Automatic spool welding machine

An automatic welding machine and I-shaped wheel technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of high labor intensity of the inner tube of the I-shaped wheel, uneven position of welding points, and poor quality. Guarantee and other issues, to avoid the need for manual overturning operation, to avoid uneven spot welding, and to achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

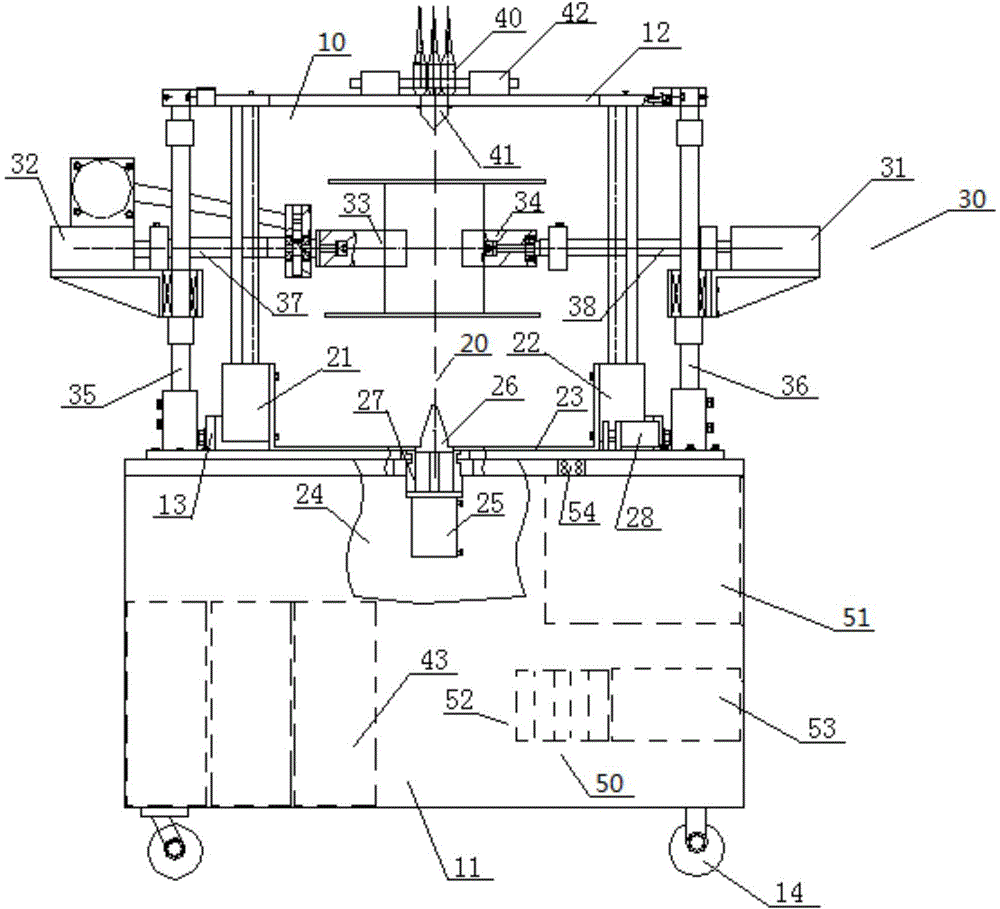

[0013] Such as figure 1 As shown, a kind of I-wheel automatic welding machine includes a mounting frame 10, a lifting device 20, a turning device 30, a welding machine 40 and a control mechanism 50, and the mounting frame 10 includes a base 11, an upper mounting plate 12, a lower mounting plate 13 and the wheels 14 arranged at the bottom of the base 11, the lower mounting plate 13 is arranged on the base 11, the welding machine 40 is arranged on the upper mounting plate 12, the lower end of the welding machine 40 is provided with an upper positioning top 41, and the welding machine 40 There are welding gun clamping devices 42 on both sides, the welding machine box 43 of the welding machine 40 is arranged inside the base 11, and the lifting device 20 and the flipping device 30 are respectively arranged in the middle of the upper mounting plate 12 and the lower mounting plate 13 , the control mechanism 50 is disposed inside the base 11 . Described elevating device 20 comprises ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com