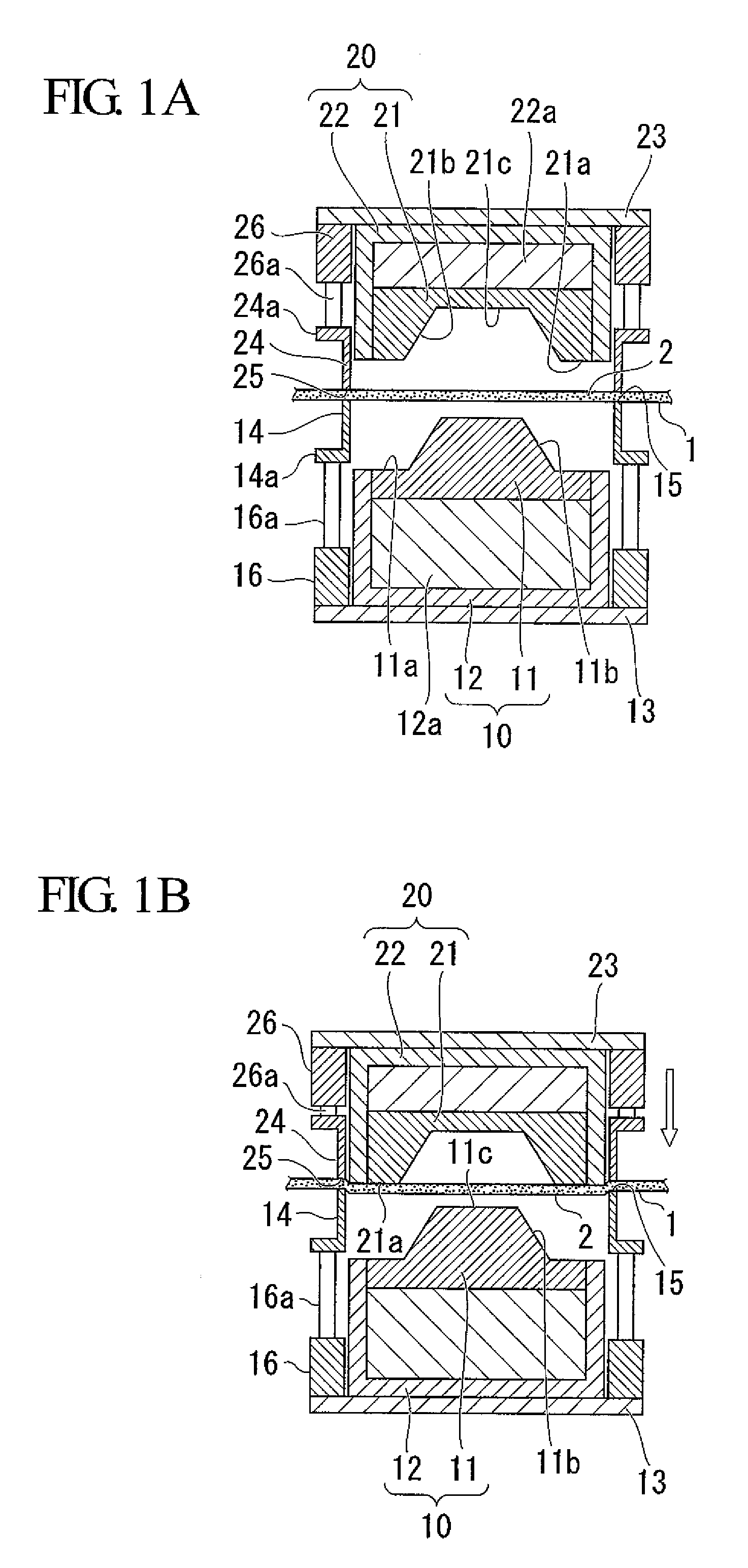

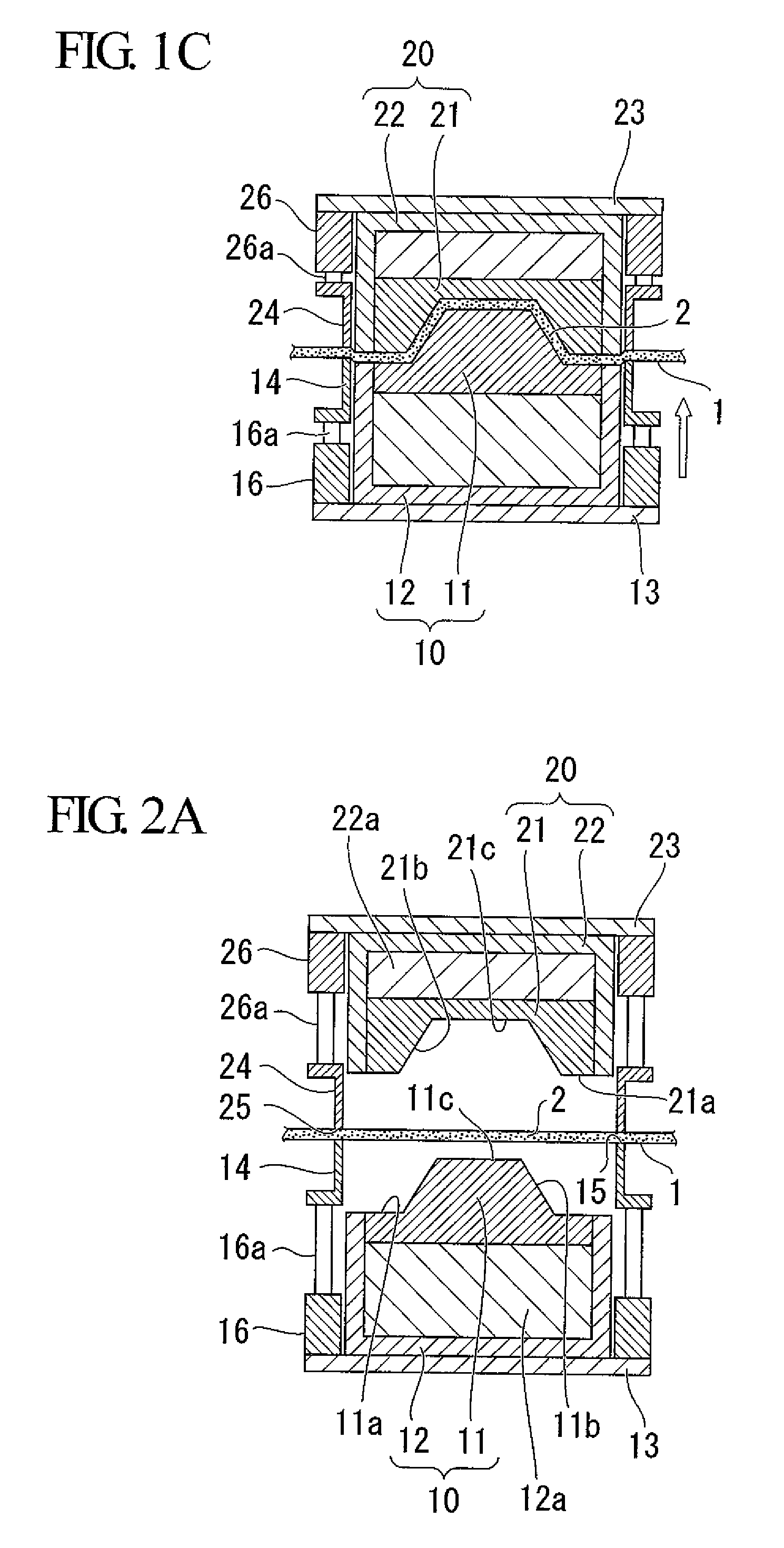

Thermoforming method for thermoforming sheet and thermoforming apparatus

InactiveUS20090039556A1Design property is not deterioratedNo wrinklesConfectioneryWood working apparatusThermoformingShell molding

The thermoforming method of the present invention is a method that includes thermoplasticizing a portion, including a part 2 which is molded with molds, of a thermoforming sheet 1 in which at least one or more thermoplastic resin layers (A) and a decorative layer (B) were laminated, at a temperature range of (Tg (A)−30)° C. to (Tg (A)+10)° C. with respect to the glass transition temperature (Tg (A)) of the thermoplastic resin layer (A); subsequently clamping by using a pair of frame clamps 14 and 24 both sides of a perimeter around the portion 2, which is molded with the molds, of the sheet 1; expanding the thermoplasticized portion between one mold and the frame clamps by pressing a portion of the one mold 20 onto one surface of the thermoplasticized portion; subsequently bringing the other mold 10 into contact with the thermoplasticized portion from the side opposite to the surface of the thermoplasticized portion that the one mold is in contact with; and mold-clamping the thermoplasticized portion with the one mold 10 and the other mold 20 to mold the thermoforming sheet. According to the present invention, forming at a low temperature in which the design properties can not be adversely affected can be achieved, and formed articles in which wrinkles or the like are not generated can be obtained.

Owner:DAINIPPON INK & CHEM INC

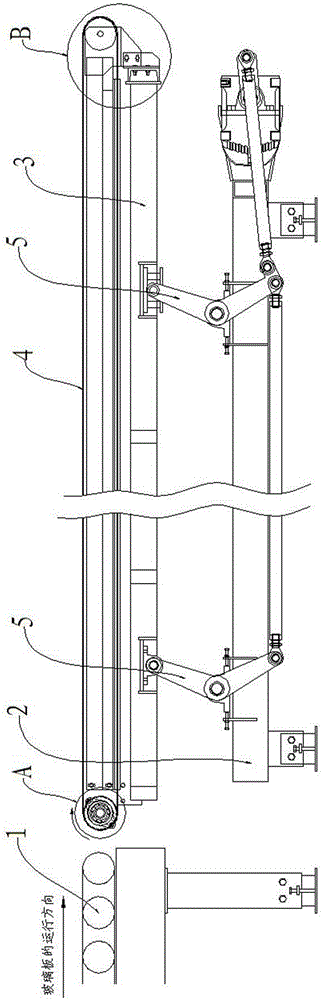

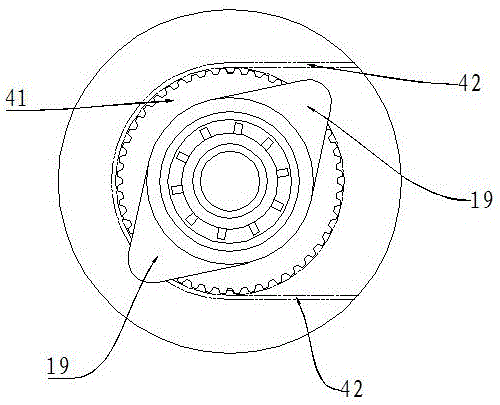

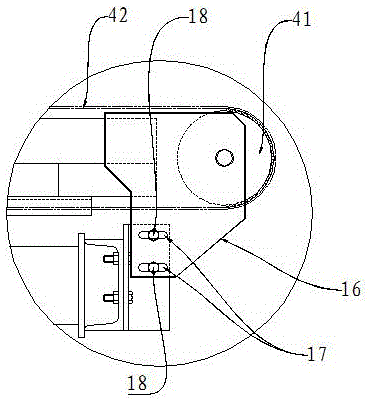

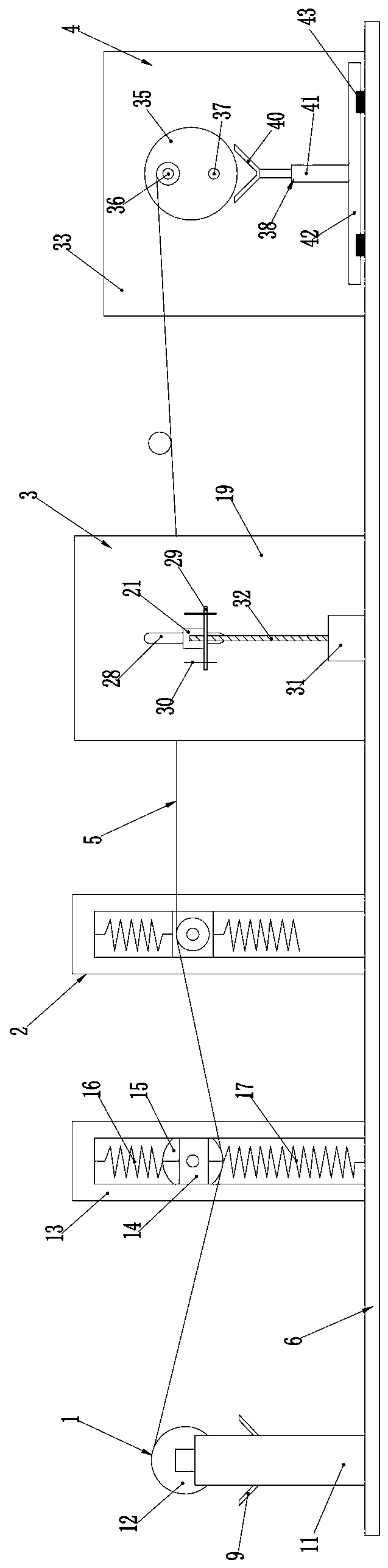

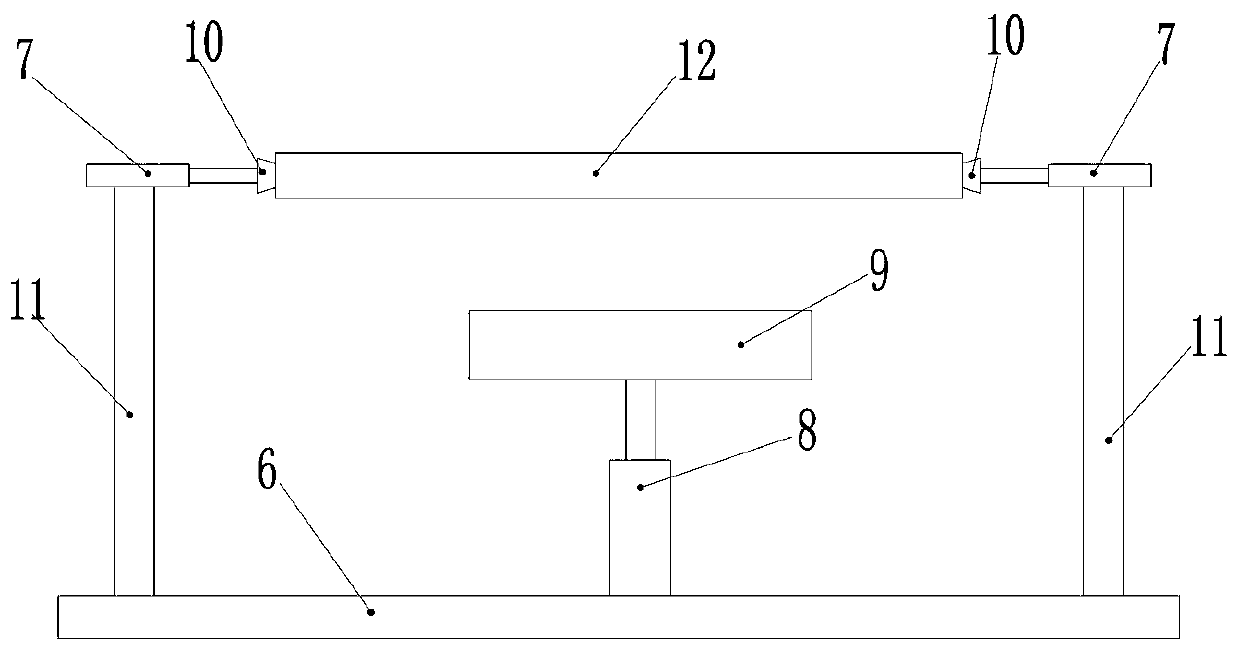

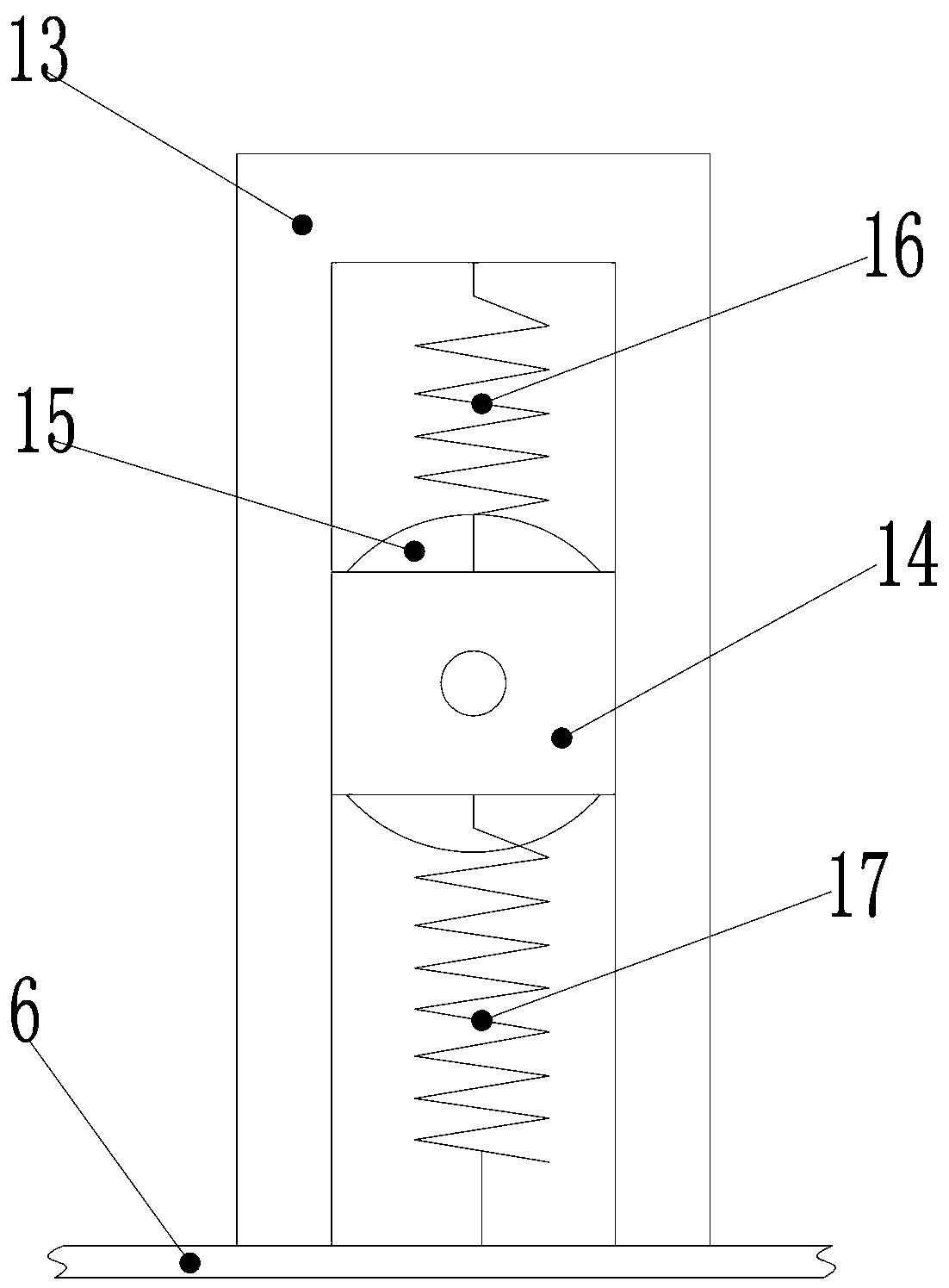

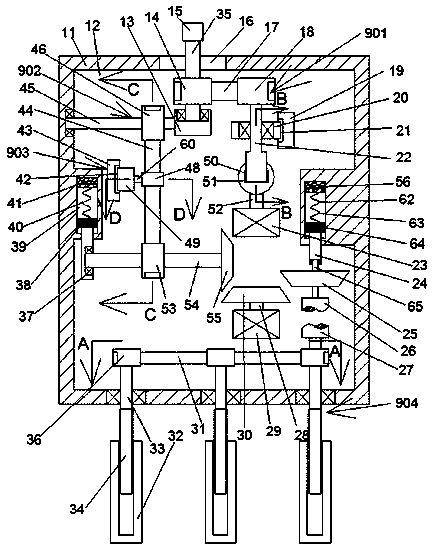

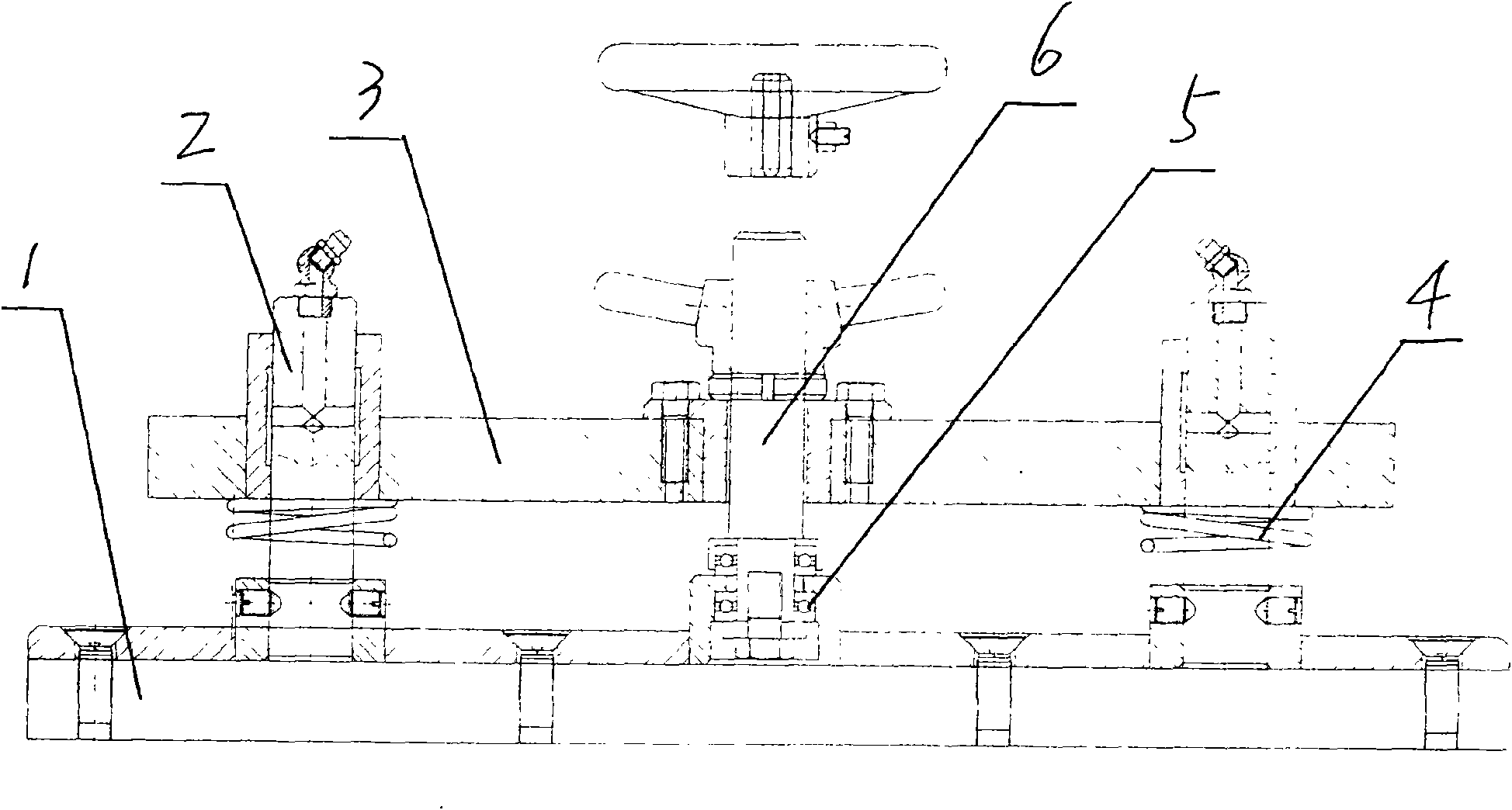

Lifting type belt plate fetching machine

ActiveCN105059896ASmooth entryEntry does not produceConveyorsConveyor partsRelative motionManufacturing line

The invention discloses a lifting type belt plate fetching machine. The lifting type belt plate fetching machine is correspondingly arranged at the tail end of a roller way used for conveying glass plates in a glass production line. The lifting type belt plate fetching machine comprises a base, a belt conveying rack, a lifting mechanism and a belt conveying mechanism horizontally mounted on the belt conveying rack. A belt conveying motor used for driving the belt conveying mechanism to operate is arranged at one end of the belt conveying rack. The belt conveying rack is horizontally mounted on the lifting mechanism. The lifting mechanism is fixed to a base. A lifting mechanism transmission station in transmission connection with the lifting mechanism is arranged on one side of the base. The lifting mechanism transmission station drives the belt conveying rack to act through the lifting mechanism so that the belt conveying mechanism can have certain displacement in the horizontal direction while the vertical height of the belt conveying mechanism is changed, and accordingly the glass plate at the tail end of the roller way is transferred onto the belt conveying mechanism. According to the lifting type belt plate fetching machine, the conveying speed of the belt conveying mechanism is the same as that of the roller way, in this way, it is guaranteed that the glass plate enters a belt of the belt conveying mechanism smoothly, relative movement is avoided, the quality of glass is improved, and the rate of finished products is increased.

Owner:HENAN HAICHUAN ELECTRONICS GLASS CO LTD

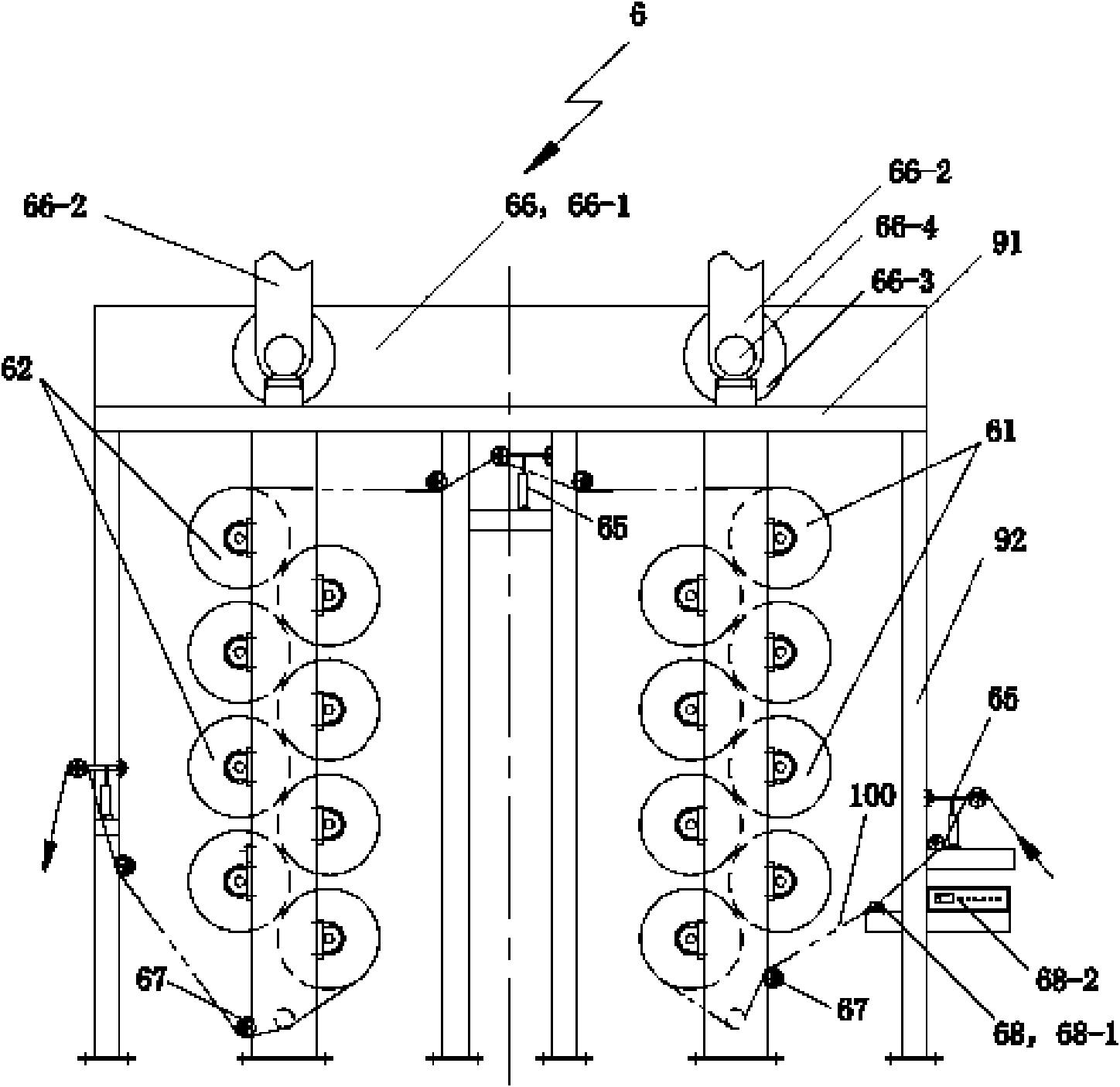

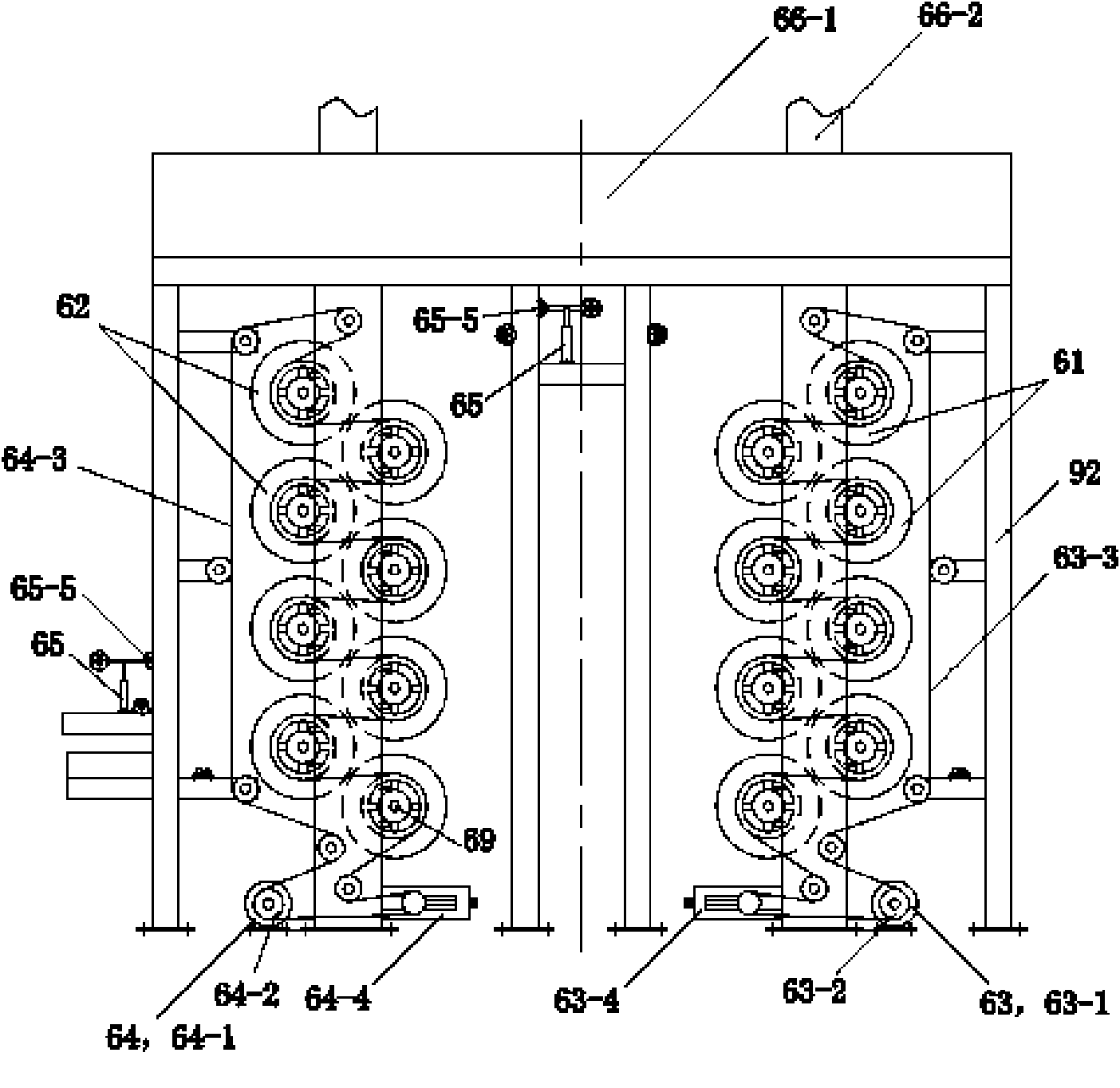

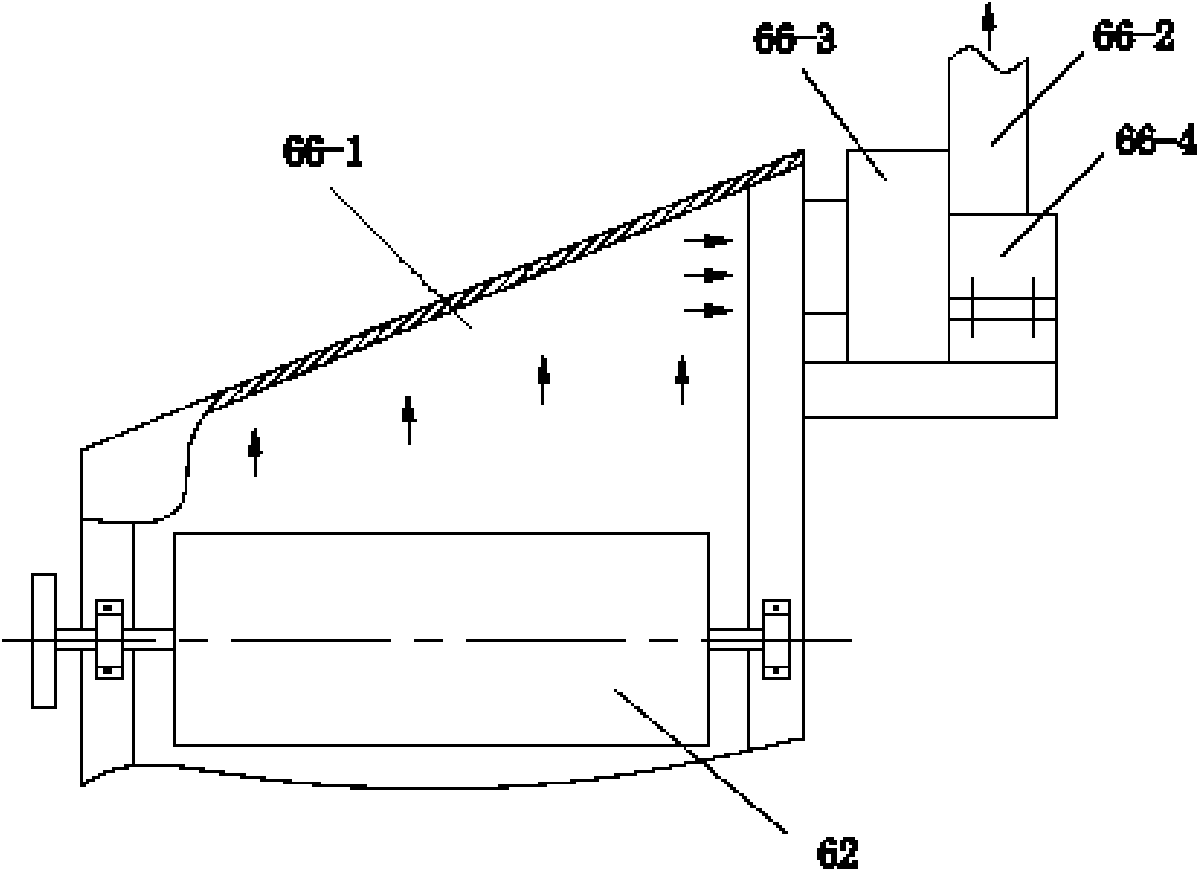

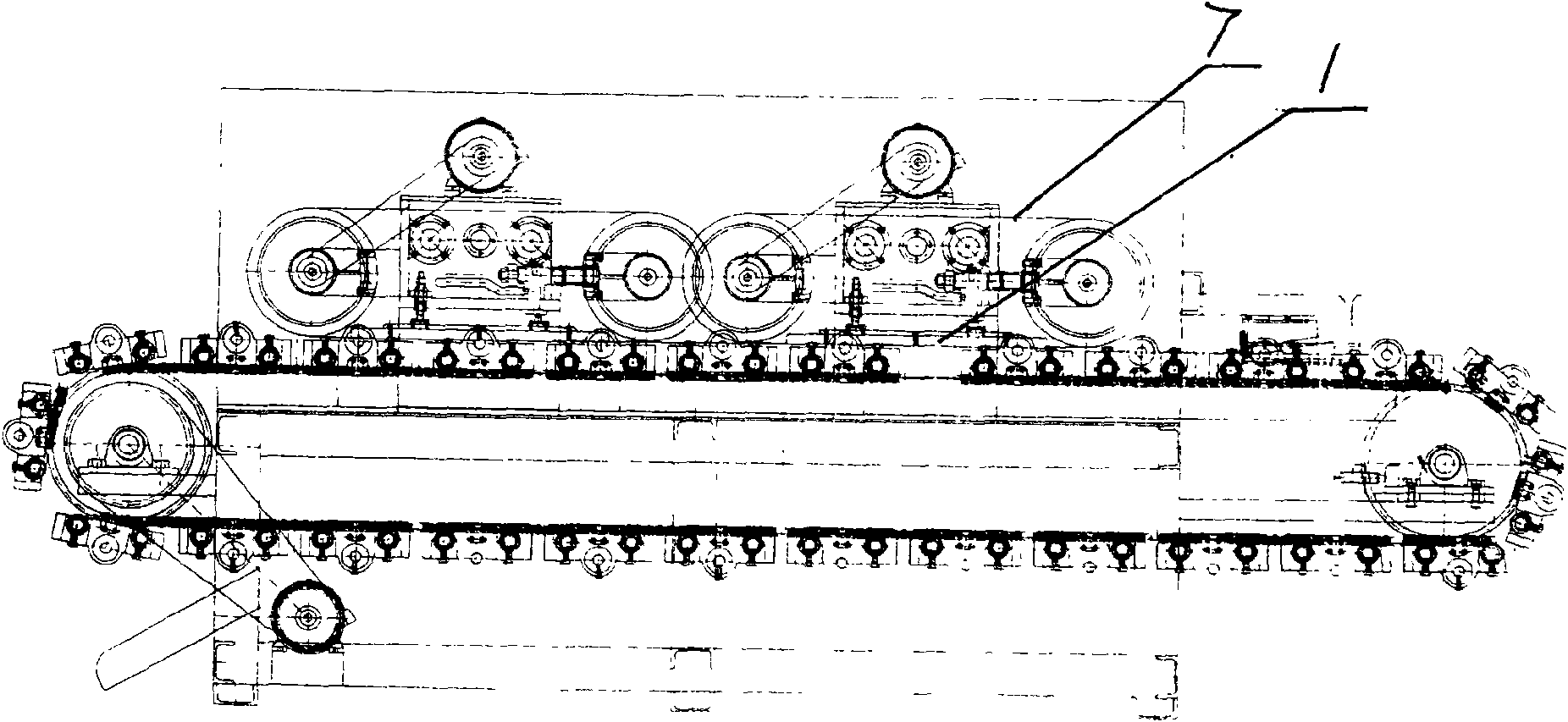

Steam drying device of continuous pigment dyeing padding mangle

InactiveCN101598489ASpeed adjustmentReduce speedDrying solid materials with heatDrying gas arrangementsPulp and paper industryDrying time

The invention relates to a steam drying device of a continuous pigment dyeing padding mangle, which comprises steam drying cylinders, drying transmission mechanisms, a second humidity-discharging device, a water ratio detecting device and an electric cabinet which are arranged on a second mangle frame, wherein the steam drying cylinders are divided into two groups; and the drying transmission mechanisms are divided into two groups correspondingly. During operation, the drying transmission mechanisms drive a fabric to advances sequentially to be dried on the steam drying cylinders. If the water ratio detecting device detects that a water ratio is overhigh, the electric cabinet can be operated in an automatic or a manual mode to reduce the rotating speed of a transmission motor to increase drying time; and otherwise, the rotating speed of the transmission motor is increased to reduce the drying time. Because two groups of steam drying cylinders are adopted to achieve a high advancing speed of the fabric, the steam drying device of the continuous pigment dyeing padding mangle improves the drying efficiency and has a high processing capacity of the drying fabric.

Owner:常州慧杰电气技术有限公司

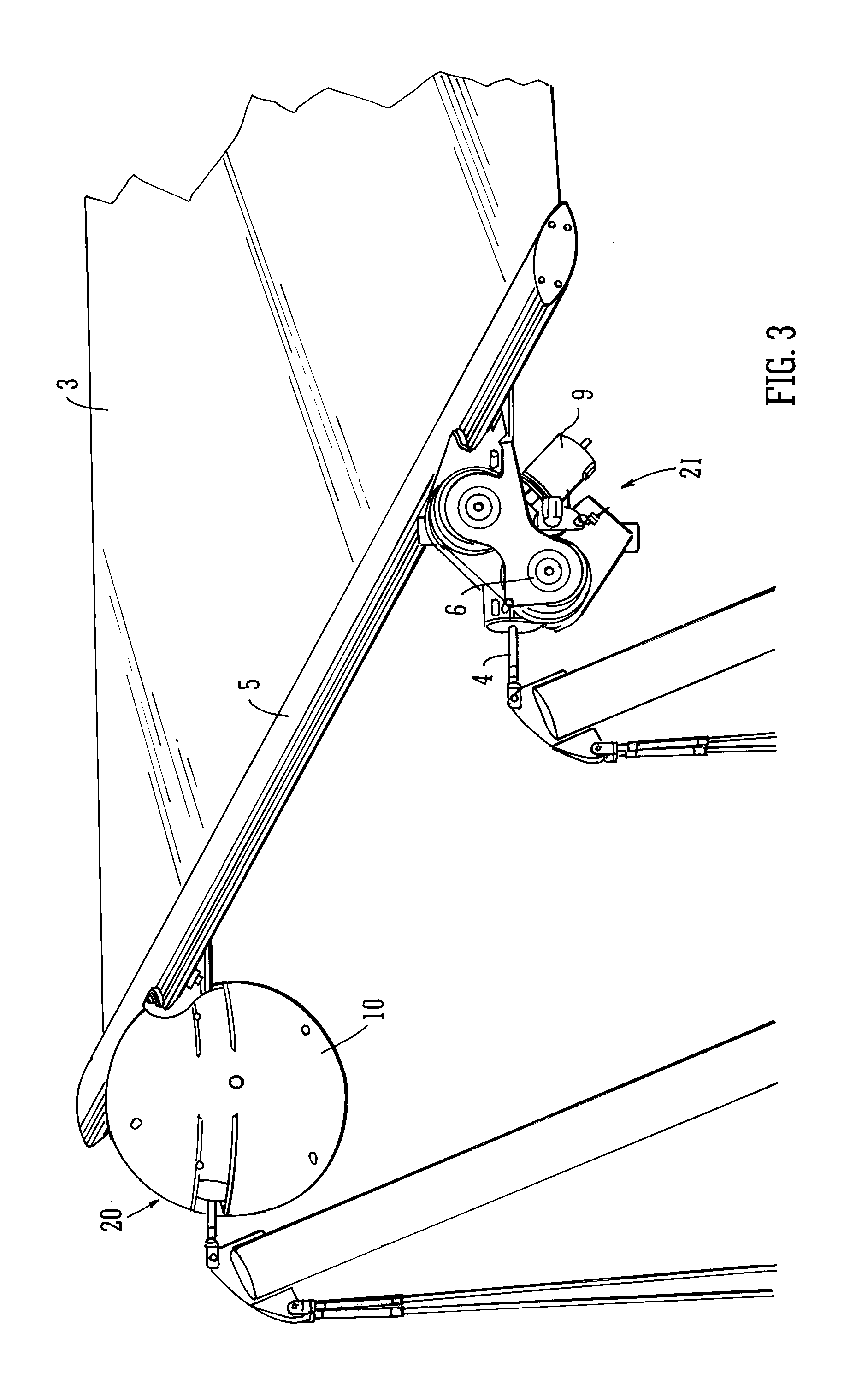

Retractable awning

InactiveUS20130037068A1Prevent saggingMaintain tensionSunshadesClimate change adaptationEngineeringControl unit

A retractable awning. The retractable awning may include a screen that may be extended and retracted, a first motor arranged to extend the screen, a second motor arranged to retract the screen, and a control unit arranged to control the first motors and the second motor.

Owner:CUTLER

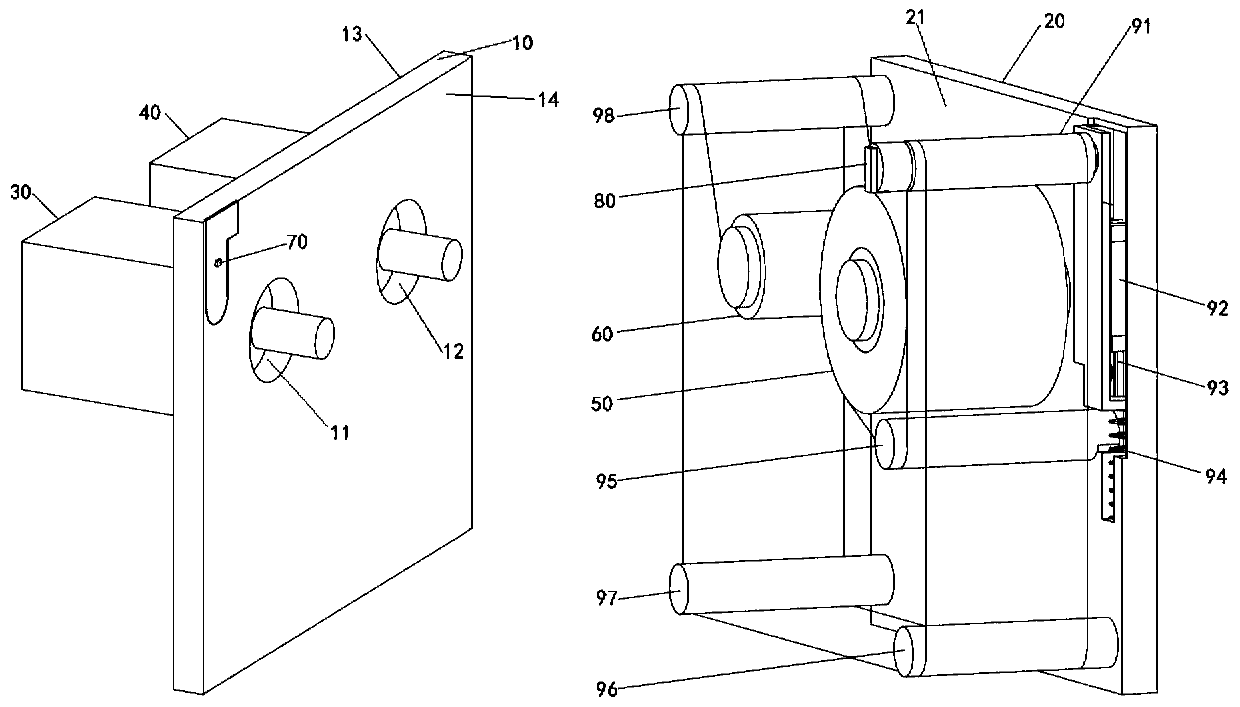

Nonwoven fabric slitting device

ActiveCN109811537ARealize automatic liftingRealize unloadingSevering textilesEngineeringNonwoven fabric

The invention discloses a nonwoven fabric slitting device and belongs to the technical field of nonwoven fabric production equipment. The nonwoven fabric slitting device aims to solve the technical problem of low production efficiency of an existing slitting machine. The nonwoven fabric slitting device comprises an unwinding mechanism, a tensioning mechanism, a slitting mechanism and a rewinding mechanism which are sequentially arranged on a base in the forward direction of nonwoven fabric, the unwinding mechanism tightly clamps an unwinding cylinder through a coaxially-arranged tip cone, rising and falling of the unwinding cylinder are realized through a V-shaped storing table, the slitting mechanism completes slitting of the nonwoven fabric through cooperation of a circular blade and a cutter groove shaft, the circular blade slides on a square shaft to realize adjusting of the nonwoven fabric slitting width, and the rewinding mechanism quickly mounts and demounts a rewinding cylinderthrough an unloading frame. The nonwoven fabric slitting device has the advantages of easy operation, high production efficiency, small workload and wide use range.

Owner:信阳颐和非织布有限责任公司

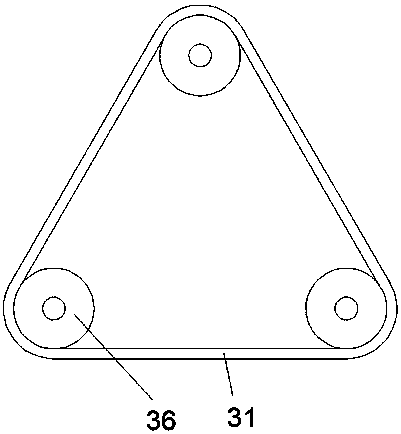

Camera supporting device capable of automatically tracking shot object

ActiveCN110740267AAppropriate tensionEasy maintenanceTelevision system detailsColor television detailsDrive wheelSimulation

The invention discloses a camera supporting device capable of automatically tracking a shot object. The device comprises a shell. An adjusting cavity is formed in the shell. The inner wall of the upper side of the adjusting cavity communicates with the outside and is provided with an adjusting opening. A driven wheel is rotationally connected to the inner wall of the left side of the adjusting cavity. The tension adjusting assembly is adopted. When the 44 is loosened or too tight, tension is adjusted timely, a proper tension force is ensured to exist during 44 transmission. A connecting ball,a limiting groove and a limiting connecting rod are adopted. The camera is ensured to be overturned forwards or backwards. The connecting belt is always connected between the main belt wheel and the auxiliary belt wheel. Meanwhile, most of adopted parts are parts available in the market, maintenance is convenient, and the current situations that when a common handheld camera shoots a moving objectfor a long time, image shaking is serious, people can have a strong fatigue feeling, and an existing automatic tracking pan-tilt is too expensive and not easy to maintain are improved.

Owner:江苏卓燃高新科技有限公司

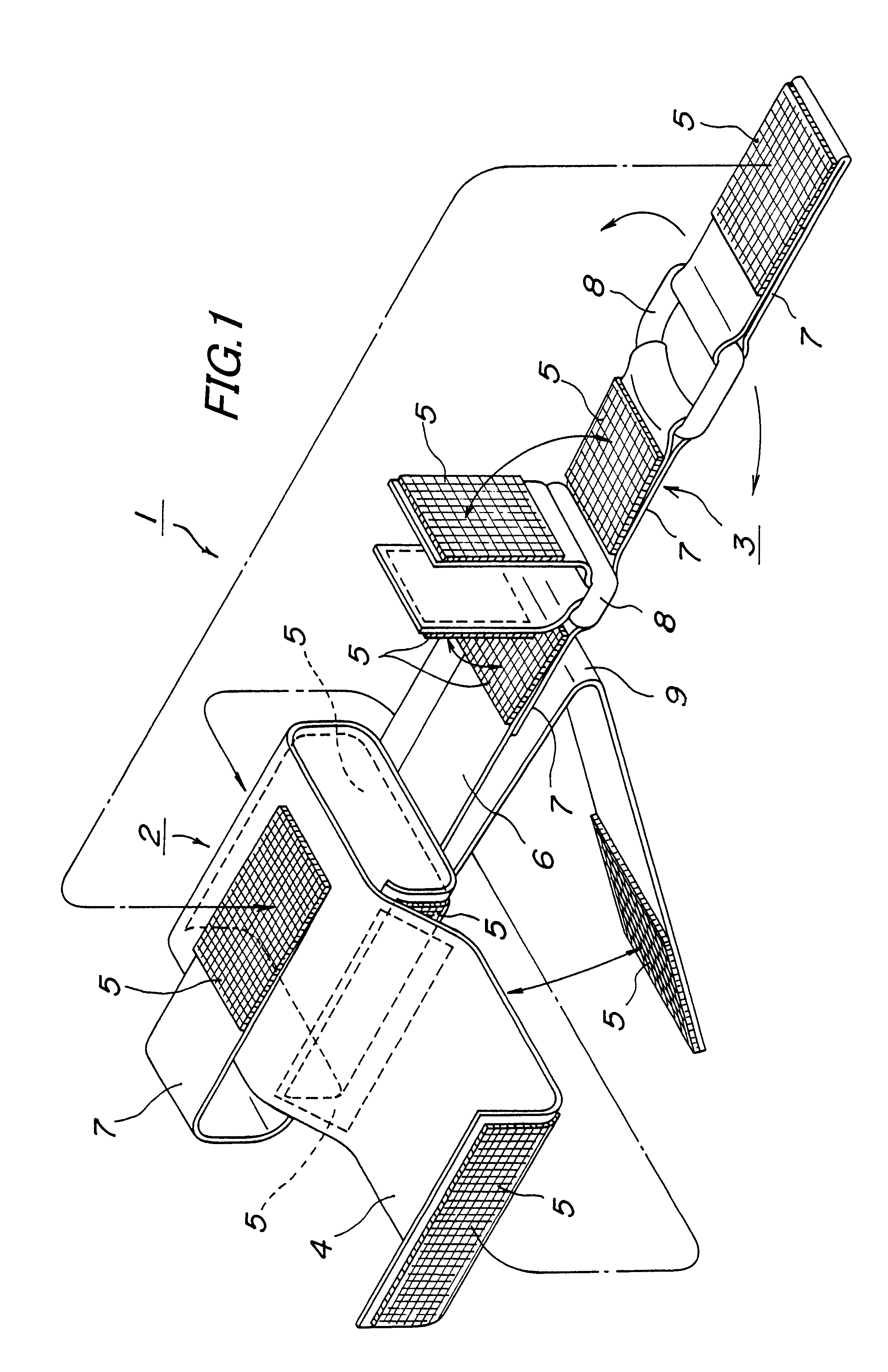

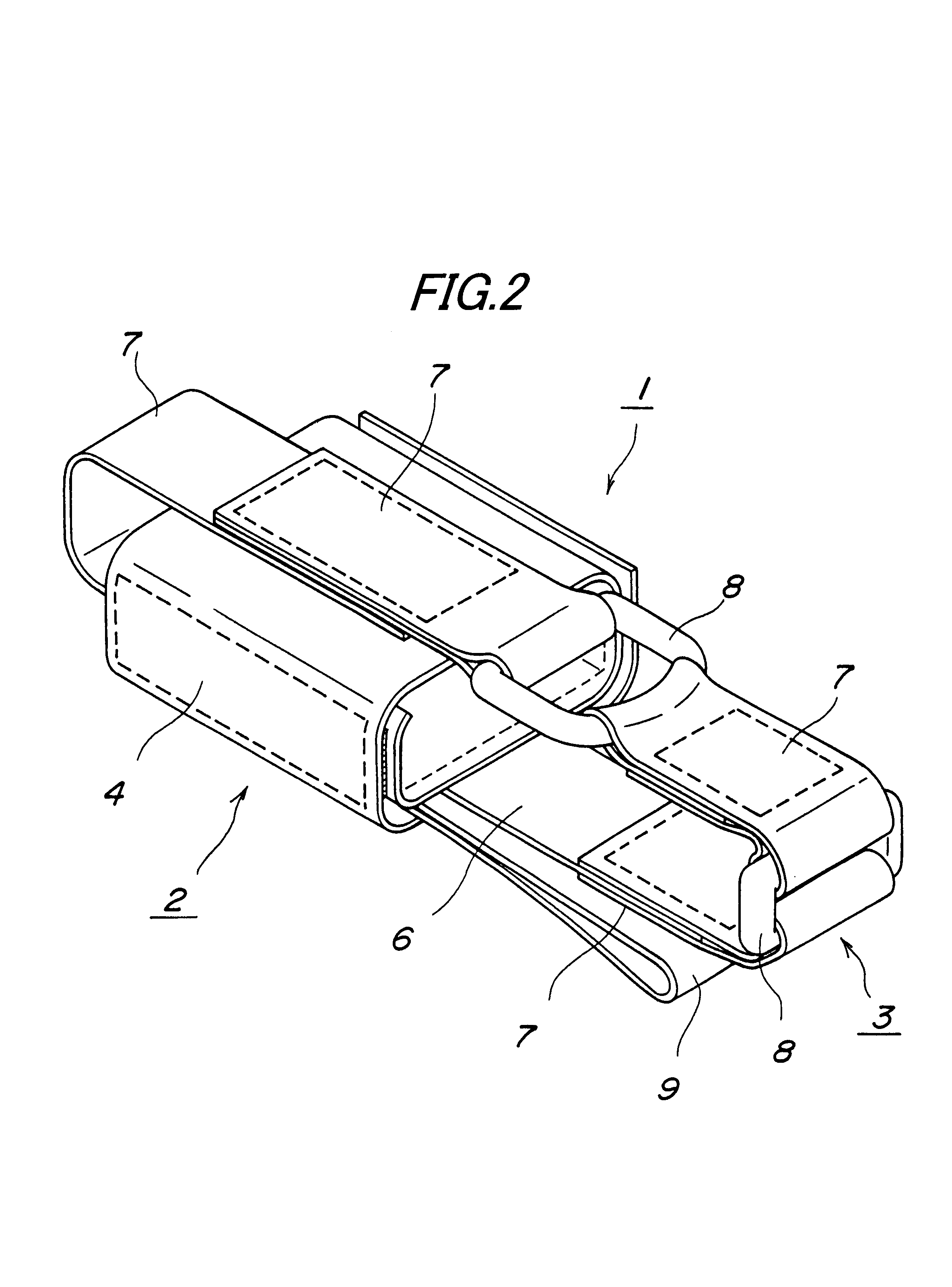

Cellular phone holder

InactiveUS6934517B2Made longerPosition and secureTravelling carriersInterconnection arrangementsEngineeringMechanical engineering

The object of this invention is to provide a cellular phone holder, which could easily hold a standard type cellular phone as well as a collapsible type cellular phone having different sizes, respectively. Thus cellular phone holder is comprised of a lateral case capable of holding cellular phones of different width, and a longitudinal strap belt attached in a manner so as to intersect with the lateral case. Thus lateral case is formed of a single trunk member in which the trunk member is bent into a cylindrical shape and secured by Velcro tape attached in plural portions. A ring couples thus longitudinal strap belt to a plurality of strap belts and thus, a portion of the longitudinal strap belt is structured by an elastic material.

Owner:KANAGAWA HOUSEISHOUKAI

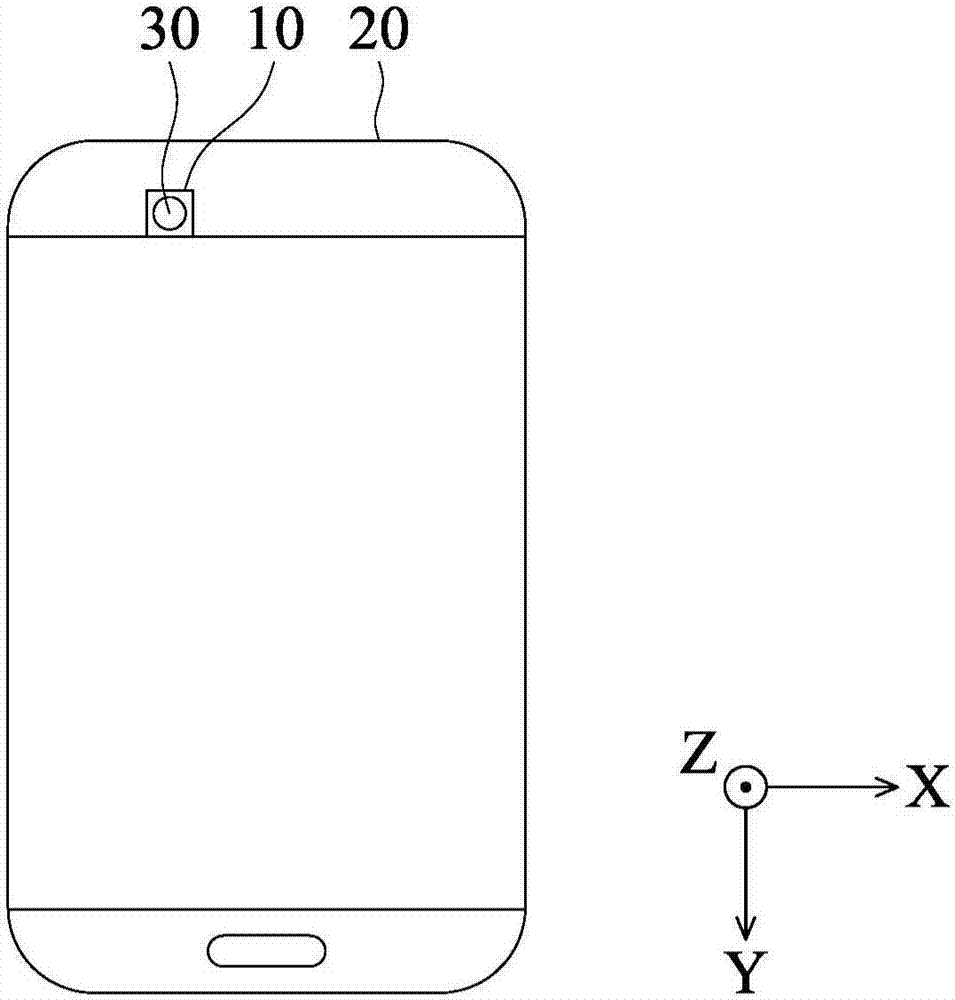

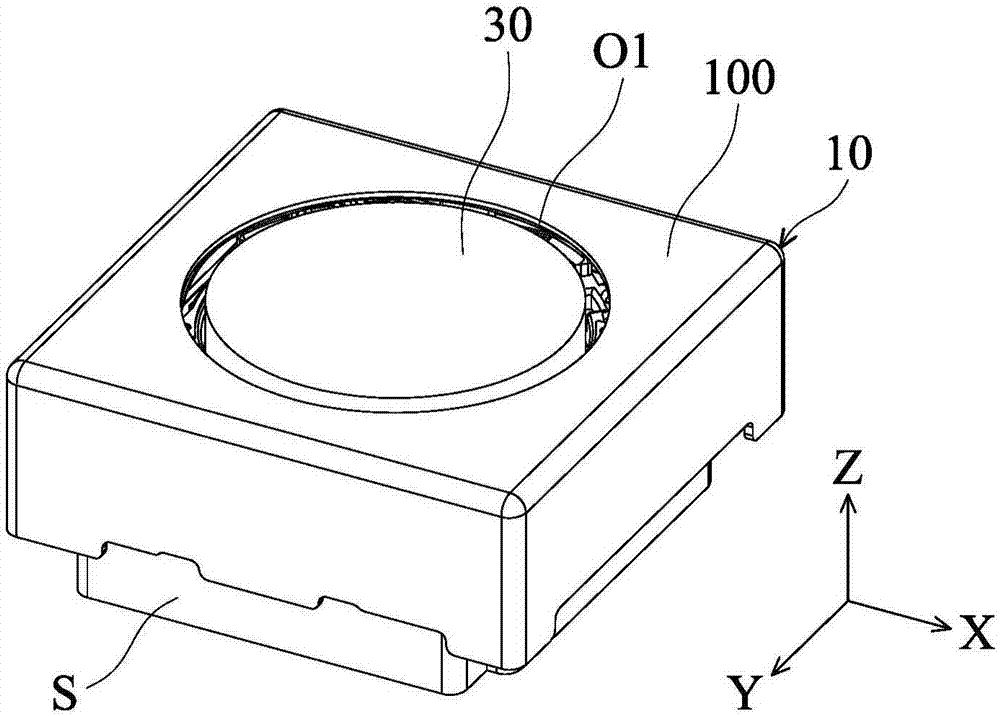

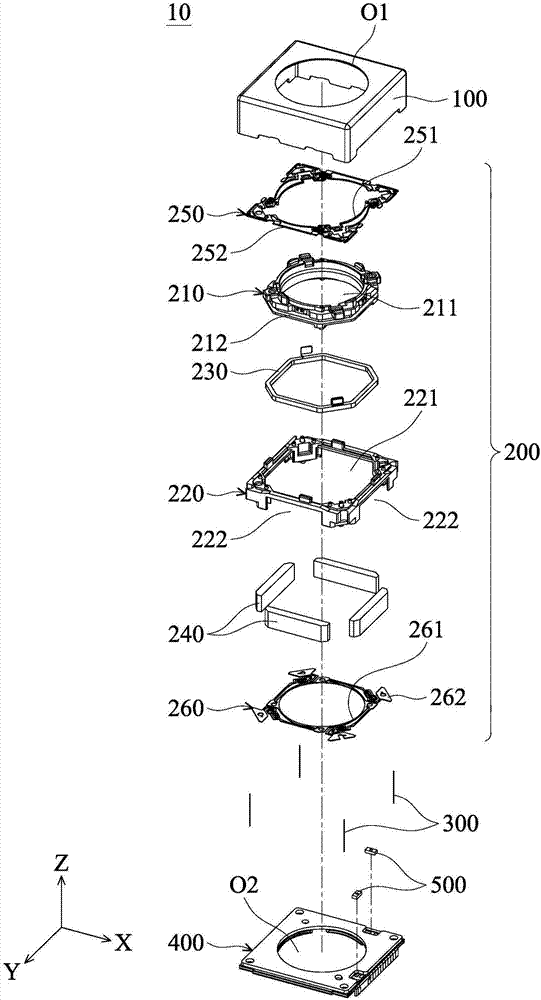

Lens driving module

ActiveCN107957616AReduce thicknessAppropriate tensionTelevision system detailsPrintersEngineeringMechanical engineering

Owner:TDK TAIWAN

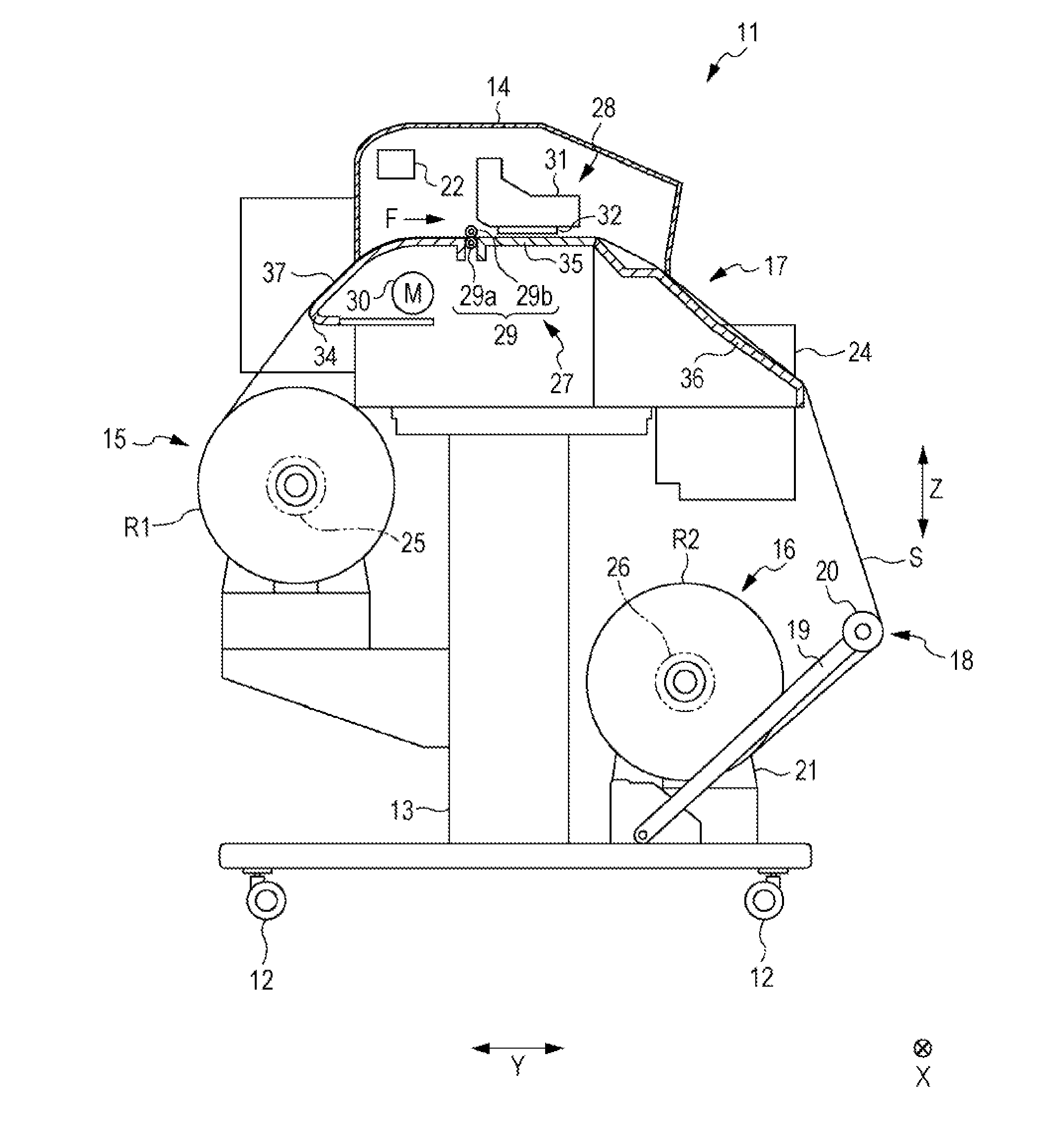

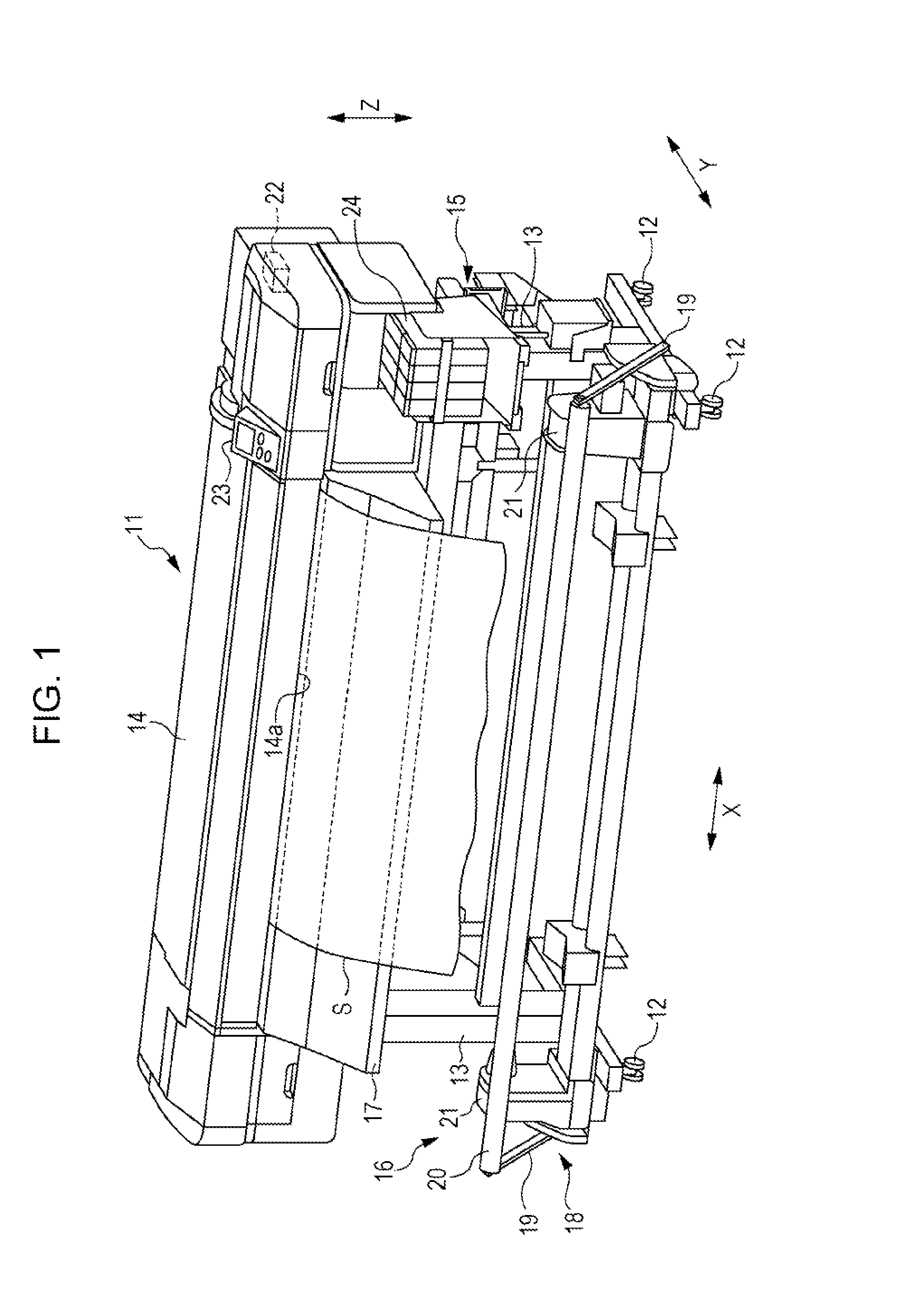

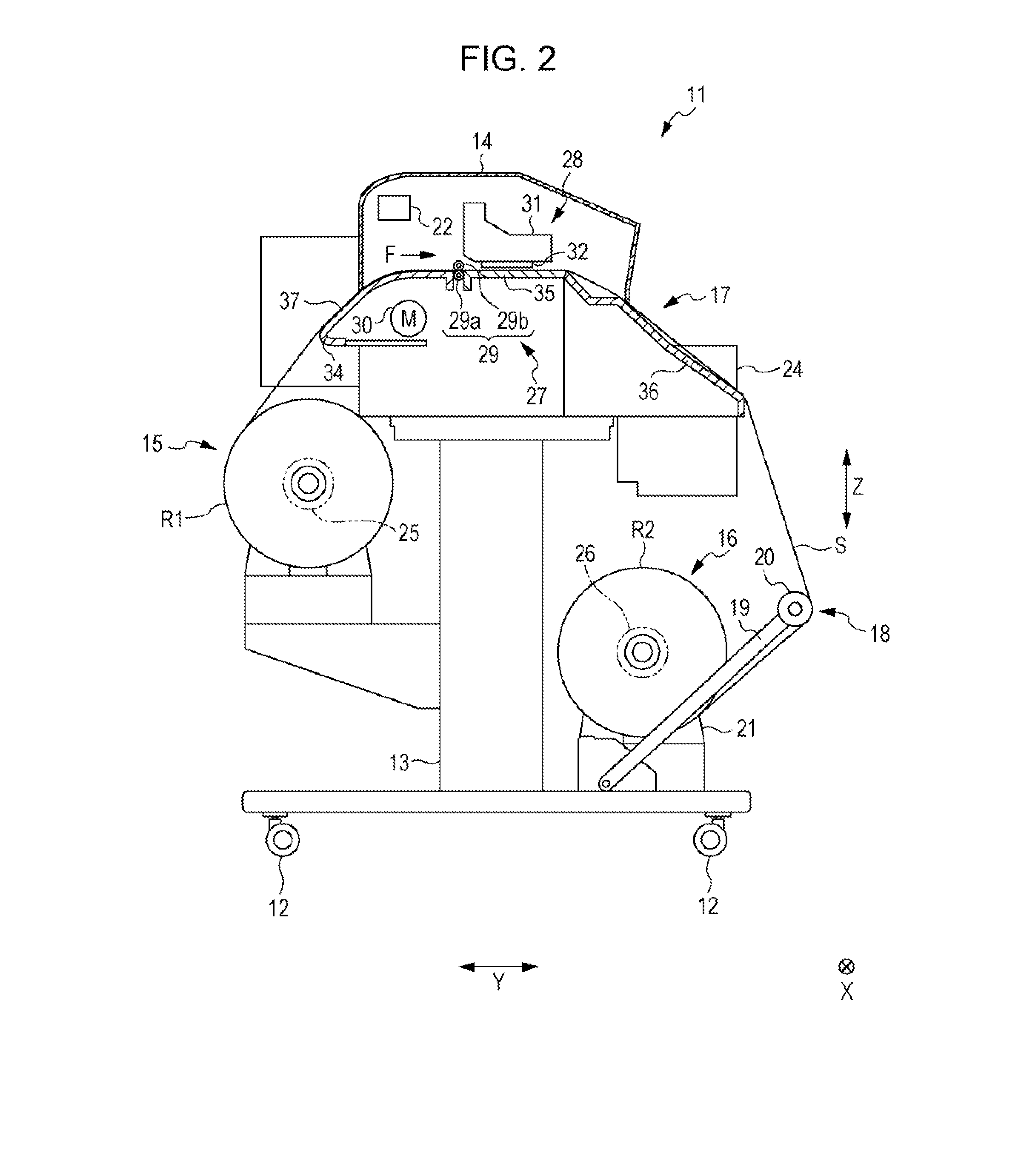

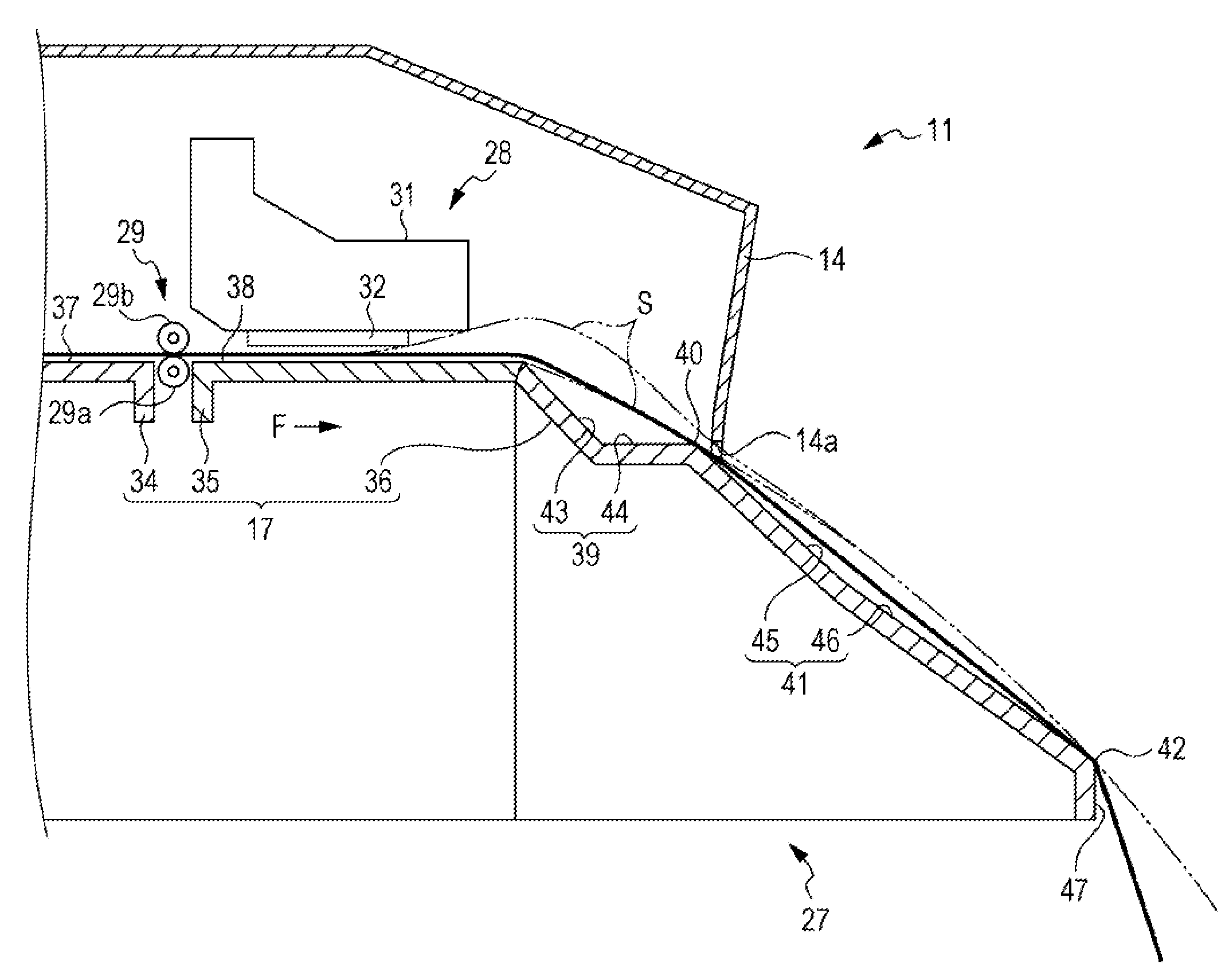

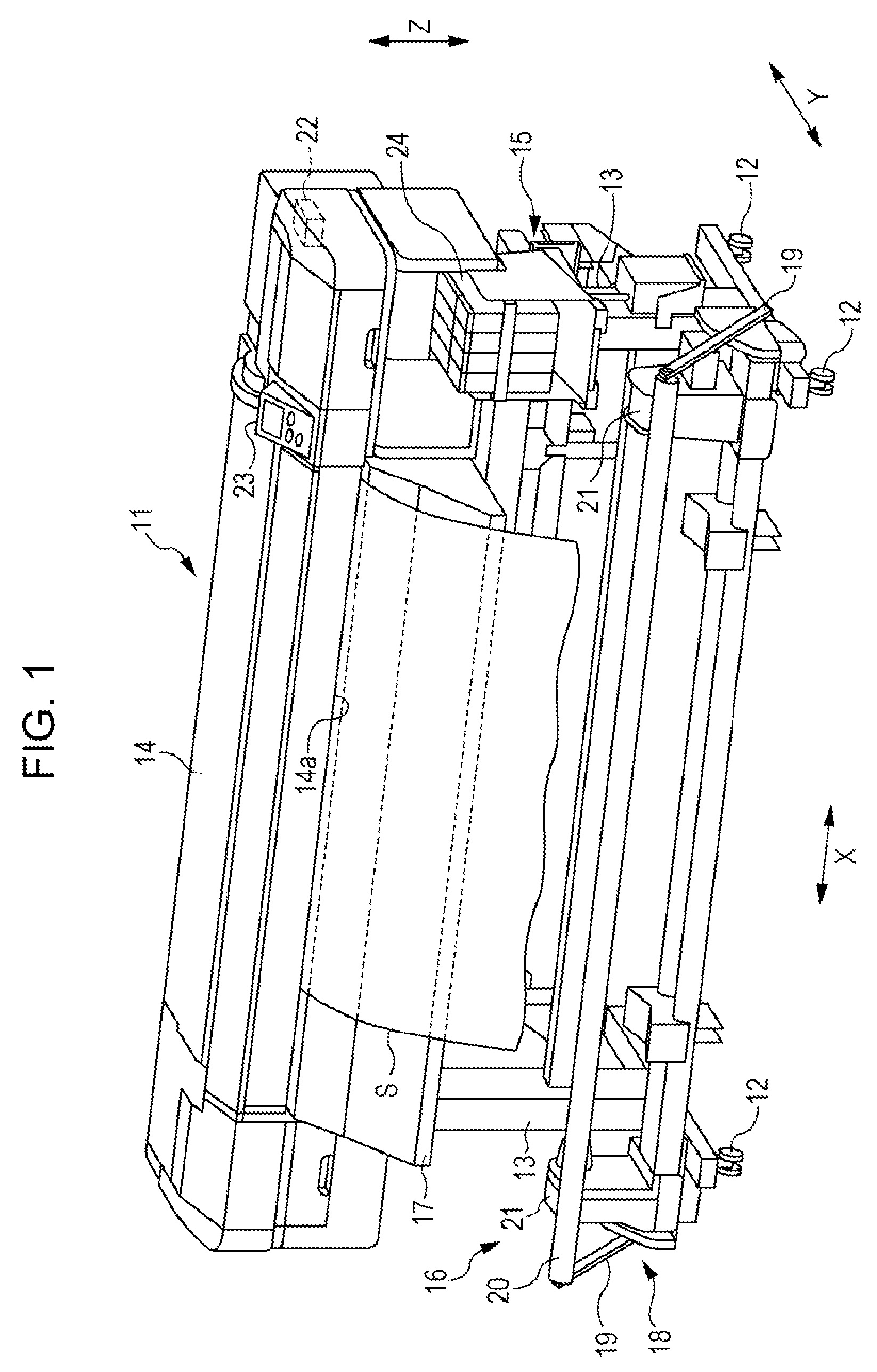

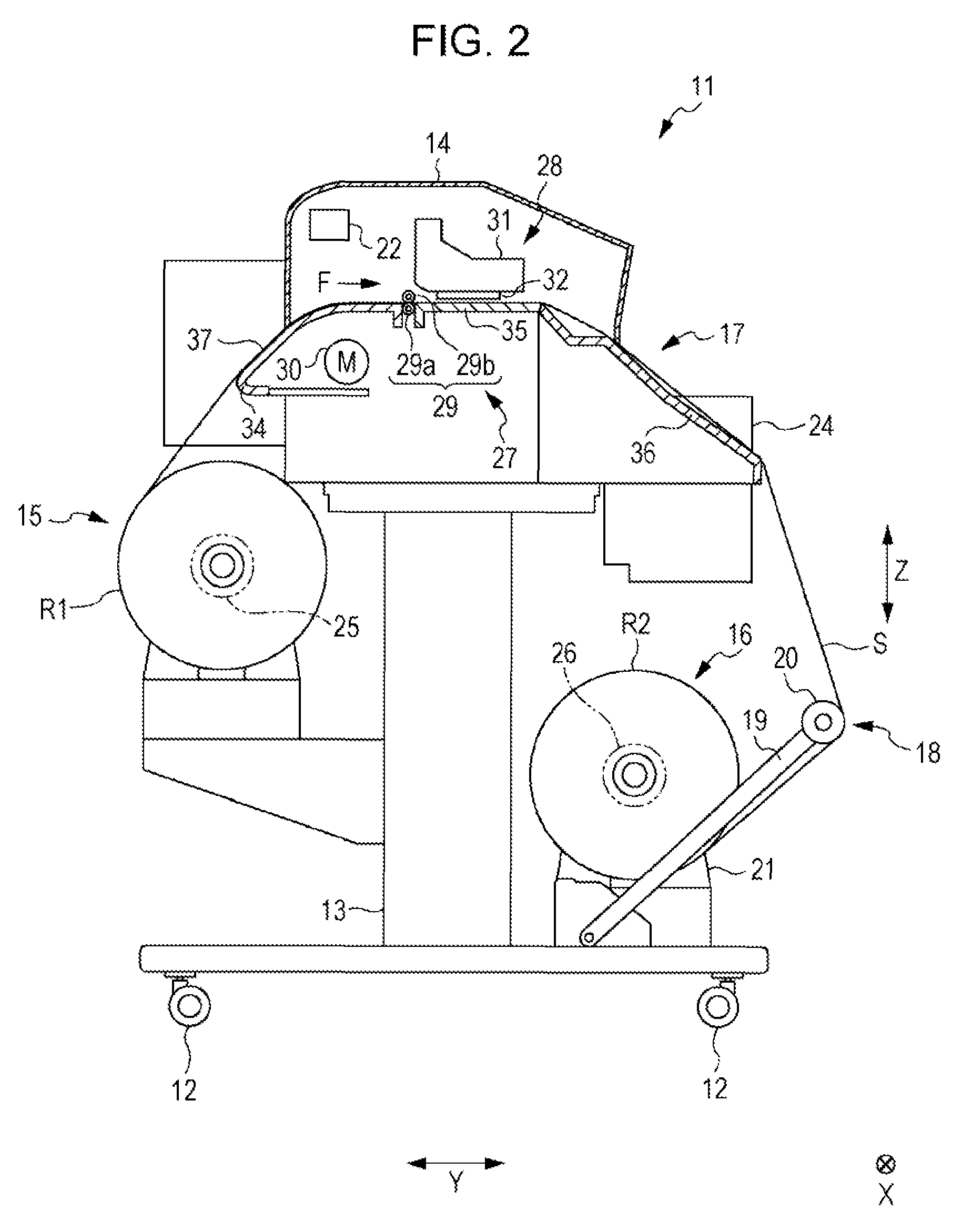

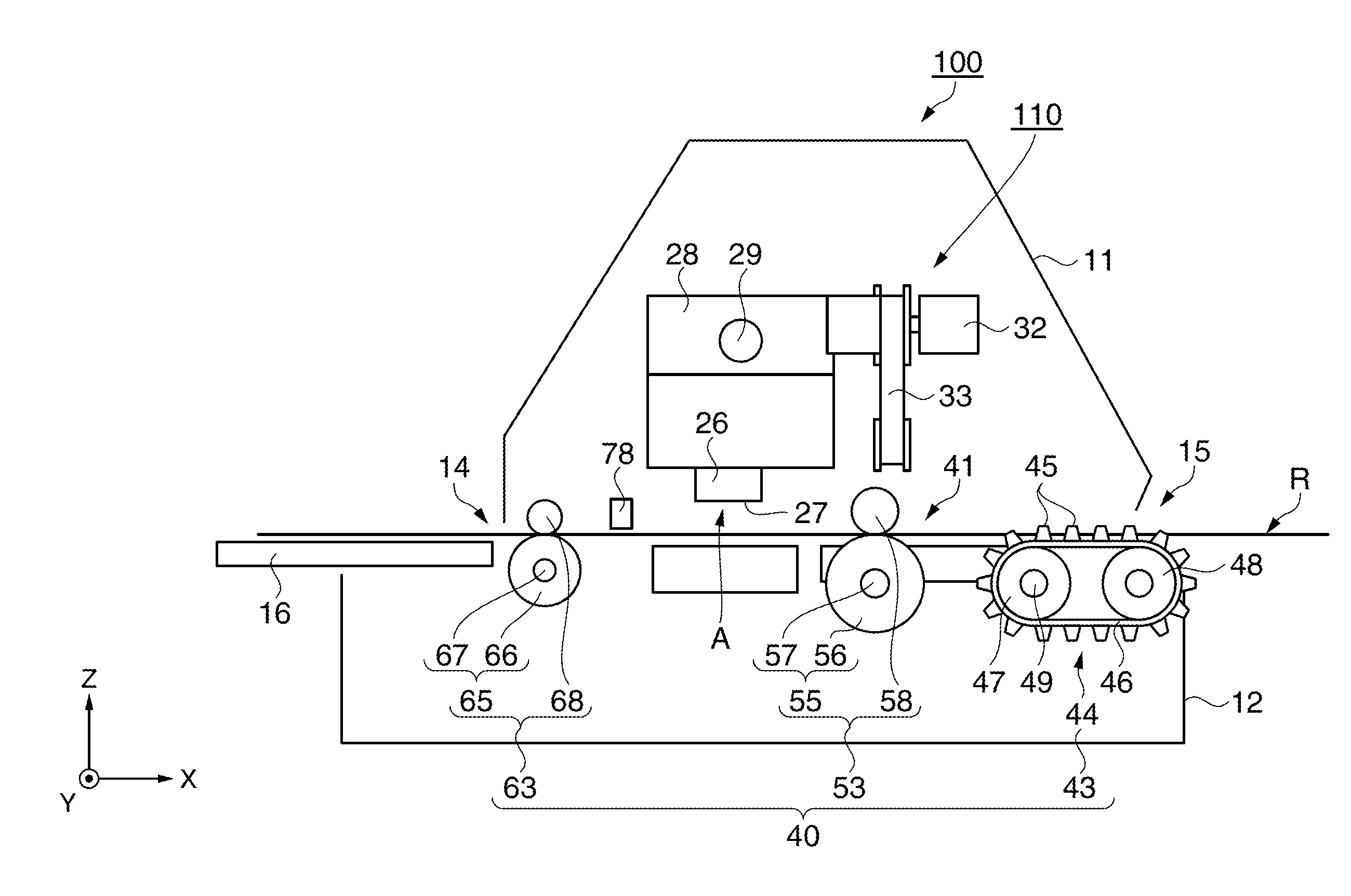

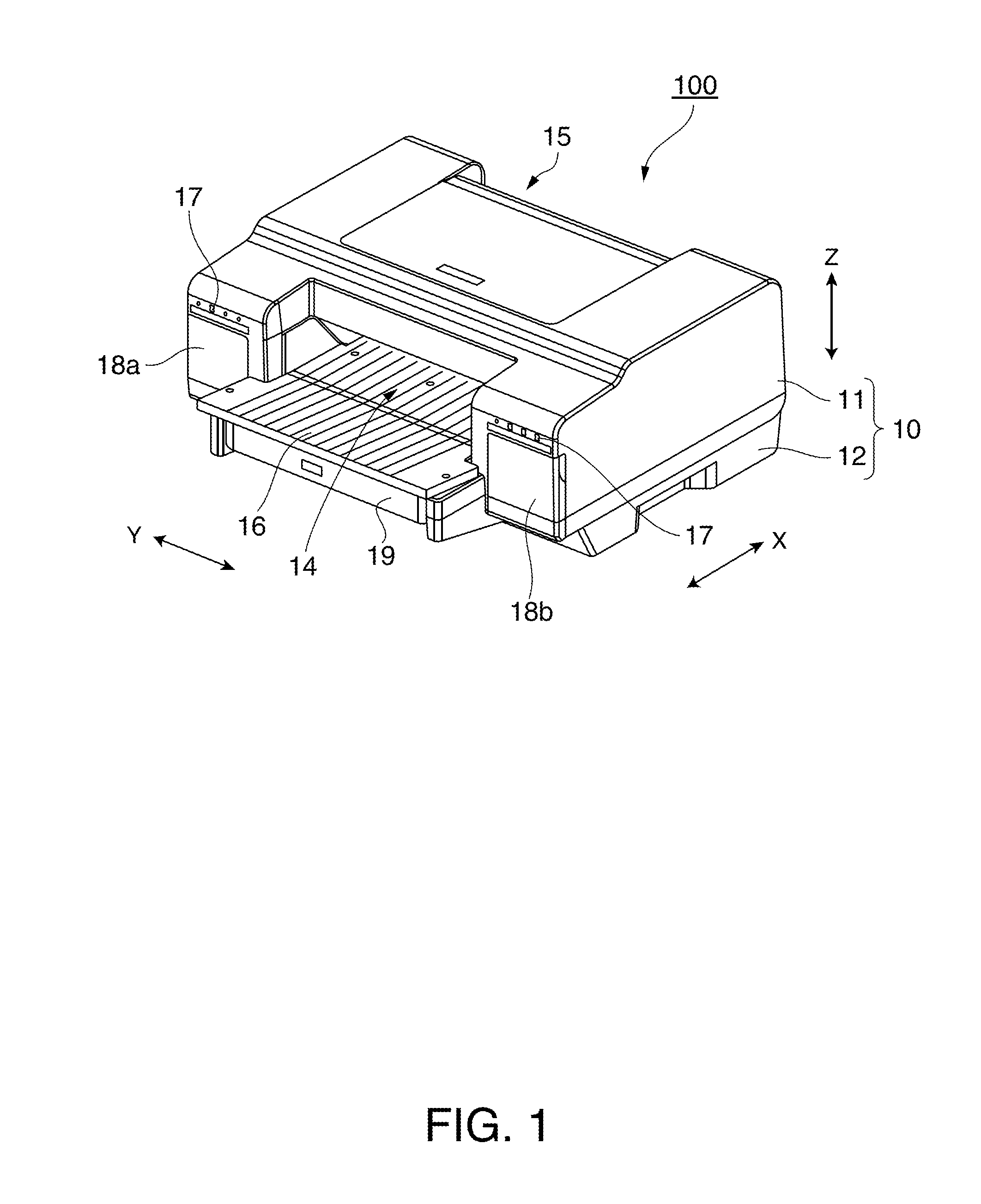

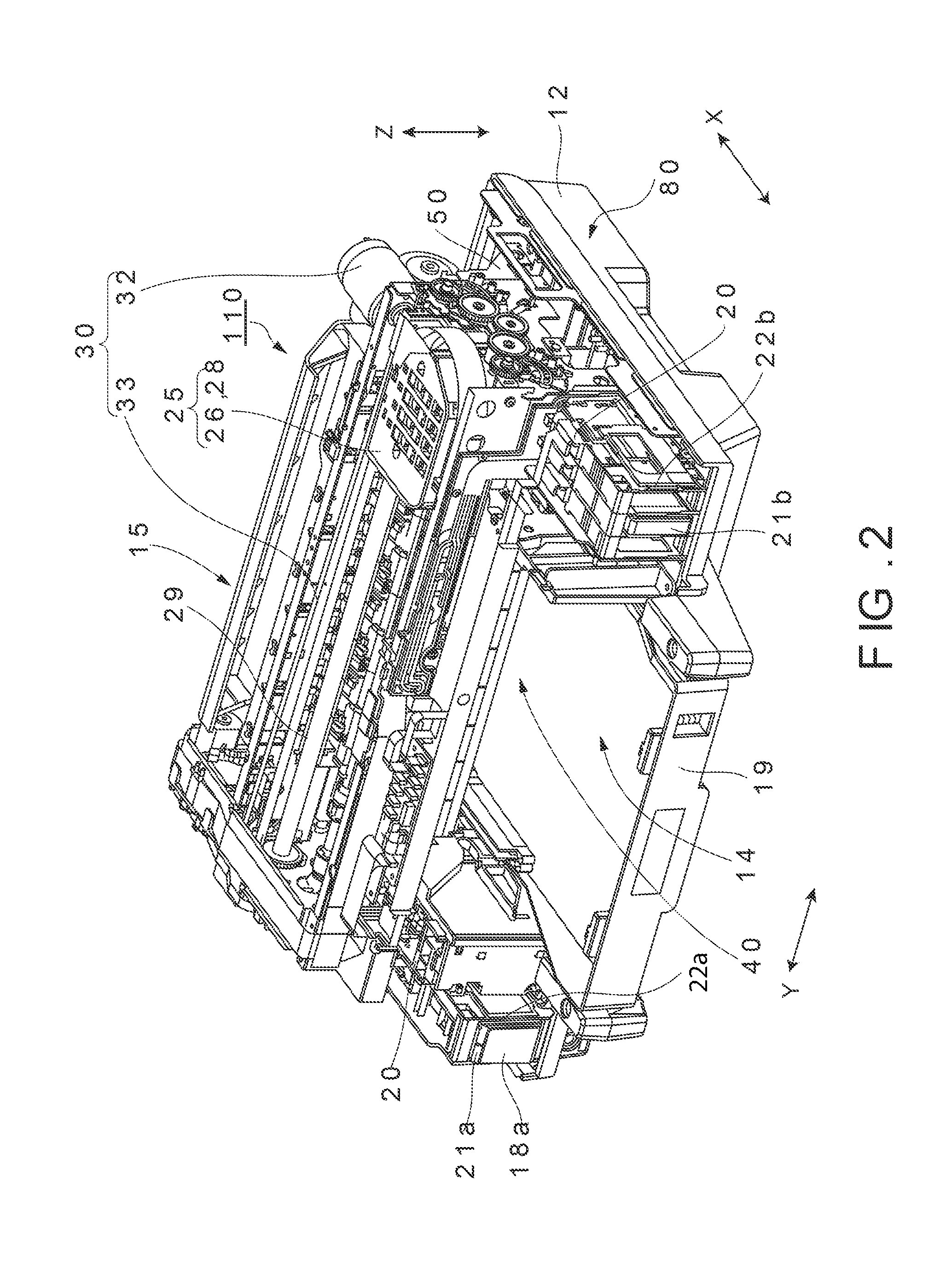

Transporting apparatus and recording apparatus

ActiveUS20140132689A1Suppress generationAvoid contactOther printing apparatusArticle feedersEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

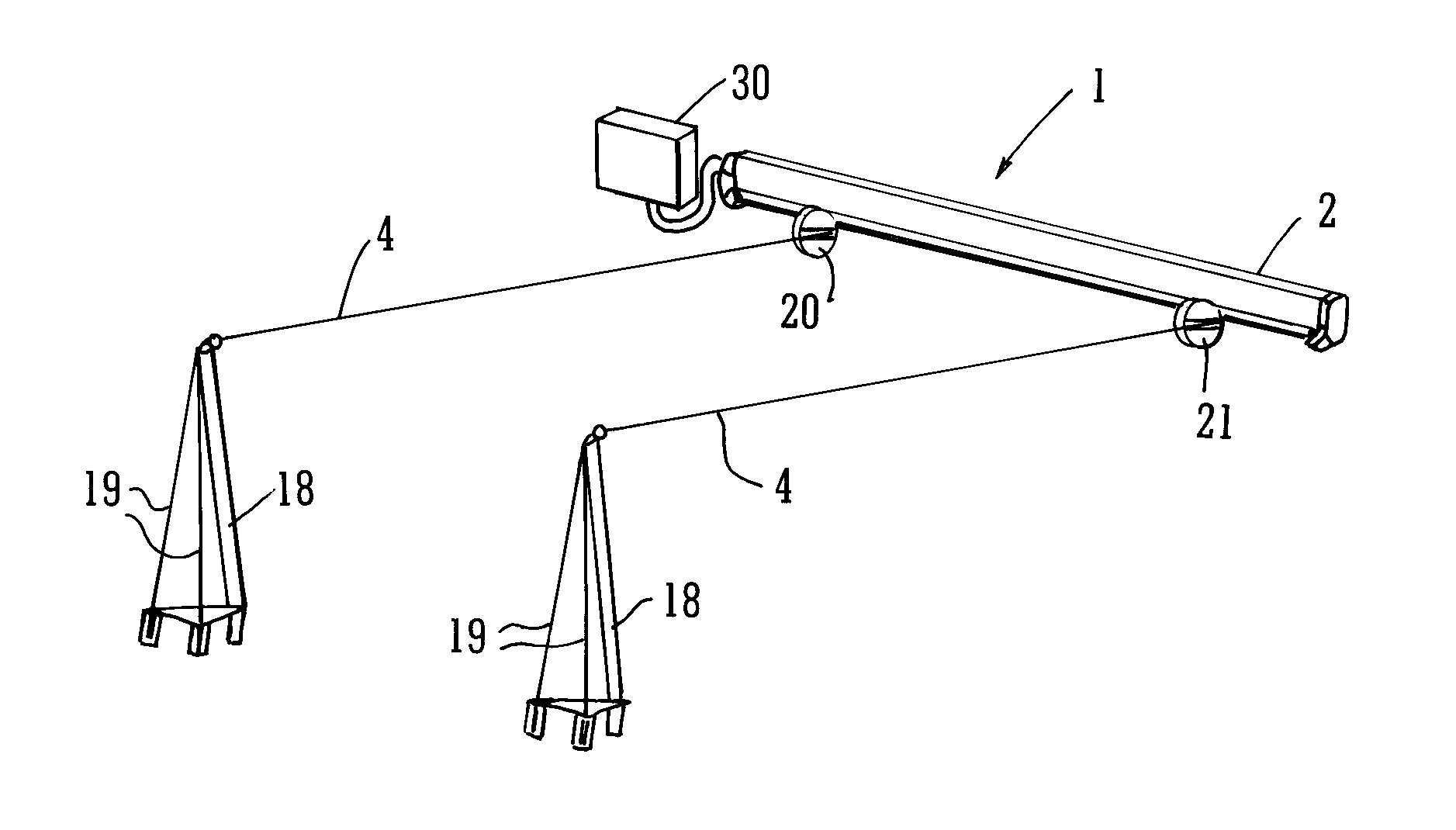

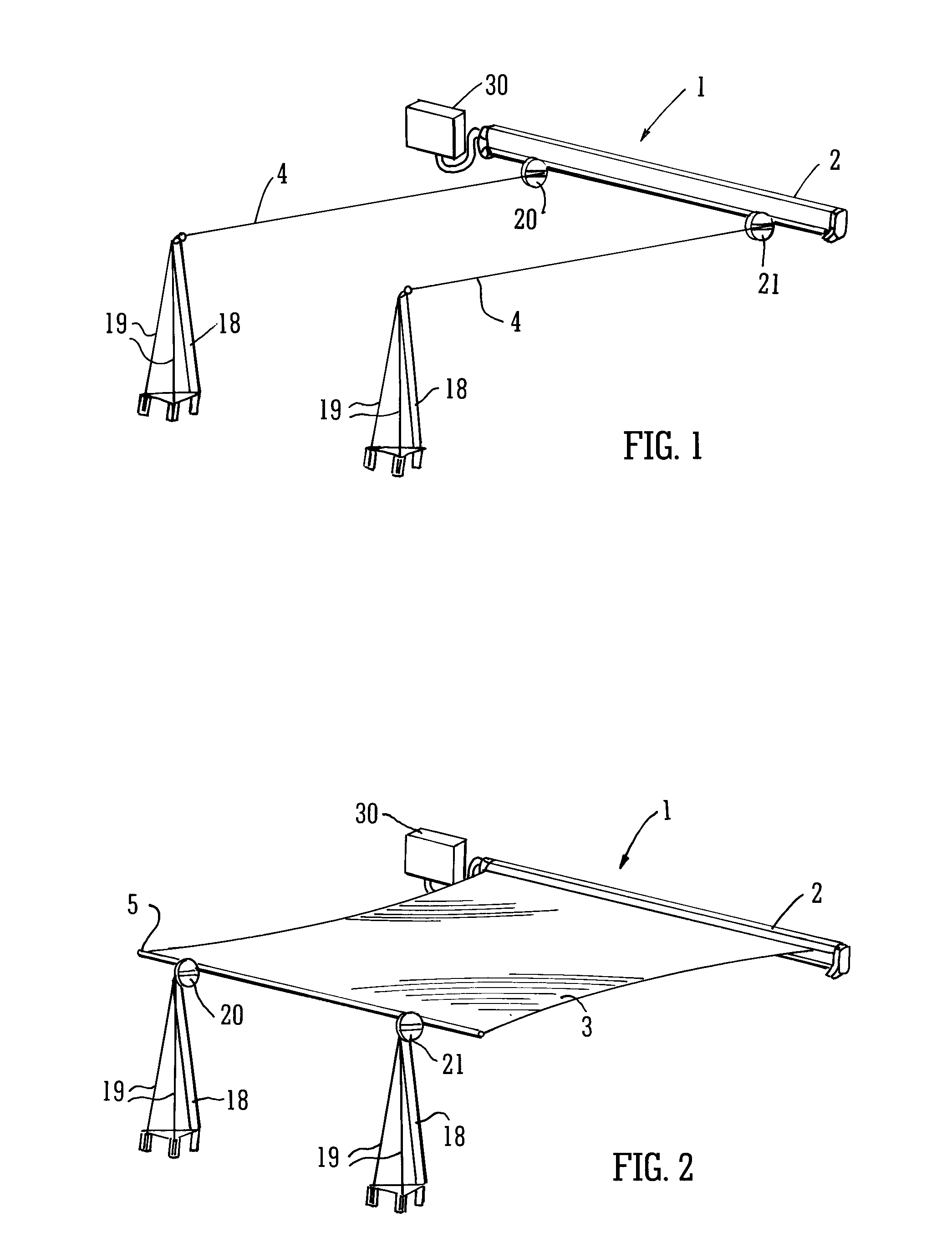

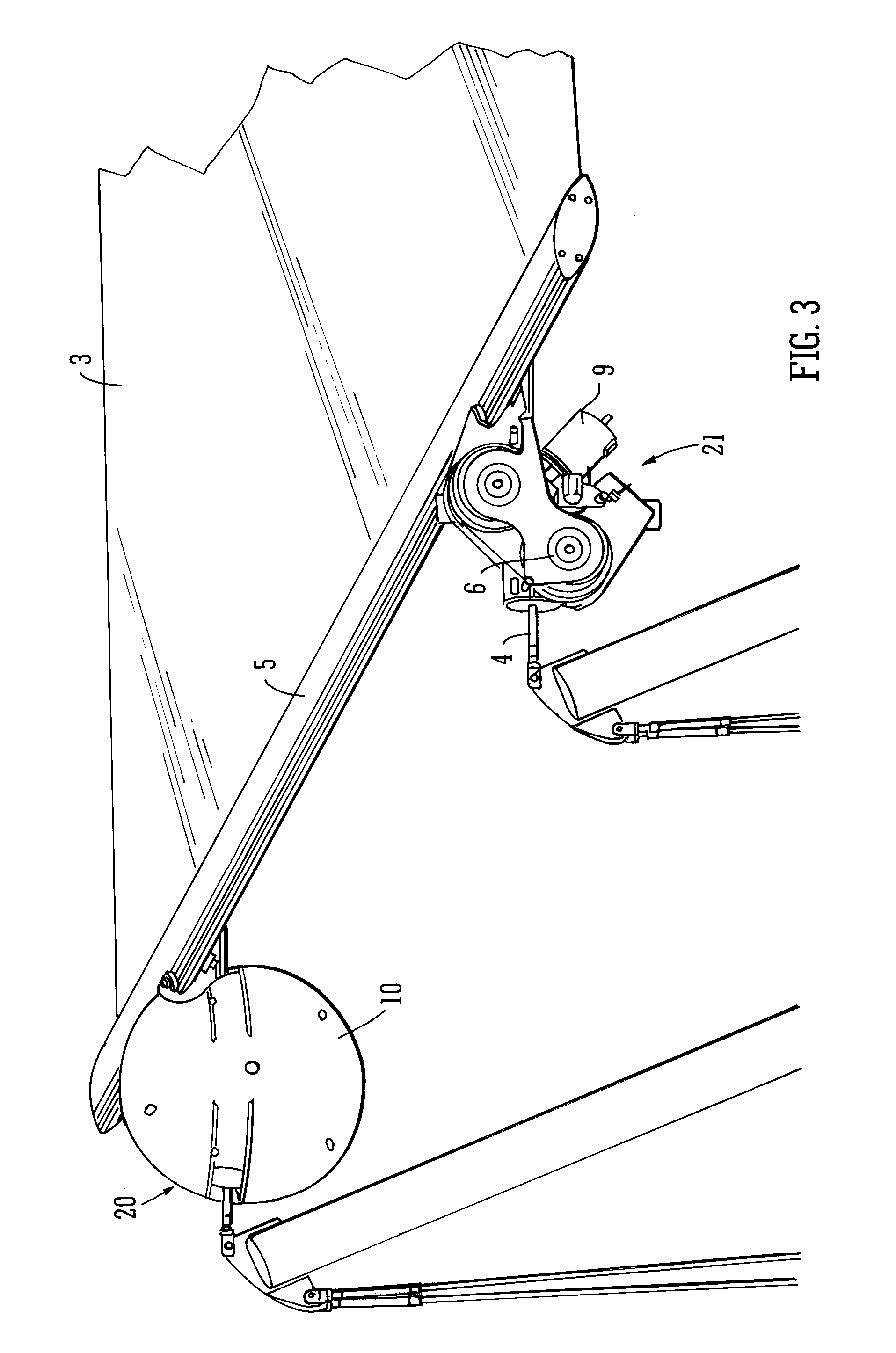

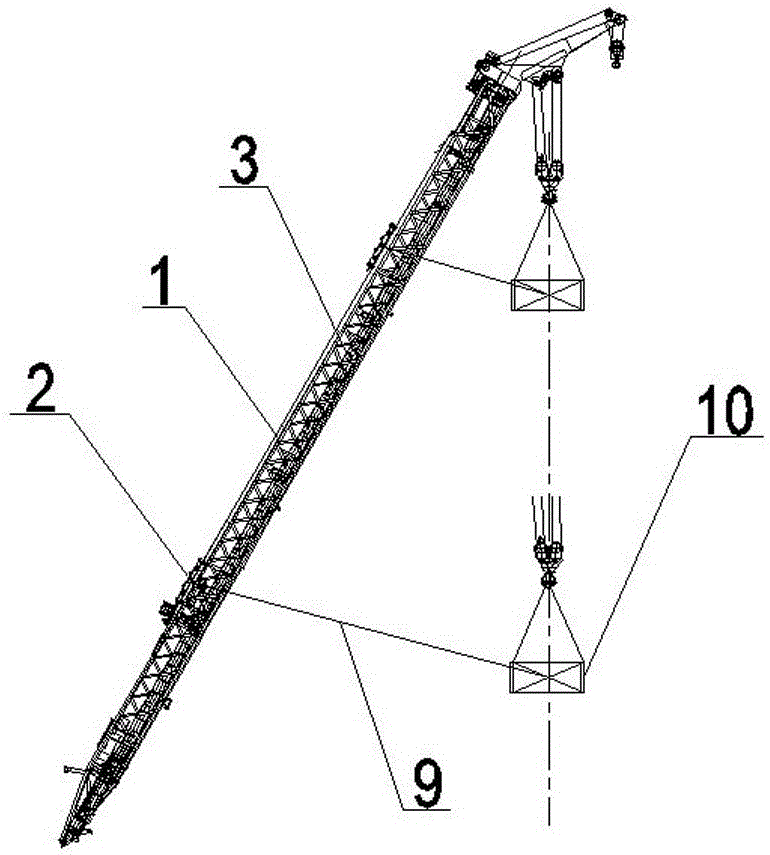

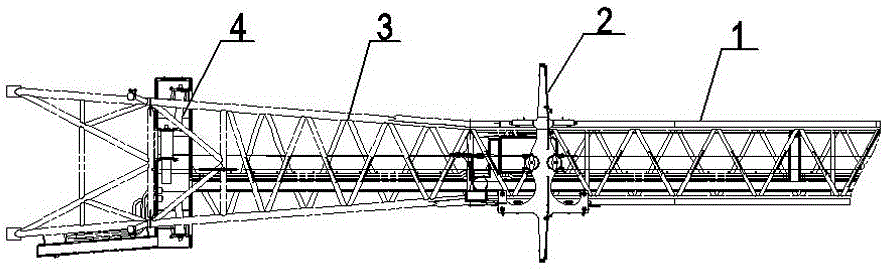

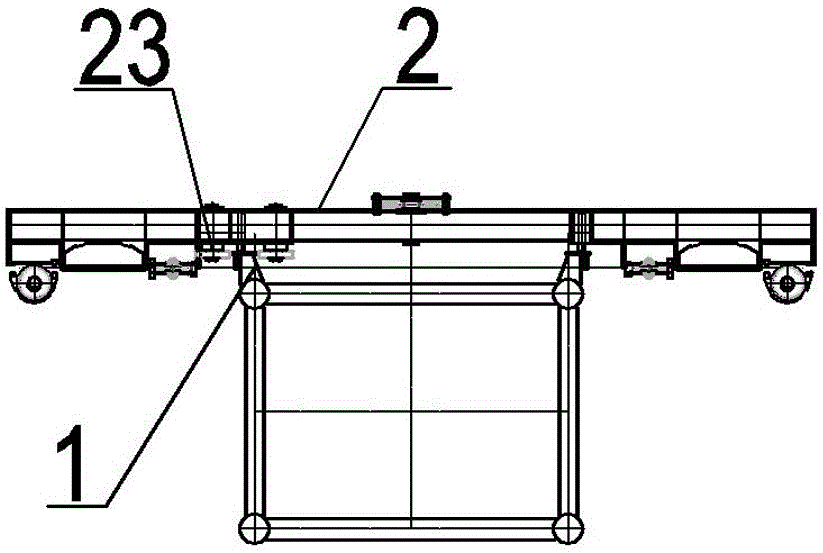

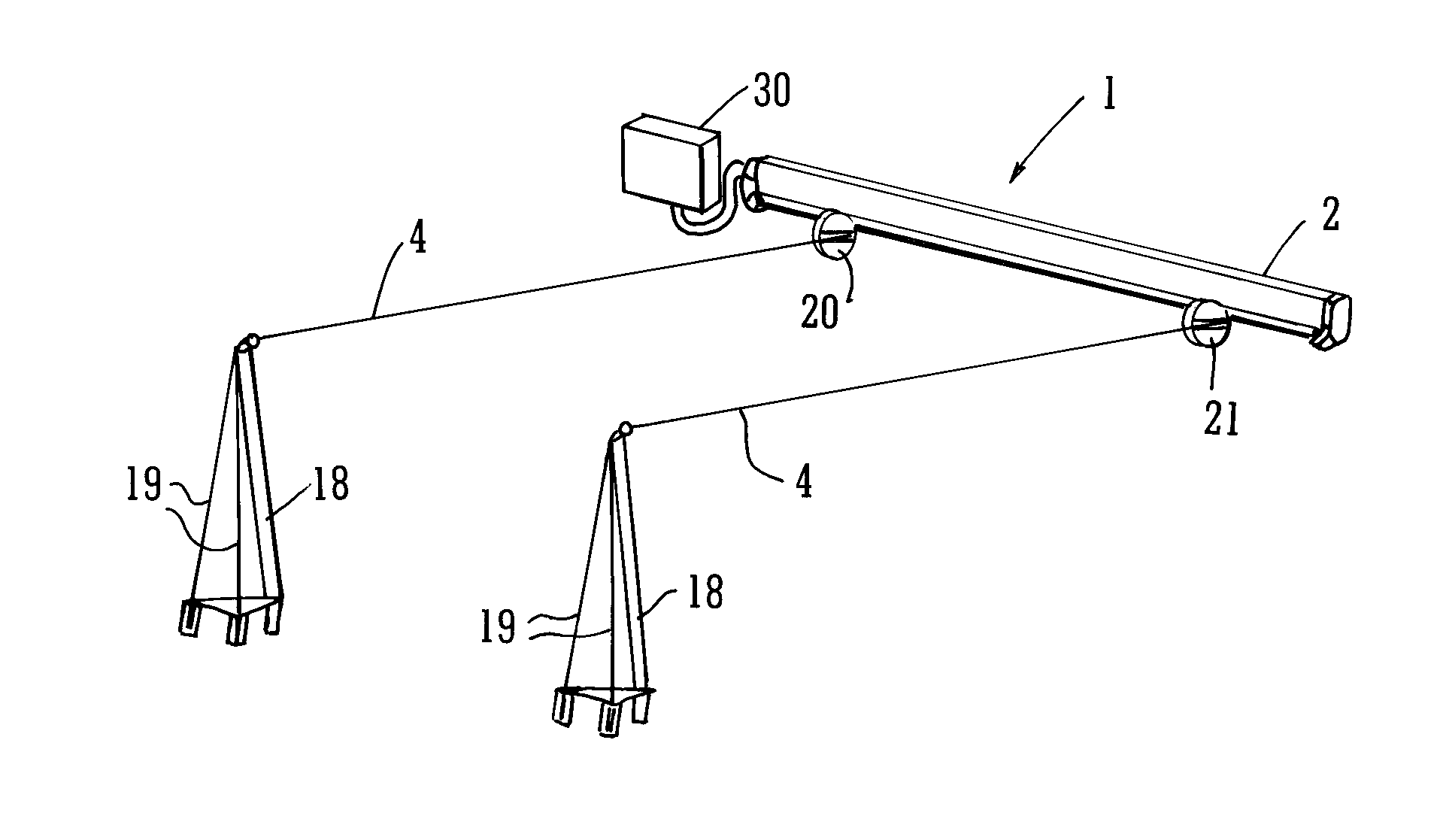

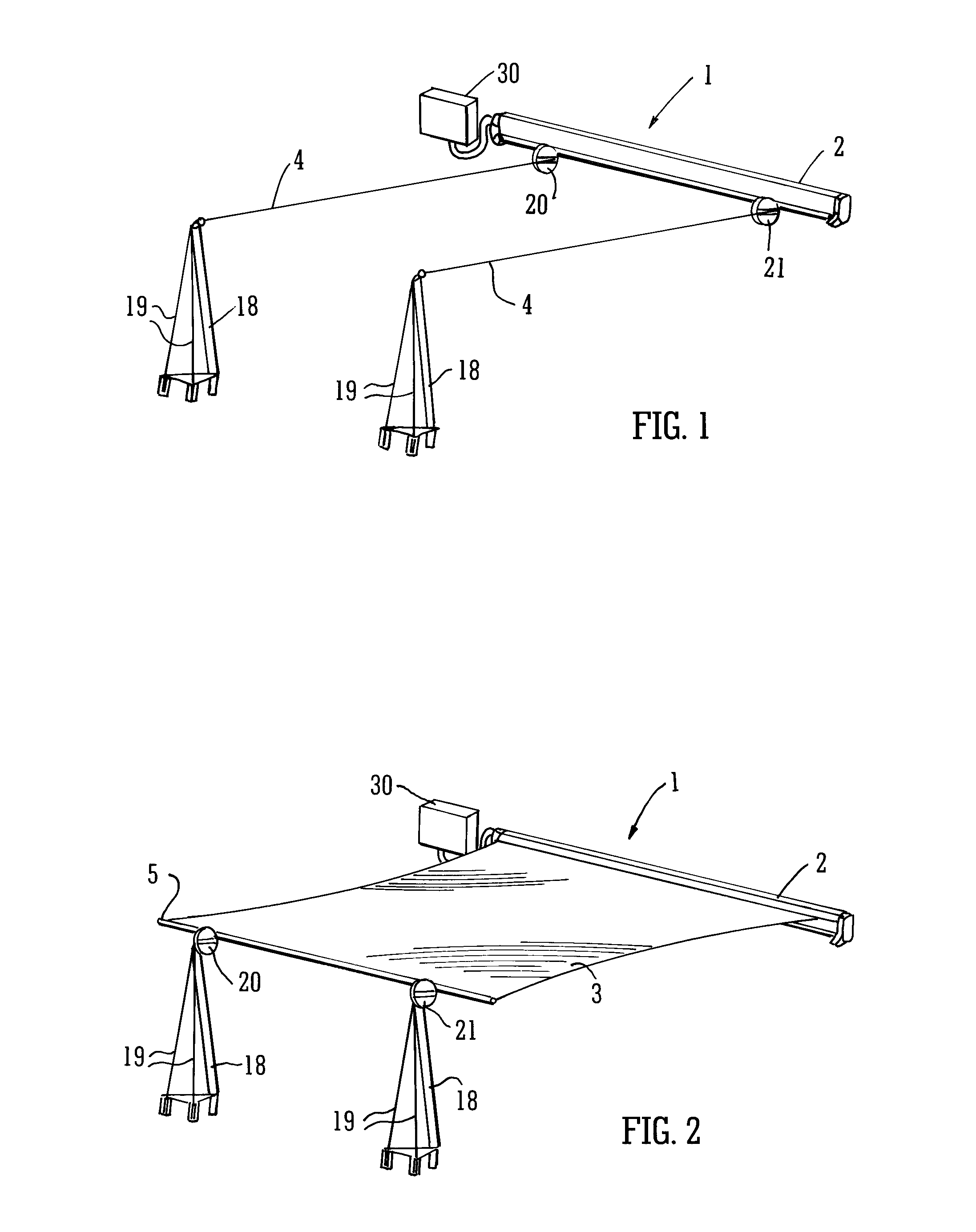

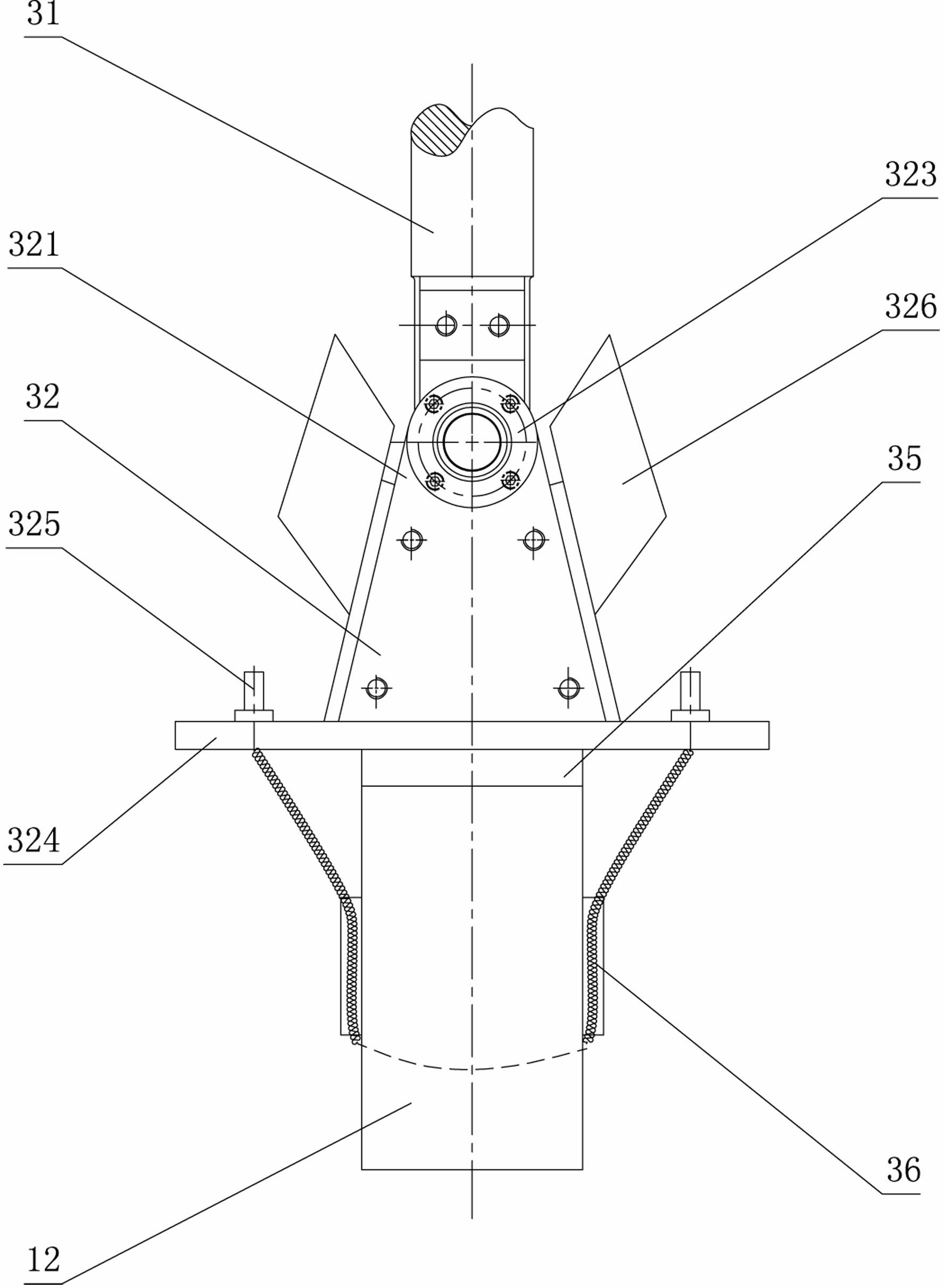

Angle-adjustable crane goods stabilizing system

ActiveCN105692448AAdjust the angle of the ropeAppropriate tensionCranesLoad-engaging elementsEngineeringWinch

The invention discloses an angle-adjustable crane goods stabilizing system. The angle-adjustable crane goods stabilizing system comprises a guide rail, a walking guide car, a car traction mechanism and a lifting weight stabilizing mechanism; the guide rail is arranged in the length direction of a lifting arm, and is fixed on the lifting arm; the walking guide car is slidingly arranged on the guide rail, and can freely slide along the guide rail; the walking guide car is driven to slide up and down along the guide rail by the car traction mechanism; and the lifting weight stabilizing mechanism includes a constant-tension goods stabilizing winch, a first goods stabilizing guide pulley, a second goods stabilizing guide pulley, a first car goods stabilizing guide pulley, a second car goods stabilizing guide pulley and a goods stabilizing steel wire rope. Through change of the position of the walking guide car mounted on the lifting arm, the rope outlet angle of the goods stabilizing steel wire rope can be conveniently adjusted to keep an optimal goods stabilizing angle and proper steel wire rope tension.

Owner:NANTONG RAINBOW HEAVY MACHINERIES

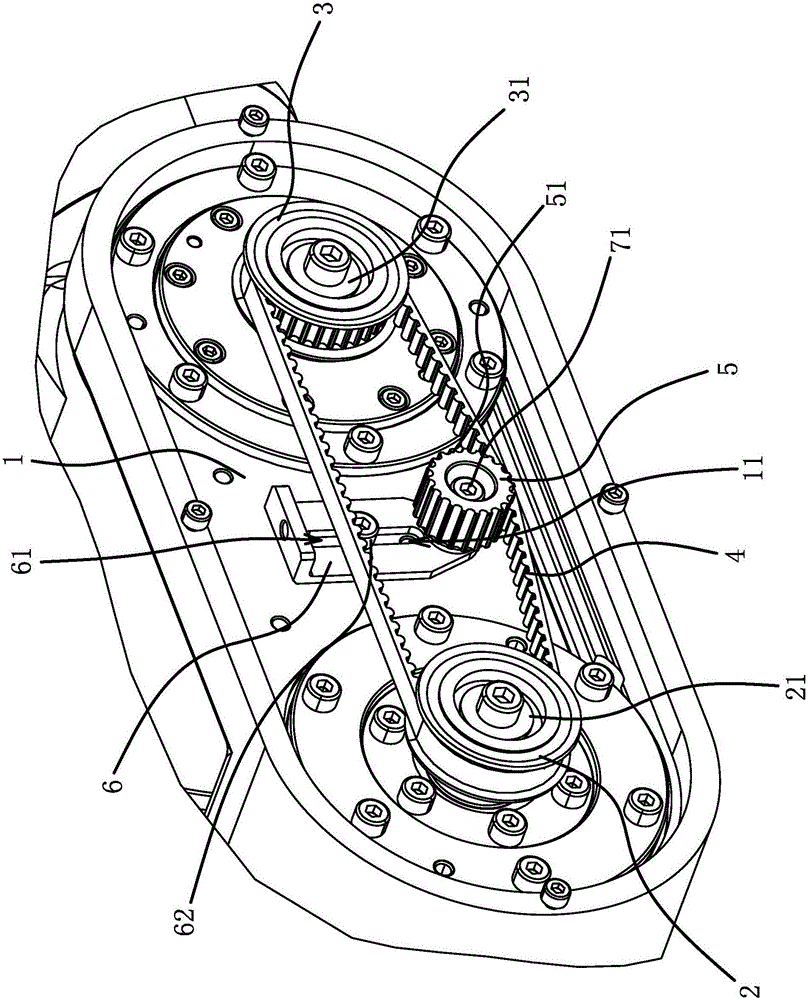

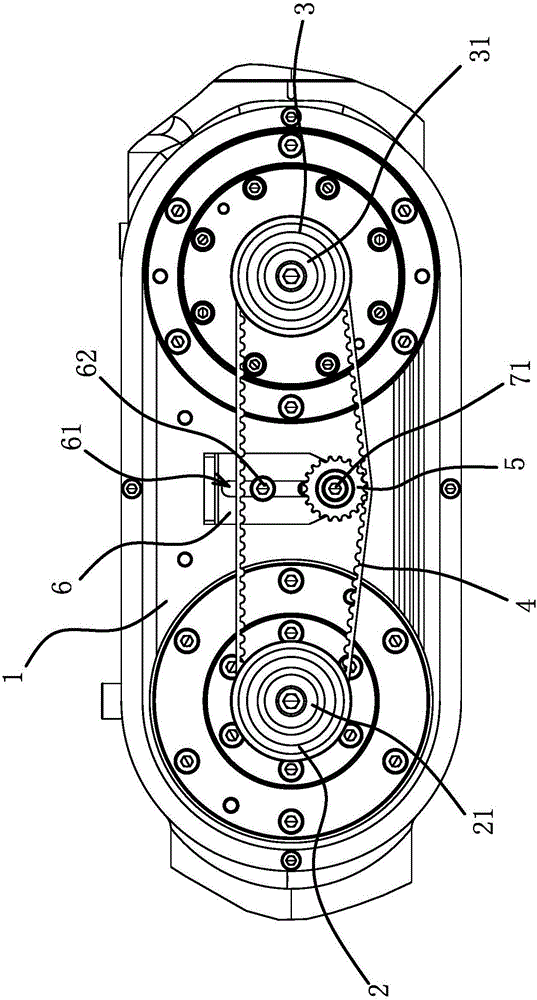

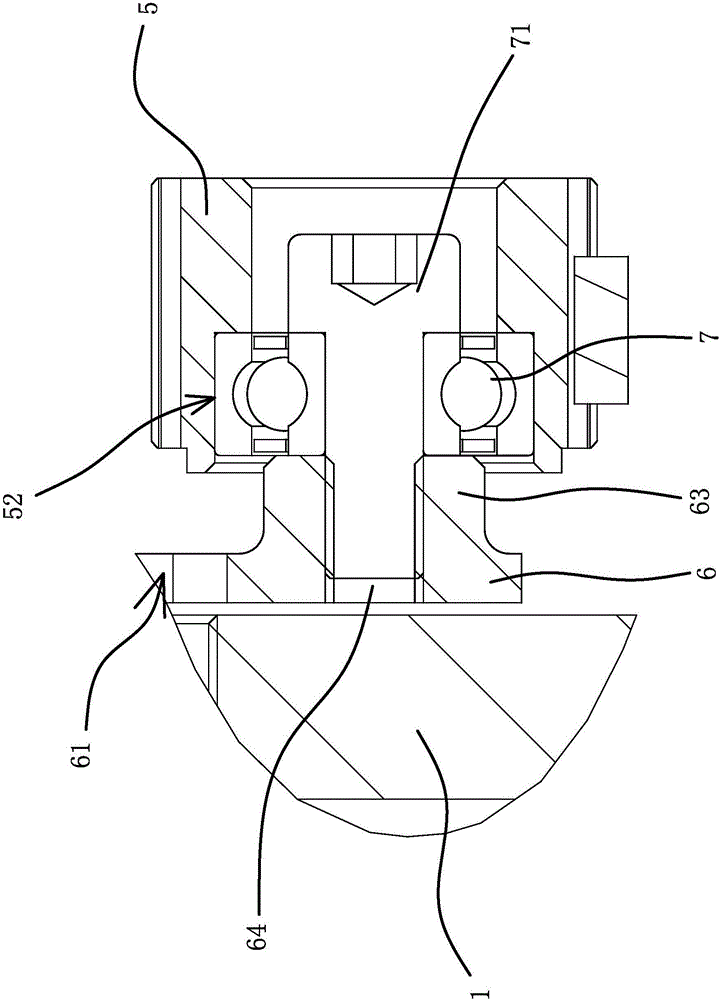

Belt wheel structure for robot

The invention provides a belt wheel structure for a robot, belonging to the technical field of mechanical arms. The technical problems that a current belt wheel structure for the robot is not suitable for the robot and the like are solved. The robot comprises a joint for being connected with a mechanical arm; the belt wheel structure for the robot comprises a driving belt wheel connected with a driving rotation shaft, a driven belt wheel connected with a driven rotation shaft and a tooth-form belt arranged between the driving belt wheel and the driven belt wheel; the driving belt wheel and the driven belt wheel are both arranged in the joint, and the distance between the driving belt wheel and the driven belt wheel is constant; an auxiliary belt wheel with wheel teeth is also arranged between the driving belt wheel and the driven belt wheel in the joint; the auxiliary belt wheel is located on the inner side of the tooth-form belt; and the auxiliary belt wheel can be meshed with one side of the tooth-form belt and enable the tooth-form belt to keep tensioned. The belt wheel structure for the robot disclosed by the invention has the advantages that the tooth-form belt can be enabled to maintain proper tensity, and the stability of transmission is improved.

Owner:ZHEJIANG QIANJIANG MOTORCYCLE +1

Retractable awning

A retractable awning, comprising a screen which may be extended and retracted, wherein there is provided a first motor arranged to extend the screen, a second motor arranged to retract the screen, and a control unit arranged to control the first and second motors, wherein the first and second motors are synchronized so as to maintain tension in the screen within predetermined values.

Owner:CUTLER

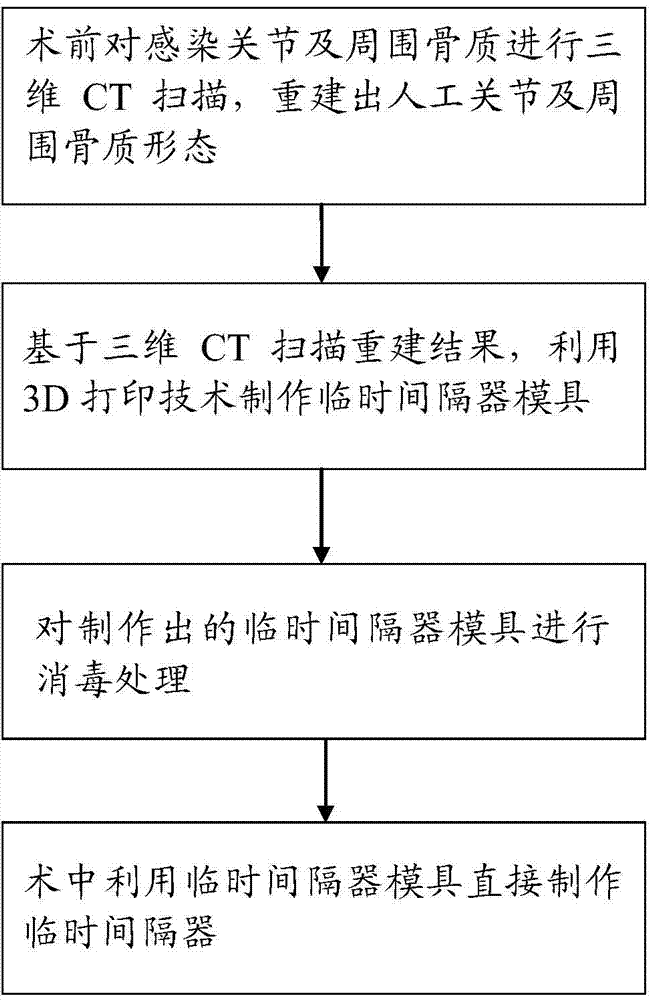

Manufacturing method of temporary spacer in artificial joint replacement operation

InactiveCN104490492ANot suitable for deformationEasy to useJoint implantsThree dimensional ctArtificial joints

The invention discloses a manufacturing method of a temporary spacer in an artificial joint replacement operation. The manufacturing method of the temporary spacer is used when the infection condition occurs after operation, and comprises the following steps that before infection operation, the injection joint and peripheral bone are subjected to three-dimensional CT (computed tomography) scanning, and the artificial joint and peripheral bone form is reestablished; on the basis of the 3D (three-dimensional) CT scanning reestablishing result, a temporary spacer mold is manufactured by a 3D printing technology; the manufactured temporary spacer mold is subjected to disinfection treatment; in the infection operation process, the temporary spacer is directly manufactured by utilizing the manufactured temporary spacer mold. The manufacturing method of the temporary spacer in the artificial joint replacement operation has the advantages that medical workers can conveniently and directly manufacture the temporary spacer according to the mold manufactured before operation, the temporary spacer more conforms to the local joint form, after the temporary spacer is placed, the proper gap and tension can be properly maintained, and the generation of joint capsule soft tissue contracture and disuse bone mass loss during the interval between two operations is avoided.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

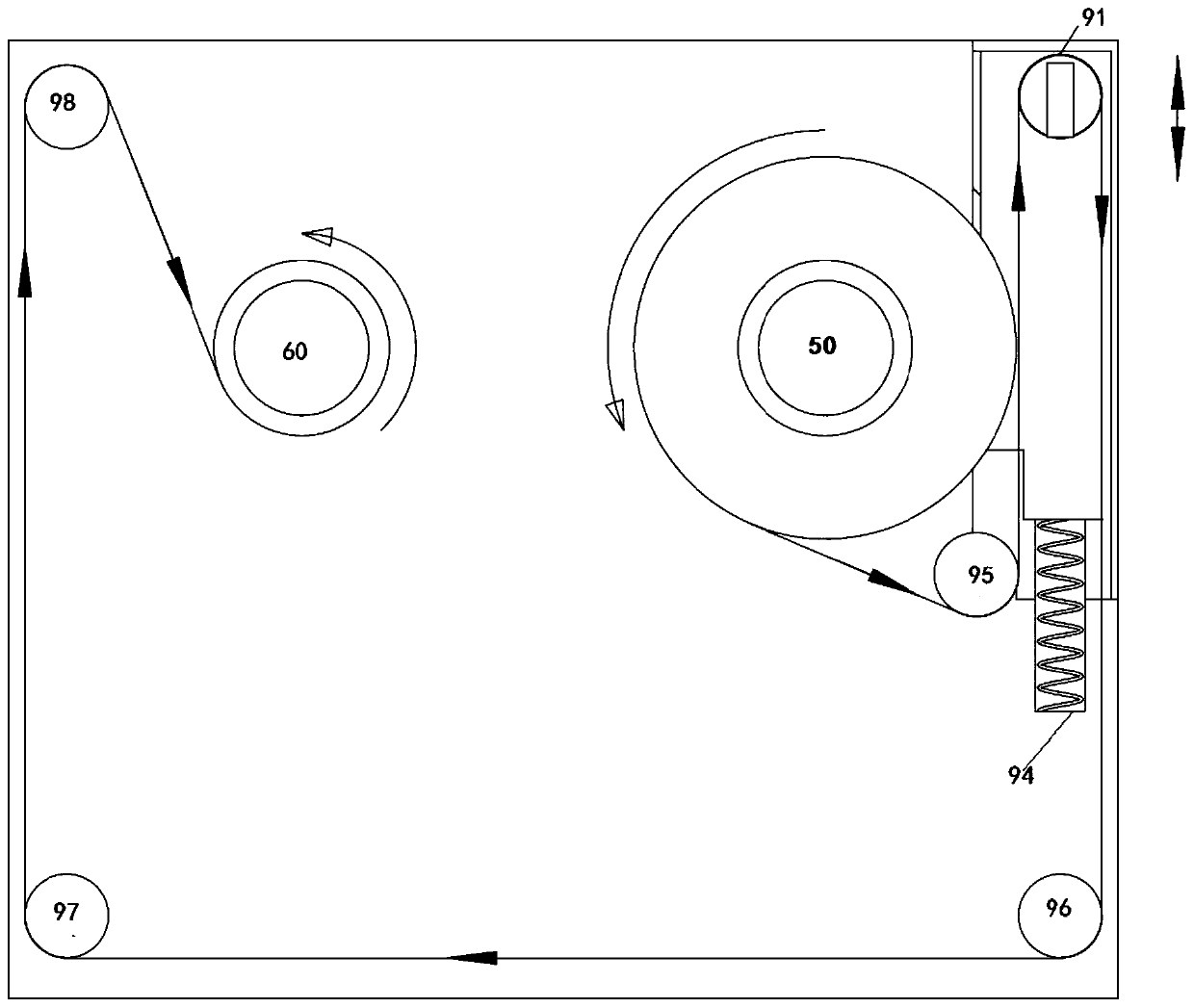

Thermal transfer printing coding machine and motor rotating speed control method and device thereof

The invention discloses a thermal transfer printing coding machine and a motor rotating speed control method and device thereof. The method comprises the following steps: detecting the position of a magnetic element; driving a second motor used for recovering thermal transfer ribbons to recover the thermal transfer ribbons based on the position until the second end of the magnetic element is aligned with a hall chip; recording the rotating angle of the second motor; driving a first motor used for distributing the thermal transfer ribbons to distribute the thermal transfer ribbons based on theposition until the first end of the magnetic element is aligned with the hall chip; recording the rotating angle of the first motor; calculating the first radius of the first thermal transfer ribbonscorresponding to the first motor and the second radius of the second thermal transfer ribbons corresponding to the second motor based on the recorded rotating angle of the second motor, the rotating angle of the first motor, and the length of the magnetic element; and acquiring the target angular speed of the first motor and the target angular speed of the second motor based on the first radius, the second radius and the preset thermal transfer ribbon running speed. With the adoption of the method, the motor angle speed can be conveniently measured and controlled, and thus the linearity speedand proper tension of the thermal transfer ribbons can be ensured.

Owner:XIAMEN HANIN ELECTRONICS TECH CO LTD

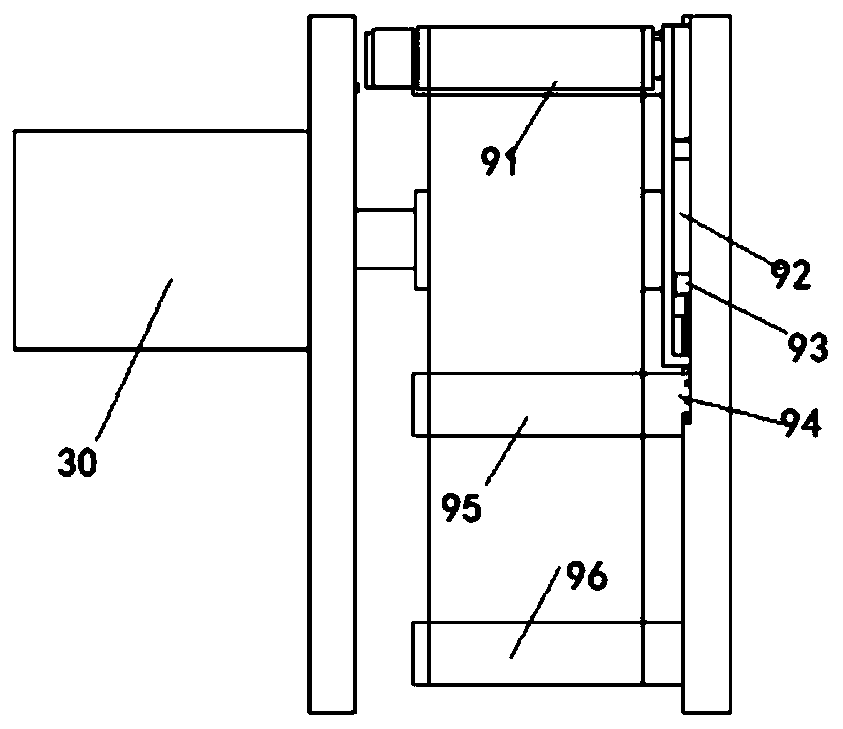

Floating support device

InactiveCN101659021AAppropriate tensionImprove polishing effectRevolution surface grinding machinesThrust bearingEngineering

The invention belongs to the technical field of machine polishing and particularly relates to a floating support device for an automatic polishing machine. The device is characterized in that: the device consists of a floating guide plate fixed on a guide plate seat; the front and back two end parts of the guide plate seat are provided with guide posts; the upper ends of the guide posts passes through guide holes of a fixed supporting plate; floating springs are arranged on guide posts between the guide plate seat and the fixed supporting plate; the middle part of the guide plate seat is provided with a thrust bearing to be connected with the lower end of a screw rod and the upper end of the screw rod is provided with a hand wheel; and the screw rod is in thread fit with a beam of a fixedsupport. The device has the advantages of saving labor and work, improving polishing effect and achieving high production efficiency.

Owner:高德程

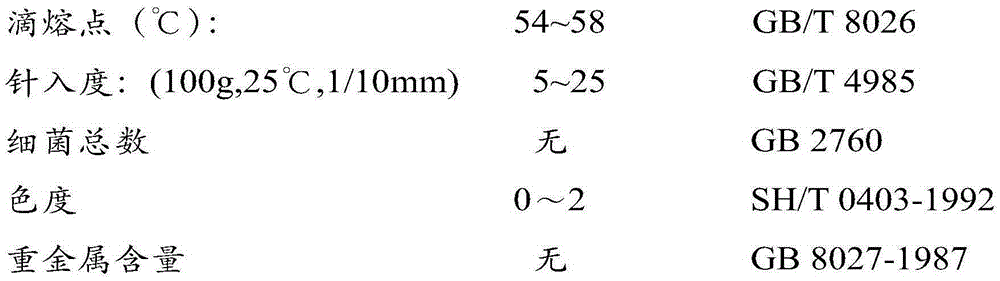

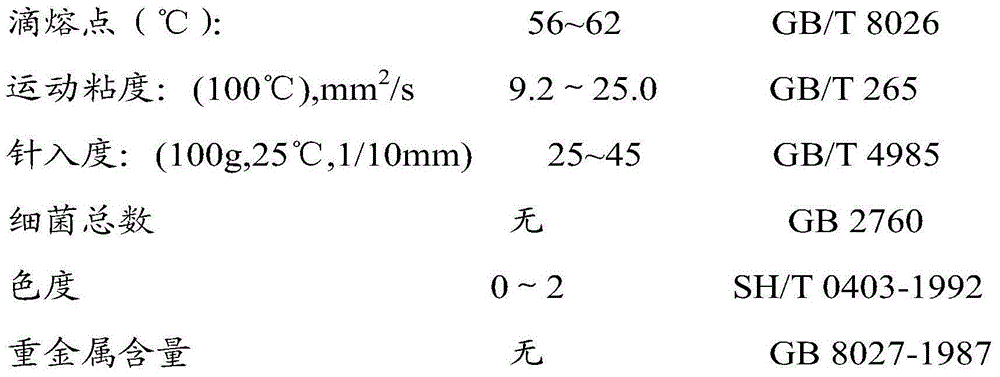

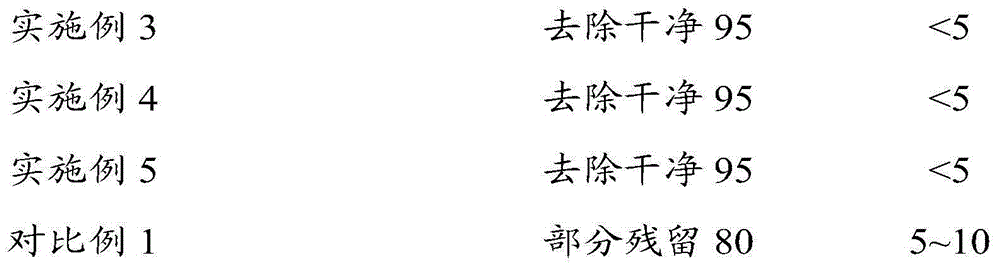

Solid depilatory wax for human bodies, and preparation method thereof

The invention relates to a depilatory wax, and concretely provides a solid depilatory wax for human bodies, and a preparation method thereof. The solid depilatory wax for human bodies comprises a tackifier, a plasticizer, a flexibilizer, a film forming agent, a stabilizer and a waxy substance. The preparation method of the solid depilatory wax comprises the following steps: heating the waxy substance for fusing, adding the tackifier, the plasticizer, the flexibilizer, the film forming agent and the stabilizer, and stirring until uniform mixing. The solid depilatory wax for human bodies has good adhesion, good film forming ability and good toughness, so the solid depilatory wax has a high depilation effect, has a very good removal effect on hair in positions difficult to process, such as underarm hair and bikini hair; and the solid depilatory wax for human bodies also has the advantages of good peeling effect, no skin sticking, and convenient and fast operation. The method has the advantages of simple process, convenient operation, and convenience for large scale production.

Owner:GUANGZHOU DEXIN WAX PROD

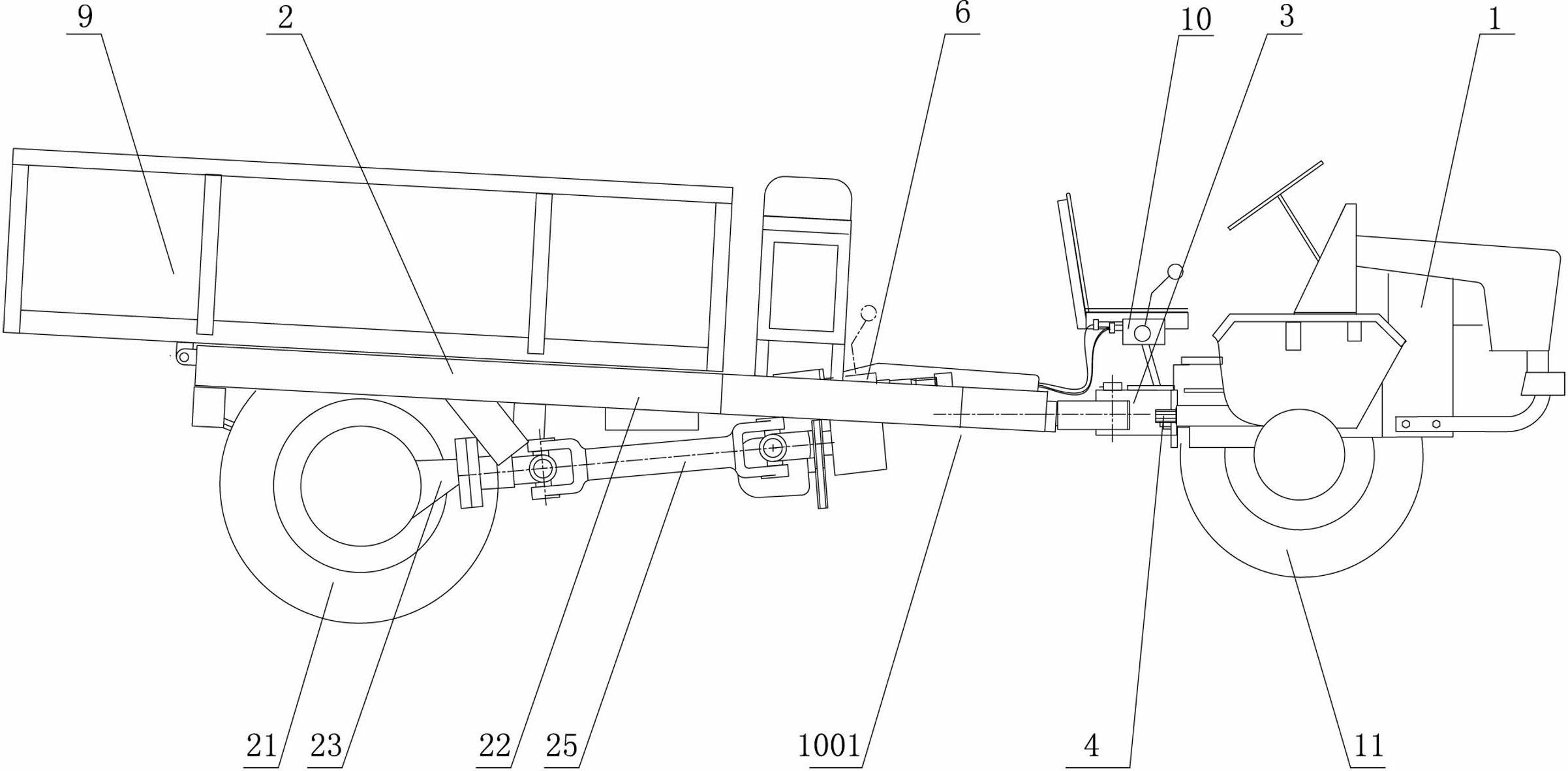

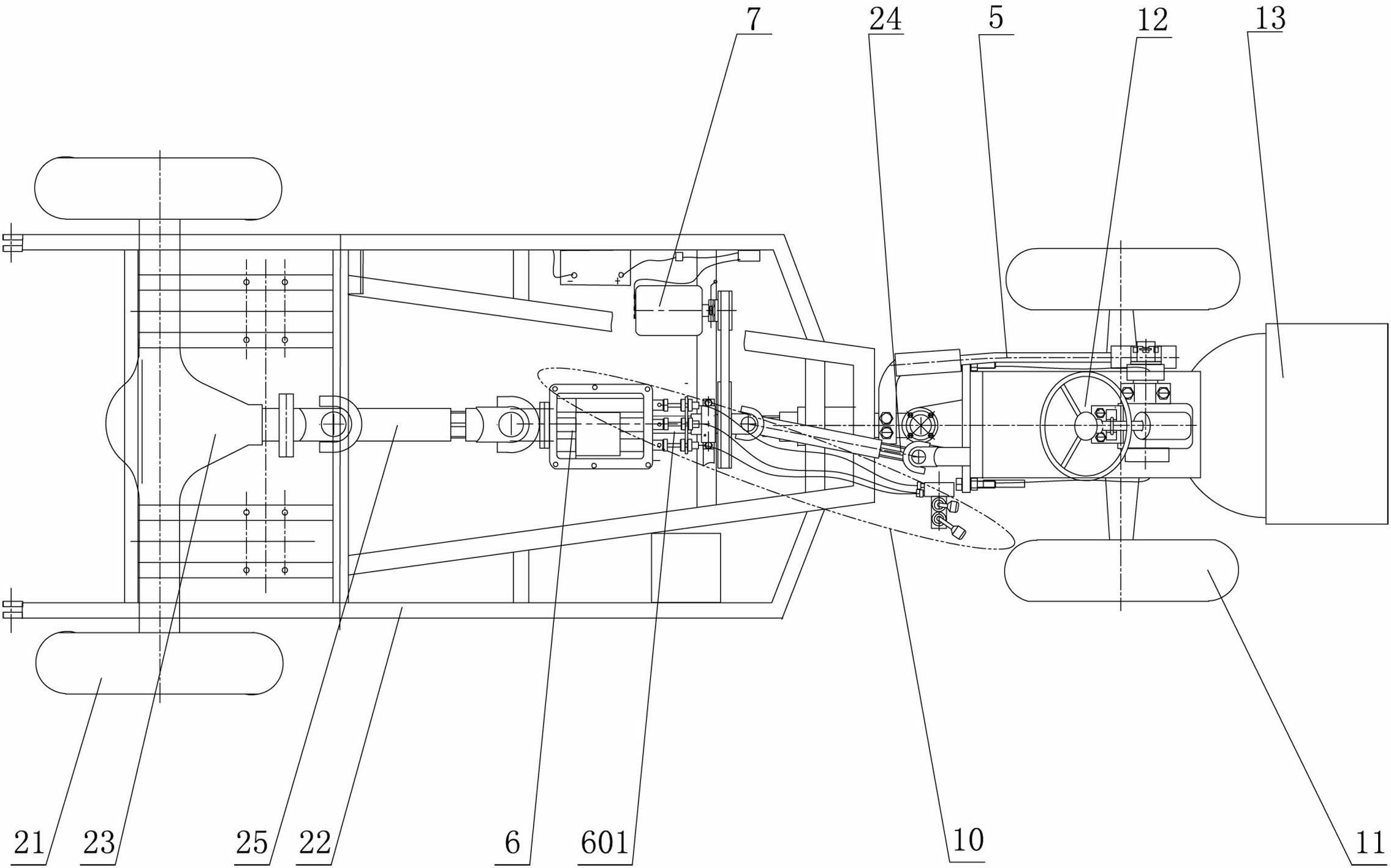

Disk type hillside tractor

ActiveCN102114875AEasy to operateAvoid deformationTilling equipmentsTractor-trailer combinationsAgricultural engineeringVehicle control

The invention discloses a disk type hillside tractor which comprises a tractor main machine, a trailer or farmland rig. The disk type hillside tractor is characterized by also comprising a safety drawing seat, a power generation charge device and remote gear-engaging devices, wherein the tractor main body is connected with the trailer through the safety drawing seat, the remote gear-engaging devices are arranged on the tractor main machine and the trailer, the power generation charge device is arranged on the trailer, or the front end of the farmland rig is connected with the tractor main machine. The disk type hillside tractor has two working types for adapting the hillside road driving and hill farmland operating; the tractor has long service life and is safe and stable; the energy sources are fully utilized for generating power and charging, thus the energy consumption is reduced; and the remote gear-engaging control meets the requirement for the traffic vehicle control. A residue liquid pumping, discharging and storing system is arranged on a trailer chassis, thus the disk type hillside tractor adapts the demand on the country methane construction in China. The invention has the advantages of multiple facilities, complete functions, good operating performance, long service life, wide application range, safety and reliability, and is favorably accepted by the hillside farmers.

Owner:CHANGSHA SUNLIGHT AGRI MACHINERY FACILITIES

Electrical heating device, particularly for a motor vehicle

ActiveUS9398641B2Improve cooling effectTolerance on thicknessAir-treating devicesHeater elementsMobile vehicleEngineering

An electrical heating device for a motor vehicle includes a frame that has openings formed on oppositely situated sides for the passage of a medium to be heated, a layer structure, arranged in the frame, and a connecting housing. The layer structure comprises layers of corrugated-rib elements and heat generating elements, and each heat generating element has at least one PTC element arranged between parallel contact plates. At least one power dissipation generating power switch is provided in the connecting housing. A heat sink lies exposed on the outside of the connecting housing. Improved and adequate cooling of the electrical heating device having the power switch is created as a result of the insertion of the heat sink into the connecting housing in a sealing manner.

Owner:EBERSPACHER CATEM

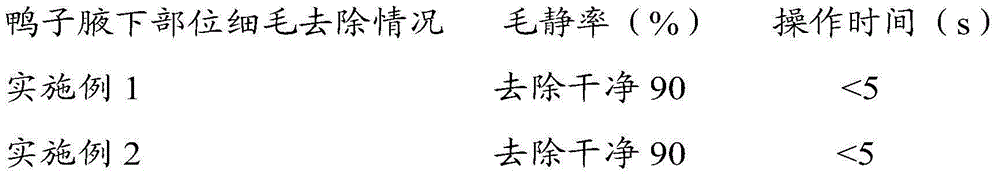

Epilating wax for living stock and preparation method of epilating wax

The invention provides epilating wax for the living stock and a preparation method of the epilating wax and belongs to the technical field of food processing auxiliaries. The epilating wax for the living stock is mainly prepared from a tackifier, a plasticizer, a flexibilizer, a film-forming agent, a stabilizer and a wax substance. The wax substance is heated and melted, then the tackifier, the plasticizer, the flexibilizer, the film-forming agent and the stabilizer are added to the wax substance, stirred and mixed uniformly, and accordingly, the epilating wax for the living stock is prepared. The epilating wax for the living stock has good adhesive force, good film-forming performance, good rigidity and high epilating rate, has a good removal effect on feather or fur at parts where the feather or fur is difficult to deal with, such as fine feather under winds, and also has a good peeling effect, and efficient epilating can be realized at higher operation efficiency of a worker or a wax peeling machine. The method is simple in process and convenient to operate and facilitates large-scale production.

Owner:广东德馨新材料科技股份有限公司

Transporting apparatus and recording apparatus

ActiveUS9308748B2Suppress generationAvoid contactOther printing apparatusArticle feedersMechanical engineering

Owner:SEIKO EPSON CORP

Paper conveyance device and printer

ActiveUS20120062675A1Appropriate tensionReduce decreaseFunction indicatorsOther printing apparatusEngineeringTractor

A paper conveyance device for a printing device is disclosed that includes a detector and first, second, and third conveyance mechanisms. The first conveyance mechanism includes a tractor that conveys continuous paper along a paper feed direction. The second conveyance mechanism is disposed between the first conveyance mechanism and a print head and includes feed and pressure rollers. The third conveyance mechanism is disposed downstream from the print head and includes feed and pressure rollers. The detector detects the paper feed distance of the first conveyance mechanism and the rotation of the feed roller of the second conveyance mechanism, and adjusts the paper feed distance of the first conveyance mechanism based on the detected paper feed distance. A paper feed distance per unit time of each of the second and third conveyance mechanisms is greater than a paper feed distance per unit time of the first conveyance mechanism.

Owner:SEIKO EPSON CORP

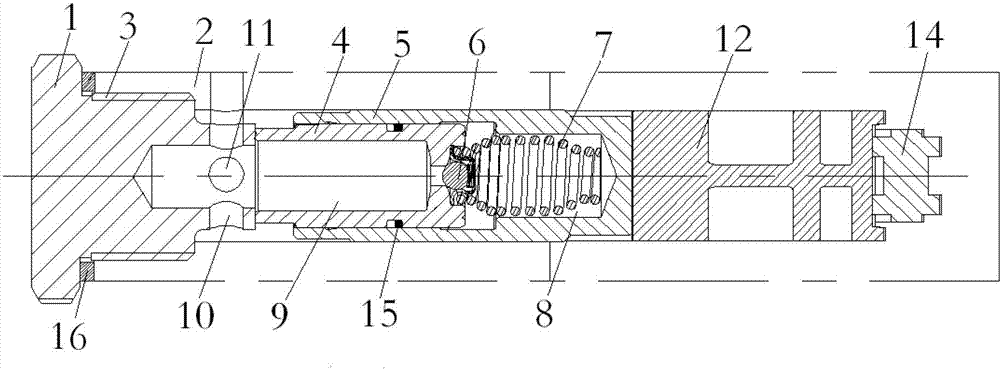

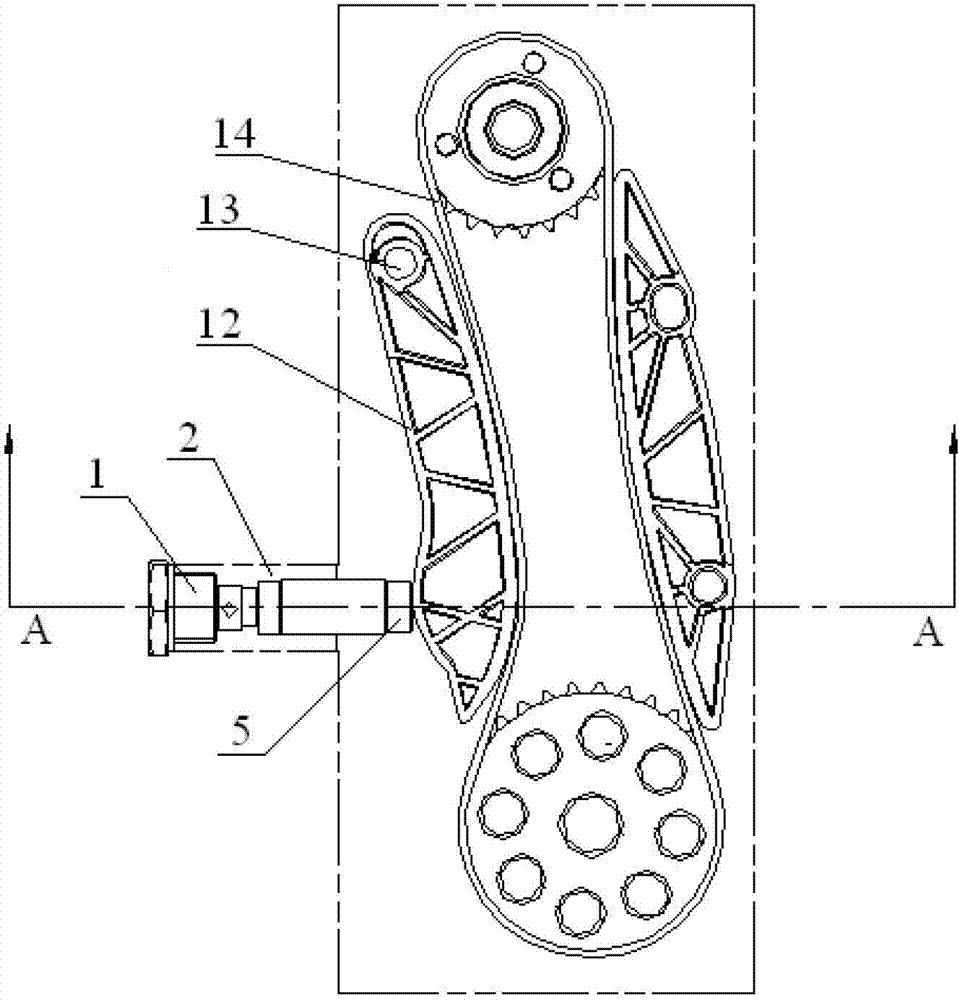

Hydraulic chain tensioner device

The invention discloses a hydraulic chain tensioner device. The structure is as follows: a tensioner fastening seat and a sprocket chamber are fastened and connected through threads, the forefront end of the tensioner fastening seat abuts against a plunger, and the plunger is arranged in a plunger bushing; a check valve and a return spring are sequentially arranged between the plunger and the plunger bushing, and the return spring is arranged in an oil storage chamber of the plunger bushing; a tensioner fastening seat oil chamber is communicated with a plunger oil chamber, and a transverse oil duct and a longitudinal oil duct are arranged in the tensioner fastening seat oil chamber; and a guide plate contacts the outer end of the plunger bushing and is fixed with the sprocket chamber through bolts, and a chain is arranged in a guide plate positioning groove. The device adopts sprocket drive, so the engine has the advantage of simple structure and compact layout. The tensioner can ensure the smooth sprocket drive, and has proper tension for the chain. The hydraulic chain drive can obviously reduce the noise. The invention is especially suitable for overhead camshaft engines, and has high popularization value.

Owner:东风朝阳朝柴动力有限公司

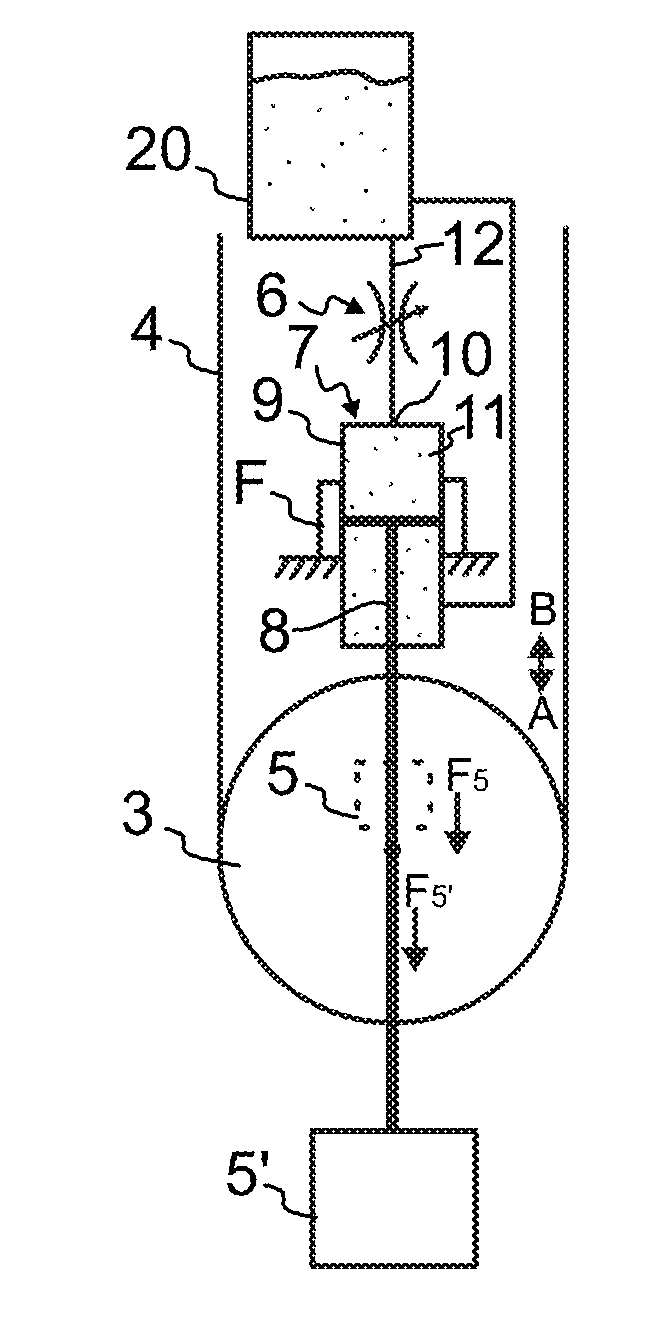

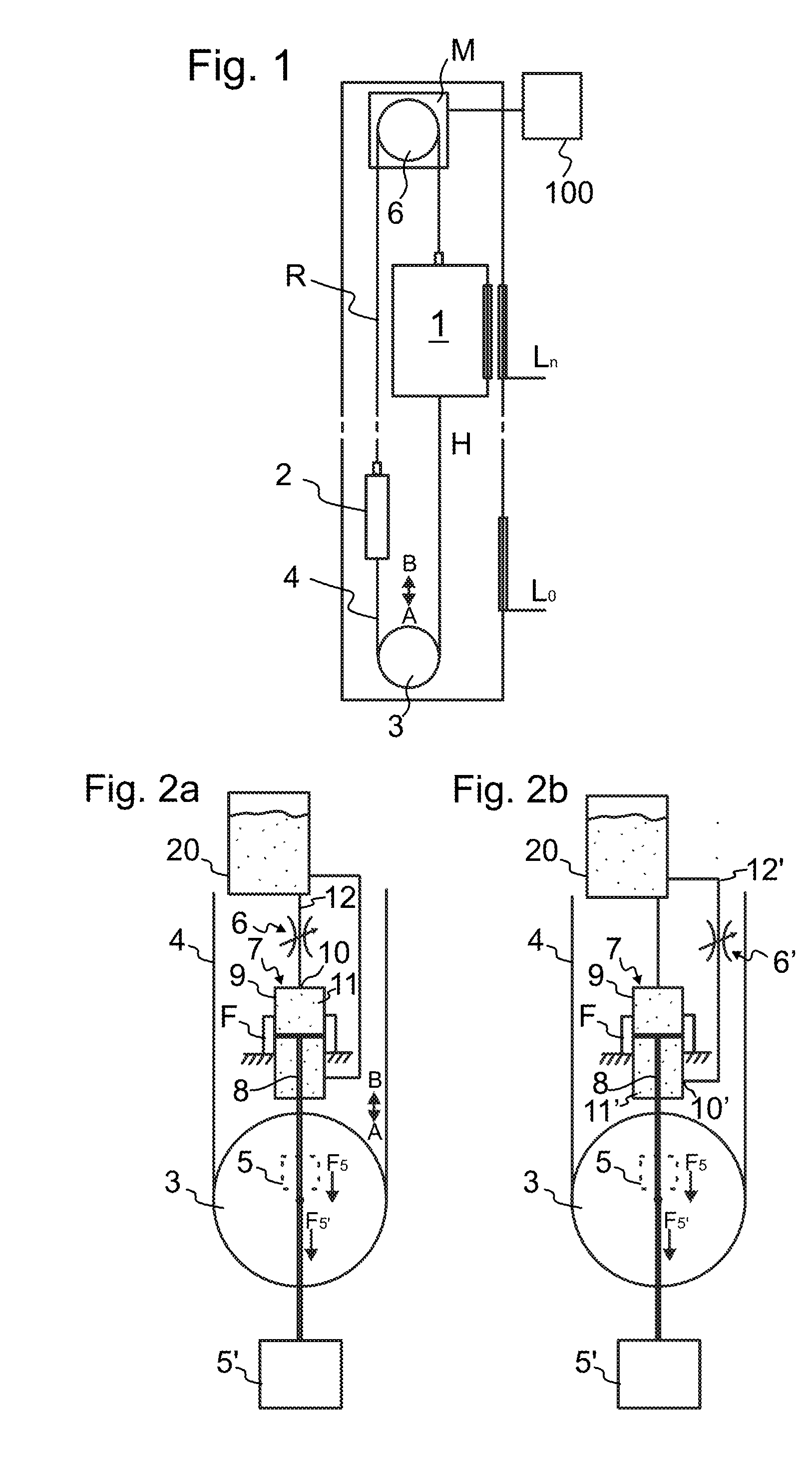

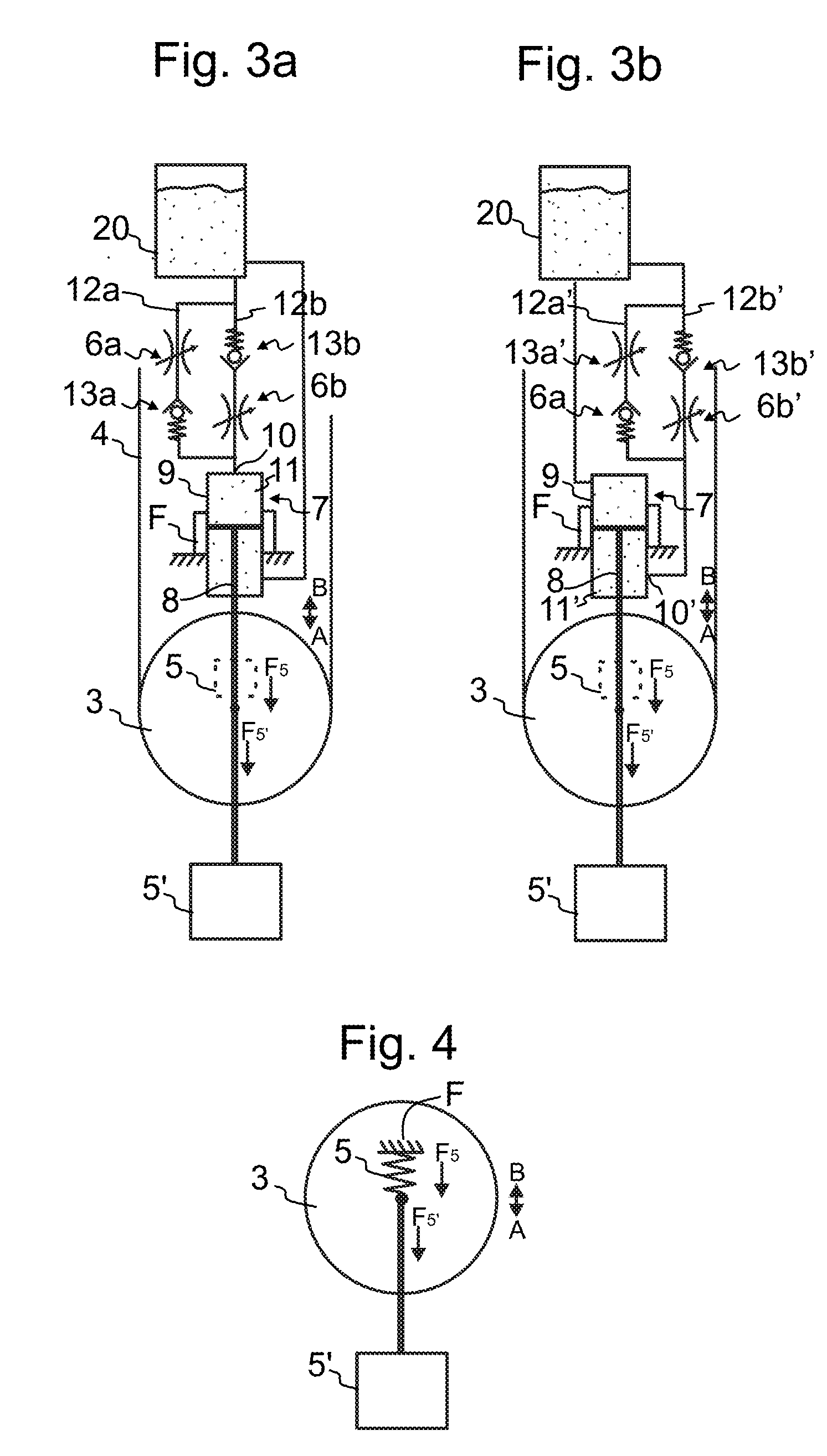

elevator

ActiveUS20150298939A1Control speedEliminate riskElevatorsBuilding liftsEngineeringMechanical engineering

An elevator comprisinga hoistway;an elevator car vertically movable in the hoistway;a counterweight vertically movable in the hoistway;at least one tightening wheel located in the lower end of the hoistway;at least one rope wheel located in or at least in proximity of the upper end of the hoistway;a first roping interconnecting the car and counterweight and passing around the at least one rope wheel located in or at least in proximity of the upper end of the hoistway;a second roping interconnecting the car and counterweight and passing around the at least one tightening wheel, the tightening wheel being mounted movably back and forth in a first direction towards the second roping, and in a second direction away from the second roping; andmeans for exerting force on the tightening wheel to move it in the first direction so as to tighten the second roping.The elevator further comprises means for limiting the movement speed of the tightening wheel towards the first direction and the second direction.

Owner:KONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com