Nonwoven fabric slitting device

A non-woven, placing table technology, applied in the direction of textile and papermaking, textile material cutting, etc., can solve the problem of low production efficiency of the slitting machine, and achieve the effect of facilitating rapid replacement, reducing burrs, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

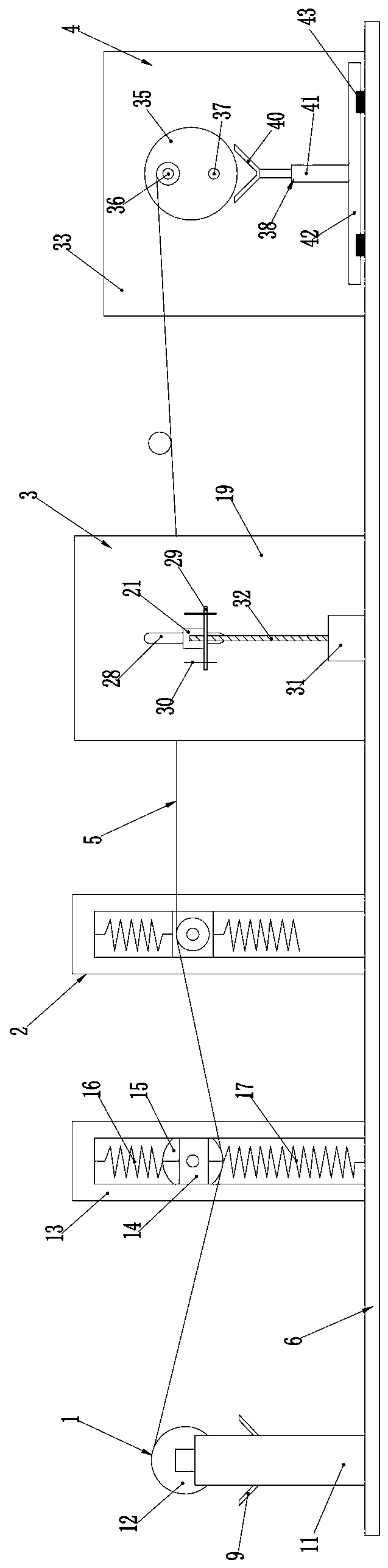

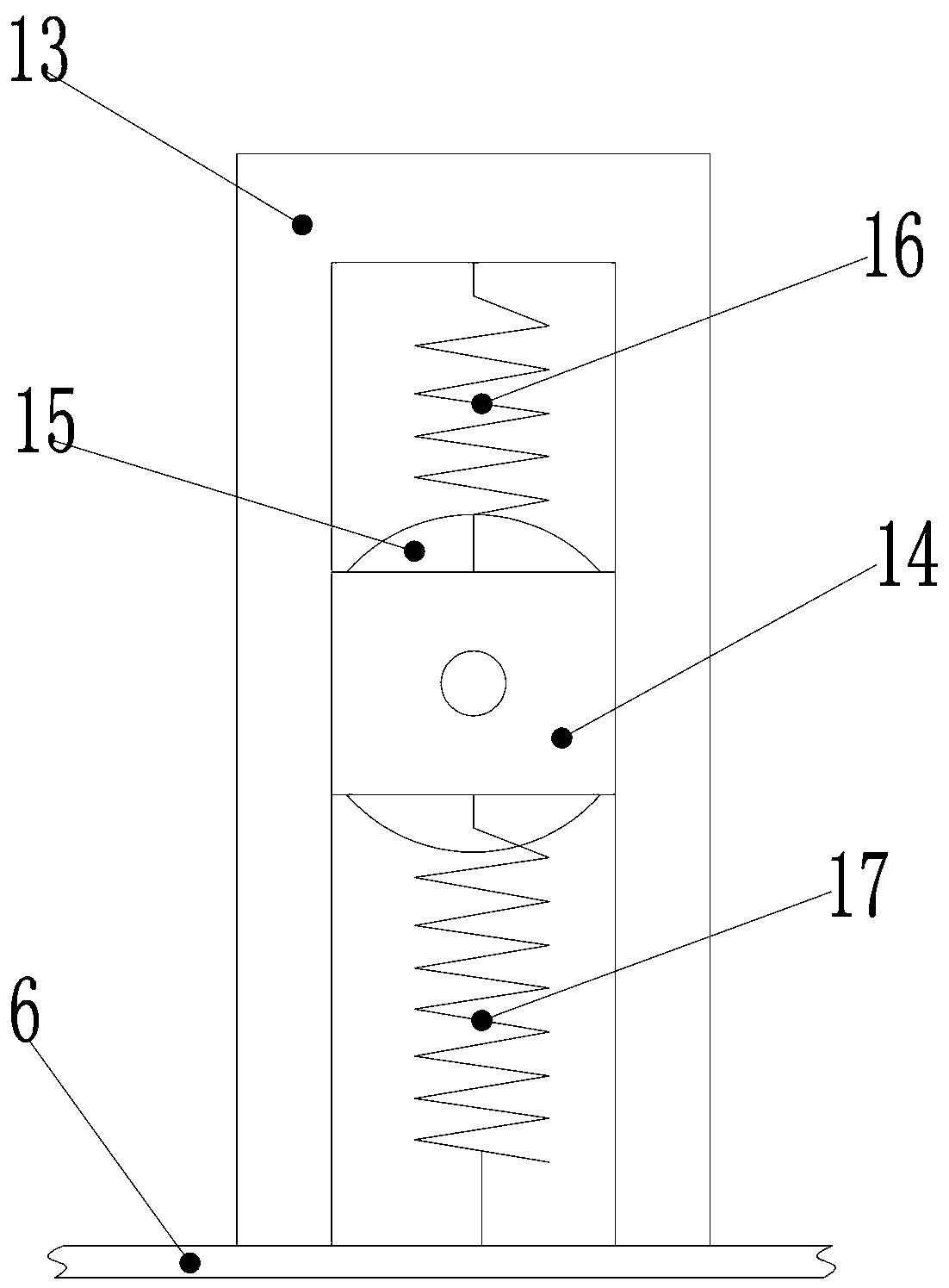

[0022] Example: such as figure 1 As shown, a non-woven fabric slitting device includes an unwinding mechanism 1 , a tensioning mechanism 2 , a slitting mechanism 3 and a rewinding mechanism 4 sequentially arranged on a base 6 along the advancing direction of the nonwoven fabric 5 .

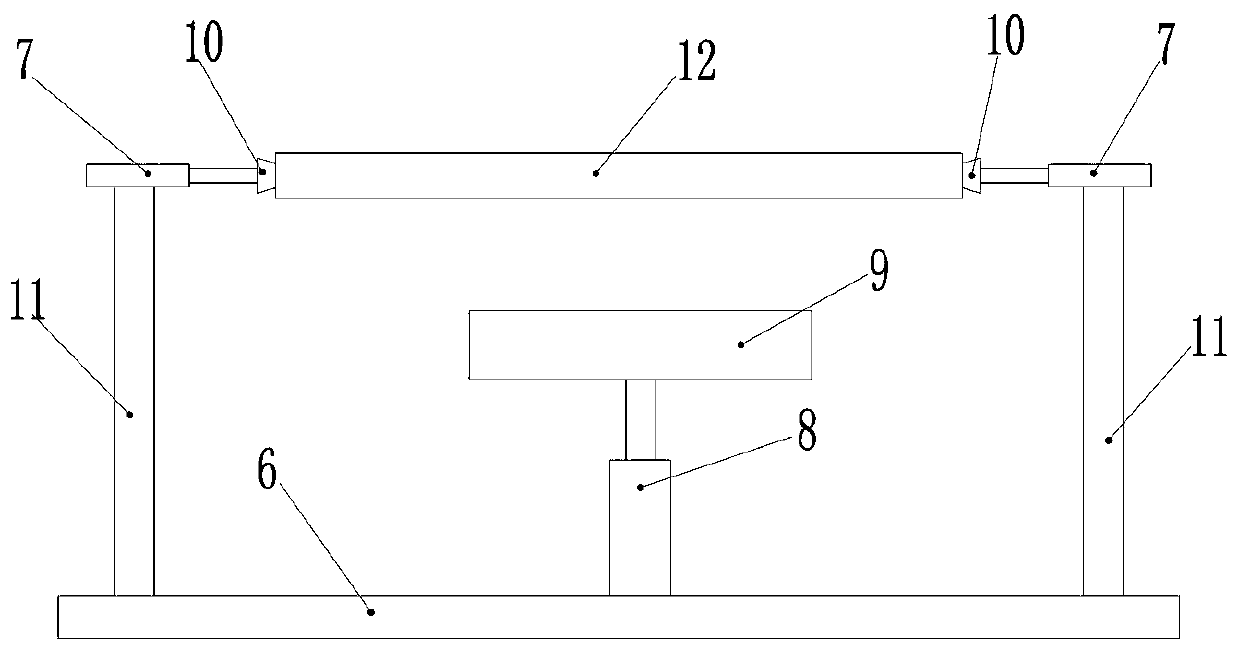

[0023] like figure 1 , figure 2 As shown, the unwinding mechanism 1 includes a first support frame 11, a clamping hydraulic cylinder 7, a lifting hydraulic cylinder I8, a V-shaped placing table 9 and a top cone 10, and two first support frames 11 are arranged in parallel on the width direction of the base 6. On both sides, the clamping hydraulic cylinder 7 is fixedly arranged on the top of the first support frame 11, and the piston end of the clamping hydraulic cylinder 7 is rotatably connected to the large-diameter end of the top cone 10 through a bearing, and the two top cones 10 are arranged coaxially. The two ends of the unwinding reel 12 are tightened by two top cones 10, the bottom of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com